DTF Printing: Maximize Your Art for Stunning Results

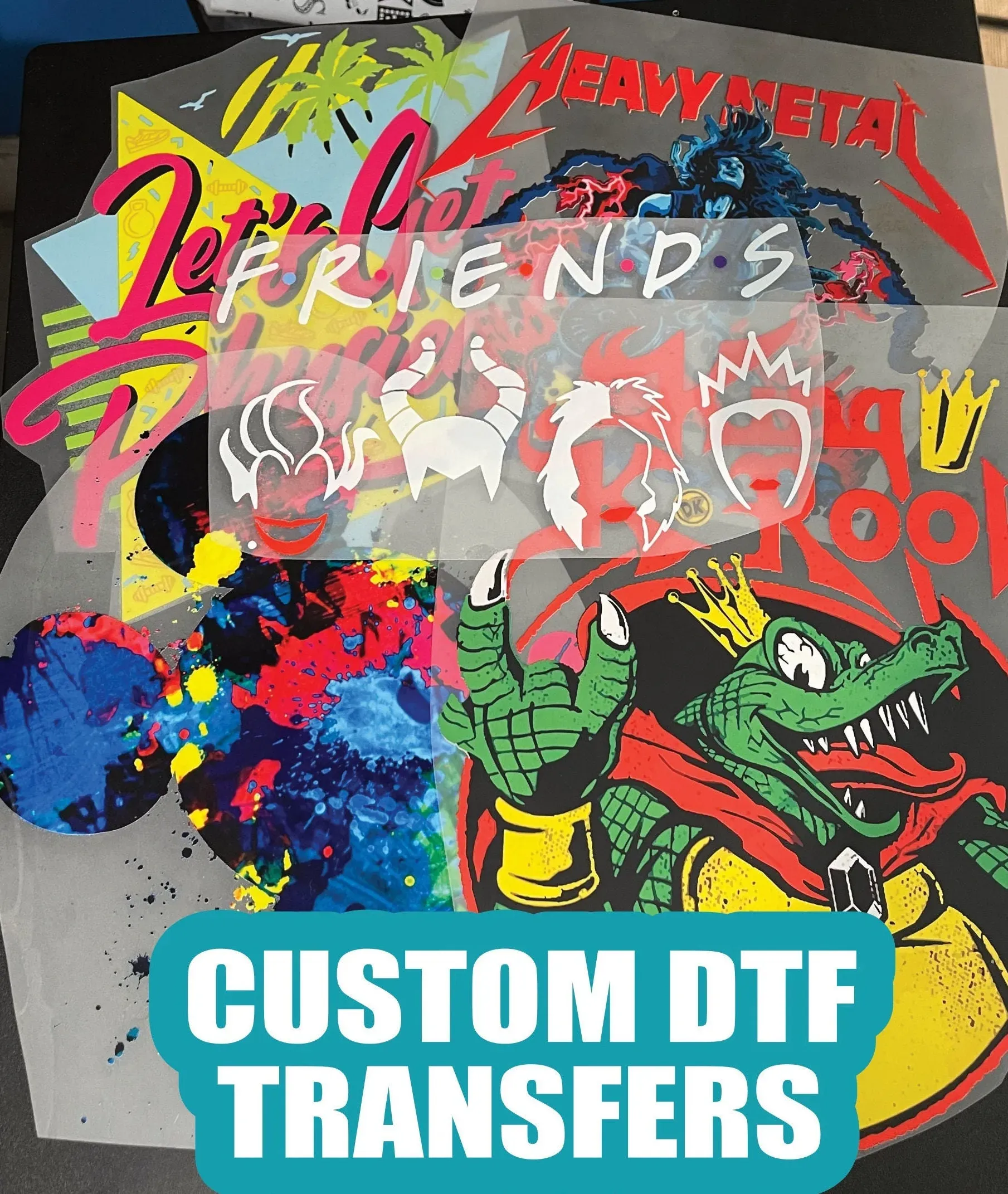

DTF printing, or Direct-to-Film printing, has revolutionized the textile industry by marrying creativity with high-quality results. This innovative technique allows artists and designers to maximize their artwork through vibrant and durable transfers that can adorn a variety of surfaces, including T-shirts and bags. With DTF technology benefits such as effective ink usage and versatility in application, it’s no wonder this method is gaining traction among creators looking to stand out. In this article, we’ll share essential DTF tips to help you achieve stunning results while providing insights into best practices for optimizing your designs. Join us as we explore how to harness the full potential of DTF printing for captivating merchandise that resonates with audiences.

