UV DTF: Maximize Your Creativity with This Innovative Printing

UV DTF printing is making waves in the creative industries, thanks to its innovative blend of UV printing technology and Direct-to-Film printing methods. This cutting-edge approach allows for high-quality, vibrant prints that are not only visually striking but also durable across a variety of materials. With its emphasis on printing versatility, UV DTF has become a go-to solution for artists and businesses looking to produce unique items tailored to specific market needs. In a world increasingly focused on sustainable printing, this method stands out by minimizing waste and energy consumption while maximizing creative potential. Join us as we delve into the world of UV DTF, exploring its advantages and diverse applications that set it apart from traditional printing solutions.

Also known as ultraviolet Direct-to-Film printing, UV DTF represents a significant leap in the realm of creative printing technologies. This dynamic process utilizes ultraviolet light to cure inks rapidly, ensuring vibrant colors and a durable finish on various substrates. As a sustainable and eco-friendly alternative to conventional printing methods, it allows designers to create eye-catching products while promoting environmental responsibility. The versatility inherent in this technology empowers professionals across multiple industries—from fashion to promotional materials—to push the boundaries of their creativity. Join us as we navigate the transformative impact of UV DTF and its growing influence in modern printing.

Understanding UV DTF Printing Technology

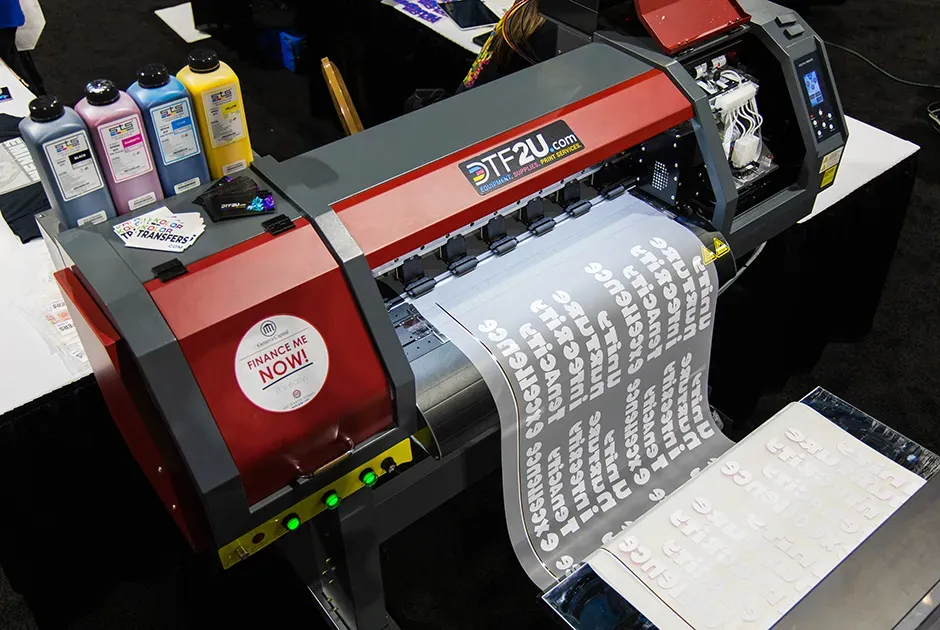

UV Direct-To-Film (DTF) printing merges two powerful printing technologies: UV printing and direct-to-film technology. This innovative process utilizes ultraviolet light to cure inks instantly onto various substrates, allowing for immediate production without the need for drying time. The ink adheres strongly to surfaces, which can include textiles, plastics, wood, and metals, providing creative professionals with the tools to explore diverse applications. UV DTF printing stands out in the realm of printing technology due to its capacity to produce high-quality images with impeccable detail and vibrant colors, setting the standard for future developments in the industry.

