UV DTF Gangheet: Revolutionizing Fabric Printing Today

UV DTF Gangheet technology is transforming the fabric printing landscape, blending the advanced capabilities of UV printing with the efficiency of DTF (Direct to Film) methods. This innovative approach enables artisans and businesses to create stunning, high-quality prints on a variety of textiles, paving the way for exciting possibilities in custom apparel and fabric design. With its rapid curing process, UV DTF Gangheet produces vibrant colors that not only stand out visually but also boast impressive durability, ensuring that designs last wash after wash. As the demand for personalized custom apparel surges, this cutting-edge technology emerges as a vital solution for fabric printing tasks both simple and intricate. In this article, we will delve deeper into the benefits, processes, and future of UV DTF Gangheet, uncovering how it is reshaping the fabric printing industry.

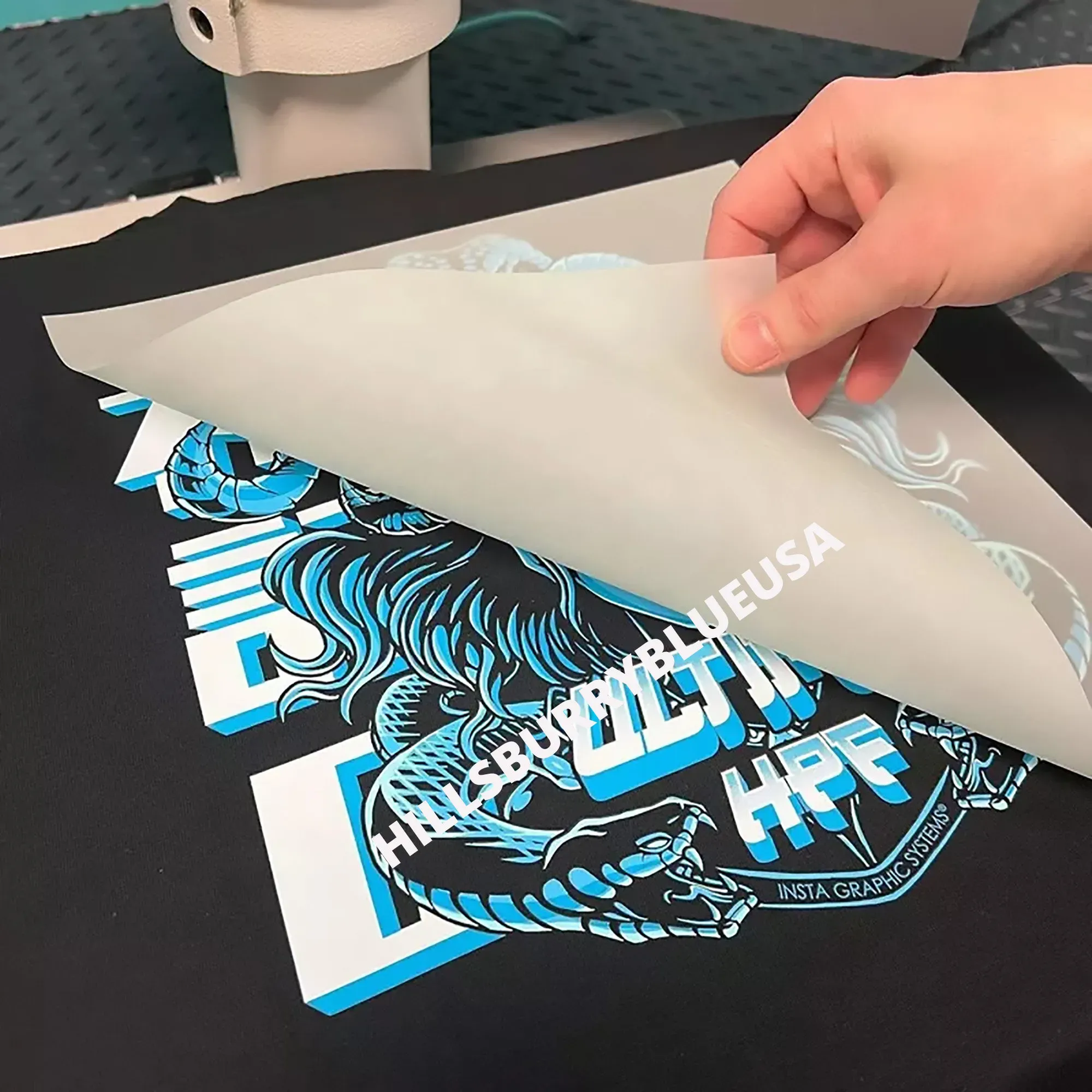

The realm of textile printing is witnessing a groundbreaking evolution with the advent of UV DTF technology, often referred to as direct-to-film printing. This state-of-the-art method merges the precision of UV printing inks with a streamlined film transfer process, enabling the creation of vibrant and durable fabric designs. By utilizing UV curing, this technique allows for stunning graphics to be applied onto diverse types of fabrics, thus enhancing the customization options available for apparel and other fabric items. As custom fabric design continues to rise in popularity, adopting such innovative printing solutions becomes essential for manufacturers and creators alike. In this article, we will explore the nuances of this technology and its impact on the future of fabric printing.

The Benefits of UV DTF Gangheet in Fabric Printing

UV DTF Gangheet technology presents significant benefits for fabric printing, particularly in achieving heightened visual fidelity. As modern consumers increasingly demand vibrant and creative designs, the use of UV inks in DTF printing plays a crucial role. These inks offer a brilliant color gamut that can transform ordinary fabric into captivating apparel, making it an essential choice for custom apparel businesses. This capability not only enhances the aesthetic appeal of garments but also elevates their market competitiveness. In addition, the durability of prints produced through UV DTF Gangheet is noteworthy—these prints withstand rigorous washing and daily wear without fading or cracking, ensuring that your designs maintain their vividness under practical conditions.

