DTF Gangsheet Builders: Top Choices for Your Printing Needs

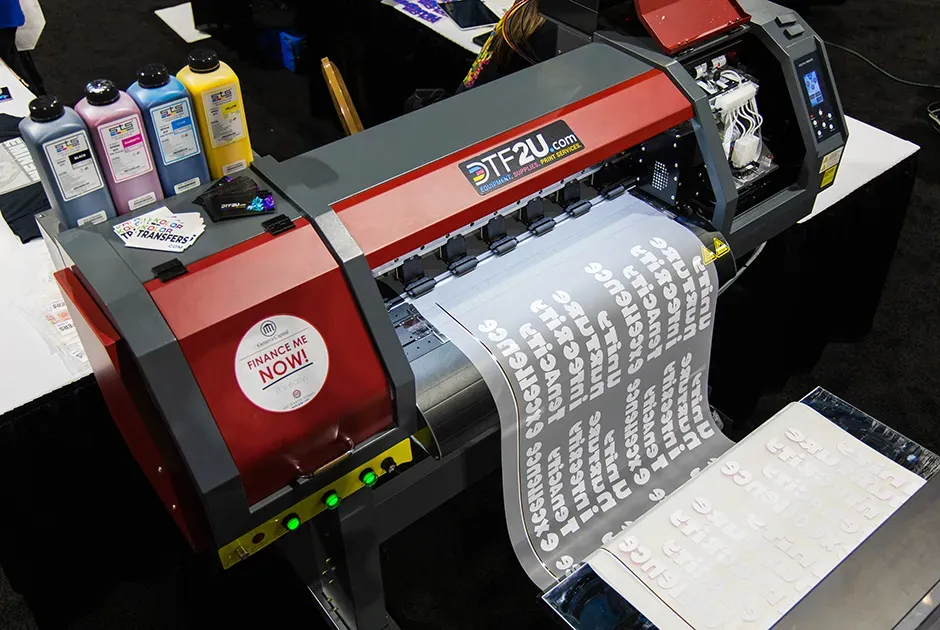

DTF bandsheet builders have revolutionized the Direct-to-Film printing landscape, catering to businesses seeking high-quality, efficient printing solutions. This innovative method enables the production of multiple designs on a single gangsheet, streamlining the DTF printing process for a variety of applications. Among the top contenders in the market, brands like Mimaki printers, Epson SureColor, and Roland VersaUV stand out for their reliability and superior print quality. These printers not only deliver vibrant colors but also offer features tailored to meet diverse substrate needs and printing demands. By exploring the best DTF printers available, users can optimize their output and ensure that their final products meet professional standards.

When it comes to creating detailed textile prints, the term ‘DTF bandsheet builders’ describes specialized tools designed for crafting high-quality gang sheets in Direct-to-Film applications. Also referred to as DTF printing solutions, these devices enable the efficient placement of multiple designs on one film sheet, enhancing production efficiency. In the competitive landscape of printing technology, brands like Mimaki, Epson SureColor, and Roland VersaUV lead the way, merging quality with innovation. Each of these manufacturers provides unique features and capabilities, allowing for a tailored printing experience. Understanding the landscape of DTF printing tools is essential for businesses looking to elevate their production processes.

The Advantages of Using DTF Bandsheet Builders

DTF bandsheet builders have revolutionized the printing industry by simplifying the production of large-scale designs on fabric and other materials. One of the primary advantages of using these builders is their ability to maximize efficiency. By allowing multiple designs to be printed on a single sheet, users can significantly reduce material waste and save on production costs. Additionally, DTF printing offers exceptional detail and color depth, making it ideal for complex designs that require precision. This feature is especially beneficial for businesses aiming to produce high-quality garments or merchandise.

Another key advantage of DTF bandsheet builders is their compatibility with a wide range of materials, from cotton to polyester blends. This versatility enables both small businesses and large-scale operations to cater to a diverse clientele. Moreover, advancements in DTF printing technology have led to improvements in ink formulations, such as the recent updates from brands like Epson SureColor, ensuring vibrant prints that withstand the test of time. As a result, companies can meet growing customer demands and create durable products that are not only visually appealing but also long-lasting.