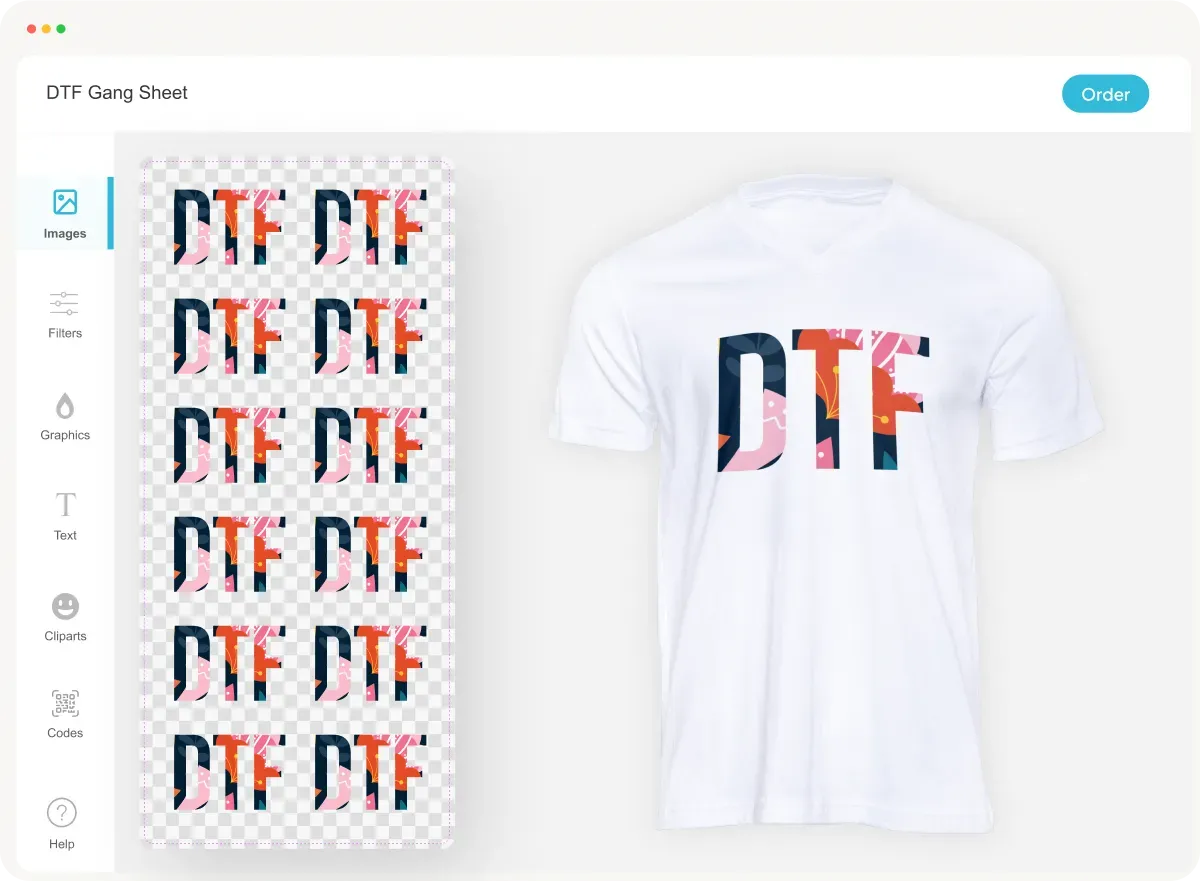

As demand for versatile and durable printing solutions rises, UV DTF has become a staple for businesses seeking to enhance their product offerings. This technology facilitates quick turnarounds, which is critical for industries focused on short-run productions and customizations. The ease of use and adaptability of UV DTF equipment allows even those new to the printing process to dive right in, transforming creative ideas into tangible products with minimal learning curve.

The Versatility of UV DTF Printing

One of the most compelling features of UV DTF printing is its remarkable versatility, enabling creatives to print on a range of materials that were previously challenging to work with. From promotional items like wristbands and tote bags to personalized household items, UV DTF expands the possibilities for branding and consumer engagement. This printing technology accommodates various complex designs and textures, allowing for unique creations that reflect individual styles or corporate identities.

Additionally, the adaptability of UV DTF printing means that industries such as fashion, décor, and promotional merchandise can produce limited-edition items with ease. The flexible nature of the DTF process, coupled with the durability of the UV-cured finishes, means that prints can stand up to rigorous wear and tear, aligning perfectly with the demands of today’s fast-paced marketplace.

Eco-Friendly Aspects of UV DTF Printing

In an era where sustainability is at the forefront of consumer consciousness, UV DTF printing presents a responsible choice for eco-friendly production. This printing process consumes significantly less energy compared to traditional printing methods, reducing the overall carbon footprint associated with manufacturing. Along with lower energy consumption, UV DTF produces minimal waste because it allows for precise ink application and eliminates the need for excess materials.

Moreover, UV DTF inks are often formulated to be free of harmful solvents, making them safer for both the environment and the workers handling them. Creatives and businesses can confidently market their products as eco-friendly, thereby attracting a growing demographic that values sustainability without compromising on quality or aesthetics.

Outstanding Durability of UV DTF Prints

The durability of prints produced by UV DTF technology is a significant selling point that sets it apart from other printing methods. UV-cured prints are not only vibrant but also exhibit impressive resilience against everyday wear, including scratches, fading, and water damage. This durability ensures that products maintain their integrity even after prolonged use, making them ideal for both indoor and outdoor applications.

