DTF Transfers: Maximize Your Creativity with Tips & Tricks

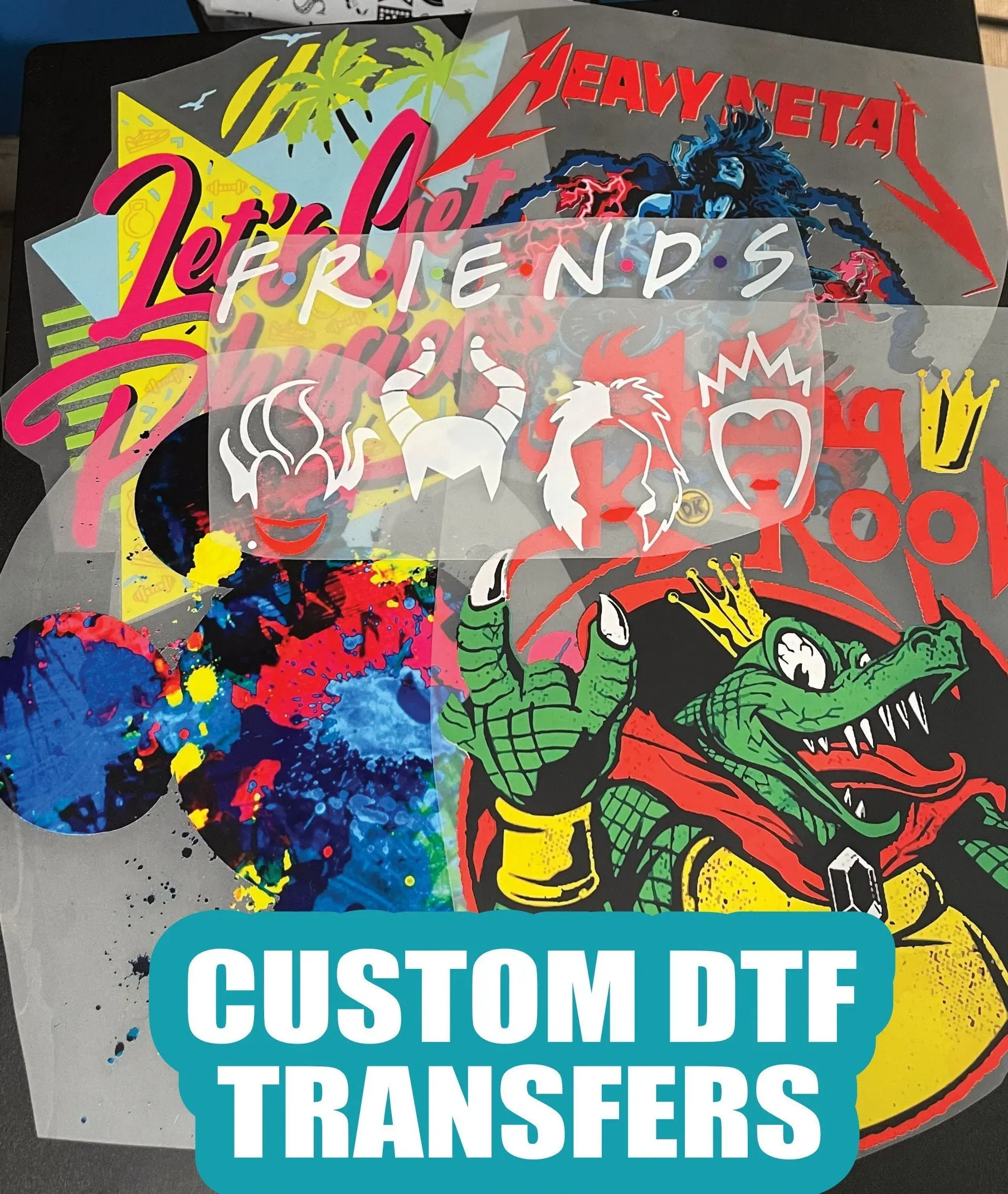

In the exciting realm of fabric customization, DTF transfers are becoming a favorite tool among artists and hobbyists alike. This innovative technique, which stands for Direct to Film transfers, allows for vibrant designs to be printed onto a special film and then effortlessly applied to various fabrics. Whether you’re exploring how to use DTF transfers for custom t-shirts or looking for DTF printing tips to enhance your projects, the potential for creative expression is vast. Imagine the possibilities as you experiment with the best fabrics for DTF transfers and incorporate layering DTF prints to bring your ideas to life. With DTF transfers, your design journey is limited only by your imagination, offering avenues for unique, professional-quality results.

