DTF Transfers: A Beginner’s Guide to Home Printing

DTF transfers have quickly gained traction among DIY enthusiasts and small business owners looking for innovative ways to personalize apparel right from their homes. Direct-to-Film (DTF) printing revolutionizes the traditional garment decoration process, allowing for vibrant and durable designs to be effortlessly applied to various fabrics. This method combines ease of use with striking visual appeal, making it a go-to choice for those exploring how to do DTF printing. Throughout this blog, we will delve into the DTF transfer process, highlighting the essential equipment needed and how you can create stunning custom designs with minimal fuss. Whether you’re embarking on a new hobby or starting a business, DTF transfers offer an exciting avenue for creative expression in clothing printing.

Understanding DTF transfers, or Direct-to-Film transfers, opens the door to a world of possibilities in home printing and custom apparel. This innovative technique harnesses advanced printing technology to embed designs onto special films, which can then transform any garment into a personalized work of art. If you’re exploring your options in DIY clothing printing, this method allows for high-quality, intricate details that are often difficult to achieve with traditional printing methods. With the right equipment and a little practice, you can effortlessly navigate the DTF transfer process, making it an ideal solution for both newcomers and experienced creators alike. As we dive deeper into this guide, you’ll discover the essential tools and techniques that make DTF printing accessible for everyone.

