UV DTF Printing: Revolutionizing Print Technology Today

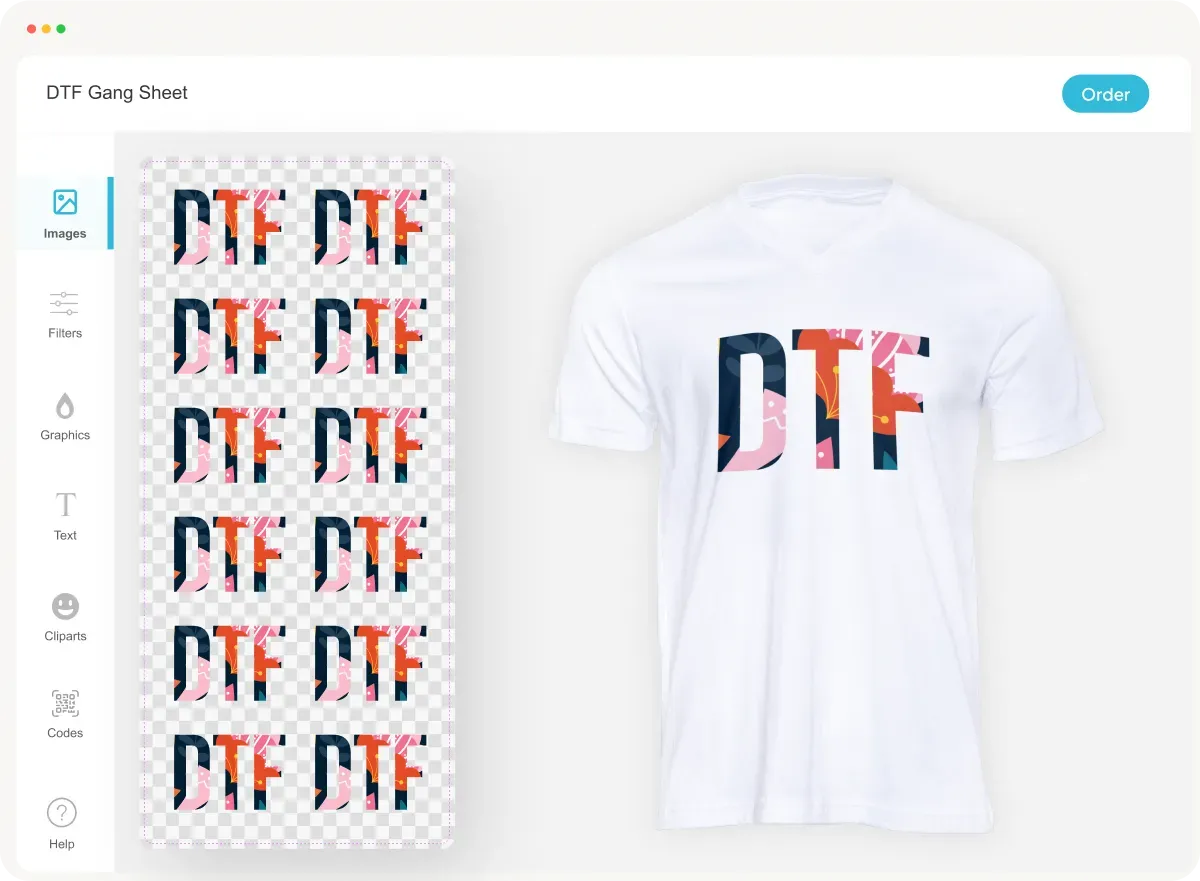

In the dynamic sphere of print technology, **UV DTF printing** stands out as a revolutionary method reshaping how creative professionals conceptualize and produce printed materials. By merging traditional UV printing’s quality with the innovative techniques of Direct to Film (DTF) printing, this advanced print technology offers unmatched versatility and rapid output. With its vibrant ink formulations and quick curing process, UV DTF enables professionals to bring intricate designs to life on a variety of surfaces. As businesses increasingly lean towards sustainable printing solutions, UV DTF proves to be a greener alternative, reducing harmful emissions compared to conventional methods. Join us as we explore the endless possibilities and advantages this cutting-edge printing technique brings to the industry.

