UV DTF Gangheet: A Game Changer for Designers

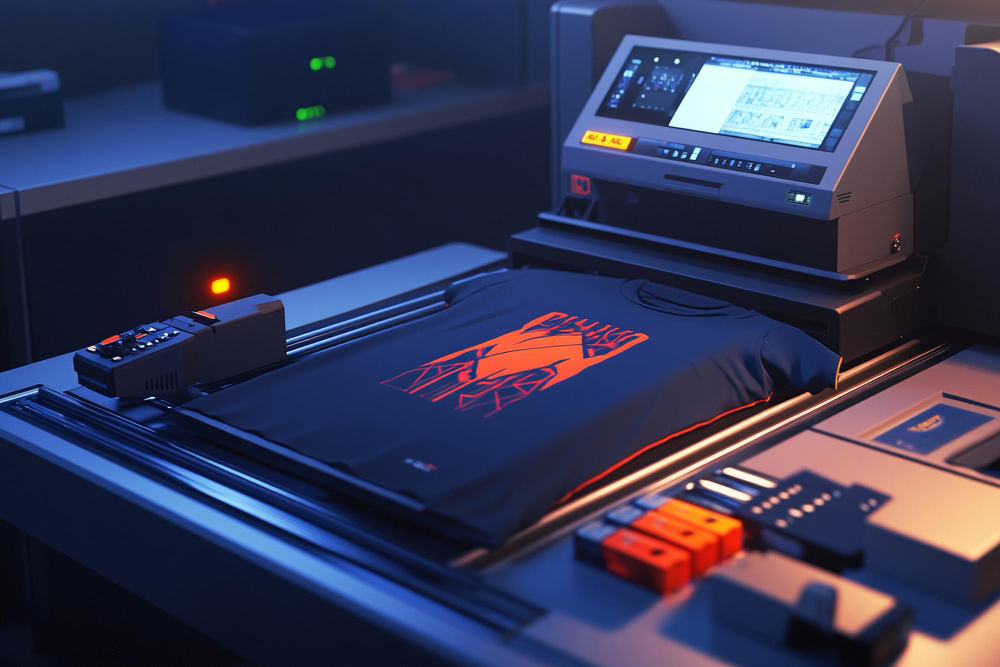

In the ever-changing world of design, UV DTF gangheet stands out as a revolutionary printing method that every designer should explore. This cutting-edge technology allows for vibrant, high-quality prints that can be applied to a diverse range of materials, making it a versatile choice for custom merchandise printing. The benefits of UV DTF extend beyond aesthetics; it also offers quick turnaround times and durability, essential for creating lasting products. Moreover, this innovative solution represents a sustainable printing option that aligns with the increasing demand for eco-friendly practices in the industry. By integrating UV DTF gangheet into their projects, designers can significantly elevate their creative offerings, ensuring both quality and environmental responsibility.

Also known as UV Direct to Film printing, the UV DTF gangheet technique utilizes ultraviolet light to swiftly cure inks on various substrates, allowing for exceptional detail and color vibrancy. This state-of-the-art printing method has emerged as a game-changer within the realm of design printing technologies, providing artists and businesses alike with the ability to produce custom items on demand. With applications ranging from personalized apparel to unique promotional materials, the versatility of UV DTF ensures that creators can respond effectively to diverse market trends. Additionally, this approach emphasizes sustainable printing solutions by reducing waste associated with traditional methods, thus enabling responsible design practices. As the demand for high-quality, customizable design solutions grows, embracing alternative terms like UV DTF will keep designers ahead in a competitive landscape.

Understanding UV DTF Printing Technology

UV DTF (Direct to Film) printing is a revolutionary technique that employs ultraviolet light for curing inks immediately on various materials. This method allows for the direct printing of stunning visuals that are both high-quality and durable. Designers leveraging UV DTF can produce intricate designs that maintain clarity and color depth, making it an attractive choice especially for projects requiring precision. Additionally, the instant drying property of UV DTF significantly reduces production times, allowing designers to meet tight deadlines without compromising on quality.

The technology behind UV DTF is advanced yet user-friendly, allowing even those new to printing technologies to achieve professional results. By bypassing traditional lengthy drying times associated with other printing methods, UV DTF enhances workflow, enabling designers to focus more on creativity rather than production limitations. This ease of use, combined with reliable output, makes UV DTF an essential tool for modern designers looking to innovate.

The Benefits of UV DTF for Custom Merchandise

Custom merchandise printing has seen a shift towards more innovative solutions, with UV DTF gangheet emerging as a top choice for designers seeking efficiency and quality. This technology allows for vibrant prints on diverse substrates, which is crucial for creating unique promotional items, clothing, and accessories. Designers can produce striking designs that stand out, engage consumers, and meet the demands of the evolving marketplace.

Moreover, UV DTF offers designers greater flexibility in terms of design experimentation. They can easily create bespoke merchandise tailored to specific client requests or current market trends. This adaptability not only enhances customer satisfaction but also opens up new revenue streams for designers looking to expand their offerings in the custom printing space.

Exploring the Environmental Impact of UV DTF Printing

In an age where sustainability is at the forefront of many brand’s missions, UV DTF gangheet presents a greener alternative to traditional printing options. Unlike solvent-based inks that can emit harmful volatile organic compounds (VOCs), UV DTF utilizes eco-friendlier materials that reduce air pollution during production. This commitment to environmental care not only benefits the planet but also resonates well with eco-conscious consumers who are more likely to support brands that prioritize sustainable practices.

