DTF Transfers: A Step-by-Step Tutorial for Beginners

DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of fabric printing, enabling enthusiasts and entrepreneurs to create stunning designs with ease. This innovative printing method offers vibrant color reproduction and intricate detail, making it ideal for a wide range of applications, from personalized t-shirts to custom bags. In this DTF transfer tutorial, we’ll explore the step-by-step process of using this advanced technique, suitable for both DIY projects and small business endeavors. Understanding how to make DTF transfers can unlock endless creative possibilities, as this method allows for high-quality designs without the complexities of traditional printing. Join us as we dive into the exciting realm of DTF printing, where your artistic visions can come to life on fabric.

Crafting DTF transfers is quickly gaining traction among crafters and small-business owners alike, thanks to its versatility and ease of use. This Direct-to-Film printing technique permits the application of intricate graphics onto diverse fabric materials with remarkable clarity and vibrancy. Whether you’re looking to personalize home decor or jumpstart a startup, mastering the method of creating these transfers can enhance your creative projects significantly. With this guide, you’ll discover tips and strategies for successful DTF transfer creation, simplifying the often intricate process into manageable steps. Embrace the world of transfer printing, where the only limit is your imagination!

The Basics of DTF Printing: What You Need to Know

DTF printing, or Direct-to-Film printing, has revolutionized the way we create custom designs for fabrics. This innovative technique involves printing images onto a special transfer film which can then be heat-pressed onto fabric surfaces. Unlike traditional printing methods, DTF allows for vibrant colors and intricate designs that can be easily transferred onto a variety of substrates. This versatility makes it an ideal choice for crafters and entrepreneurs looking to bring their creative visions to life, offering a more accessible option than methods like Screen Printing.

To use DTF printing effectively, it’s crucial to understand the process and materials involved. The right printer, DTF inks, transfer films, and a heat press are essential tools for ensuring high-quality transfers. Many enthusiasts appreciate DTF for its ability to produce full-color, detailed images that stand out on garments. With some practice and the right resources, anyone can master the art of DTF transfers and create remarkable products for personal use or small businesses.