The future of printing is being redefined with innovative techniques such as **UV Direct to Film (DTF)** printing, a hybrid model that seamlessly combines the best elements of various print technologies. This groundbreaking method leverages ultraviolet light to effectively cure inks during the printing process, offering creatives a state-of-the-art alternative for their projects. Often touted for its exceptional versatility and compatibility with multiple substrates—from fabric to rigid materials—UV DTF printing is quickly gaining traction as a go-to choice for businesses focused on customization and high-quality output. Additionally, its eco-friendly qualities make it an attractive option for those looking to reduce their environmental footprint in production. As the printing industry evolves, the adoption of advanced ink formulations and technology continues to pave the way for extraordinary applications and stunning results.

The Innovations Driving UV DTF Printing Forward

The UV DTF printing technology stands at the forefront of modern print solutions, thanks in large part to its innovative capabilities. This method merges ultraviolet printing techniques with traditional direct-to-film processes, resulting in an incredibly versatile printing solution. As businesses increasingly seek outputs that combine quality with speed, UV DTF has quickly demonstrated its superiority, offering rapid curing times that not only enhance productivity but also guarantee vibrant print colors. The ongoing technological advancements within this field further elevate its potential, allowing for faster, more efficient production processes.

Moreover, the progress in ink formulations has spiraled upward, introducing UV inks that are not just vibrant but also environmentally friendly. These new formulations ensure excellent adhesion and flexibility on various surfaces, solidifying UV DTF’s position as a preferred choice for businesses in diverse sectors. Clients can now have their designs printed on challenging substrates, expanding their creative possibilities while meeting the demand for high-quality prints.

Understanding the Benefits of UV Direct to Film Technology

UV Direct to Film (DTF) technology offers a host of benefits that make it a game-changer in the print landscape. One of the most significant advantages is its versatility; UV DTF can efficiently print on a myriad of materials, from fabrics like cotton and polyester to rigid surfaces such as wood and metal. This adaptability allows print service providers to cater to a diverse clientele, expanding their product offerings and enhancing customer satisfaction. In an industry where customization is key, the ability to deliver high-quality prints across different materials sets UV DTF apart from traditional methods.

Another standout benefit of UV DTF technology is its commitment to sustainability. Using UV inks that are devoid of volatile organic compounds (VOCs), this printing method contributes significantly to reducing the environmental impact often associated with traditional printing processes. Thus, businesses that adopt UV DTF not only satisfy customer demands for quality and customization but also align themselves with eco-friendly practices, reinforcing their brand’s commitment to sustainable development.

The Surge of UV DTF in the Market

As awareness of UV DTF technology grows, the market is witnessing a considerable surge in demand. Businesses are now prioritizing cost-effective and sustainable printing solutions that not only decrease waste but also improve efficiency. This has led to an increased focus on UV DTF technology within sectors that thrive on customization, such as fashion and promotional products. According to recent studies, the global market for UV DTF printing is expected to fluctuate positively, opening up new avenues for businesses ready to innovate.

Furthermore, the expansion of e-commerce and online platforms has amplified the need for rapid production and personalized products. With UV DTF printing, businesses can respond quickly to market demands, providing custom designs that meet the evolving needs of consumers looking for unique items. This trend positions UV DTF as not merely an alternative but as a necessary technology for survival and growth in today’s competitive print landscape.

Technological Advancements in UV DTF Printing

Technological advancements in UV DTF printing continue to redefine what is possible within the industry. Manufacturers have prioritized improvements in printer mechanics and ink formulations, resulting in higher-quality output with every print run. Newly developed inks enhance adhesion and flexibility across materials that were traditionally difficult to print on, further extending the range of products that can be created with UV DTF technology. This improvement underscores the importance of keeping pace with innovation to remain competitive.

Additionally, advancements in printer speed and efficiency have been remarkable. Modern UV DTF printers are designed for rapid output without sacrificing quality, a crucial feature for print shops that handle high volumes of orders. This efficiency not only allows for quicker turnaround times but also reduces operational costs, providing businesses with greater opportunities to optimize profit margins.