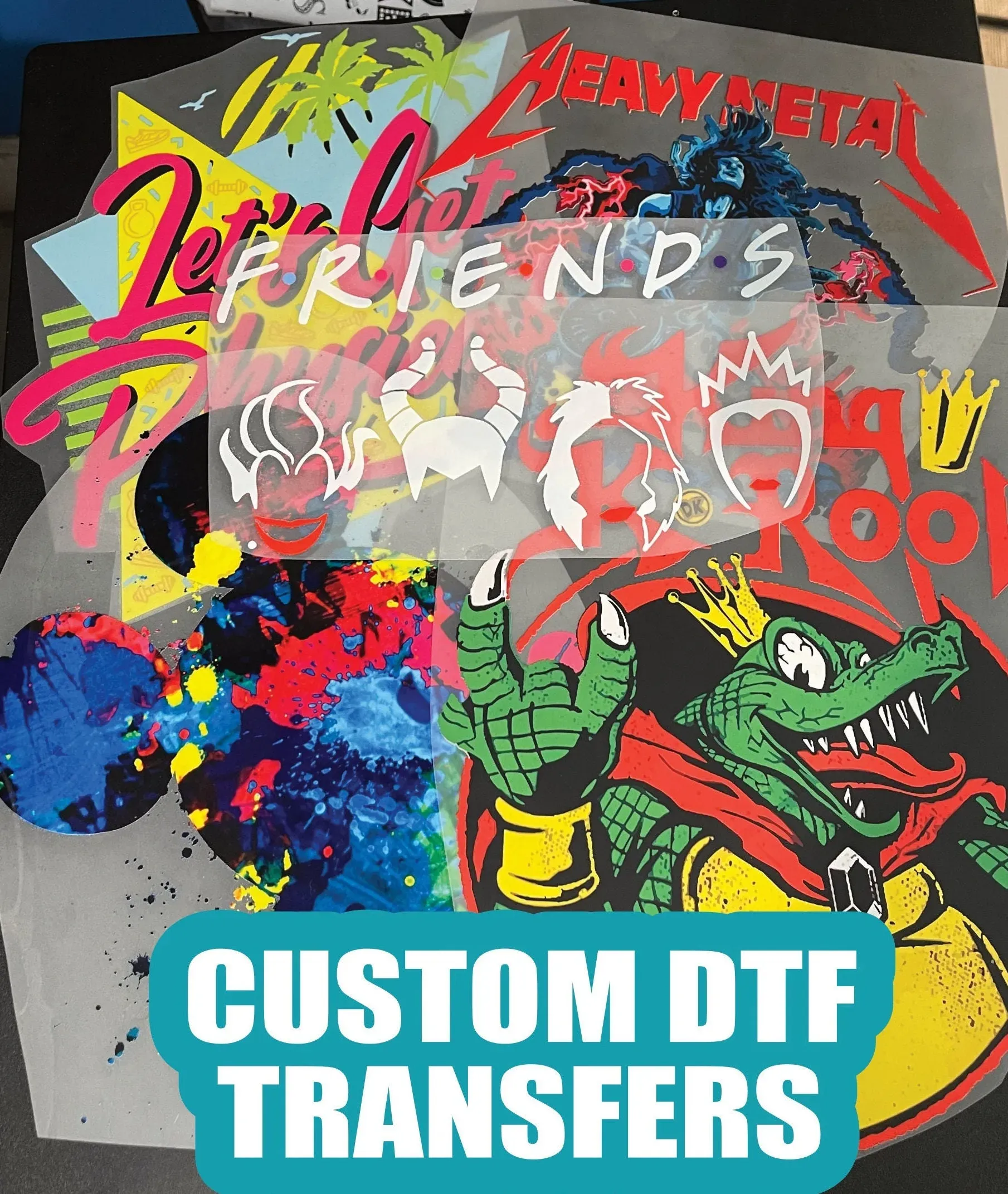

Another major advantage lies in the versatility afforded by UV DTF Gangheet technology. Unlike conventional methods that limit creators to specific fabric types, UV DTF printing accommodates a diverse range of materials. This flexibility permits custom printers to experiment with different textiles, leading to innovative creations that meet diverse consumer preferences. Whether you’re printing on cotton, polyester, or blends, the compatibility of UV DTF inks expands the horizons for fabric design. Furthermore, this technology facilitates swift turnaround times, enabling businesses to meet the evolving demands of the custom printing market and provide their clients with quick, high-quality products.