When it comes to textile design and printing methods, Direct to Film technique, often referred to as DTF, is transforming the craft scene. This approach enables designers to print eye-catching graphics on a special film, which can then be heat-transferred to a broad selection of textiles. Unlike conventional methods, the DTF printing technique introduces unparalleled versatility, allowing for intricate artwork and durable finishes. Whether creating custom apparel or engaging in creative DTF projects, understanding the nuances of material selection and print layering can significantly enhance your outcome. Embracing DTF technology paves the way for a new era of textile artistry, where creativity knows no bounds.

How to Use DTF Transfers Effectively

Using DTF transfers effectively begins with understanding the fundamental steps involved in the process. To start, ensure that you have high-quality images ready for printing. These images should be designed with a resolution of at least 300 DPI to maintain clarity and detail once transferred onto your chosen fabric. After printing, it’s essential to let the transfer film cool down before proceeding with the application. This helps in achieving a perfect adhesion to your fabric, ensuring that the design pops with vibrant colors and withstands various washes.

Next, the application of DTF transfers requires a precise heat press setup. Make sure to adjust the temperature and time settings according to the type of fabric you are using. The pressure applied during this step also plays a critical role in the transfer’s success. Different fabrics react differently to heat, so it’s advisable to conduct a few tests on scrap pieces before committing to your final project. This approach not only minimizes errors but also enhances your overall experience with DTF printing.

Best Fabrics for DTF Transfers

When considering the best fabrics for DTF transfers, versatility is key. DTF transfers can be applied successfully to various materials, including 100% cotton, polyester blends, and tri-blend fabrics. Each type of fabric offers a unique texture and finish, allowing for an array of creative expressions. Cotton, for instance, provides a soft feel and excellent print quality, making it a popular choice for t-shirts. On the other hand, polyester blends have the added benefit of durability and vibrant color display, ideal for athletic wear and bags.

It’s also worth exploring less traditional fabrics for DTF printing, such as stretchy materials like spandex or even denim. The results can be surprisingly beautiful, merging the characteristics of DTF transfers with unique fabric properties to achieve dynamic designs. Therefore, don’t hesitate to experiment with different textiles to gain insight into how DTF transfers behave across various substrates. This experimentation not only enhances your skillset but also opens doors to innovative design possibilities.

Creative DTF Projects to Inspire You

DTF transfers unlock a world of creativity, leading to numerous exciting project ideas. One popular project is customizing tote bags with unique patterns or personal artwork, turning an ordinary accessory into a statement piece. Similarly, consider creating limited edition t-shirts with seasonal designs that reflect current trends or events. These projects not only provide a platform for creativity but can also serve as a fantastic way to promote your brand or share your personal style.

Another innovative project idea using DTF transfers is designing home decor items like cushions, wall art, or even table runners. By applying DTF transfers to fabric surfaces around your home, you can showcase your artistic flair while updating your living space with custom, personalized touches. Think about using quotes, abstract art, or family photos transferred onto textiles that contribute to the ambiance of your home. Each piece can tell a story, making your decor as unique as you are.

Layering DTF Prints for Unique Effects

Layering DTF prints is an advanced technique that allows for greater depth and visual interest in your designs. This method involves applying multiple layers of transfers, with each layer adding its unique color and texture. The key to a successful layered design is to allow each layer to cool before applying the next. This prevents smudging and ensures that each layer adheres properly to the fabric. By mixing contrasting colors and textures, you can create stunning effects that elevate your projects to a professional level.

Additionally, layering isn’t just about colors; it can also incorporate various patterns and designs. Experiment with mixing different DTF prints, such as floral designs with geometric patterns, to create a standout piece. This eclectic approach enables you to push the boundaries of your creativity further while exploring the possibilities of what layered DTF prints can achieve in your projects. Each layering experience helps perfect the technique and contributes to your artistic growth.

DTF Printing Tips for Professional Quality

Achieving professional-quality results with DTF printing comes down to understanding a few key techniques and tips. One of the most important aspects to consider is the type of transfer powder used. Applying the right amount of powder is crucial for ensuring a successful adhesion of the print to the fabric. Aim for an even distribution to avoid heavy or discolored finishes that detract from the print’s overall appearance. Mastering this aspect makes a significant difference in the quality of your DTF transfers.