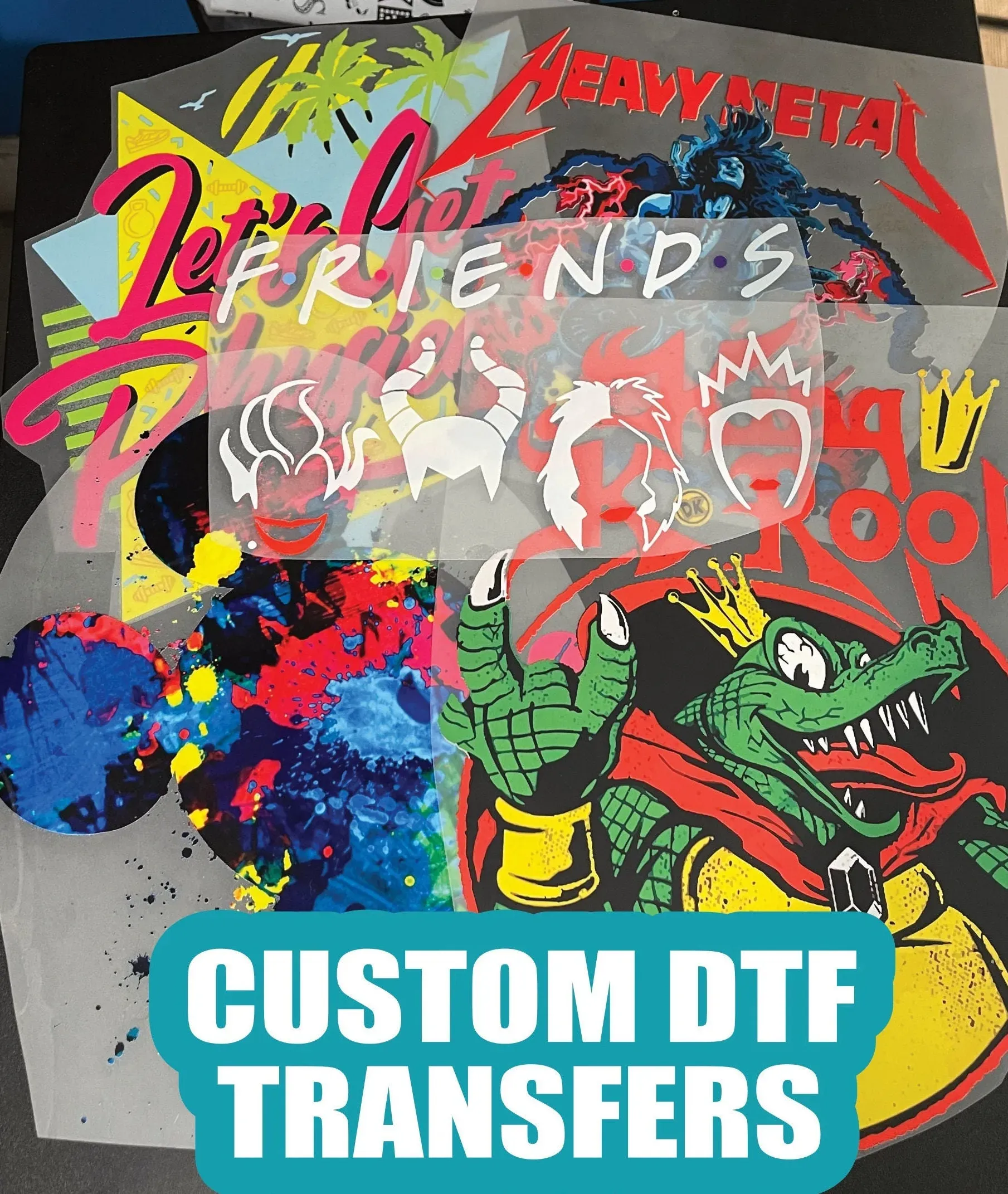

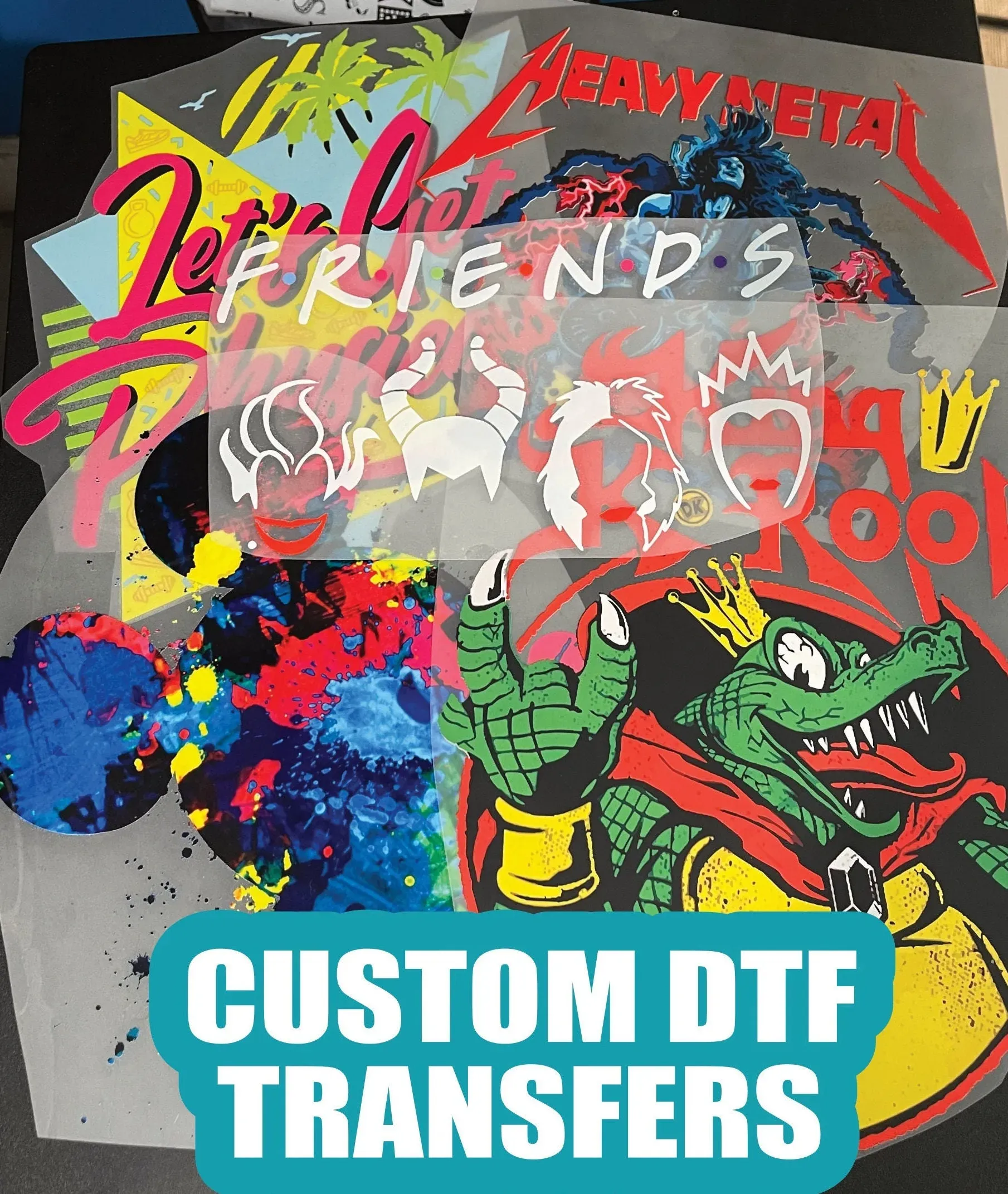

Understanding the DTF Transfer Process

The DTF transfer process is intricate yet straightforward, making it an attractive option for beginners in the world of DIY clothing printing. It starts with the creation of a digital design that reflects the desired artistic expression. This design is then printed onto a specialized DTF film using a dedicated DTF printer, which ensures that the colors and details come out vividly. What sets DTF apart from conventional printing methods is its use of hot melt adhesive powder, which bonds the ink to the fabric, thus providing durability and vibrancy even after multiple washes.

Once the design is printed, the application of adhesive comes next. This step is crucial as it determines the overall quality of the transfer. The hot melt adhesive is evenly sprinkled over the design and heat-cured, preparing it for the final transfer. Finally, the prepared DTF transfer is placed face down on the fabric and subjected to pressure and heat using a heat press machine. This pivotal moment seals the deal, ensuring that the designs adhere well to both light and dark fabrics, offering flexibility in creative expression.

Key Equipment Needed for DTF Printing

When embarking on your DTF printing journey, having the right equipment is essential. A well-chosen DTF printer designed specifically for this printing method plays a pivotal role in the overall success of your project. Nowadays, many affordable DTF printers are accessible for home users, allowing you to dive into the world of DIY clothing printing without breaking the bank. Complementing the printer, high-quality DTF transfer film is crucial—this film acts as the canvas for your designs and directly influences the final output.

In addition to the printer and film, a reliable heat press machine is indispensable. It not only transfers the design but also ensures that the application is even and durable. Lastly, do not overlook the importance of hot melt adhesive powder and fabric selection, as these elements tie everything together for a successful DTF transfer process. Choosing the right garments, typically cotton or polyester blends, can enhance the final appearance and longevity of your prints.

Benefits of Choosing DTF Transfers

