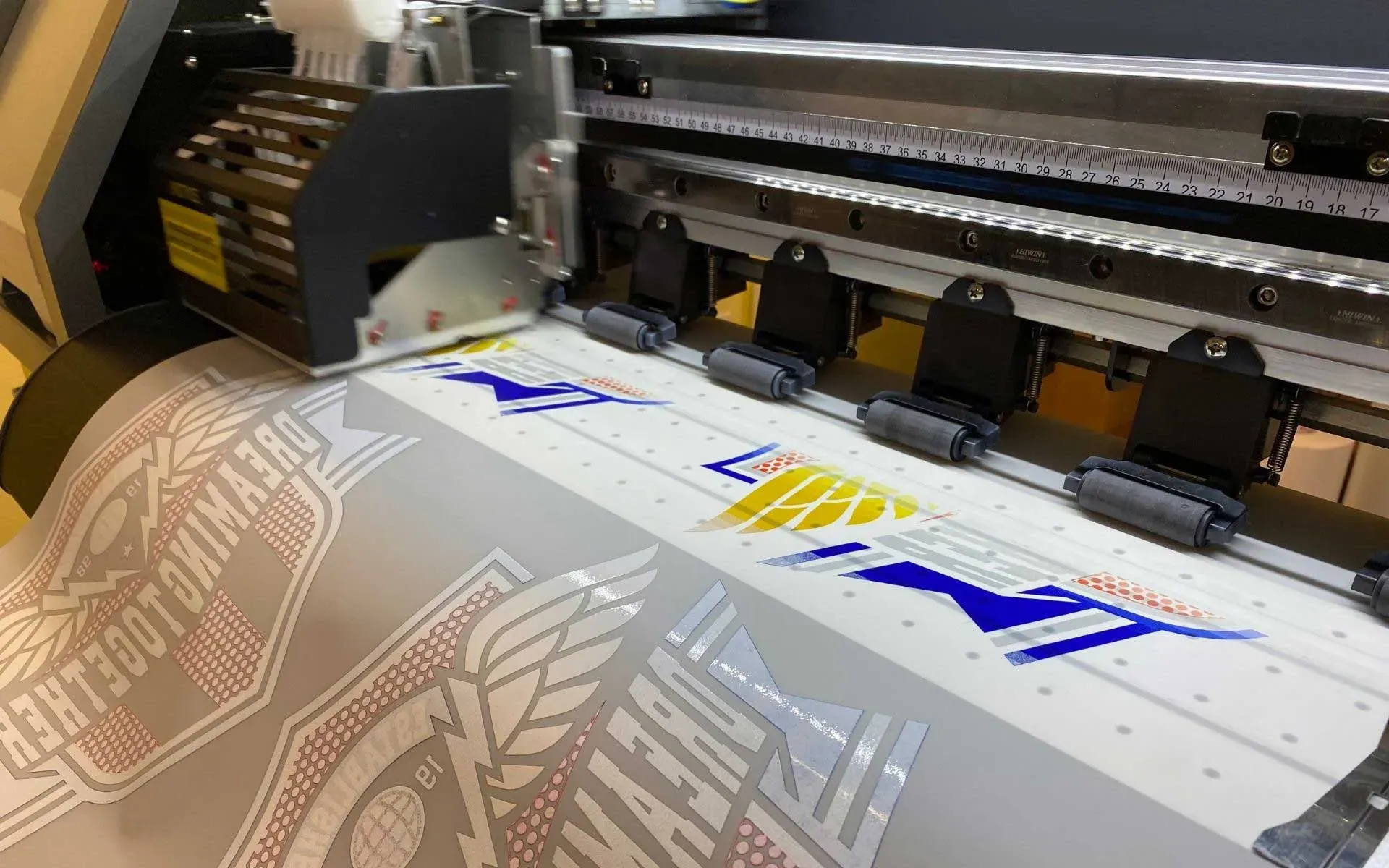

UV DTF Gangheet: Revolutionizing Print Technology Today

In the dynamic realm of modern printing, **UV DTF Gangheet** represents a groundbreaking evolution that is transforming the industry landscape. This advanced printing technology utilizes cutting-edge UV printing processes, enabling operators to create vibrant, high-quality prints with remarkable efficiency. By merging superior custom printing solutions with sustainable practices, UV DTF Gangheet not only meets diverse client demands but also upholds environmental responsibility. Its versatility shines as it caters to various substrates, revolutionizing the way brands approach promotional items and custom apparel. As businesses increasingly seek innovative approaches to stay competitive, understanding the potential of UV DTF Gangheet becomes crucial for future growth and success in the market.

