DTF Supplies: Choosing the Best for Your Printing Business

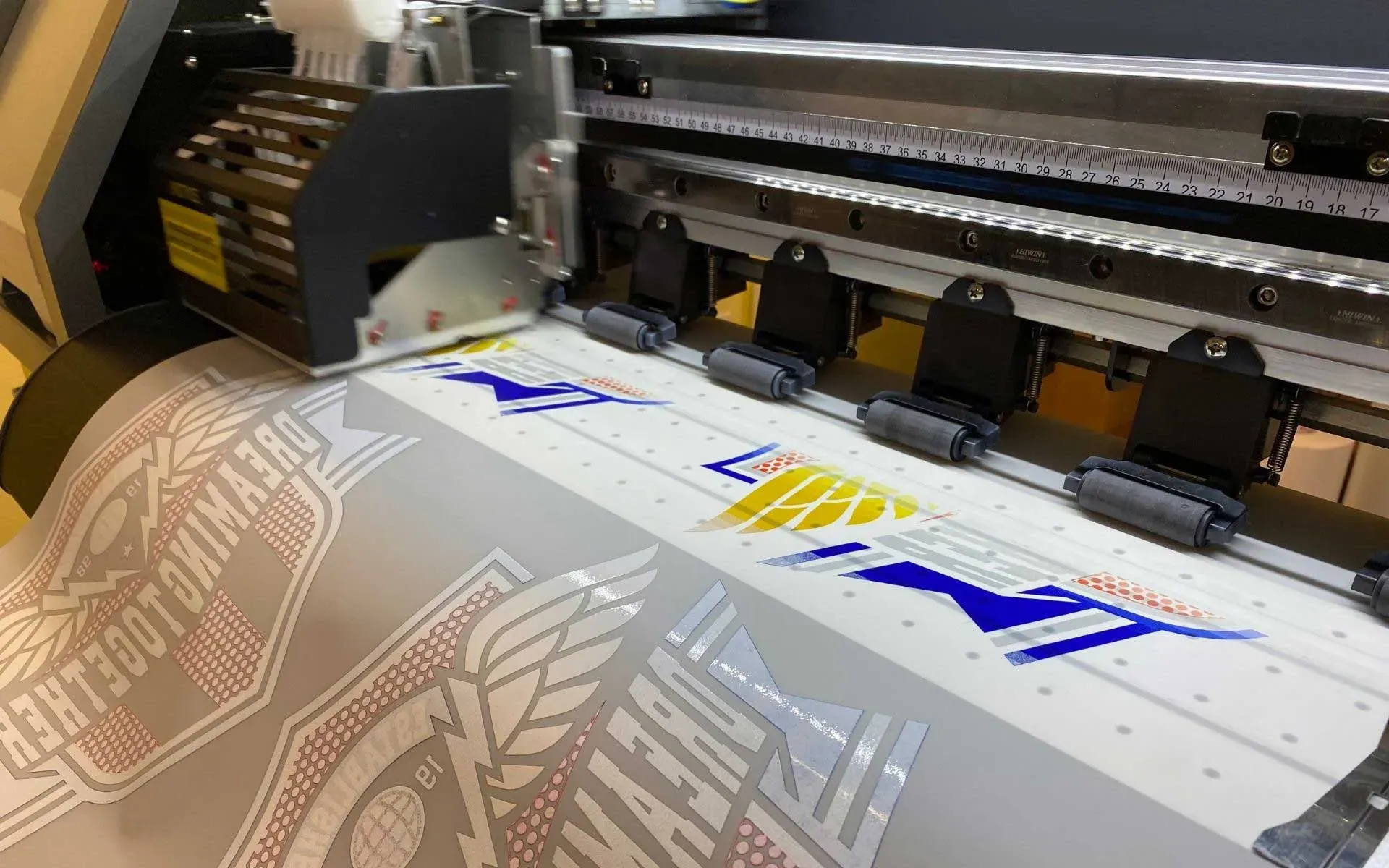

DTF Supplies are the backbone of any successful DTF printing operation, crucial for producing vibrant and lasting prints. As the demand for high-quality prints on a variety of fabrics continues to rise, selecting the right DTF supplies becomes paramount. From the DTF printer that lays down your designs to the DTF transfer films that carry your creations, each component plays a vital role in achieving optimal results. Quality DTF inks are equally important, ensuring that your prints boast vivid colors and sharp details. In this guide, we’ll explore how to choose the best DTF supplies to elevate your printing business to new heights.