By adopting UV DTF technology, designers can position themselves as environmentally responsible creatives. This approach can lead to improved brand loyalty and positive consumer perception, as more customers actively seek out brands that align with their values. Embracing sustainable printing solutions like UV DTF can thus enhance a designer’s marketability while making a significant contribution to global sustainability efforts.

Durability and Quality in UV DTF Prints

One of the standout features of UV DTF printing is its remarkable durability. The UV curing process ensures that inks bond tightly to substrates, resulting in prints that are highly resistant to scratches, UV fade, and weathering. This means that products made using UV DTF are perfect for outdoor use or for items that see frequent handling, making it a practical choice for designers aiming to deliver long-lasting merchandise.

Additionally, the high-quality finish achieved through UV DTF technology not only enhances the aesthetic appeal of the prints but also boosts client satisfaction. Knowing that their products can withstand wear while maintaining vibrant colors and sharp details is a definite selling point for clients in a competitive market. This combination of durability and quality serves to elevate a designer’s work, ultimately leading to higher value projects and repeat business.

UV DTF as a Cost-Effective Solution

In the realm of printing technologies, the initial investment in UV DTF may seem steep, but the long-term savings and benefits make it a worthwhile choice for designers. The efficiency of printing on-demand minimizes waste, allowing designers to order just the right amount of materials needed without excessive overproduction. This not only helps in reducing costs but also aligns with a more sustainable approach to design and manufacturing.

Furthermore, the rapid turnaround times associated with UV DTF technology enable designers to deliver projects faster, thereby enhancing customer satisfaction. Satisfied clients are more likely to return for future projects, contributing to a sustainable business model. In this way, UV DTF printing not only elevates workflow efficiency but also drives profitability for design businesses.

Elevating Your Design Projects with UV DTF Gangheet

Implementing UV DTF gangheet can significantly elevate the quality and uniqueness of your design projects. The technology provides designers with the ability to produce custom solutions that fulfill client’s distinct visions while maintaining an efficient production process. By leveraging the capabilities of UV DTF, designers can create a diverse range of products that showcase intricate designs, seamless color variations, and striking finishes.

This level of customization and quality allows designers to push the boundaries of creativity, enabling them to explore new artistic avenues and expand their service offerings. Whether engaged in commercial projects, artistic endeavors, or promotional items, embracing UV DTF gangheet empowers designers to provide a superior product that reflects their creative vision and meets the market’s demands.

Frequently Asked Questions

What is UV DTF gangheet and how does it differ from traditional printing methods?

UV DTF gangheet is a printing technology that utilizes ultraviolet light to cure inks directly onto various substrates, resulting in high-quality, vibrant prints with intricate details. Unlike traditional printing methods that often require drying time, UV DTF printing cures inks instantly, allowing for faster production and superior print quality.

What are the benefits of UV DTF printing for custom merchandise?

UV DTF printing offers numerous benefits for custom merchandise, including vibrant colors, durability, and versatility across different materials like plastics and textiles. This technology ensures designs maintain their quality even in harsh environments, making it ideal for promotional products and personalized items.

How does UV DTF gangheet contribute to sustainable printing solutions?

UV DTF gangheet contributes to sustainable printing by using inks that emit fewer volatile organic compounds (VOCs) compared to traditional solvent-based inks. This reduces the ecological footprint of the printing process, making it an eco-friendly choice for businesses looking to appeal to environmentally conscious consumers.

What types of substrates can be used with UV DTF printing technology?

UV DTF printing is incredibly versatile, allowing for printing on a wide range of substrates such as plastic, metal, glass, textiles, and rigid surfaces. This flexibility enables designers to explore various applications and meet diverse market demands for their projects.

How does UV DTF gangheet enhance design quality?

UV DTF gangheet enhances design quality through its ability to produce vibrant colors and fine details. The inks used in UV DTF printing dry quickly and offer a broad color gamut, ensuring that complex designs and branding materials are accurately represented and visually striking.

Is investing in UV DTF gangheet cost-effective for designers?

Yes, investing in UV DTF gangheet can be cost-effective in the long run. Although the initial equipment cost may be higher than traditional methods, the reduced waste from on-demand printing and quicker turnaround times can lead to significant savings and increased profitability for designers.

| Key Point | Description |

|---|---|

| Innovative Printing Technique | Uses UV light for instant ink curing, producing high-quality, vibrant prints with fast turnaround times. |

| Versatility of Substrates | Can print on a vast range of materials including plastic, metal, glass, and textiles. |

| Vibrant Colors and Detail | Produces rich colors and intricate details, maintaining vibrancy even in harsh conditions. |

| Environmental Benefits | Uses eco-friendly inks with lower emissions compared to traditional methods. |

| Increased Durability | Strong bond between ink and substrate, resistant to scratches, UV fading, and water damage. |

| Cost-Effectiveness | Initial investment may be higher, but offers long-term savings through on-demand printing. |

Summary

UV DTF gangheet is a transformative technology that designers should prioritize for their projects. By leveraging this innovative printing technique, they can achieve unparalleled quality, vivid color reproduction, and exceptional durability. Furthermore, its ability to print on multiple substrates ensures that designers can experiment and cater to a variety of market needs with ease. With environmental sustainability becoming increasingly crucial, UV DTF gangheet also offers a greener alternative to traditional printing methods. In conclusion, adopting UV DTF gangheet not only enhances a designer’s creative capabilities but also establishes them as pioneers in an evolving industry.