DTF Transfers: Avoid Common Mistakes for Better Prints

DTF transfers, short for Direct-to-Film transfers, have emerged as an exciting innovation in the realm of custom printing, providing high-quality, durable prints with relative ease. However, as with any printing technology, there are common DTF mistakes that can hinder results if not addressed. By understanding how to optimize DTF processes and avoiding typical pitfalls, users can significantly improve DTF prints that stand out for their vibrancy and longevity. In this guide, we will explore essential DTF printing tips that will help you navigate the complexities of the DTF transfer process successfully. Whether you are a seasoned print professional or a newcomer, mastering the art of DTF transfers can take your printing projects to new heights.

DTF printing, also known as Direct-to-Film technology, has transformed the way designs are transferred onto fabrics, making it easier for innovators and creatives alike to produce stunning custom prints. This method not only enhances the vibrancy of colors but also ensures durability, thereby making it a preferred choice among print businesses. However, it’s crucial to recognize the typical pitfalls that could affect your end product, with common DTF mistakes often stemming from inadequate preparation or improper handling during the transfer process. To truly unlock the potential of your DTF applications, understanding how to optimize different aspects of this cutting-edge printing technology is key. In this article, we’ll provide you with vital insights and practical tips to avoid common errors and improve the overall quality of your transfers.

Essential DTF Printing Tips for Beginners

When diving into the world of Direct-to-Film (DTF) printing, beginners often face a steep learning curve. One essential tip is to familiarize oneself with the technology and the nuances of the printing process. Understanding the equipment, including printers and heat presses, is vital for producing high-quality prints. Moreover, taking the time to learn about various materials and ink compatibility will help prevent mishaps that can lead to costly errors.

Additionally, beginners should pay close attention to file preparation. Ensuring images are high resolution and properly adjusted for the printing process is crucial. It’s recommended to practice creating designs that not only meet the technical requirements but also resonate with the target audience. This knowledge will enhance creativity while streamlining the printing workflow.