The polished finish that results from UV DTF printing further enhances the aesthetic appeal of products. This sheen not only makes colors pop, but it also provides an extra layer of protection, ensuring that designs remain crisp and vivid over time. Whether for apparel, signage, or merchandise, businesses can rely on the longevity of UV DTF prints to reflect their quality and professionalism.

User-Friendly Innovations in UV DTF Printing

Recent advancements in UV DTF printing technology have made the process even more user-friendly, making it accessible for individuals and businesses of all sizes. Newer models of UV DTF printers come equipped with intuitive interfaces and automated features that simplify the printing process, reducing the amount of technical knowledge required. Graphics designers and small business owners can now harness this technology to bring their creative visions to life with minimal hassle.

These user-centric innovations not only save time but enhance productivity by allowing artists to focus more on the creative aspects of their projects rather than the complexities of printing. The integration of software solutions for better design management streamlines workflows, enabling faster adaptations to changing market trends. This focus on usability positions UV DTF technology as a valuable resource for both seasoned printers and newcomers alike.

Future Prospects of UV DTF Printing Technology

As the creative printing landscape evolves, UV DTF printing is set to play a pivotal role in shaping the future of personalized products. With ongoing research and development, we can expect enhancements in printing speeds, resolutions, and an even broader range of substrate compatibilities. Upcoming trends may include the incorporation of smart technology, where printers can automatically adjust settings based on material types or project requirements, further optimizing workflows and output quality.

Moreover, the potential for integrating UV DTF printing with digital marketing strategies cannot be overlooked. Businesses could leverage augmented reality experiences on printed materials, creating an interactive dimension that captivates audiences and elevates marketing effectiveness. In this dynamic environment, UV DTF is positioned to redefine what is possible for artists and professionals, continually inspiring innovation and creativity.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or UV Direct-To-Film printing, is a cutting-edge printing technology that uses ultraviolet light to instantly cure ink on various substrates. This method combines the durability of UV printing with the flexibility of DTF, allowing for vibrant, high-quality prints on materials like textiles, plastics, metals, and more.

What are the main advantages of using UV DTF printing?

The primary advantages of UV DTF printing include its versatility across multiple surfaces, vibrant color output, superior durability, and a sustainable printing process that minimizes waste and energy consumption. These characteristics make it an appealing choice for creatives looking to produce high-quality, long-lasting products.

How does UV DTF printing support sustainable printing practices?

UV DTF printing supports sustainable practices by using less energy and generating minimal waste compared to traditional printing methods. As the process relies on UV curing, it avoids the need for harmful solvents, making it a more environmentally friendly option for creative professionals.

Can UV DTF printing be integrated with other printing technologies?

Yes, UV DTF printing can be integrated with other printing technologies and workflow software. This integration enhances efficiency, enabling automated quality control, faster turnaround times, and improved management of production workflows, making it easier for businesses to meet larger orders.

What materials can be printed using UV DTF technology?

UV DTF printing is highly versatile, allowing for printing on a wide range of materials including textiles, plastics, metals, wood, glass, and more. This versatility enables artists and designers to explore various applications, adding significant creative potential.

Is UV DTF printing user-friendly for beginners?

Absolutely! UV DTF printing is designed to be user-friendly, making it accessible to those with limited printing experience. The modern UV DTF printers feature straightforward setups that minimize downtime and allow creatives to quickly start their projects.

| Key Aspect | Details |

|---|---|

| UV DTF Technology | A revolutionary method combining UV printing and DTF for vibrant, durable prints. |

| Versatility | Applicable on various substrates including textiles, plastics, metals, wood, and glass. |

| Vibrant Color Output | Rich color output that stands out in a market saturated with dull printing options. |

| Durability and Finish | Scratch-resistant and water-resistant prints with a glossy finish. |

| Sustainability | Produces minimal waste and lower energy consumption compared to traditional methods. |

| User-Friendly Process | Easy setup for both beginners and experienced users, enhancing productivity. |

| Recent Developments | Emergence of advanced printers and integration with other technologies for efficiency. |

Summary

UV DTF printing is rapidly transforming the landscape of creative industries, offering innovative solutions for artists and designers alike. The unique combination of durability and versatility ensures that UV DTF stands out as a preferred choice in printing technology. With its vibrant color output and sustainability benefits, it caters to various applications from textiles to promotional materials. Furthermore, the recent advancements in equipment and automation add to its appeal, enabling efficient workflows. As this technology evolves, it presents endless opportunities for creativity and product differentiation in the market. Embrace UV DTF and unlock your ultimate creative potential!