DTF Gangsheet Builder: Step-by-Step Instructions

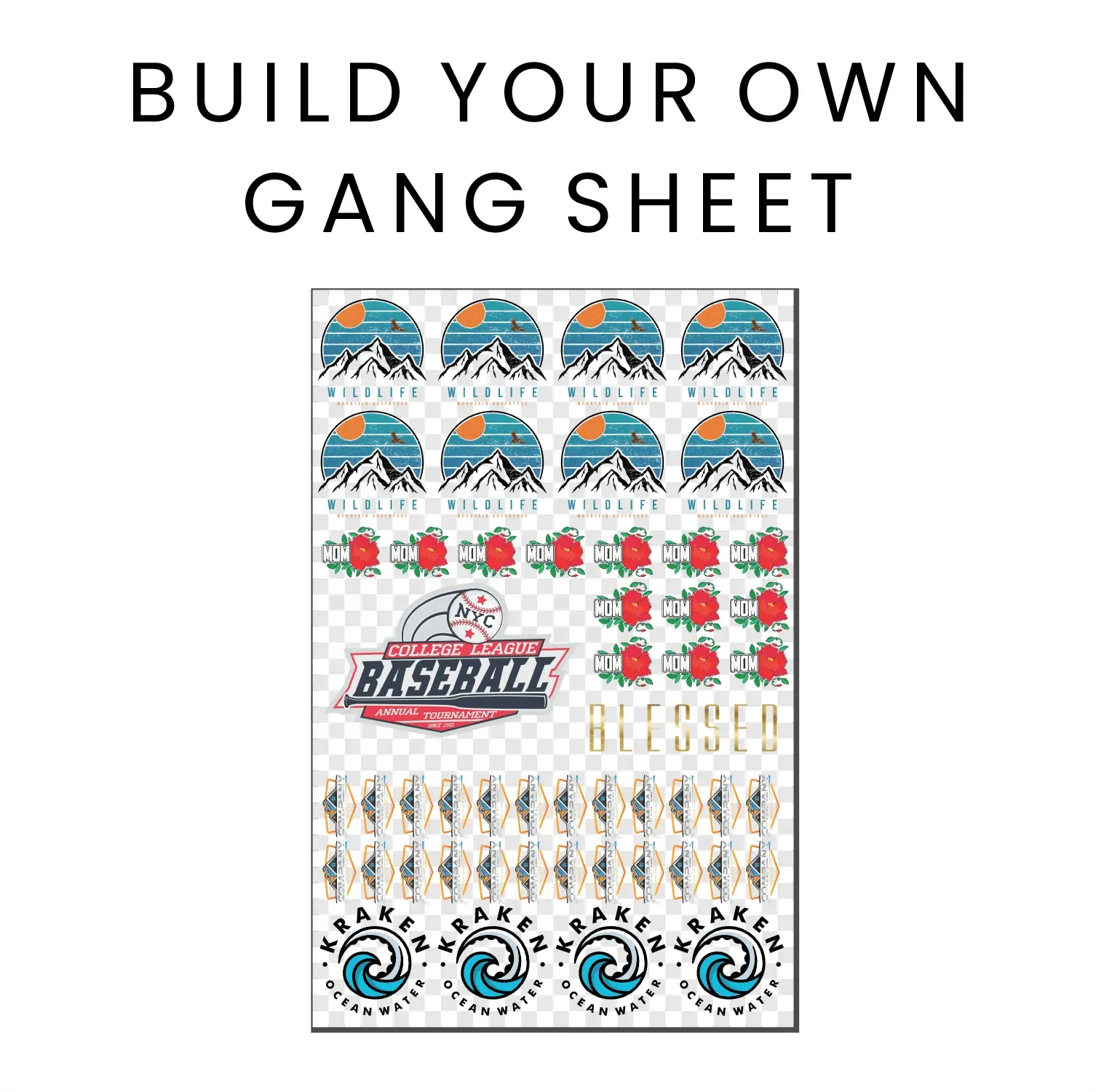

The DTF gangsheet builder has become an essential tool for professionals in the custom apparel printing industry, revolutionizing how designs are prepared for DTF printing. By allowing multiple designs to be printed on a single sheet of DTF transfer film, this innovative approach optimizes material usage and reduces costs significantly. In this guide, we’ll explore the step-by-step process of creating the perfect gangsheet layout, ensuring that your projects are not only efficient but also yield high-quality results. Whether you are printing intricate graphics or simple logos, mastering the DTF gangsheet builder will enhance your printing capabilities. Join us as we delve into the details of DTF printing and uncover tips for perfecting your heat press DTF applications.