Essential Materials for Creating DTF Transfers

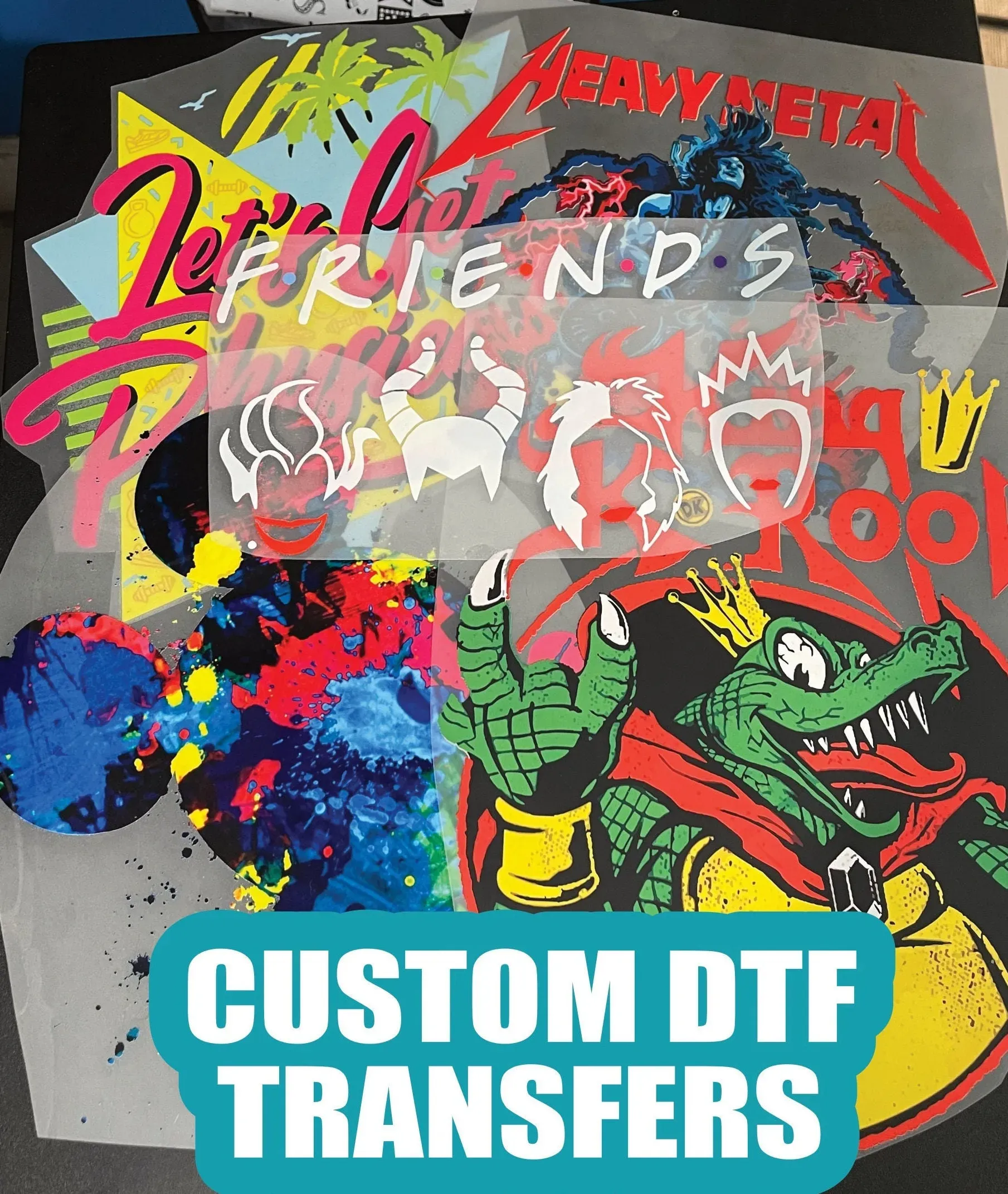

Gathering the right materials is paramount when starting your DTF journey. You’ll need a compatible DTF printer, which can range from modified inkjet models to specialized DTF machines designed specifically for this purpose. Additionally, DTF inks are critical; these inks are formulated to ensure the best adherence and vibrancy on the transfer film, setting them apart from conventional inkjet pigments.

Alongside the printer and inks, it’s essential to procure high-quality DTF transfer film and adhesive powder. The PET film used in DTF printing provides a smooth surface that helps achieve vibrant transfers. The adhesive powder is equally vital as it adheres the printed ink to the fabric during the heat pressing process, ensuring longevity and a professional finish. Investing in quality materials not only ensures superior results but also enhances the overall efficiency of the printing process.

Step-by-Step Guide to Making DTF Transfers

Creating DTF transfers is a straightforward process, but it requires attention to detail at every step. The first phase is designing your artwork, which can be crafted using graphic design software like Adobe Illustrator. It’s crucial to consider elements such as color contrasts and fabric compatibility, as different materials may react differently to various inks. Once your design is finalized, it’s time to prepare for printing.

The printing process involves adjusting printer settings to accommodate the DTF transfer film. Make sure to print on the film’s matte side and mirror your design to ensure a flawless transfer. After printing, apply the adhesive powder while the ink is still wet, creating a perfect bond when heated. Following this, the film should be cured in a heat press before transferring it onto your chosen fabric. This careful and methodical approach ensures your designs turn out vibrant and durable.

Tips for Success in DTF Printing

Achieving the best results in DTF printing involves a few invaluable tips. Start by using high-quality materials throughout your process – from the printer to the inks and transfer films. Quality plays a significant role in the end product, with premium materials ensuring better adhesion and color vibrancy. It’s also helpful to conduct test runs on sample fabrics before committing to larger projects. This provides an opportunity to adjust your designs or settings based on real-world outcomes.

Furthermore, printer maintenance is crucial. Regularly check for any clogs in the printer heads and keep your inks fresh to avoid inconsistencies. Temperature control during the heat pressing stage is also essential; different substrates may require different settings, and researching specific fabric types can prevent mishaps. Following these guidelines will enhance your ability to produce professional-grade DTF transfers consistently.

