DTF Printing Process: From Concept to Creation Explained

The DTF printing process, or Direct-to-Film printing, is revolutionizing the custom apparel printing landscape by offering an innovative and versatile approach to fabric decoration. This advanced printing method allows for high-quality fabric prints with vibrant colors and intricate details that cater to a diverse range of textiles, including both light and dark fabrics. As more businesses and hobbyists embrace DTF printing technology, they are discovering its advantages over traditional methods like sublimation, particularly in terms of ease of use and design flexibility. By transforming digital images into physical prints without the extensive pre-treatment procedures often required by other techniques, the DTF printing process is quickly becoming a favored choice in the creative community. This blog post seeks to explore the nuances of this captivating process, providing insights into its benefits, applications, and the latest advancements in the industry.

The realm of fabric printing has evolved dramatically, and one of the standout techniques gaining recognition is the Direct to Film (DTF) printing method. This technology offers a seamless transition from digital designs to stunning apparel graphics, capturing the attention of both manufacturers and consumers in the custom textile market. When comparing DTF with other printing methods such as sublimation, it is clear that DTF provides an edge with its capability to produce vibrant designs on various fabric types, all while ensuring durability and longevity. As we delve deeper into this modern printing method, we will unravel the intricacies of how DTF encompasses the creative potential of artists and entrepreneurs alike, solidifying its place as a game-changer in custom prints.