Exploring alternate phrases for **UV DTF Gangheet**, one might refer to it as UV Direct to Film technology or innovative print solutions. This process encapsulates a unique approach to high-quality printing that emphasizes both sustainability and efficiency. With its capacity to adapt to various materials, this modern printing method sets itself apart as a versatile option for businesses looking to diversify their product offerings. As global trends lean toward eco-friendly solutions, this alternative technology emerges prominently within the realm of sustainable printing initiatives. Whether in the realm of fashion, promotional merchandise, or custom designs, this innovative approach brings quality and creativity to the forefront of print applications.

Understanding UV DTF Gangheet and Its Impact on Print Solutions

UV DTF Gangheet represents a transformative approach in the world of custom printing solutions. By combining direct inkjet technology with UV curing, this innovation not only enhances the quality of prints but also simplifies the production process. Companies adopting UV DTF can expect to create high-resolution graphics that are rich in color and detail, a monumental leap forward from conventional methods. This summit of technology seamlessly integrates with various substrates, including the likes of textiles, plastics, and metals, enabling businesses to expand their product offerings without compromising on the print quality.

Moreover, the emergence of UV DTF Gangheet has moved beyond just enhancing print quality. It has fundamentally shifted how businesses operate in terms of speed and efficiency. Traditional printing methods often involve extensive setup times and numerous steps, whereas UV DTF technology offers a streamlined process that allows companies to respond to market demands swiftly. This agility not only helps businesses serve customers better but also improves overall productivity by reducing waste and overhead, proving crucial in today’s fast-paced commercial environment.

Speed and Efficiency: A Game-Changer in Printing

The paramount advantage of UV DTF printing lies in its remarkable speed and efficiency. Traditional printing methods, often marred by long lead times, cannot keep pace with the rapid demand for customized products. UV DTF technology cuts down on these delays significantly, allowing businesses to turn around orders almost instantaneously. This exceptional efficiency enables companies to take on larger orders or meet stringent deadlines with ease, giving them a competitive edge in the marketplace.

Furthermore, the printing technology inherently promotes faster workflows, which is particularly beneficial for industries that rely on quick product launches or seasonal promotions. Businesses can now capitalize on market trends without the lengthy wait associated with older printing techniques. With UV DTF Gangheet, firms can easily adapt to changing consumer preferences while maintaining high-quality standards, making it a must-have in the arsenal of modern printing solutions.