Diverse Applications of UV DTF Technology

The versatility of UV DTF printing extends its reach to various industries, each benefiting from its unique capabilities. In the fashion industry, for example, UV DTF technology enables the creation of stunning custom designs at high volume, satisfying consumer trends for personalized apparel. Fashion brands can leverage the rapid print capabilities to launch collections that reflect current styles and customer preferences, ensuring a competitive edge.

Furthermore, the promotional products sector has also embraced UV DTF technology’s potential. Businesses can quickly create unique branded items that stand out from competitors, from customized drinkware to personalized gifts. This ability to produce eye-catching, quality promotional items fosters customer loyalty and encourages brand recognition, effectively meeting the increasing demand for personalized marketing solutions.

Future Prospects for UV DTF Printing

Looking ahead, the future prospects of UV DTF printing appear exceedingly bright. As industries increasingly embrace digital printing technologies, the ability to produce high-quality, customizable products efficiently positions UV DTF for continued growth and innovation. With the rise of consumer demands for unique, sustainable products, UV DTF’s eco-friendly features will become even more appealing.

Moreover, ongoing research and development in UV DTF technology promise to unveil even more advanced features and applications. From enhancing durability for outdoor uses to improving ink formulations for better color reproduction, the potential for UV DTF printing is expansive. Thus, businesses adopting this technology will likely find themselves well-positioned to lead in the ever-evolving landscape of print technology.

Frequently Asked Questions

What is the process of UV DTF printing and how does it work?

UV DTF printing, or UV Direct to Film printing, uses ultraviolet light to cure specially formulated inks onto transfer films. This process allows for immediate drying, ensuring vibrant and high-quality prints that can be transferred onto various substrates, including fabric, metal, and wood.

What are the main benefits of using UV DTF printing technology?

The benefits of UV DTF printing include high-quality detail reproduction, compatibility with a wide range of materials, faster production times due to instant curing, and an environmentally friendly profile thanks to UV inks that are generally free from VOCs.

Can UV DTF printing be considered a sustainable printing option?

Yes, UV DTF printing is a sustainable printing option. The technology utilizes UV inks that emit little to no volatile organic compounds (VOCs), thereby reducing its environmental impact when compared to traditional solvent-based print methods.

What types of materials can be printed using UV DTF technology?

UV DTF printing is versatile and can print on multiple materials such as textiles (cotton and polyester), rigid substrates (metal and wood), vinyls, and more, making it suitable for a wide range of applications across industries.

How does UV DTF printing compare to other printing technologies like traditional DTF or UV printing?

UV DTF printing combines the strengths of traditional DTF and UV printing. It offers faster drying times due to UV curing, superior print quality, and the ability to work with a variety of substrates, which traditional DTF may struggle with when it comes to adhesion and detail.

What industries are currently adopting UV DTF printing technology?

UV DTF printing is gaining traction in industries such as fashion, promotional products, interior design, and custom merchandise, where the need for high-quality, customizable, and sustainable print solutions is paramount.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A hybrid technology using ultraviolet light to cure inks on transfer films, ensuring rapid drying and quality output. |

| Advantages of UV DTF Printing | Includes versatile material compatibility, high quality, sustainability, and fast production times. |

| Market Growth | Growing interest in cost-effective, eco-friendly printing methods with wide potential in customization sectors. |

| Technological Advancements | Focus on enhanced ink formulations, increased efficiency, and user-friendly systems. |

| Applications Across Industries | Benefit industries such as fashion, promotional products, and interior design by providing custom print solutions. |

Summary

UV DTF printing is revolutionizing the print technology landscape by combining quality, versatility, and sustainability. This innovative technique utilizes ultraviolet light to cure inks quickly, allowing for vibrant colors and detailed designs on various materials. As businesses seek eco-friendly solutions that cater to quick turnaround times, the adoption of UV DTF is projected to grow across multiple industries. With advancements in technology improving performance and output, UV DTF printing is setting a new standard for the future of printed products.