Exploring Current Trends in DTF Printing

The DTF printing landscape is continually evolving, marked by emerging trends that cater to both hobbyists and small businesses. One significant trend is the growing demand for eco-friendly DTF inks. As consumers become more environmentally conscious, manufacturers are responding by creating biodegradable inks that do not sacrifice quality or performance. This shift towards sustainability is not only beneficial for the planet but also resonates with customers seeking responsible choices.

Another noteworthy trend is the availability of pre-designed DTF transfers. For those who prefer to bypass the design process altogether, companies are now offering a range of ready-to-use transfers. This innovation caters to the needs of those who wish to produce custom apparel quickly and efficiently without compromising on creativity. By staying updated with these trends, those involved in DTF printing can better align their offerings with consumer preferences.

The Future of DTF Transfers: Creativity and Business Opportunities

The future of DTF transfers looks bright and promising, particularly regarding the intersection of creativity and business opportunity. As more creators embrace direct-to-film printing, the demand for custom designs is likely to soar. Small entrepreneurs are finding success by offering personalized products using DTF techniques, allowing for creative expression while generating income. Whether it’s unique apparel or bespoke gift items, the scope for innovation in this field is limitless.

Additionally, advancements in DTF technology, including faster printers and improved inks, are set to enhance the overall crafting experience. As the technology matures, we can expect to see more efficiency and versatility, making it easier than ever for individuals to tap into the world of custom fabric printing. Those ready to invest time in mastering the DTF process will find themselves at the forefront of this exciting and evolving domain.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve a printing technique where intricate designs are printed onto a special film and then transferred onto fabric using heat. This method allows for vibrant colors and complex graphics, making it ideal for personal and commercial projects.

What materials do I need to create DIY DTF transfers?

To make DIY DTF transfers, you’ll need a DTF printer (or a modified inkjet printer), DTF inks specifically designed for this printing method, PET transfer film, adhesive powder, a heat press, and a suitable fabric substrate like cotton or polyester.

Can I learn how to make DTF transfers through tutorials?

Absolutely! There are many DTF transfer tutorials available online, including detailed guides and video content that provide step-by-step instructions on how to successfully create your own DTF transfers at home.

What are the key steps in the DTF transfer creation process?

The key steps in making DTF transfers include designing your artwork, printing on special transfer film, applying adhesive powder, curing the powder, transferring the design onto your fabric using a heat press, and finally peeling off the film to reveal your design.

What are common mistakes to avoid when crafting DTF transfers?

Common mistakes in crafting DTF transfers include not using the correct side of the film for printing, applying uneven adhesive powder, using incorrect heat settings, and neglecting printer maintenance, which can lead to poor print quality.

What are the latest trends in DTF printing technology?

Recent trends in DTF printing include the use of eco-friendly, biodegradable inks and the availability of pre-designed DTF transfers, which offer quick and easy solutions for those looking to produce customized designs without the need for complex setups.

| Key Steps in DTF Transfers | Description | Importance | Tips | ||

|---|---|---|---|---|---|

| Understanding DTF Transfers | Direct-to-Film (DTF) transfers involve printing images onto a special film that can then be heat-transferred to fabric. | Allows for intricate designs, suitable for personal and commercial projects. | |||

| Materials Needed | Essential materials include DTF printer, inks, transfer film, adhesive powder, heat press, and fabric. | Quality materials lead to better results in the final product. | |||

| Step-by-Step Process | The process includes designing artwork, printing, applying adhesive powder, curing, transferring, and peeling the film. | Each step is crucial for a successful DTF transfer. | |||

| Current Trends and Innovations | Innovations such as eco-friendly inks and pre-designed transfers cater to consumer preferences. | Stay updated with trends to enhance your offerings. | |||

Summary

DTF transfers allow for vibrant and detailed designs to be transferred onto a variety of fabrics right from home. This method has gained traction among crafting enthusiasts and small business owners alike. By understanding the fundamentals of DTF printing, gathering the right materials, and following a comprehensive step-by-step guide, anyone can create high-quality DTF transfers. As innovations in the industry continue to emerge, including eco-friendly options and pre-designed transfers, now is an exciting time to explore the world of DTF transfers and unleash your creativity!