Moreover, after applying the transfers, it is essential to conduct a post-press treatment by ensuring the prints are properly cured. This step involves allowing the prints to set and cool completely, improving durability and color vibrancy. Regularly refining your technique and learning from past projects will help enhance your DTF printing skills, resulting in consistently high-quality outcomes. Each project is an opportunity to apply these tips and elevate the professionalism of your printed creations.

Testing Your DTF Projects for Success

Before moving on to larger production runs, testing is a vital practice in the DTF printing process. Conducting small test prints allows you to assess how each design interacts with different fabric types. This preliminary testing phase is essential for fine-tuning colors, adjusting placements, and determining the optimal sizes for text and images. By taking the time to test your designs, you can mitigate potential issues that may arise during full-scale production.

Testing not only helps in achieving the desired aesthetic but also provides insights into the durability and performance of your DTF transfers. By washing test samples and observing how they hold up under various conditions, you can make informed adjustments and ensure that your final products meet your standards. This diligence in the testing phase lays a strong foundation for successful DTF projects, fostering confidence as you explore your artistry further.

Frequently Asked Questions

How to use DTF transfers effectively?

To use DTF transfers effectively, start by printing your design on a specialized DTF film using a high-resolution image. Once printed, apply a layer of transfer powder evenly over the design, then cure it with heat to ensure it adheres well. Finally, position the film on your fabric, cover it with a protective sheet, and press with heat to transfer the design. These steps will help achieve vibrant and durable results in your DTF projects.

What are some essential DTF printing tips?

To improve your DTF printing results, consider using high-quality images with a minimum resolution of 300 DPI for clarity. Experiment with different fabrics to see their effects on color and texture—both cotton and polyester blends work great. Additionally, mastering the amount of transfer powder used and the correct heat settings will ensure professional application. Lastly, layering your designs can add depth and creativity to your DTF transfers.

What are the best fabrics for DTF transfers?

The best fabrics for DTF transfers include 100% cotton, polyester, and poly-cotton blends. Each fabric type reacts differently to the transfer process, affecting the final look and feel of your designs. Cotton offers a soft touch and good breathability, while polyester provides vibrant color retention. Combining these fabrics can yield unique textures and styles, expanding the creative possibilities of your DTF projects.

What are some creative DTF projects to try?

Creative DTF projects you can try include customizing t-shirts with your original artwork, designing unique tote bags with personal quotes, or creating striking home décor items like pillow covers and wall art. You can also experiment with layering techniques to make intricate designs pop. The versatility of DTF transfers allows for endless creative expressions.

How should I approach layering DTF prints?

When layering DTF prints, ensure to apply contrasting colors and textures to create depth. Allow each layer to cool completely before adding the next to avoid smudging and ensure good adhesion. Experiment with different layering techniques to discover unique design combinations that enhance the dimensionality of your DTF transfers.

How can testing prior to production benefit my DTF transfers?

Testing prior to production allows you to experiment with different materials and designs without wasting resources. Conducting small test prints helps you assess how colors and placements look on various fabrics, ensuring that your final DTF transfers meet expectations. This practice leads to refined processes and ultimately more successful and visually appealing outcomes in your projects.

| Key Points | Details |

|---|---|

| Maximizing Creativity with DTF Transfers | DTF transfers allow for intricate designs on various fabrics using heat, offering a modern approach to textile printing. |

| Use High-Resolution Images | Images should be at least 300 DPI for clarity and professional finishes. |

| Experiment with Fabrics | Different fabrics provide varied textures and finishes, influencing design outcomes. |

| Layering Techniques | Applying layers can create depth; allow each layer to cool to prevent smudging. |

| Incorporate Personal Elements | Adding personal touches makes designs unique and meaningful. |

| Use Transfer Powders Wisely | Balance in powder application is crucial for adhesion and finish quality. |

| Test Prior to Production | Perform small tests to ensure designs meet expectations before large runs. |

| Stay Updated | Continue learning about DTF techniques through articles and community discussions. |

Summary

DTF transfers are an innovative method to enhance your creativity in textile design, offering the ability to produce vivid prints on various fabrics with ease. By understanding and applying high-resolution images, experimenting with different materials, and leveraging layering techniques, you can unlock new levels of creativity. Personalizing designs with unique elements not only sets your work apart but also adds emotional value to the creations. Mastering the nuances of transfer application, including effective powder use, is essential for achieving professional results. Embrace the unique possibilities presented by DTF transfers, explore the medium, and watch your artistic visions flourish.