UV DTF Technology: Top Tips for Getting Started

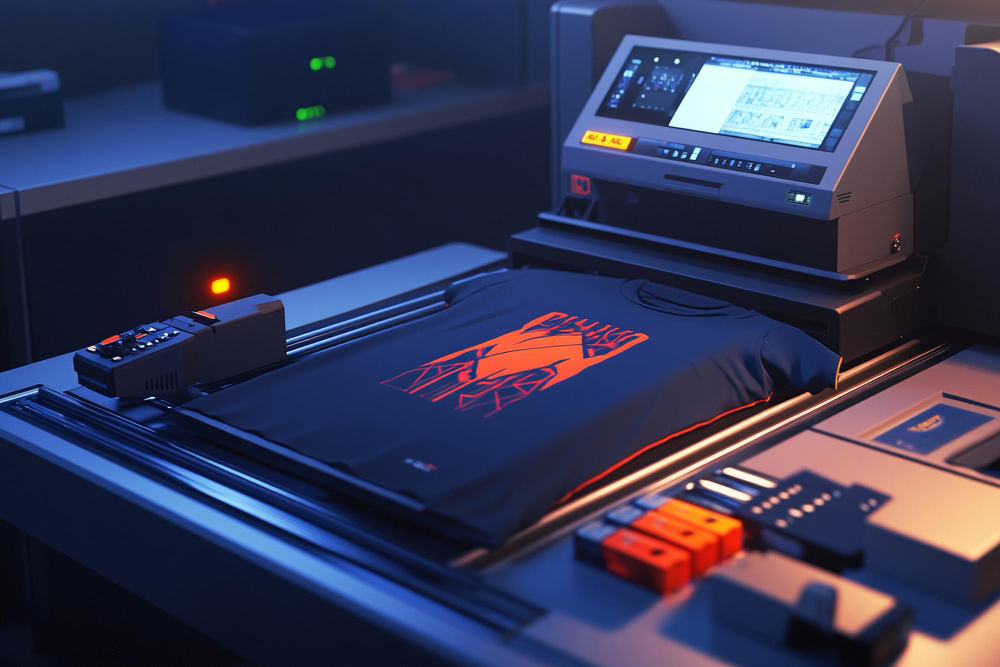

In the realm of innovative printing solutions, **UV DTF technology** (Ultraviolet Direct-to-Film) has emerged as a game changer for businesses eager to tap into custom product printing. This cutting-edge method blends the advantages of UV and DTF printing techniques to deliver exceptional results across various surfaces, including glass, metal, and plastics. As we delve deeper into the benefits of UV DTF, you’ll discover practical tips on how to use UV DTF effectively, ensuring that your creations are not only visually stunning but also durable and long-lasting. From understanding the basics to mastering transfer techniques, this comprehensive guide aims to equip both beginners and seasoned practitioners with the knowledge necessary to excel in this exciting field. Join us as we unlock the potential of UV DTF technology and explore its transformative impact on the printing industry.

Often referred to as Ultraviolet Direct-to-Film printing, this innovative technique revolutionizes the way we approach custom prints, offering heightened levels of versatility and durability. By integrating the principles of UV and DTF methodologies, this technology allows users to print vibrant colors on diverse materials such as ceramics and metals. With the rising popularity of this approach, many are keen to learn about the functionalities and techniques involved, leading to an increased interest in the beginner guide to UV DTF. From exploring its numerous benefits to understanding transfer processes, anyone venturing into this printing landscape can find valuable insights that will enhance their crafting endeavors. Let’s embark on a journey to discover how embracing UV DTF can elevate creative possibilities and business opportunities alike.

The Benefits of UV DTF Technology for Custom Products

UV DTF technology stands as a game-changer in the realm of custom product printing, offering numerous benefits that can enhance both the quality and versatility of prints. One of the standout features of UV DTF printing is its ability to produce vibrant colors with exceptional detail. Unlike traditional printing methods, UV printing uses ultraviolet light to cure the ink as it is printed, resulting in colors that pop and designs that stand out. This is particularly advantageous for businesses looking to deliver high-quality custom products that capture customer attention.

In addition to color vibrancy, UV DTF technology provides increased durability for printed materials. The prints resist fading, scratches, and general wear, making them ideal for items that may be exposed to harsh conditions or heavy handling. For instance, when printing on items such as promotional merchandise, signage, or personalized gifts, the longevity of UV DTF outputs ensures that they retain their appeal over time. This not only adds value to products but also enhances customer satisfaction.

How to Use UV DTF in Your Printing Projects

Using UV DTF technology in your printing projects involves a clear understanding of its processes and the equipment required. To get started, select a high-quality UV DTF printer designed to handle various materials, including non-porous surfaces like metal and glass. Ensure that your equipment is compatible with specialty DTF films that enhance print quality and adhesion. Learning about the different film types available can help you choose the best option that suits your project’s needs.

Once you’ve set up the right equipment, mastering the design software plays a crucial role in successful UV DTF printing. Familiar programs like Adobe Illustrator or CorelDRAW allow you to create intricate designs that are tailored specifically for DTF printing. It’s important to focus on how colors will translate onto the printed medium, as well as file preparation. Utilizing templates and understanding resolution settings will help achieve optimal results in your projects.

Mastering DTF Transfer Techniques for Success

To achieve outstanding results in UV DTF printing, mastering transfer techniques is essential. These techniques vary depending on the material being printed and the specific requirements of the project. For instance, it’s vital to experiment with different pressure settings, temperatures, and application times to find the best combination for successful transfers. Following guidelines from established resources can help streamline the learning process and enhance the quality of your final product.