Also known as Direct-to-Film technology, DTF printing offers a unique solution for artists seeking to enhance their creative ventures. This contemporary printing method, which facilitates the transfer of intricate designs onto fabrics and other substrates, distinguishes itself from traditional printing techniques like screen printing or direct-to-garment applications. Embracing DTF alternatives opens up new possibilities for merchandise, enabling creators to develop eye-catching products that meet the demands of today’s consumers. By implementing DTF best practices and understanding the nuances of this innovative approach, artists can produce exceptional results that reflect their individual styles. Let’s delve deeper into the mechanics and advantages inherent to DTF technology.

Overview of Direct-to-Film Printing Technology

Direct-to-Film (DTF) printing technology has revolutionized the textile printing landscape. By enabling artists to print vibrant designs onto a specialized film, this innovative method allows for an impressive blend of quality and versatility. Unlike traditional printing techniques, DTF technology caters to the demands of modern creators, offering a solution that can seamlessly adapt to various materials. This adaptability extends beyond mere fabric; DTF can adhere to rigid surfaces, providing unique opportunities for businesses looking to expand their product lines.

The essence of DTF printing lies in its precise application of inks combined with a specially formulated adhesive that helps ensure durability and adherence. This means that whether artists are creating intricate patterns for T-shirts or bold graphics for tote bags, DTF technology excels at delivering stunning reproductions that remain true to the original artwork. The efficiency of this process, coupled with its ability to minimize waste, makes DTF printing a sustainable choice for creative professionals.

Key Benefits of Implementing DTF Printing

One of the leading advantages of adopting DTF technology is the exceptional print quality it delivers. Artists can achieve a remarkable level of detail and color vibrancy, making their designs come alive. The versatility in substrates is another significant advantage; DTF can print on a variety of materials, including cotton, polyester, and even certain hard surfaces, enabling creatives to explore a broader market without limitation.

Additionally, DTF printing is an economically sound option for small and medium-sized enterprises. By utilizing this technology, businesses can reduce inventory costs because they can print on-demand. This flexibility empowers creators to test the market without committing to large production runs, ensuring that they only create what sells. As DTF technology continues to evolve, the benefits become increasingly clear for artists looking to maximize their creative expression.

Best Practices for DTF Printing Success

To maximize successful outcomes with DTF printing, adhering to best practices is essential. Firstly, selecting high-quality films and inks is crucial. Not only do premium materials enhance the overall final product, but they also contribute to improved adhesion and durability. For instance, investing in specialized DTF inks ensures that colors remain vibrant and long-lasting, even after multiple washes.

Moreover, understanding the importance of prepress preparation can drastically affect the success of the print. Implementing color management strategies, such as utilizing RGB color profiles, helps mitigate any discrepancies that may arise when transitioning from a digital canvas to a physical print. Conducting test prints before finalizing designs for larger runs also allows artists to identify potential issues with color accuracy, ensuring the final product meets their high standards.

Creative Applications of DTF Printing

DTF printing opens up a realm of creative possibilities for artists and designers. This technology is not limited to apparel but extends to a diverse range of products, including bags, home decor items, and promotional materials. For instance, tote bags designed with stunning DTF prints not only serve practical purposes but also act as canvas spaces for artistic expression, making them ideal for capturing consumer interest.

Additionally, DTF’s ability to print on rigid surfaces allows artists to explore custom gift items and promotional products. By creating personalized gifts or branded merchandise, businesses can enhance their offerings and foster stronger customer connections. This versatility makes DTF printing an invaluable tool for artists seeking to expand their creativity and marketability.