In the realm of custom clothing production, the concept of a gangsheet creator is transforming apparel design and printing methods. This powerful tool streamlines the process by allowing multiple images to be arranged neatly on a single DTF film, facilitating both time and cost savings in production. As we examine this process, we will highlight the significance of efficient design layouts and the proper use of transfer films to achieve flawless prints. Additionally, the synergy between graphic design software and heat transfer techniques plays a crucial role in maximizing the quality of the final product. Understanding how to leverage these tools effectively will empower designers and printers alike to elevate their offerings to new heights.

Understanding DTF Technology and Its Benefits

Direct-to-Film (DTF) printing is transforming the custom apparel landscape. This innovative technology utilizes a specialized transfer film, allowing vivid designs to be printed with precision and detail. Unlike traditional screen printing processes, DTF offers a reduced setup time and the flexibility to print intricate designs, making it ideal for custom apparel creators. The quick turnaround and ability to print on various fabric types have made DTF a game changer in the fashion and merchandise sectors.

Moreover, the DTF transfer film is designed to withstand the rigors of printing and pressing processes, ensuring vibrant colors and excellent adhesion. The use of high-quality DTF inks alongside advanced heat press techniques yields durable results, suitable even for high-wash environments. This translates into greater customer satisfaction and repeat business, reinforcing the idea that DTF printing is gaining traction in the competitive world of custom apparel.

Mastering the DTF Gangsheet Builder

Creating an effective DTF gangsheet involves understanding the fundamental elements of design and material management. The DTF gangsheet builder enables users to optimize their layouts by maximizing the use of DTF transfer film. This not only reduces waste but also lowers production costs, making it a vital component for small businesses and large-scale printing operations alike. Precise planning in the gangsheet layout can significantly impact the efficiency and quality of the final product.

Incorporating multiple designs into a single gangsheet requires careful consideration of each design’s size and placement. By overlapping designs slightly, you can eliminate empty spaces and make the most of your transfer film. The DTF gangsheet builder simplifies this process, allowing you to visualize and adjust your designs easily. Understanding these principles will ensure that your output is not only visually appealing but also economically viable.

Essential Tools for DTF Printing

To embark on your DTF printing journey, a few essential tools are required to ensure smooth operation and outstanding results. First and foremost, a dedicated DTF printer is necessary, typically an Epson or similar modified printer equipped to handle DTF inks. The quality of DTF transfer film plays a crucial role in the transfer process, making it imperative to choose high-quality materials for the best outcomes. Additionally, your design software, such as Adobe Illustrator or CorelDraw, must be capable of managing high-resolution artwork.

Furthermore, a reliable heat press is pivotal for the successful application of your DTF designs onto fabrics. The right heat press should accurately maintain temperature and pressure settings to ensure proper adhesion of the DTF transfer. With these tools in place, your DTF printing process will be streamlined, enabling consistent production of high-quality custom apparel.

Designing Effective Gangsheet Layouts

Crafting an optimized gangsheet layout is crucial in minimizing waste and maximizing production efficiency. As you prepare your designs for printing, arranging them compactly on your digital canvas should be a priority. Using DTF software that allows for precise design placement can save both time and materials. Overlapping designs strategically can also lead to better utilization of the DTF transfer film, ultimately contributing to lower costs and improved output efficiency.

When designing your gangsheet layout, it is essential to ensure proper alignment. Misalignment can lead to wasted materials and unsatisfactory results. Utilizing grid lines in your design software can help maintain accuracy in placement. These layout considerations will not only enhance the aesthetic appeal of your printed items but also ensure seamless operation during the transfer process.