Furthermore, understanding the importance of proper handling during the transfer process cannot be understated. Each material reacts differently to UV DTF prints, which can affect the overall outcome. For example, adjusting the heat press settings based on whether you are applying prints to ceramics or plastics can lead to significantly different results. By developing a keen sense of how each component interacts, you can elevate your UV DTF projects to new heights.

Exploring the Latest Trends in UV DTF Printing

Staying ahead of the curve in UV DTF technology requires continuous education and awareness of industry trends. The printing landscape is always evolving, with new techniques and materials becoming available regularly. Subscribing to industry publications, following blogs, and participating in workshops can be beneficial for catching up on the latest innovations in UV DTF printing. Understanding these trends enables businesses to adapt their strategies, remain competitive, and attract a broader customer base.

Additionally, embracing advancements in software and hardware related to UV DTF printing can result in significant efficiency gains. For example, improved color management tools and software plugins can streamline the design and printing workflow, helping businesses produce high-quality outputs faster than ever. By integrating these innovations into your printing processes, you’re not only enhancing the quality of your work but also positioning your business as a forward-thinking leader in the industry.

Getting Started with UV DTF: A Beginner’s Guide

If you’re new to UV DTF technology, starting your journey may seem daunting. However, breaking it down into manageable steps can simplify the process. Begin by researching the equipment and resources you will need, such as a suitable UV DTF printer, films, and design software. Many online tutorials and guides are available, providing insight into best practices and common pitfalls to avoid. Taking advantage of these resources can fast-track your understanding of UV DTF.

In addition to researching equipment, connecting with professionals in the field can provide valuable insights. Joining communities dedicated to UV DTF printing can be a great way to find mentorship and support as you navigate this new territory. Engaging with peers allows for the sharing of experiences and techniques, which can significantly boost your learning curve and help you become proficient in UV DTF technology.

Optimizing Your Printing Process with UV DTF

Once you have established a foundational understanding of UV DTF technology, it is crucial to optimize your printing process for the best results. This includes fine-tuning your printer settings to ensure high-quality outputs. Adjust settings related to resolution, color profiles, and media types based on the material you’re using. It’s often beneficial to conduct regular test prints and make adjustments as needed to perfect your process.

Furthermore, focusing on post-printing processes can greatly enhance the final product’s durability and overall appeal. Techniques such as heat pressing your prints can improve adhesion and prevent peeling or fading over time. Additionally, implementing routine maintenance checks on your equipment ensures that everything functions properly, further guaranteeing that your UV DTF projects maintain consistent quality. In summary, optimizing your printing workflow can directly impact your success in using UV DTF technology.

Frequently Asked Questions

What is UV DTF technology and how does it work?

UV DTF technology, or Ultraviolet Direct-to-Film printing, works by combining UV printing techniques with DTF methods to create vibrant and durable prints. The process involves printing designs onto a special DTF film using UV light to cure the inks, allowing them to adhere to various surfaces such as glass, metal, and plastics.

What are the benefits of using UV DTF printing for custom designs?

The benefits of UV DTF printing include exceptional color vibrancy, increased durability against scratches and fading, and enhanced efficiency in production. This technology allows businesses to create high-quality custom products that can withstand wear and tear, making it a versatile choice for various applications.

How to use UV DTF technology effectively for beginners?

For beginners, effective use of UV DTF technology starts with choosing the right printer and DTF films, mastering design software, and understanding transfer techniques. Moreover, optimizing print quality settings and experimenting with post-printing processes can significantly enhance results and ensure successful printing outcomes.

What types of surfaces can benefit from UV DTF transfer techniques?

UV DTF transfer techniques can be applied to a wide range of non-porous surfaces, including glass, ceramics, metals, and certain plastics. This versatility makes it an ideal choice for custom product printing across different industries.

Is there a beginner guide to UV DTF printing that can help my learning process?

Yes, there are many resources available for beginners, including comprehensive guides that cover the fundamentals of UV DTF printing. These guides typically provide tips on equipment selection, software usage, and practical applications of UV DTF technology.

How can I improve the quality of my UV DTF prints?

Improving the quality of UV DTF prints involves prioritizing printer settings for resolution and color accuracy, using the right DTF films, and refining your design files for optimal output. Regular test printing can also help identify adjustments needed to achieve the best print quality.

| Key Point | Details |

|---|---|

| Introduction | UV DTF technology offers advanced printing capabilities for custom product printing, enhancing traditional methods with versatility and durability. |

| Understanding UV DTF Technology | Combines UV printing with Direct-to-Film methods, suitable for printing on glass, metal, ceramics, and plastics. Benefits include color vibrancy, durability, and efficiency. |

| Choose the Right Equipment | Invest in quality UV printers and compatible DTF films with advanced features. |

| Understand Film Types | Different DTF films impact print outcome. Familiarize with specialty films for UV printing. |

| Master Your Design Software | Use tools like Adobe Illustrator and Photoshop for intricate designs adapted for UV DTF. |

| Experiment with Transfer Techniques | Try various pressure, temperature, and application times for best print results. |

| Prioritize Print Quality Settings | Optimize printer settings for resolution, color, and media type, frequently testing print quality. |

| Focus on Post-Printing Processes | Enhance durability through heat pressing and understanding post-print procedures. |

| Stay Updated with Industry Trends | Keep informed on industry trends via blogs and resources to leverage innovations. |

Summary

UV DTF technology is revolutionizing the printing industry by providing unique capabilities for custom print applications. With its ability to print on a wide range of surfaces and produce vivid colors that are durable, UV DTF technology is becoming a go-to choice for businesses looking to innovate. By understanding the various aspects of this technology—from equipment selection to design mastery—businesses can leverage UV DTF technology to not only enhance their product offerings but also improve their production efficiency. As you dive deeper into this exciting domain, remember that the ongoing learning process is essential for success. Embrace this innovative printing method, and watch as it transforms your creative potential and market opportunities.