DTF transfers come with a host of benefits that cater to beginners and seasoned crafters alike. One of the standout advantages is the cost-effectiveness of this method compared to traditional screen printing. It eliminates the need for complex setups and allows hobbyists and small businesses to produce high-quality, professional-looking prints without significant upfront investment. This affordability opens the door for creative exploration and the possibility of launching custom apparel ventures.

Moreover, DTF printing’s versatility is another significant benefit, as it provides a seamless way to create both small and large print runs. This adaptability allows users to experiment with various designs and techniques, making it ideal for personalized gifts, family reunions, or even starting a side business. The user-friendly nature of the process also encourages beginners to rapidly improve their skills and gain confidence in their printing capabilities.

Common Challenges Faced by Beginners

Despite its user-friendly reputation, DTF printing does come with its challenges, particularly for those just starting out. One common issue is the initial setup of the DTF printer and mastering the heat press’s operation. New users may find the learning curve daunting, as improper settings could lead to less than optimal prints. Patience and practice are essential, as many beginners report improvement with each subsequent project.

Additionally, adhesion issues can arise during the transfer process. Ensuring that designs stick properly to various fabrics may take some trial and error. Factors such as fabric type, adhesive application, and heat settings all play critical roles in achieving beautiful results. Overcoming these challenges not only enhances the overall DTF printing experience but also fosters a deeper understanding of the process.

Exploring the Future of DTF Printing

As the DTF printing technology continues to evolve, its future looks promising, especially for those interested in home-based apparel production. New innovations are emerging, driving quality and efficiency improvements, and prompting entrepreneurs to explore this lucrative avenue. Recent developments in DTF transfer kits have made it easier for beginners to get started, simplifying the setup process and minimizing barriers to entry.

