DTF gangsheet builder: Studio doubles output Case study

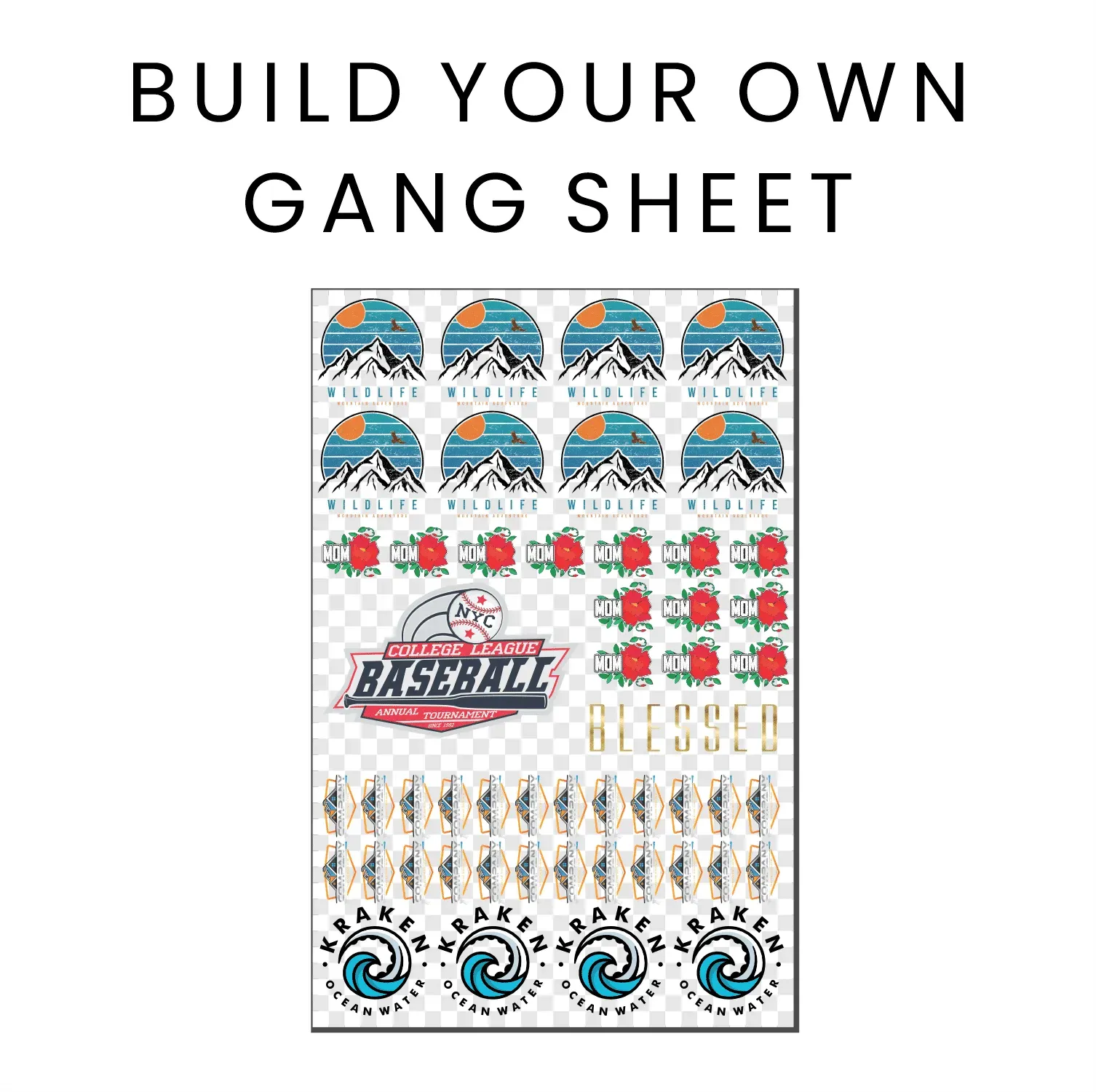

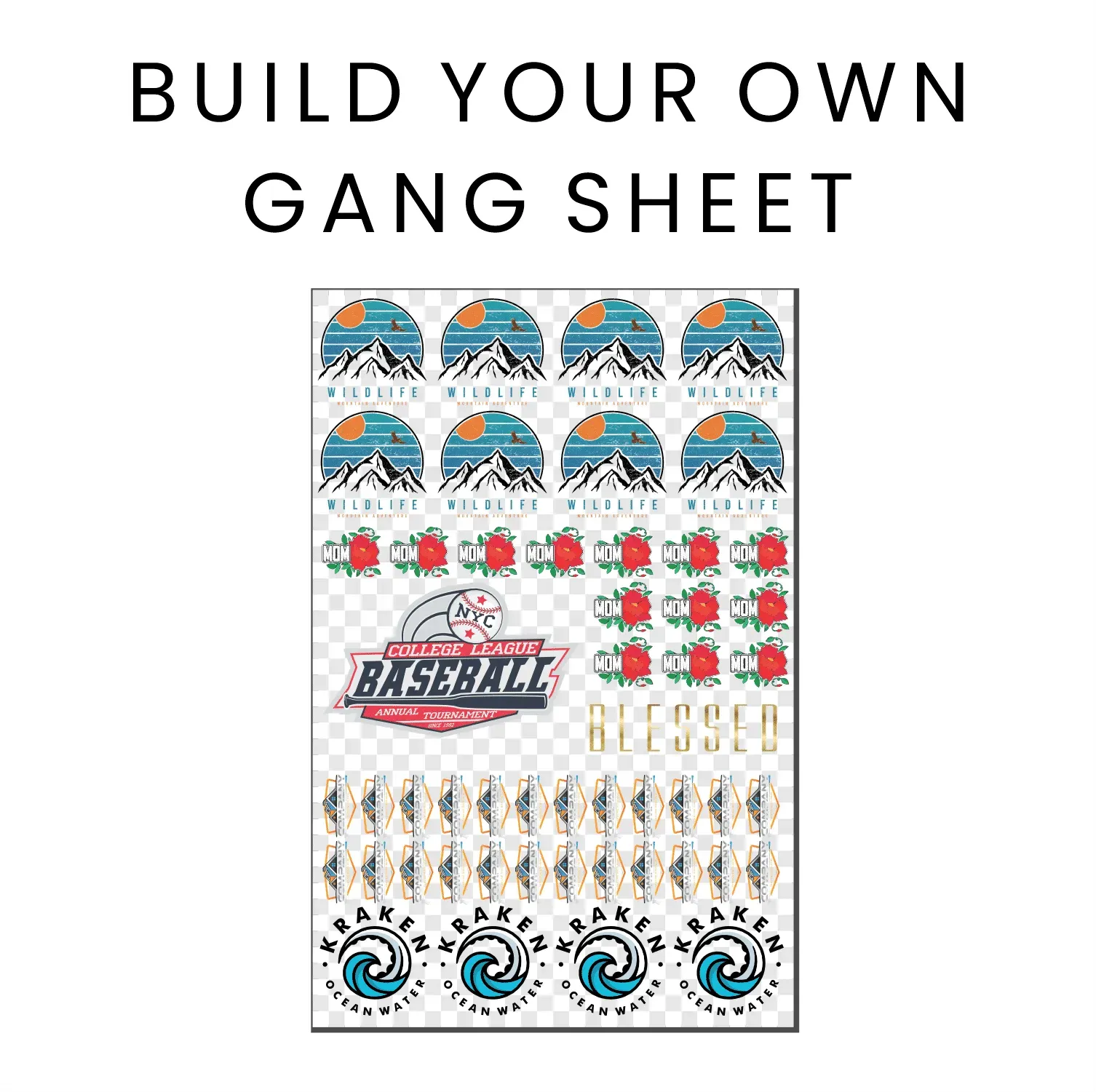

DTF gangsheet builder is transforming pre-press for garment decoration by turning scattered designs into coordinated gang sheets that travel smoothly from concept to print, supported by a user-friendly interface, robust automation, and clear templates that reduce manual steps. In practice, this tool supports the DTF printing workflow by automatically arranging multiple designs into optimized layouts, reducing touchpoints, preventing overlaps, and minimizing the risk of misalignment across color channels, media, and printer calibrations, and to safeguard consistency across shifts. By providing templates and layout logic, it delivers gang sheet optimization across common garment families, ensuring consistent margins, bleed, and color alignment, while enabling more predictable proofs and faster iteration even when design sets vary. Its template automation for DTF enables rapid job setup, so teams can drop artwork into predefined zones, generate print-ready gang sheets in minutes, store proven configurations, and reproduce them for repeat orders with minimal rework, and provide an audit trail for accountability. For studios aiming to improve production efficiency in garment printing, the result is more stable throughput, reduced waste, shorter lead times, and a scalable pre-press process that supports growth across multiple clients and product lines.

Beyond the specific tool, the approach maps to a broader, tech-enabled pre-press workflow that streamlines design-to-print transitions and aligns teams around a common standard. This latent semantic indexing approach emphasizes related ideas such as automated layout logic, color management discipline, template-based standardization, and scalable production planning, which together reduce variability and speed execution. For shops weighing automation investments, the key outcomes to watch include throughput gains, lead-time reductions, diminished material waste, and improved consistency of color and placement across garment categories. If you’re considering a similar upgrade, start by cataloging your most common products, define templates for each print area, and plan integration with your order management stack to generate gang sheets automatically as orders flow in. For teams pursuing multi-product DTF printing, the system’s flexibility across garments, inks, and sizes is especially valuable.

DTF Gangsheet Builder: Template-Driven Layouts to Boost Production Efficiency in Garment Printing

The introduction to the case study shows how a DTF gangsheet builder changes the pre-press landscape by providing reusable templates for different garment types and automated layout logic. By standardizing print areas, margins, and bleed, operators can drop designs into predefined zones and let the system auto-position them, reducing manual design time and human error. This shift directly supports the DTF printing workflow by turning a reactive process into a repeatable, data-driven one.