The Fundamentals of Direct to Film Printing

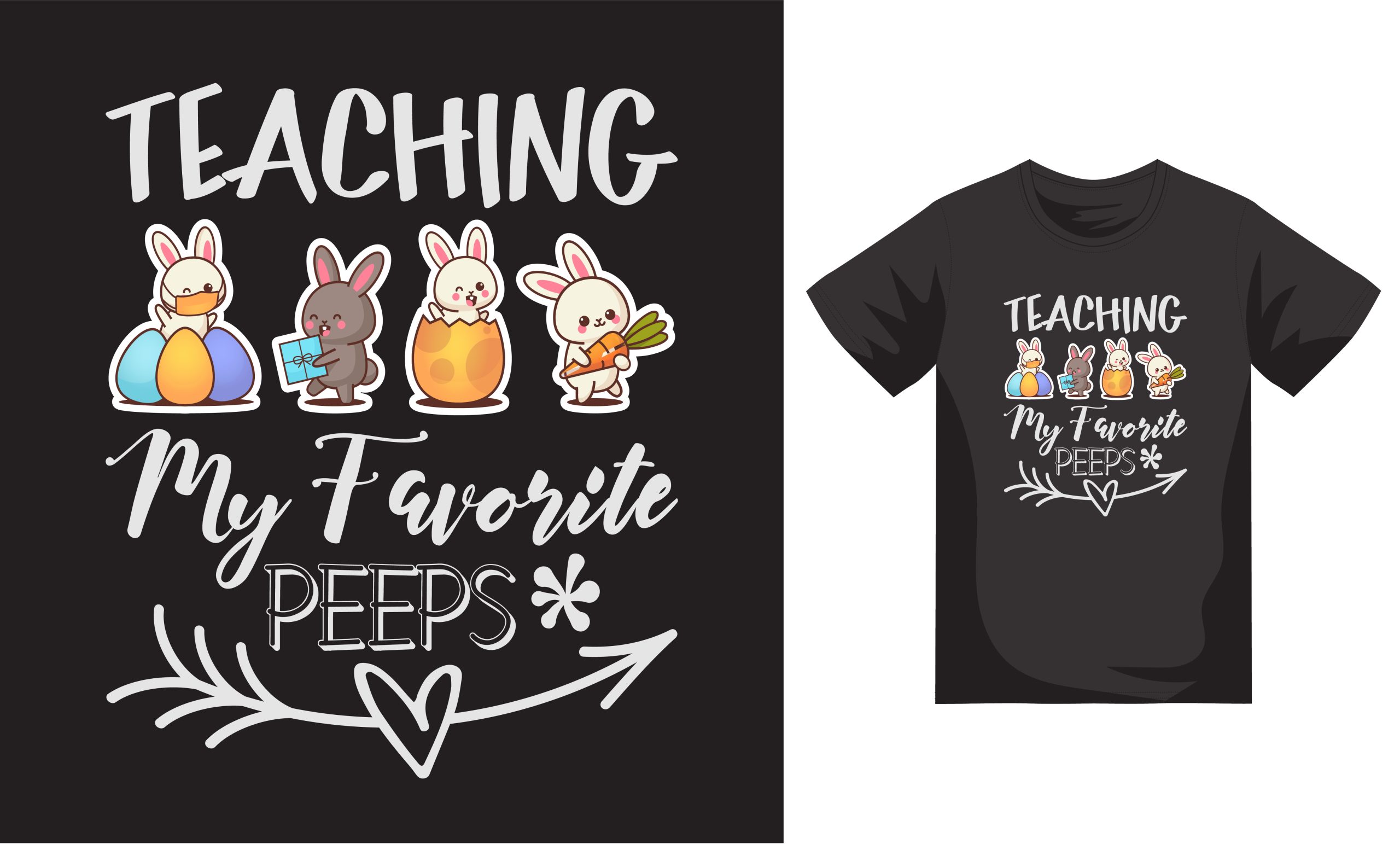

Direct to Film (DTF) printing is revolutionizing the custom apparel industry. This innovative process allows designers to create intricate images that can be printed on a variety of fabrics, catering to both casual wear and specialized clothing. DTF printing stands out due to its ability to produce vibrant colors and detailed designs, making it an appealing choice for businesses and hobbyists alike. The process is streamlined and efficient, eliminating many of the limitations found in traditional printing methods, and making it accessible for smaller operations.

Understanding the fundamentals of DTF printing involves recognizing its key benefits over other printing techniques. For instance, DTF technology does not restrict users to a single fabric type, as it accommodates different materials, including cotton, polyester, and blends, opening up opportunities for a diverse range of products. Additionally, the DTF process requires less pre-treatment than sublimation printing, ensuring a faster turnaround time and lower production costs, which are critical factors for small businesses aiming to remain competitive.

How DTF Printing Compares with Sublimation

When comparing DTF printing to sublimation, it’s essential to recognize the specific strengths of each method. Sublimation is often lauded for its ability to produce vibrant and durable graphics; however, it is limited primarily to polyester or coated fabrics. Conversely, DTF printing excels with various materials, including darker garments that sublimation cannot effectively handle. This flexibility allows designers to cater to a broader clientele, which is particularly beneficial when working with custom designs that demand diverse fabric options.

Moreover, the process of DTF printing eliminates the need for extensive preparation or pre-treatments typically associated with sublimation. In DTF, the image is printed onto a film and then transferred via heat to the fabric, ensuring a seamless application that maintains high quality. As a result, many apparel businesses are pivoting towards DTF technology for its straightforward workflow and adaptability, positioning it as an increasingly popular alternative to sublimation.

Exploring the Advantages of DTF Printing Technology

One of the most noteworthy advantages of DTF printing technology is its exceptional print quality. This process uses specialized inks that produce vibrant colors and fine details, ensuring that the final product meets the high-quality standards expected in custom apparel. Users have reported that garments printed with DTF inks retain their vibrancy and durability through numerous washes, making the method ideal for both personalized items and bulk orders.

Additionally, DTF printing allows for full-color images and even gradients, which can be quite challenging with traditional printing methods. This technological edge not only expands creative options for designers but also increases customer satisfaction, as end-users receive products that closely match their original visions. The dynamic capabilities of DTF printing open doors for unprecedented artistic expression, solidifying its place in the custom apparel market.

Step-by-Step Breakdown of the DTF Printing Process

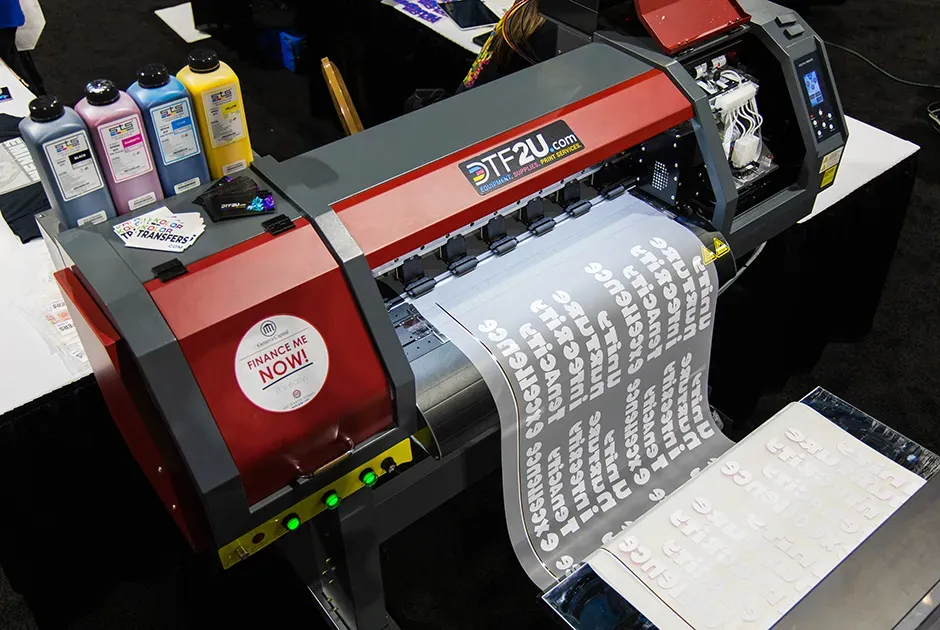

The DTF printing process can be broken down into several key steps, each playing a vital role in producing high-quality prints. It begins with design and image preparation, where graphic designers utilize design software to create stunning visuals tailored to specific fabric requirements. Following this, the image is printed onto a special DTF film using advanced inks, capturing every hue and detail with precision.