The Transfer Process: Keys to Successful DTF Transfers

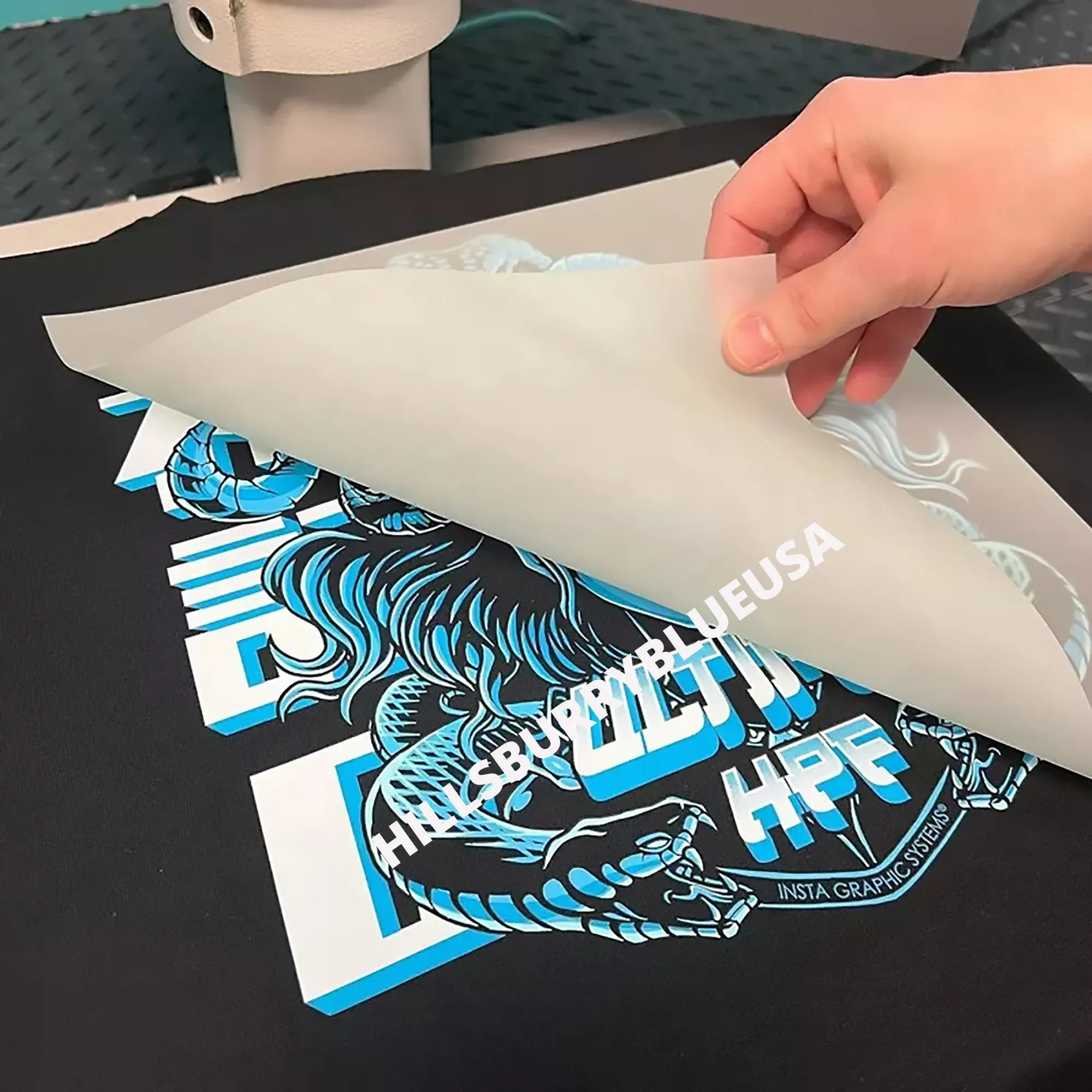

The transfer process is the heart of DTF printing, impacting the overall quality of the final product. One common mistake is neglecting the importance of precise heat settings and time during the pressing. Misjudgments here can lead to peeling or uneven transfers, damaging the aesthetic appeal of the prints. It’s recommended to use a reliable heat press and to double-check the recommended temperature settings before initiating the transfer.

To present the highest quality designs, operators should also be meticulous about the placement of the transfer on the garment. Misalignment can lead to uneven prints. Practicing consistency in applying transfers and following best practices can greatly improve the result. Regularly reviewing and adjusting transfer techniques based on feedback can produce superb results over time.

Avoiding Common DTF Mistakes for Higher Quality Prints

Common DTF mistakes, such as inadequate printer settings or improper use of adhesive powders, can severely affect print quality. Many users overlook the necessity of fine-tuning printer saturation levels, which can lead to dull colors. It’s advisable to experiment with different settings within the printer’s capabilities to achieve the best color outcomes. Comparing test prints can provide valuable insights into adjustments needed.

Another frequent error is the mishandling of adhesive powder application, either using too much or too little. This requires a careful balance and understanding of the right technique to achieve optimal adhesion. For best results, applying a thin, even layer of adhesive can ensure that prints adhere properly and maintain vibrancy after curing.

Post-Transfer Care for Longevity of DTF Prints

After the DTF transfer process, the care of the prints can significantly determine their longevity and appearance. Users often disregard essential post-transfer care guidelines, which can result in fading or damage to the prints over time. It’s crucial to educate customers about washing and drying practices, suggesting cold water washes and air drying to preserve the integrity of prints.

Furthermore, proper storage of garments post-printing should not be overlooked. Keeping printed items away from direct sunlight and moisture will help maintain their colors and quality. Instituting a feedback loop with customers about the longevity and care of their prints can also facilitate improvements in future designs and printing practices.

Improving Your DTF Prints: Additional Techniques and Tips

To enhance the quality of DTF prints, several advanced techniques can be beneficial. Experimenting with different substrates can yield surprising results in print quality. Certain fabrics may absorb ink differently than others, leading to enhanced detail and color depth in the final product. It’s helpful to test various materials to determine the best combinations for achieving vibrant and durable prints.