The Evolution of UV DTF Printing Technology

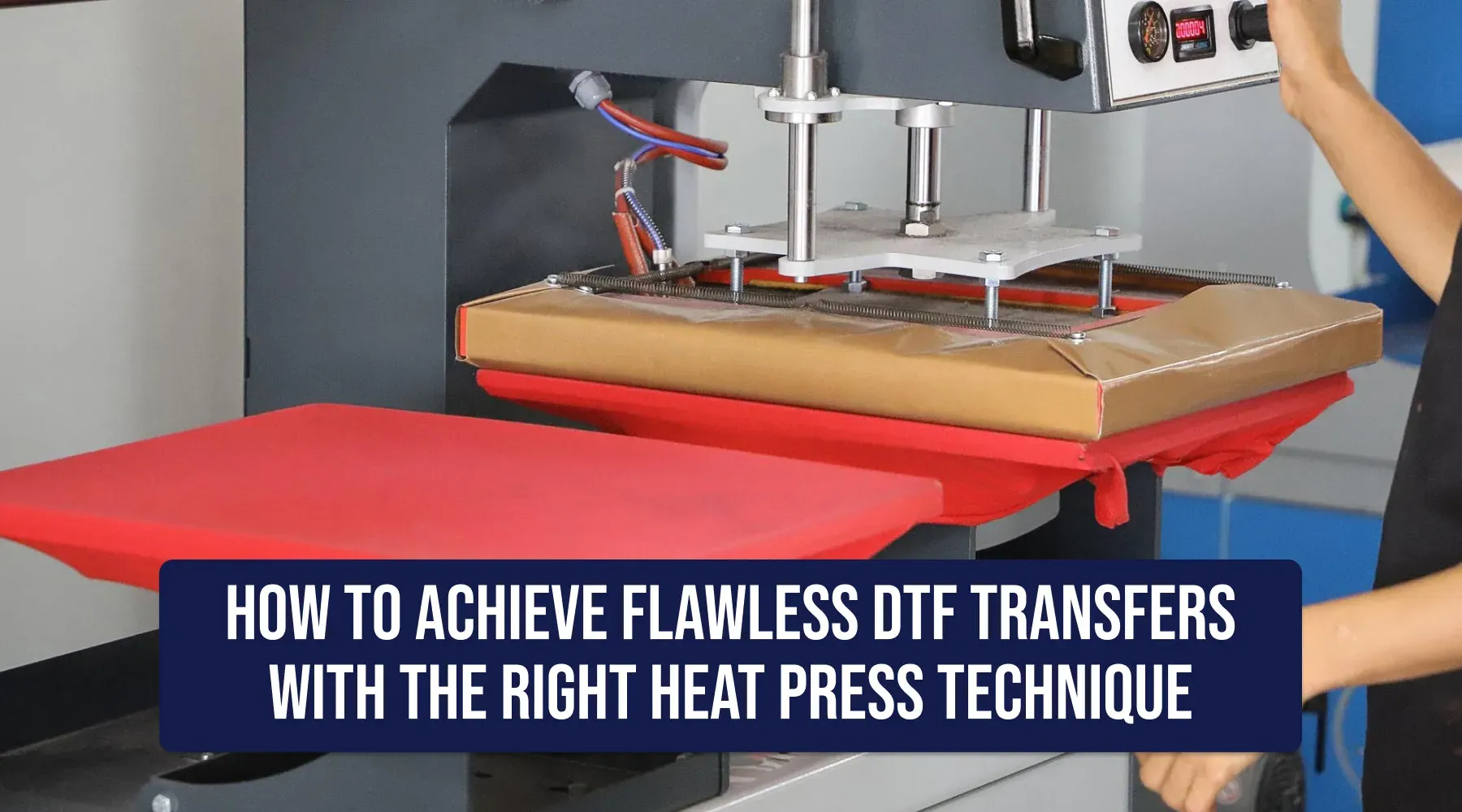

Over recent years, the evolution of UV DTF printing technology has been remarkable, indicating a shift towards more efficient and sustainable production methods. The immediacy with which UV inks cure—thanks to UV light—allows printers to bypass lengthy drying times that characterize traditional methods. This innovation not only accelerates manufacturing processes but also minimizes resource consumption, rendering practices more eco-friendly. As the industry prioritizes sustainability, UV DTF technology aligns well with these broader goals while still providing exceptional quality and versatility.