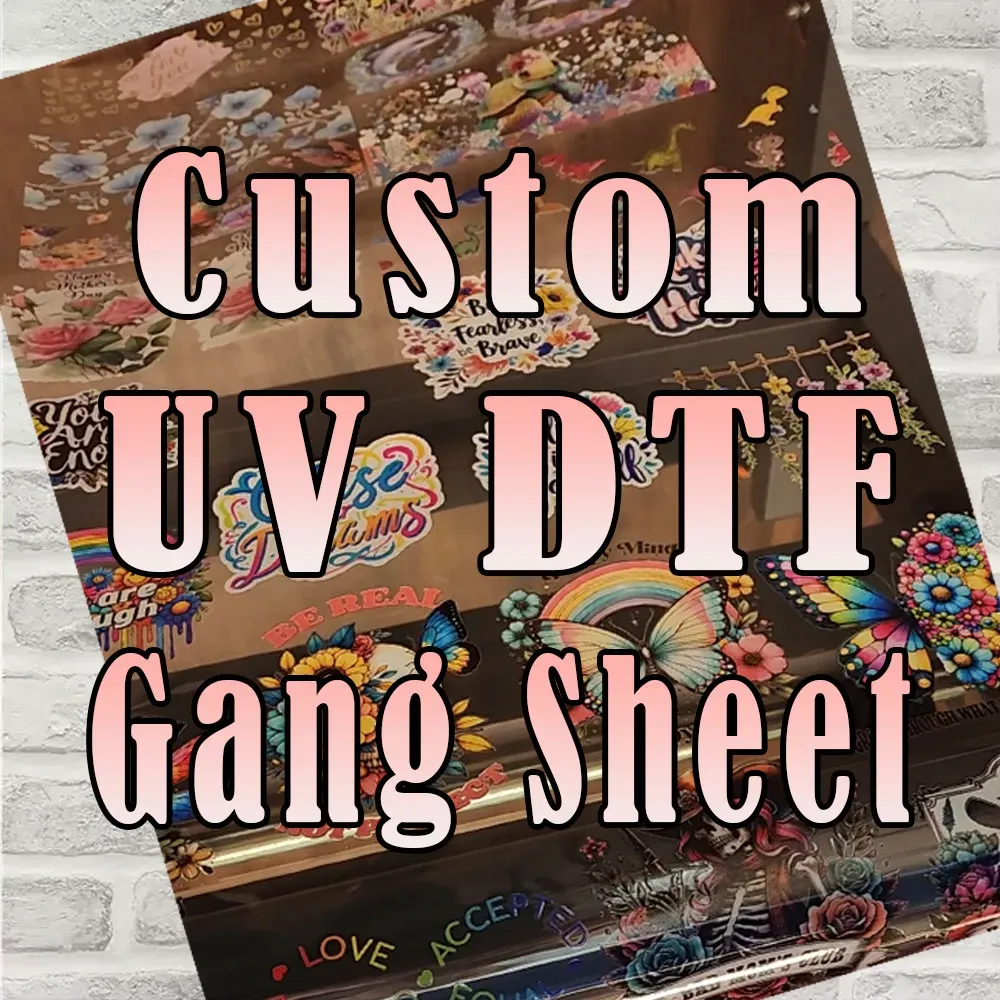

Versatility Across Substrates: Unlocking New Opportunities

One of the most striking features of UV DTF printing is its unparalleled versatility across different substrates. Unlike traditional methods which are often restrictive in terms of the materials used, UV DTF technology enables printing on an array of surfaces—from textiles to hard materials like metal and glass. This opens up endless possibilities for businesses looking to customize products for various markets and client needs.

For instance, a marketing company can develop unique promotional items such as bespoke t-shirts, branded merchandise, and customized packaging solutions all under one roof. The flexibility brought about by UV DTF Gangheet not only allows for the expansion of product lines but also invites creativity from designers and marketers, making it easier to produce eye-catching, innovative products that resonate with consumers.

Eco-Friendly Printing: A Sustainable Future with UV DTF

In recent years, sustainability has become a focal point in the printing industry. UV DTF printing is positioned as an eco-friendly alternative, primarily due to its usage of low-VOC inks. This resonates well with environmentally-conscious consumers and businesses looking to reduce their carbon footprint. The instant curing process in UV DTF technology not only minimizes waste but also ensures a cleaner operation compared to traditional printing methods that often utilize harmful solvents.

Furthermore, by integrating sustainable practices into their production lines, businesses are likely to enhance their brand reputation among consumers increasingly demanding corporate responsibility. Choosing UV DTF Gangheet technology allows companies not only to deliver high-quality prints but also to align with global sustainability goals, an essential consideration in today’s market landscape.

Quality and Durability: Setting New Standards

When it comes to print quality and durability, UV DTF technology excels in delivering high-resolution outputs that stand out for their vibrancy and clarity. The advanced curing process used in this printing method ensures that the inks bond well with the substrates, resulting in prints that are less prone to fading, scratching, or weathering. Businesses can produce items that maintain their aesthetic appeal even in challenging conditions, ensuring long-term customer satisfaction.

