DTF Transfers: Comparing Printing Methods for Best Output

DTF transfers, or Direct to Film transfers, have emerged as a game-changing option in the world of custom apparel printing. This innovative method allows for vibrant designs to be transferred onto a variety of fabrics, making it a compelling alternative to traditional techniques like sublimation printing and heat transfer printing. As businesses seek efficient and versatile solutions, the comparison of DTF vs sublimation highlights the unique advantages DTF offers in fabric compatibility and turnaround times. With a growing interest in printing methods comparison, many creators are beginning to appreciate how DTF transfers can meet diverse artistic needs. In this guide, we will delve into the nuances of DTF transfers, exploring their benefits and how they stand apart from other popular printing methods.

When discussing modern printing techniques, terms like Direct to Film (DTF) and heat transfer printing come into play, each offering distinct benefits for customizing apparel. The evolution of these methods has sparked a fascinating conversation around the effectiveness of DTF transfers compared to various alternatives such as sublimation printing. As creative entrepreneurs navigate their way through the options available for custom designs, understanding the differences in fabric compatibility and print qualities becomes essential. Whether you’re considering DTF for its speedy production or sublimation for its color vibrancy, the choice between these approaches can significantly influence the outcome of your projects. Let’s dive deeper into the realm of DTF and related techniques to uncover which printing solutions best suit your needs.