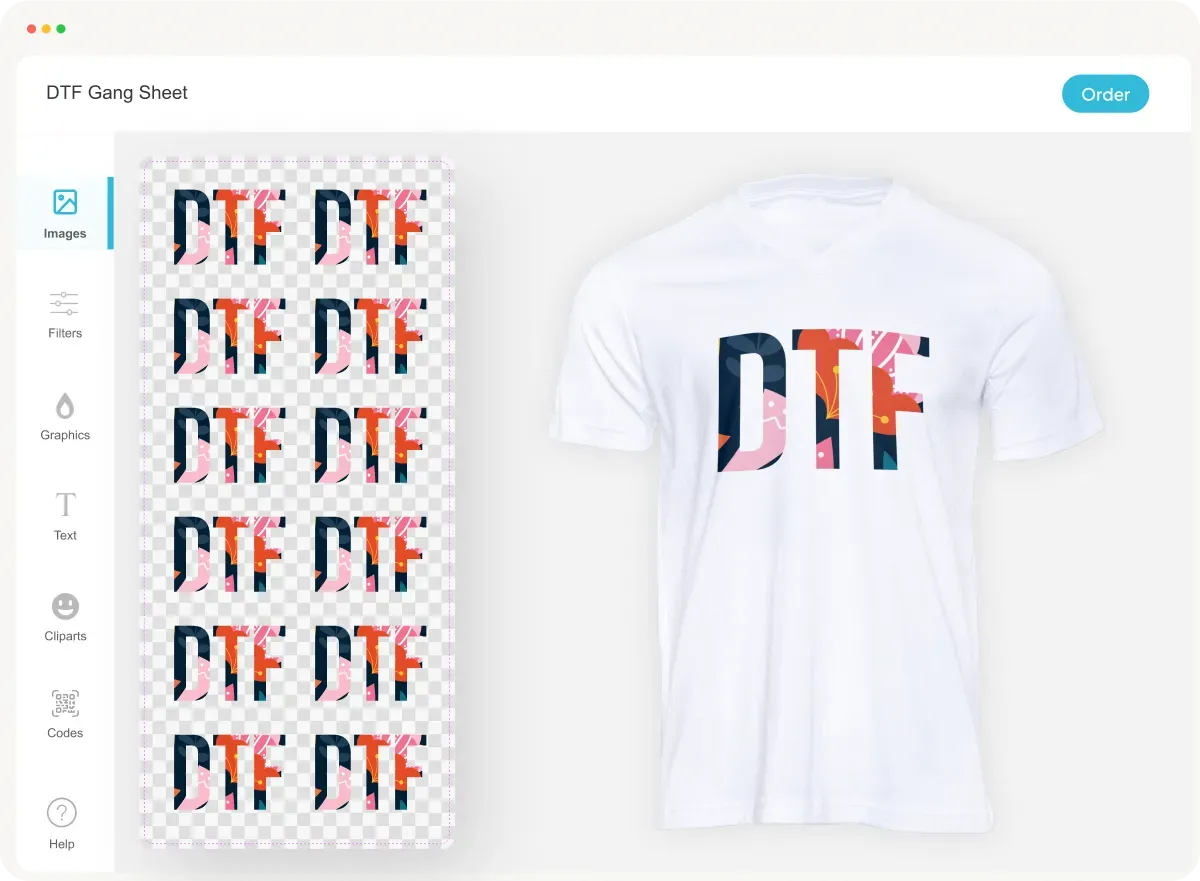

Additionally, advancements in machinery and techniques associated with UV DTF Gangheet have opened up new opportunities for creators. Equipment manufacturers are continuously incorporating cutting-edge technology, allowing small businesses and independent crafters to access professional-grade capabilities. Recent developments, including user-friendly software and automated processes, have simplified the approach to fabric printing. Consequently, more entrepreneurs are empowered to explore custom designs, encouraging creativity across the fabric design landscape. This democratization of technology fosters a thriving marketplace filled with unique, personalized products.

Trends Shaping Custom Printing with UV DTF Technology

The fabric printing industry is currently witnessing dynamic trends driven by the rise of UV DTF technology. One prominent trend is the growing importance of personalization in custom apparel. Consumers today frequently seek out unique items that reflect their individual styles, and UV DTF printing provides the means to achieve this. With its ability to render intricate designs and vibrant colors, creators can now offer bespoke apparel solutions that cater to specific customer desires. This shift towards richness in fabric design means that businesses must prioritize quality and creativity to stand out in a saturated market.

Another critical trend involves the integration of online platforms designed for easy access to custom printing tools. Services like DesignBundles are revolutionizing the way crafters and small businesses interact with UV DTF printing. These platforms streamline the design process, providing templates and resources that simplify techniques traditionally seen as complex. By eliminating the learning curve associated with fabric design and printing, they encourage more people to experiment with DTF technologies and foster a sense of community among creators. As these trends continue to develop, it’s clear that UV DTF Gangheet technology will remain at the forefront of the custom printing industry.

The Role of UV Inks in DTF Printing Success

UV inks play a pivotal role in the success of DTF printing, thanks to their unique properties. Unlike water-based or solvent-based inks, UV inks contain photoinitiators that allow them to cure instantly under UV light, which results in vibrant colors and sharp details. This rapid curing process minimizes the risk of smudging or bleeding, ensuring high fidelity in designs transferred onto fabric. Moreover, UV DTF Gangheet technology can produce intricate patterns that push the boundaries of traditional fabric printing, making it a favored choice for those looking to create standout custom apparel.