Additionally, the durability of UV DTF Gangheet prints translates into substantial long-term value for businesses. This pioneering technology not only enhances the visual impact of products but also assures companies of the longevity of their prints. Customers can enjoy high-quality, durable products, allowing businesses to build an image of reliability, which is crucial in retaining and attracting clientele in competitive markets.

The Future of UV DTF Printing: Market Trends and Innovations

UV DTF printing technology is on the brink of a significant revolution, with market forecasts predicting a substantial growth trajectory in the coming years. Rising demand for customized products across diverse sectors is driving this shift, as consumers seek tailored solutions that reflect personal preferences. Analysts suggest that the exploration of personalized printing applications will only intensify, positioning UV DTF Gangheet technology at the forefront of this evolving landscape.

Moreover, ongoing innovations in the UV DTF space promise to further enhance efficiency and quality. New features like advanced color matching systems and automated print settings are continually improving the user experience and enabling faster production cycles. As businesses increasingly integrate these technologies into their operations, we can anticipate a profound impact on the overall printing market, paving the way for a more dynamic and competitive future.

Frequently Asked Questions

What are the benefits of using UV DTF Gangheet technology in custom printing solutions?

UV DTF Gangheet technology offers several benefits, including high-speed printing, versatility across various substrates, and exceptional print quality. This technology enables businesses to deliver customized products quickly, adapting to different materials such as wood, metal, and textiles, which broadens their printing capabilities.

How does UV DTF Gangheet contribute to sustainable printing practices?

UV DTF Gangheet technology is eco-friendly as it utilizes UV inks that are low in volatile organic compounds (VOCs), reducing harmful emissions. The instant curing process also minimizes waste, making it a sustainable choice for businesses looking to adopt greener printing methods.

What makes UV DTF Gangheet prints durable and high-quality?

Prints generated through UV DTF Gangheet boast high resolution, vivid color output, and are resistant to scratching, fading, and weathering. This durability makes them suitable for both indoor and outdoor applications, ensuring that products maintain their quality over time.

In which industries is UV DTF Gangheet technology being adopted?

UV DTF Gangheet technology is becoming popular across several industries, including fashion, home décor, automotive, and promotional products. Its ability to produce custom prints quickly and at high quality makes it ideal for businesses aiming to stand out in competitive markets.

How does UV DTF Gangheet improve turnaround times for businesses?

The efficiency of UV DTF Gangheet technology allows for faster print speeds compared to traditional methods. This capability enables businesses to turn around large orders or customizations rapidly, meeting tight deadlines without compromising on quality.

What recent trends are impacting the growth of UV DTF Gangheet technology?

Recent trends include technological innovations in printing efficiency, increased adoption by small businesses, and a rising demand for customized products. These factors are driving the expansion of UV DTF printing solutions in the market, with forecasts indicating significant growth in the coming years.

| Key Points | Description |

|---|---|

| Introduction to UV DTF Gangheet | UV DTF printing combines inkjet methods with UV curing, enhancing quality and transforming print production. |

| Speed and Efficiency | UV DTF offers faster operation than traditional printing, improving turnaround times significantly. |

| Versatility Across Various Substrates | Can print on plastics, metal, wood, and textiles, broadening product customization options. |

| Eco-Friendly Advantages | Low VOC UV inks reduce emissions and waste, promoting sustainable production practices. |

| Quality and Durability | High-resolution prints that are scratch and fade resistant, suitable for various applications. |

| Market Growth | Predictions indicate a 20% CAGR over the next 5 years, driven by demand for customization. |

| Recent Trends | Innovations enhance printer capabilities; diverse industries adopt UV DTF; small businesses thrive. |

Summary

UV DTF Gangheet technology is at the forefront of revolutionizing print technology, bringing unmatched speed and versatility to the printing industry. This innovative process allows for quick and efficient printing on a variety of substrates, catering to a range of demands from businesses seeking to differentiate themselves in a competitive landscape. Its eco-friendly advantages further enhance its appeal, aligning with growing sustainability initiatives. As it continues to evolve, UV DTF Gangheet is not just meeting current market needs but is also paving the way for future trends in personalized and customized printing solutions.