Exploring the Best DTF Printers on the Market

When it comes to selecting the best DTF printers, the choices can be overwhelming. However, some top contenders consistently emerge as favorites among professionals in the industry. The Mimaki UJF Series stands out for its superior print quality and reliability, making it well-suited for businesses that prioritize detailed and vibrant designs. Additionally, the Epson SureColor F-Series has garnered attention for its color accuracy and cost-effective ink options. These printers utilize advanced technology to ensure that the output meets high standards while providing flexibility in handling various substrates.

Furthermore, Roland VersaUV printers are recognized for their user-friendly design, allowing even newcomers to navigate DTF printing with ease. Their blend of UV and eco-solvent technology provides a versatile solution that is perfect for a range of applications. On the other hand, the Brother GTX Pro caters specifically to garment printing, showcasing impressive speeds and high-quality outputs that meet commercial demands. Ultimately, identifying the best printer involves understanding your unique printing needs, budget, and the types of materials you intend to work with.

Navigating the DTF Printing Process

The DTF printing process involves several steps, beginning with design creation and ending with the application of the print onto the desired material. After a design is created, it is transferred to a special film where the DTF inks are printed. This step is crucial as it determines the quality and vibrancy of the final product. Brands like Brother and Roland have crafted their printers to optimize film quality and printing speed, thereby enhancing the overall workflow. Understanding the nuances of the DTF process can significantly impact the end results, influencing both the quality of prints and efficiency.

Once the designs are printed on the film, they undergo a heat transfer process that ensures proper adhesion to the material. This stage is critical, as it involves specific temperatures and timings that can alter the print’s durability and finish. It’s essential to have a well-calibrated heat press, particularly when working with different substrates. As technology evolves, brands like Epson and Mimaki have introduced cutting-edge equipment that simplifies the heat transfer process, allowing for consistent results. Familiarity with the DTF printing process not only improves the quality of outputs but also enhances productivity and user satisfaction.

Understanding Material Compatibility in DTF Printing

Material compatibility is a fundamental aspect to consider when engaging in DTF printing. Different printers may have specific requirements or limitations regarding the types of substrates they can effectively print on. For instance, while the Epson SureColor excels with synthetic materials, the Roland VersaUV may offer more versatility across various surfaces, including rigid substrates. Understanding the compatibilities can help businesses gain a competitive edge, ensuring that they can cater to diverse client needs without compromising print quality.

Moreover, recent advancements in DTF printing technology have led to the development of specialized inks that improve adhesion and durability on various materials. Manufacturers are continually updating their printer capabilities to stay ahead of competitors, emphasizing the need for businesses to stay informed. For example, Mimaki’s recent updates focus on enhancing gangsheet alignment, allowing for better material use without sacrificing quality. By choosing the right DTF printer that aligns with material compatibility, businesses can achieve superior results that meet evolving market demands.

Cost Considerations in DTF Printing

When evaluating DTF printing options, cost considerations play a pivotal role in decision-making. Initial investments can vary widely among different DTF band sheet builders, with high-quality options from brands like Mimaki and Epson typically coming with a higher price tag. Businesses need to assess their budget constraints while considering the potential return on investment. While a higher upfront cost may seem daunting, it often assures better durability, less frequent maintenance, and ultimately, a more efficient printing process.

Additionally, operational costs, including ink consumption and maintenance, must also be factored into the overall budget. Printers like the Brother GTX Pro are designed for high-volume outputs but may incur higher ink costs due to their speed and color vibrancy. Conversely, models that offer lower upfront costs may end up being more expensive in the long run if they require frequent repairs or maintenance. By thoroughly analyzing both initial and ongoing costs, businesses can make informed decisions that align with their financial goals while achieving the desired print quality.