With integrated color management and ICC profiles aligned to the RIP, the builder ensures consistent color fidelity across gang sheets. The template-driven approach minimizes color tweaks during production and lowers the cognitive load on staff, contributing to higher production efficiency in garment printing. In short, the DTF gangsheet builder turns complex multi-design orders into predictable, repeatable outputs that scale with demand.

Template Automation for DTF and Gang Sheet Optimization to Enable Multi-Product DTF Printing

This subheading explores how template automation for DTF enables gang sheet optimization across multiple product lines. By crafting templates for basic tees, hoodies, tote bags, and other garments, studios can rapidly assemble optimized gang sheets that respect margins, bleed, and safe printing areas. Automated layout logic packs as many designs as possible onto a single sheet while preserving print quality, dramatically reducing setup time and minimizing waste.

The result is a scalable workflow that supports multi-product DTF printing without sacrificing accuracy or color consistency. As orders flow in, templates drive the arrangement, while standardized color targets and presets ensure reliable results across products and colors. This combination strengthens production efficiency in garment printing and lays the groundwork for larger-scale operations, including integration with order management systems and parallel printer utilization.

Frequently Asked Questions

How does the DTF gangsheet builder improve production efficiency in garment printing for multi-product DTF printing?

The DTF gangsheet builder replaces manual gang sheet design with a template-driven workflow, accelerating pre-press and reducing setup errors. It optimizes gang sheets by automatically packing designs within margins and bleed, and it centralizes color management with ICC profiles to ensure consistent results. For multi-product DTF printing, reusable templates for garment families enable fast placement of designs and quicker proofs, reducing rework. In the referenced case study, throughput roughly doubled and lead times were shortened by 25–40%, delivering more prints per shift without sacrificing color fidelity.

What are the key steps to implement a DTF gangsheet builder for template automation for DTF and gang sheet optimization within a DTF printing workflow?

Follow these steps: 1) Audit current orders and baseline existing gang sheet layouts to capture margins, bleed, and color targets; 2) Create templates for common garment families (tees, hoodies, totes) with standardized print areas and guidelines; 3) Move to a template-driven workflow where designs are dropped into templates and the builder auto-positions items; 4) Establish printer-specific color presets and ICC profiles aligned with your RIP; 5) Add lightweight QA checks and proofs to verify layout and color before printing; 6) Train staff with quick-start guides to drive adoption; 7) Track metrics (throughput, lead times, waste, reprints) to refine templates and presets; 8) Plan for scalability by enabling more printers and handling increased job complexity without a full workflow rebuild.

| Aspect | Key Points |

|---|---|

| Overview | DTF printing disrupts garment decoration; pre-press bottleneck is a common hurdle; the case study shows a mid-sized studio doubling output by adopting a DTF gangsheet builder. Emphasis on structured gang sheet layout, template automation, and a data‑driven production approach for scalable results. |

| Problem / Challenge | Manual design and layout per design led to long lead times, margins/bleed mismatches, color mismatches, and a patchwork workflow. Lack of repeatable gang-sheet layout and color management processes hindered scalability. |

| Solution | Adopted a DTF gangsheet builder that integrates with existing design and RIP workflows. Key benefits: reusable templates for garment types, automated and optimized gang sheet layouts, and integrated color management. |

| Implementation Steps | 1) Audit and baseline measurement; 2) Create garment templates; 3) Implement template‑driven workflow; 4) Establish color management presets; 5) QA checks; 6) Training and change management. |

| Results | About a twofold increase in completed orders per day; lead times shortened by 25–40%; reduced ink/media waste; improved color consistency; faster onboarding and more predictable production. |

| Best Practices | Start with garment families and templates; standardize margins/bleed; align color targets with RIP ICC profiles; automate where it matters; maintain QA proofs; track throughput, lead times, waste, and reprints; plan for scalability. |

| Outlook / Future | Expand templates to additional garment lines; integrate with order management to auto‑generate gang sheets; scale across more printers and operators while preserving template quality and color control. |

| Sustainability | Template‑driven automation reduces waste and ink usage, lowers per‑unit costs, and supports a sustainable, scalable production model adaptable to demand. |

Summary

DTF gangsheet builder is a powerful enabler of template‑driven automation in pre‑press workflows. The case study demonstrates how standardizing layouts, automating the arrangement of designs on gang sheets, and unifying color management across devices can deliver meaningful gains in throughput, lead time, and material efficiency. For studios aiming to scale, adopting a robust DTF gangsheet builder supports production efficiency in garment printing while preserving design integrity and color fidelity. Key recommendations include starting with templates for your most common garments, enforcing standardized margins and bleed, integrating ICC profiles with RIP settings, balancing automation with QA checks, and tracking metrics to guide continuous improvement. With scalable templates and order‑flow integration, studios can expand across additional printers and shifts, turning the pre‑press bottleneck into a controllable, repeatable part of the workflow.