Tips for Maximizing Art with DTF Technology

Maximizing art with DTF technology involves understanding the nuances of the printing process. One key tip is to experiment with different substrates to determine which materials yield the best results for specific designs. Each fabric type may interact differently with DTF printing, influencing the vibrancy and adherence of colors. Conducting sample tests on various slabs of material can provide valuable insights into how each canvas represents the printed artwork.

Aside from substrate testing, adjusting the heat settings correctly during the transfer process is critical. Too much heat can distort the printed image, while insufficient heat may lead to poor adhesion. Finding the perfect balance is essential to achieving a clean and professional final product that accurately reflects the artist’s vision.

Environmental Considerations in DTF Printing

As sustainability becomes a rising concern within the printing industry, DTF printing technology offers eco-friendly possibilities. By utilizing non-toxic inks and sustainable materials, artists can make environmentally conscious choices that align with their values. This not only minimizes the ecological footprint of their work but also appeals to a growing demographic of eco-aware consumers looking for responsible purchasing options.

Furthermore, DTF technology reduces waste through its efficient printing process. Since it allows for on-demand production, artists and businesses can avoid overproduction and excess inventory. Embracing these sustainable practices not only contributes to a healthier planet but also shapes a positive reputation for brands committed to responsible artistry.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, involves printing designs onto a special film using an inkjet printer. The printed film is then heat-transferred onto various surfaces, creating high-quality, vibrant images that adhere well to textiles and other materials.

What are the benefits of using DTF technology for artists?

DTF technology offers numerous benefits for artists, including the ability to produce detailed, colorful designs with minimal ink waste. It allows for versatile applications across different fabrics and even rigid surfaces, making it ideal for expanding product offerings.

What tips can improve results when using DTF printing?

To achieve stunning results with DTF printing, focus on using high-quality films, inks, and adhesives. Ensure proper prepress preparation, conduct test prints, and adjust heat transfer settings carefully to ensure high-quality adhesion and color fidelity.

How can one maximize art with DTF printing?

Maximizing art with DTF printing involves selecting the right materials, implementing color management techniques, and continually testing prints. Understanding the capabilities of DTF technology allows artists to create striking and durable products that stand out.

What are best practices for successful DTF printing?

Best practices for DTF printing include maintaining a clean workspace, using appropriate heat settings, and conducting regular maintenance on printing equipment. These steps help ensure consistent quality and longevity of printed designs.

Are there environmental considerations with DTF printing?

Yes, DTF printing can involve eco-friendly practices, including the use of non-toxic inks and sustainable materials. Adopting these approaches allows artists to minimize their environmental impact while still producing high-quality prints.

| Aspect | Details |

|---|---|

| What is DTF Printing? | DTF (Direct-to-Film) printing is a technology allowing high-quality, vibrant designs to be printed onto a film that can then be heat transferred onto various surfaces. |

| How it Works | DTF technology involves printing designs onto a special film, applying adhesive, and then transferring the image to the target surface. |

| Benefits | Allows intricate designs, reduces ink waste, and is compatible with multiple surfaces. |

| Key Techniques | 1. Use high-quality film. 2. Choose durable DTF inks and adhesives. 3. Ensure proper prepress preparation. 4. Conduct test prints before production. |

| Applications | 1. Apparel (T-shirts). 2. Bags and accessories. 3. Home decor. 4. Rigid surfaces. |

| Environmental Considerations | Innovations in DTF are focused on sustainability, using non-toxic inks and eco-friendly practices. |

Summary

DTF printing is a revolutionary technique that empowers artists and designers to unleash their creativity across a wide variety of surfaces. By understanding the intricacies of DTF technology—including its benefits, applications, and best practices—creators can achieve stunning results that captivate their audience. Not only does DTF printing allow for intricate, vibrant designs, but it also opens up numerous merchandising possibilities that cater to diverse market demands. As sustainability becomes increasingly crucial in the printing industry, DTF printing stands out as an eco-friendly option, paving the way for responsible artistic expression. Embracing DTF printing is not just about mastering a new technique; it is about transforming your art into a lasting impression that resonates with consumers.