Understanding DTF Transfers and Their Process

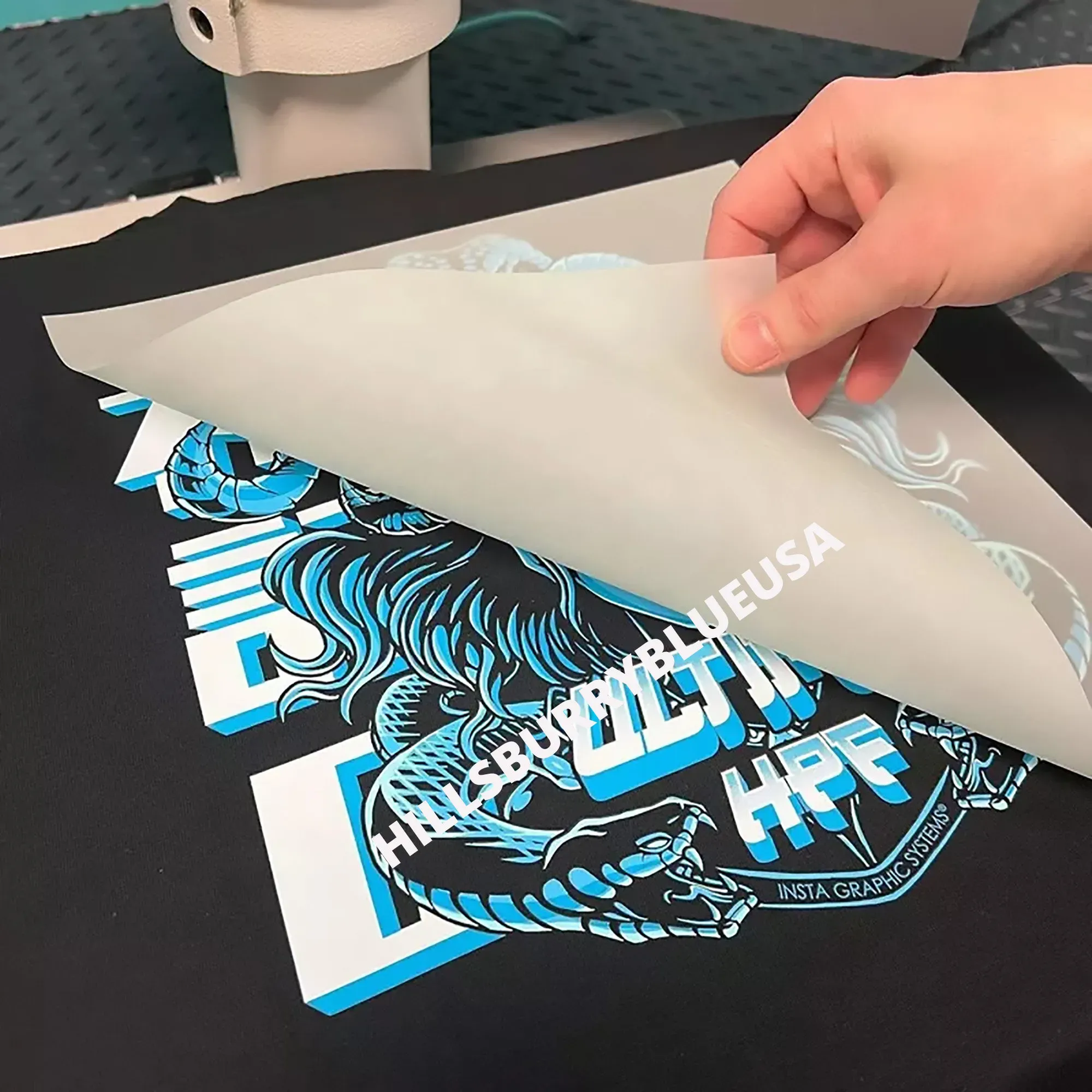

DTF transfers, or Direct to Film transfers, represent a significant advancement in custom printing technology. This method involves printing designs onto a specialized film using a high-quality textile printer. Once the design has been printed, a hot-melt adhesive is applied, enabling the transfer of the design onto various fabric types. This process utilizes a combination of heat and pressure, allowing the printed film to adhere effectively to the fabric surface. The versatility of DTF transfers makes them an attractive option for businesses looking to produce custom apparel.

What sets DTF transfers apart from other methods is their compatibility with a wide range of materials. Unlike sublimation printing, which works best on lighter-colored polyester fabrics, DTF transfers can be applied to cotton, polyester blends, and even dark fabrics. This flexibility opens up new avenues for custom apparel production, making it a preferred choice for many businesses that require diverse applications in their product lines.

Frequently Asked Questions

What exactly are DTF transfers in custom apparel printing?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film using a textile printer. After printing, a hot-melt adhesive is added, allowing the design to be transferred to various fabrics with heat and pressure. This method is versatile, making it suitable for cotton, polyester, and blended fabrics.

How do DTF transfers compare to sublimation printing?

DTF transfers have significant advantages over sublimation printing, especially in fabric compatibility. While sublimation is best for lighter polyester fabrics, DTF can be successfully applied to cotton, dark fabrics, and blends, making it a more versatile option in custom apparel printing.

What are the main benefits of using DTF transfers for custom designs?

The primary benefits of DTF transfers include their versatility across multiple fabric types, quick turnaround times offered by providers like Sam’s DTF Transfers, and improved durability thanks to advancements in DTF technology. These features make DTF a strong contender in the custom printing market.

Are there any downsides to using DTF transfers compared to other printing methods?

While DTF transfers offer many advantages, some downsides include the potential texture left on fabrics after application, which may not be desirable for all users. Additionally, those accustomed to traditional methods may face a learning curve when adapting to the DTF process.

What recent innovations have been made in DTF printing technology?

Recent innovations in DTF printing technology include enhancements in print quality, vibrancy, and durability. Companies like Insta Graphic Systems are leading the charge with advanced DTF heat transfer products that promise superior results, helping DTF remain competitive against sublimation and other printing methods.

Which method is better for custom apparel: DTF transfers or sublimation?

The choice between DTF transfers and sublimation largely depends on your specific printing needs. DTF transfers excel in versatility and fabric compatibility, making them ideal for a range of materials. Conversely, sublimation is preferred for vibrant designs on polyester. Assess your project’s fabric requirements to choose the best method.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF (Direct to Film) is a custom printing method that shows versatility over traditional techniques like sublimation and screen printing. |

| What Are DTF Transfers? | Involves printing designs on a special film with a textile printer, applying a hot-melt adhesive to allow transfers on various fabrics. |

| DTF vs. Sublimation | DTF transfers are more versatile as they can be applied to cotton, polyester, and dark fabrics, while sublimation is limited mostly to lighter polyester. |

| Vibrancy and Quality | DTF technology is improving rapidly, enhancing vibrancy and durability to compete with sublimation’s quality. |

| Texture and Feel | DTF prints may have a visible texture, which could be a pro or con based on the product’s desired feel. |

| Innovations in DTF Technology | Companies are launching innovations that enhance the quality of DTF transfers, boosting their market appeal. |

| Pros of DTF Transfers | 1. Works on a wide range of fabrics including dark materials. 2. Quick turnaround with same-day services. 3. Increasing durability. |

| Cons of DTF Transfers | 1. Potential texture may not appeal to all. 2. A learning curve for those used to traditional methods. |

| Making the Right Choice | The choice between DTF and other methods depends on project specifics; businesses needing flexibility may prefer DTF. |

Summary

DTF transfers represent a revolutionary method in custom printing, emphasizing versatility and efficiency in the apparel industry. As this technology continues to advance, it holds significant promise for meeting various fabric needs and delivering high-quality results. Unlike traditional methods, DTF transfers are suitable for multiple fabric types, including cotton and dark materials, making them a valuable option for diverse applications. With businesses like Sam’s DTF Transfers setting a standard for quality and service, opting for DTF transfers in your printing endeavors can notably enhance your creative and commercial prospects. Embracing such innovation ensures that your custom apparel is both unique and competitive in today’s market.