When it comes to enhancing your printing business, understanding the essentials of direct-to-film printing supplies is key. These materials, including specialized printers and versatile transfer films, are designed to work cohesively, ensuring the highest standards of print quality. Opting for superior inks and reliable heat application equipment is part of the journey toward achieving impressive results on a range of fabrics. As you navigate the world of DTF technology, consider how these foundational elements, often overshadowed by the allure of new trends, significantly impact both efficiency and customer satisfaction.

Understanding DTF Printing and Its Advantages

Direct to Film (DTF) printing represents a significant advancement in the printing industry, characterized by its ability to produce high-quality graphics on various fabric types. Unlike traditional screen printing, which can be limited by the colors and details it can reproduce, DTF printing excels in versatility, allowing for intricate designs with stunning color vibrancy. This method is particularly beneficial for businesses looking to capitalize on the growing demand for custom apparel, as it is suitable not only for cotton but also for polyester and blends.

Additionally, one of the key advantages of DTF printing is its ability to work with different types of DTF transfer films. This flexibility means that businesses can cater to a wider range of clients and fabric preferences, setting themselves apart in a competitive market. The process involves using specially formulated DTF inks that ensure adhesion and durability when heat-applied to substrates, thereby enhancing the longevity of the prints.

Essential Components of DTF Supplies

When it comes to DTF printing, understanding the essential components is crucial. High-quality DTF supplies can significantly impact the output quality, which includes DTF printers, films, inks, and heat press equipment. Your choice of DTF printer should prioritize compatibility with DTF transfer films and inks, providing optimal output. Brands like Epson are often recommended due to their advanced technology and reliability.

The choice of DTF transfer films is equally important. Not all films are created equal; factors such as the film’s thickness and coating directly influence print vibrancy and adherence. It’s wise to invest in reputed brands known within the community for their performance, ensuring that the end product meets customer expectations for quality and durability.

Choosing the Right DTF Printer for Your Needs

Selecting the right DTF printer is one of the most critical steps in setting up a successful DTF printing business. Not only should the printer be capable of producing high-resolution images, but it should also be optimized for DTF processes. This includes checking for capabilities such as ink deposition settings and color accuracy. Brands like Mimaki and Epson are frequently favored for their specific designs that cater directly to DTF printing needs.

Moreover, investing in a printer that offers easy maintenance and support is essential. The long-term viability of your printing business heavily relies on the efficiency and reliability of your printing equipment. Regular maintenance and the availability of replacement parts can make a big difference in minimizing downtime and costly repairs.

Importance of DTF Transfer Films

DTF transfer films are arguably the backbone of the printing process. They are responsible for transferring the ink onto fabric, making it imperative to choose the right type. High-quality DTF films work seamlessly with your printer and inks, ensuring that colors appear vibrant and details remain sharp after the heat application. The choice of films can vary in thickness and type, influencing both the tactile quality of the finished product and its reliability.

Investing in the best DTF transfer films typically means better adhesion, flexibility, and overall print quality. For a successful DTF printing venture, understanding different film types and their applications is crucial. By analyzing user reviews and professional recommendations, you can find suitable options that align with your printing objectives.

Selecting High-Quality DTF Inks and Powders

The quality of DTF inks and powders directly affects the overall vibrancy and durability of your prints. It is advisable to choose inks that are specifically designed for DTF processes, as they offer better adhesion and color fastness. Brands that have established a solid reputation within the DTF community are often your best bet for achieving premium results.