Next, the process involves applying an adhesive powder to the printed film while it’s still wet. This step is critical, as it ensures that the design will adhere firmly to the fabric during the heat transfer stage. Once the adhesive is cured through a heat tunnel, the film is ready for transfer to the garment, where heat and pressure activate the adhesive, bonding the design permanently. This meticulous process showcases DTF as a standout method for producing detailed and durable fabric prints.

Recent Innovations in DTF Printing Technology

Recent advancements in DTF printing technology have further solidified its position in the custom apparel market. Companies like XTool have launched next-generation DTF printers that integrate AI-assisted features, enhancing image precision and reducing waste during production. These innovations not only streamline workflows but also empower small and medium-sized enterprises (SMEs) to maintain high standards of quality while managing costs effectively.

Moreover, the absence of the need for specialized curing equipment with developments like Sawgrass’s VersiFlex technology showcases significant improvements in DTF’s usability. By simplifying the workflow and expanding options for fabric transfers, businesses can adapt more rapidly to consumer demands and stay ahead in a competitive market. These enhancements underscore the remarkable evolution of DTF printing, positioning it as a viable alternative to traditional methods.

The Future of Custom Apparel Printing with DTF

As the custom apparel industry continues to evolve, DTF printing is poised to play a significant role in shaping its future. With its ability to adapt to market trends and consumer preferences, DTF technology is becoming a go-to solution for businesses aiming to offer versatile and high-quality prints. The growing acceptance of DTF printing among designers and consumers alike reflects a shift towards more innovative and efficient methods of production.

Furthermore, the environmental impact of printing processes is becoming increasingly important. DTF printing, which generally uses fewer resources and generates less waste than traditional methods, stands to gain traction as sustainability becomes a crucial consideration for both businesses and consumers. By embracing eco-friendly practices and adapting to changing consumer demands, DTF printing technology not only ensures its relevance but also promises a vibrant future in the custom apparel landscape.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct-to-Film printing, involves creating high-quality fabric prints by transferring designs onto a special film. This process includes designing images, printing them on DTF film using specific inks, applying adhesive powder, curing the adhesive with heat, and finally using a heat press to transfer the design to the fabric. This technique provides vibrant designs that adhere well to various fabric types.

How does DTF printing technology differ from sublimation printing?

DTF printing technology differs from sublimation printing primarily in its application. While sublimation is limited to polyester or similar fabrics, DTF printing can be used on a wider range of materials, including cotton and blends, making it more versatile for custom apparel printing. Additionally, DTF does not require extensive pre-treatments, simplifying the workflow compared to sublimation.

What are the benefits of using DTF printing for custom apparel printing?

DTF printing offers several benefits for custom apparel printing, including the ability to print on both light and dark fabrics, high-quality and vibrant colors, and a simpler production process without extensive pre-treatments. Additionally, DTF technology is adaptable and cost-effective for small businesses, making it an attractive option for custom fabric prints.

Can DTF printing produce high-quality fabric prints?

Yes, DTF printing is capable of producing high-quality fabric prints. The DTF printing process utilizes specialized inks and a unique powder adhesive that ensures designs are vibrant and durable. The method allows for detailed and colorful designs that can withstand multiple washes and maintain their integrity over time.

What advancements have been made in DTF printing technology recently?

Recent advancements in DTF printing technology include innovations such as XTool’s next-generation DTF printer, which incorporates AI functionalities for precision, and EazyDTF’s enhancements in large-format printing capabilities. Additionally, Sawgrass’s VersiFlex technology simplifies the DTF process by eliminating the need for pre-treatments, thus improving efficiency and versatility in custom printing.

Is DTF printing suitable for beginners in the custom printing industry?

Yes, DTF printing is suitable for beginners in the custom printing industry. Its user-friendly process, requiring less technical expertise compared to some other methods, and the ability to print on a variety of fabrics make it an ideal choice for small businesses and hobbyists looking to create custom apparel with ease.

| Step | Description |

|---|---|

| 1. Design and Image Preparation | Graphic designers create tailored images using design software. |

| 2. Film Printing | The design is printed onto DTF film using specialized inks. |

| 3. Powder Application | Special adhesive powder is applied to the wet ink for adherence. |

| 4. Curing the Adhesive | The ink and powder are cured through a heat tunnel. |

| 5. Transfer to Garment | The film is heat-pressed onto the fabric, bonding the design. |

Summary

The DTF printing process has revolutionized the custom printing landscape, integrating innovative technologies that enhance quality and efficiency. With a straightforward multi-step approach involving design creation, film printing, powder application, adhesive curing, and final garment transfer, DTF printing caters to a diverse range of fabrics. As highlighted by advances from companies like XTool, EazyDTF, and Sawgrass, the DTF printing process continues to evolve, making it an appealing choice for businesses and hobbyists alike. This method not only produces vibrant designs on various fabrics but also emphasizes simplicity and versatility, ultimately shaping the future of the textile printing market.