Furthermore, the growing community surrounding DTF printing provides ample resources for newcomers, ranging from online tutorials to forums where users share experiences and troubleshooting tips. As technology progresses, we can expect even more beginner-friendly options, making it an exciting time to delve into DTF printing and unleash creative potential within the custom apparel market.

Resources for Learning DTF Printing

For beginners eager to master DTF printing, a wealth of resources awaits online. Various platforms offer step-by-step tutorials highlighting each stage of the DTF transfer process, from design creation to application techniques. Video content on platforms like YouTube allows visual learners to follow along, further enhancing their understanding of this innovative printing method. Equipped with helpful tips from experienced printers, newcomers can navigate common hurdles with greater confidence.

Community forums are another invaluable resource, where camaraderie and shared knowledge abound. Websites like Reddit host active discussions, allowing users to seek advice on specific challenges or share their success stories. As beginners engage with these communities, they not only enhance their learning experience but also cultivate connections that can lead to collaborative projects and inspiration.

Frequently Asked Questions

What is the DTF transfer process in home printing?

The DTF transfer process for home printing involves several key steps. First, create a design using graphic design software. Next, print the design onto a special DTF transfer film using a DTF printer. Then, apply hot melt adhesive powder to the printed film and heat it to cure the adhesive. Finally, use a heat press to transfer the design onto your garment, ensuring the design adheres well to the fabric.

How do you achieve high-quality DTF printing results?

To achieve high-quality DTF printing results, ensure you have quality equipment like a reliable DTF printer and high-grade DTF transfer film. Use the correct settings on your printer to secure vibrant colors and details, and evenly apply the hot melt adhesive powder before heat pressing. Finally, practice the heat press technique to find the ideal temperature and pressure for your chosen fabric.

What materials are best for DTF transfers?

For DTF transfers, it’s best to use garments made from cotton blends or polyester fabrics. These materials provide excellent adhesion for the transferred designs. When selecting DTF transfer film and hot melt adhesive powder, choose high-quality options to ensure durable and vibrant prints.

Can beginners easily learn how to do DTF printing?

Yes, beginners can easily learn how to do DTF printing. With user-friendly equipment and available resources like online tutorials and forums, newcomers can understand the DTF transfer process. While initial setup may require some practice, many find the learning curve manageable and can achieve professional results with patience.

Are there any challenges associated with the DTF transfer process?

While the DTF transfer process is generally straightforward, beginners may face challenges such as initial setup complexities, ensuring proper adhesive application, and achieving consistent heat transfer results. However, with practice and access to online resources, these issues can be overcome.

What are the benefits of using DTF printing for DIY clothing projects?

DTF printing offers several benefits for DIY clothing projects, including cost-effectiveness compared to traditional printing methods, versatility for both small and large print runs, and the ability to create intricately detailed designs. It’s also user-friendly, making it accessible for hobbyists and those new to fabric printing.

| Section | Key Points |

|---|---|

| Introduction to DTF Transfers | DTF transfers offer a method for personalizing clothing using Direct-to-Film technology. |

| What is DTF Printing? | A modern printing method using a special film and adhesive powder for bright, detailed designs on fabrics. |

| Essential Equipment for Beginners | Key equipment includes DTF printer, transfer film, hot melt adhesive powder, heat press machine, and suitable garments. |

| The DTF Printing Process | The process involves design creation, printing, applying adhesive, and heat transferring to garments. |

| Benefits of DTF Printing | Cost-effective, flexible for print runs, and user-friendly for beginners. |

| Challenges in DTF Printing | Initial setup can be tricky, and adhesion issues may arise requiring practice. |

| Recent Developments in DTF | Growing market with beginner-friendly kits and continual improvements in technology. |

| Resources for Beginners | Online tutorials, community forums, and blogs provide tips and support for starters. |

Summary

DTF transfers represent a transformative technique in the world of home apparel printing, allowing enthusiasts to create vibrant and customizable clothing designs. With advancements in technology and a growing availability of resources, individuals can engage in this rewarding craft without needing extensive training or equipment investments. The process of DTF printing not only opens up creative avenues for personal expression but also offers cost-effective solutions for small businesses looking to enter the custom apparel market. As more tutorials and community support become accessible, beginners can confidently explore DTF transfers, embracing the artistic opportunities they present with minimal hassle.