Printing and Preparing DTF Designs

Once your gangsheet layout is complete, the next phase involves the actual printing of your designs on the DTF transfer film. It is vital to configure your printer settings appropriately before starting the print job. Most DTF printers have specific settings that need to be adjusted to handle the nuances of DTF inks. Ensuring you select high-quality print settings will play a significant role in the vibrancy and durability of the final product.

Conducting a test print is a prudent step before executing the final print on transfer film. This allows you to evaluate the alignment, color accuracy, and overall design quality, preventing any costly mistakes. Once satisfied with your test print, you can confidently proceed with printing your DTF designs, knowing that they will transfer beautifully to your fabric.

Applying DTF Transfers with Precision

The application of DTF transfers is a critical step that requires careful attention to detail. After printing, it’s essential to apply DTF powder adhesive while the design is still wet. This adhesive is crucial for ensuring that the transfer properly adheres to the fabric when heat is applied. Timing is key, as the powder must be applied promptly before the ink dries, enabling optimal bonding under heat.

Using the heat press to transfer your DTF film onto garments requires accuracy in temperature and pressure settings. Standard practice typically involves pressing at 150-160°C for about 10-15 seconds. Adequate pressure must be applied to ensure a complete transfer without any areas lifting post-application. A careful approach will yield durable designs that withstand wear and washing, vital for any successful custom apparel business.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work?

A DTF gangsheet builder is a tool or process used to create a layout for Direct-to-Film (DTF) printing. It allows you to arrange multiple designs on a single transfer film to optimize material usage and reduce waste. By compactly placing designs within the printable area, a DTF gangsheet builder enhances efficiency in custom apparel printing.

What materials do I need for DTF gangsheet printing?

To build a DTF gangsheet, you’ll need specific materials including a DTF printer (often modified Epson printers), DTF transfer film, DTF inks, and a heat press. Additionally, graphic design software like Adobe Illustrator or CorelDraw is essential for creating your designs and layout before printing.

How do I create a gangsheet layout for DTF printing?

Creating a gangsheet layout for DTF printing involves using graphic design software to arrange your designs compactly on a digital canvas. Ensure designs fit within the limits of your DTF transfer film and align properly to maximize material usage while minimizing waste.

What printer settings should I use for DTF gangsheet printing?

When printing a DTF gangsheet, configure your printer settings to match the type of DTF ink and desired quality. Use high-quality settings specifically designed for printing on DTF transfer film to ensure vibrant colors and precise details.

How do I apply the DTF transfer after printing the gangsheet?

After printing the DTF gangsheet, you need to apply a powder adhesive while the ink is still wet. Cure the film with a heat press at around 150-160°C for 1-2 minutes, then place it onto the garment. Use a heat press set to the correct temperature (usually 150-160°C) for 10-15 seconds to ensure a successful transfer.

What are the benefits of using a DTF gangsheet for custom apparel printing?

Using a DTF gangsheet for custom apparel printing offers several benefits, including cost efficiency by minimizing waste, increased production speed by printing multiple designs at once, and maintaining high-quality results with vibrant colors. This method is ideal for businesses looking to optimize their DTF printing setup.

| Step | Key Points |

|---|---|

| 1. Understanding DTF Printing | Learn about the necessary materials such as DTF printer, transfer film, inks, and heat press. |

| 2. Software Setup | Use graphic design software for creating and sizing your designs appropriately. |

| 3. Creating the Gangsheet | Arrange designs compactly to minimize waste and ensure proper alignment. |

| 4. Printing | Adjust printer settings for ink type and perform a test print for verification. |

| 5. Applying the Transfer | Apply powdered adhesive to the wet ink, then heat press onto the garment. |

| 6. Finishing Up | Peel the transfer film and optionally press again for improved durability. |

Summary

DTF gangsheet builder is a crucial asset for anyone engaged in custom apparel printing, allowing for efficient material use and cost reduction. This guide provides a comprehensive overview of the necessary materials, software setup, design techniques, and application methods to create stunning gang sheets. Following these step-by-step instructions ensures that your production process is streamlined and produces high-quality results. Stay informed with further learning resources to enhance your DTF printing skills and elevate your projects.