Employing technology can also streamline processes and improve outputs. Utilizing software that assists with color management can ensure that prints accurately reflect digital designs. Consistently aiming for optimal color calibration and saturation will enhance the overall effectiveness of the DTF printing process and yield professional-grade results.

Researching DTF Printing Equipment Compatibility

One pivotal step in maximizing DTF transfer quality is researching equipment compatibility. Ensuring that printers, heat presses, and inks are compatible with DTF technology can save a lot of time and resources in the long run. Incompatible components often lead to inconsistent print quality and increased failure rates, which can hinder productivity.

Moreover, staying informed about equipment advancements and best practices can provide a competitive edge. Following industry trends and seeking out reliable reviews and feedback can guide purchasing decisions and upgrades. Establishing a network with other DTF users can also facilitate shared insights, fostering a diverse knowledge base surrounding the printing technology.

Frequently Asked Questions

What are common DTF printing mistakes to avoid during the transfer process?

Common DTF printing mistakes include using low-resolution images, improper printer settings, neglecting the transfer process, and incorrect application of adhesive powder. Avoid these pitfalls by always using high-resolution images, familiarizing yourself with printer settings for ink saturation, following the correct temperature and time for heat pressing, and ensuring even application of adhesive powder.

How can I optimize DTF transfers for better print quality?

To optimize DTF transfers, focus on using high-resolution images with at least 300 DPI, adjust your printer settings for adequate ink saturation, adhere to manufacturer guidelines during the transfer process, and ensure proper adhesive powder application. Additionally, educate on post-transfer care to maintain print quality over time.

What are the best practices for DTF printing tips to enhance results?

Key DTF printing tips include preparing files with high resolution and an RGB color profile, adjusting printer settings for accurate color reproduction, strictly following heat press guidelines for temperature and time, and ensuring even adhesive powder application. Consistent technique and post-care instruction are also crucial for enhancing print results.

What steps can I take to improve DTF prints longevity?

Improving the longevity of DTF prints involves proper file preparation, adhering to recommended heat press settings, applying adhesive powder carefully, and educating customers on post-care practices such as cold washing and air drying. These steps will help maintain the integrity and appearance of DTF prints.

How does the DTF transfer process affect print durability?

The DTF transfer process significantly affects print durability; improper heat settings can lead to peeling or fading. It’s essential to follow the manufacturer’s guidelines—typically pressing at about 305°F for 15 seconds—to ensure optimal adhesion, which directly impacts the longevity and quality of the print.

What are the essential components for successful DTF transfers?

Essential components for successful DTF transfers include high-resolution image files, compatible printer and heat press settings, consistent adhesive powder application, and thorough post-transfer care. Researching equipment compatibility and documenting successful settings also aid in achieving consistent, high-quality DTF printing results.

| Common Mistakes in DTF Transfers | Solutions |

|---|---|

| Improper File Preparation | Use high-resolution images (minimum 300 DPI) and set color profile to RGB. |

| Inadequate Printer Saturation Settings | Adjust printer settings for adequate ink saturation; increase ink volume for better color vibrancy. |

| Neglecting the Transfer Process | Adhere to manufacturer’s guidelines for temperature (305°F) and pressing time (15 seconds). |

| Improper Use of Adhesive Powder | Ensure even application of adhesive powder before melting to guarantee good transfer success. |

| Ignoring Post-Transfer Care | Recommend cold washing and air drying to maintain prints. |

Summary

DTF Transfers are a transformative approach in custom printing, offering vibrant and durable designs. However, to truly maximize their potential, it’s crucial to understand and evade common pitfalls that can negatively affect print quality. From improper file preparation to neglecting post-transfer care, each aspect plays a vital role in determining the final output. By implementing the solutions mentioned above, such as using high-resolution images and following precise heat settings, print shops can achieve remarkable results. Embracing these practices not only enhances the quality of the DTF transfers but also ensures their longevity, making them a reliable choice for custom prints.