Recent Innovations in DTF Technology

Staying abreast of recent innovations in DTF technology can significantly enhance a business’s competitive advantage. Manufacturers like Roland and Epson are continually rolling out updates that improve both printer functionality and print quality. For instance, Epson has recently introduced an improved ink formula that increases color vibrancy and longevity for DTF applications. Such advancements not only benefit print shops looking to offer high-quality outputs but also provide opportunities for businesses to attract more customers due to superior product offerings.

Moreover, the latest software developments are streamlining the gangsheet layout process, reducing time spent on setup and design. Mimaki’s recent updates to their printing software have made it easier to manage gangsheet configurations, ensuring that users can maximize efficiency when printing multiple designs. These innovations reflect a broader trend in the DTF printing landscape toward user-friendly technology that enhances productivity. By keeping up with such advancements, businesses can adapt and innovate, ensuring they remain relevant in a fast-evolving market.

Frequently Asked Questions

What are the best DTF bandsheet builders available in the market today?

Some of the best DTF bandsheet builders include the Mimaki UJF Series, Epson SureColor F-Series, Roland VersaUV Series, and Brother GTX Pro. These printers are known for their quality, reliability, and ease of use, catering to various printing needs.

How does the DTF printing process work with bandsheet builders?

The DTF printing process involves printing designs onto a film sheet which is then transferred onto the substrate, such as fabric. Bandsheet builders help streamline this process by allowing multiple designs to be printed on a single sheet, enhancing efficiency and reducing waste.

Why should I choose Mimaki printers for DTF bandsheet building?

Mimaki printers, particularly the UJF Series, are favored for their superior print quality, durability, and versatility across different substrates. Their ability to provide vibrant colors and fast print speeds makes them an excellent choice for DTF bandsheet building.

What features make the Epson SureColor a top choice for DTF bandsheet builders?

The Epson SureColor F-Series offers outstanding color accuracy and precision, making it suitable for DTF printing. It supports both DTF and dye-sublimation techniques, providing flexibility in printing options while maintaining cost-effective ink solutions.

Can the Roland VersaUV series enhance the DTF printing process?

Yes, the Roland VersaUV series combines UV and eco-solvent printing technologies, allowing for a versatile approach to DTF bandsheet building. It provides excellent reliability and a user-friendly interface, making it a suitable choice for both beginners and experienced users.

What should I consider when selecting a DTF bandsheet builder for my business?

When selecting a DTF bandsheet builder, consider the budget, print quality, speed versus quality balance, and material compatibility. Assessing these factors will help you find a model that aligns with your operational needs and business priorities.

| DTF Gangsheet Builder | Overview | Pros | Cons | Recent Development |

|---|---|---|---|---|

| Mimaki UJF Series | Highly regarded for superior print quality and durability. | Versatile with various substrates and fast printing speeds. | Higher initial investment may not suit all budgets. | Updated software for improved alignment and layout. |

| Epson SureColor F-Series | Supports DTF and dye-sublimation printing. | Impressive color range and cost-effective ink options. | Limited compatibility with materials compared to others. | New ink formula enhances longevity and vibrancy. |

| Roland VersaUV Series | Combines UV and eco-solvent technologies for versatility. | User-friendly interface, great for beginners. | Print speeds may be slower than other high-end models. | Enhanced software for managing gangsheet layouts. |

| Brother GTX Pro | High-speed outputs ideal for garment printing. | Fast print speeds with user-focused design. | Higher operational costs due to ink consumption. | Smarter ink management to reduce waste. |

Summary

DTF bandsheet builders have rapidly transformed the landscape of garment printing, providing innovative solutions that cater to various business needs. When selecting a DTF gangsheet builder, it’s essential to assess your operational requirements and financial considerations thoroughly. Each manufacturer has unique advantages and drawbacks, with recent technological advancements significantly enhancing user experience and print quality across the board. Staying up-to-date with these updates will help you maximize the potential of your DTF printing endeavors, ensuring that you choose a builder that meets your specific challenges and objectives.