Additionally, ensure compatibility between your DTF inks and your printer for optimal performance. Investing in high-quality DTF powders that are appropriate for your fabric types will also help in increasing the effectiveness of your prints. Overall, the careful selection of these supplies is essential for maintaining bright colors and a professional finish on all garments.

Cost-Effectiveness and Sustainability in DTF Supplies

In the competitive landscape of DTF printing, balancing cost-effectiveness with quality is paramount. It’s tempting to opt for lower-cost supplies, but this can lead to subpar print results and dissatisfied customers. High-quality DTF supplies might require a larger upfront investment, but their longevity and efficiency often lead to greater savings in the long run.

Additionally, businesses are increasingly focused on sustainability. Choosing environmentally friendly DTF inks and transfer films can not only appeal to eco-conscious customers but also enhance your brand image. It’s essential to stay informed on the latest eco-friendly advancements in DTF supplies, which will allow you to adopt practices that benefit both your business and the environment.

Frequently Asked Questions

What are DTF supplies and why are they important for DTF printing?

DTF supplies refer to the essential components used in Direct to Film (DTF) printing, including DTF printers, transfer films, inks, and heat press equipment. They are crucial because high-quality DTF supplies ensure vibrant prints, optimal compatibility, and overall efficiency, directly impacting print quality and customer satisfaction.

How do I choose the right DTF printer for my business?

When selecting a DTF printer, it’s important to consider factors like compatibility with DTF inks and transfer films, print quality, and user reviews. Brands like Epson and Mimaki offer reliable options specifically designed for DTF printing, ensuring optimal ink deposition and performance.

What should I look for in high-quality DTF transfer films?

High-quality DTF transfer films should feature appropriate thickness, coating, and compatibility with your DTF inks and printer. These factors influence color vibrancy and sharpness of the final prints, making it essential to invest in films that have positive user feedback.

Can I use any type of ink for my DTF printer?

No, it’s vital to use DTF inks specifically designed for your DTF printer. Different inks can produce varying results in quality and stability when transferred to fabrics. Choosing reputable brands known for their DTF inks can lead to better longevity and print quality.

Why is it essential to keep my DTF printing environment clean?

Maintaining a clean workspace is crucial in DTF printing as it helps to avoid contamination of inks and films, leading to improved print quality. Cleaning supplies ensure your DTF printer and other equipment function optimally, prolonging their lifespan and minimizing print failures.

What factors should I consider regarding the cost of DTF supplies?

When evaluating DTF supplies, consider the long-term cost-effectiveness rather than just upfront costs. Investing in high-quality DTF supplies may be more expensive initially but can save you money on reprints and ensure superior print quality, enhancing customer satisfaction.

| Key Points | Details |

|---|---|

| Understanding DTF Printing Technology | DTF printing transfers ink onto film applied to fabrics with heat, producing high-quality images on various materials. |

| Essential DTF Supplies | 1. DTF Printers – Look for models designed for DTF with better ink deposition. 2. DTF Transfer Films – Invest in high-quality films for vibrant colors. 3. Inks and Powders – Choose compatible inks and reliable brands. 4. Heat Press Equipment – Ensure even heat and pressure during transfers. 5. Cleaning Supplies – Maintain a clean environment to prolong printer life. |

| Factors to Consider | 1. Compatibility – Ensure supplies work together seamlessly. 2. Quality – Choose high-quality materials for better print outcomes. 3. User Reviews – Read insights and recommendations before purchasing. 4. Cost-Effectiveness – Invest in quality to save on reprints. 5. Stay Updated – Keep abreast of the latest DTF technologies. |

Summary

DTF Supplies are essential for your printing business, significantly affecting the quality and efficiency of your production process. Choosing the right Direct to Film supplies requires a comprehensive understanding of your equipment and the materials needed for top-notch results. It is critical to select high-quality DTF printers, vibrant transfer films, and compatible inks to ensure seamless operation. Regular maintenance and knowledge of industry advancements will further enhance your business. By investing wisely in these supplies, you not only improve the quality of your prints but also boost customer satisfaction, ultimately paving the way for your success in the competitive DTF printing market.