The durability of UV inks also contributes significantly to their effectiveness in fabric printing. Once cured, these inks bond deeply with the substrate, forming a resistant layer that withstands environmental factors such as sun exposure and washing. This durability translates to longer-lasting prints for end-users, which is a critical consideration for business owners in the custom apparel industry. Consequently, brands that leverage UV DTF technology are better positioned to deliver products that meet customer expectations for quality and longevity.

Future Innovations in UV DTF Gangheet Technology

Looking ahead, the future of UV DTF Gangheet technology appears bright, with ongoing innovations anticipated to further enhance its capabilities. Researchers and manufacturers are exploring new ink compositions that can provide even greater durability and flexibility, enabling wider applications across various fabrics. Potential advancements include the development of eco-conscious inks that maintain high vibrancy but minimize environmental impact. These innovations may transform attitudes toward fabric printing, aligning them with global sustainability goals.

Moreover, improvements in digital printing technology will likely lead to enhanced user experiences and streamlined production workflows. As automation in UV DTF printing becomes more prevalent, businesses can capitalize on increased efficiency and reduced costs while still delivering high-quality custom apparel. Networking events, such as PacPrint 2025, will serve as platforms for showcasing these advancements and fostering collaborative efforts among industry professionals. As the UV DTF landscape continues to evolve, creative individuals and businesses can stay at the forefront by embracing these innovative trends in fabric printing.

Frequently Asked Questions

What is UV DTF Gangheet and how does it work?

UV DTF Gangheet is an advanced printing technology that combines UV printing with Direct to Film (DTF) methods. It works by printing vibrant designs on a special transfer film using UV inks, which cure quickly under UV light, enabling immediate application to various fabrics.

What are the benefits of using UV DTF Gangheet for custom apparel?

The benefits of UV DTF Gangheet for custom apparel include high-quality, vibrant prints that are durable, resistant to fading and cracking, and applicable to a wide variety of fabrics, catering to diverse design needs in the fabric printing industry.

Is UV DTF Gangheet technology suitable for all types of fabrics?

Yes, UV DTF Gangheet technology is highly versatile and can be applied to multiple fabric types, allowing fabric printers to explore different materials without compatibility issues, making it ideal for custom fabric designs.

How does UV DTF Gangheet enhance the quality of fabric printing?

UV DTF Gangheet enhances fabric printing quality by using UV inks that produce bright, vivid colors. The curing process ensures that prints maintain their vibrancy and appearance over time, crucial for high-impact custom apparel.

What recent innovations are being made in UV DTF Gangheet technology?

Recent innovations in UV DTF Gangheet technology include the introduction of personal 3D-texturing printers and large-format DTF printers, which enhance printing capabilities and make custom fabric printing more accessible for small businesses and crafters.

How is UV DTF Gangheet shaping the future of fabric printing?

UV DTF Gangheet is shaping the future of fabric printing by democratizing access to advanced printing technologies, promoting personalization in custom apparel, and continuously evolving with new trends and resources that cater to creators’ needs.

| Key Points | Details |

|---|---|

| What is UV DTF Gangheet? | A revolutionary fabric printing technology combining DTF and UV printing. |

| Understanding the Process | Uses UV inks for a streamlined printing process on a special transfer film. |

| Advantages of UV DTF Printing | 1. High Quality and Vibrancy 2. Durability 3. Versatility 4. Speed and Efficiency |

| Recent Developments | Innovations like 3D-texturing printers and investments in large-format printers enhance accessibility and capabilities. |

| Current Trends | Emergence of platforms simplifying custom printing for crafters while increasing the accessibility of DTF technologies. |

| Future Outlook | Events like PacPrint 2025 will showcase advancements, driving further innovation in UV DTF technologies. |

Summary

UV DTF Gangheet is revolutionizing the way fabric printing is approached, marrying durability and vibrancy to create high-quality prints that meet diverse needs. As this technology continues to evolve, it is changing the landscape of custom printing, allowing both professionals and hobbyists to explore endless possibilities. By leveraging UV DTF Gangheet, creators can produce striking designs that withstand the test of time, leading to greater personalization and marketability in their products. The continuous integration of advanced tools and innovations further enhances the creative potential in the fabric printing industry.