DTF gangsheet layouts: Master Advanced Builder Techniques

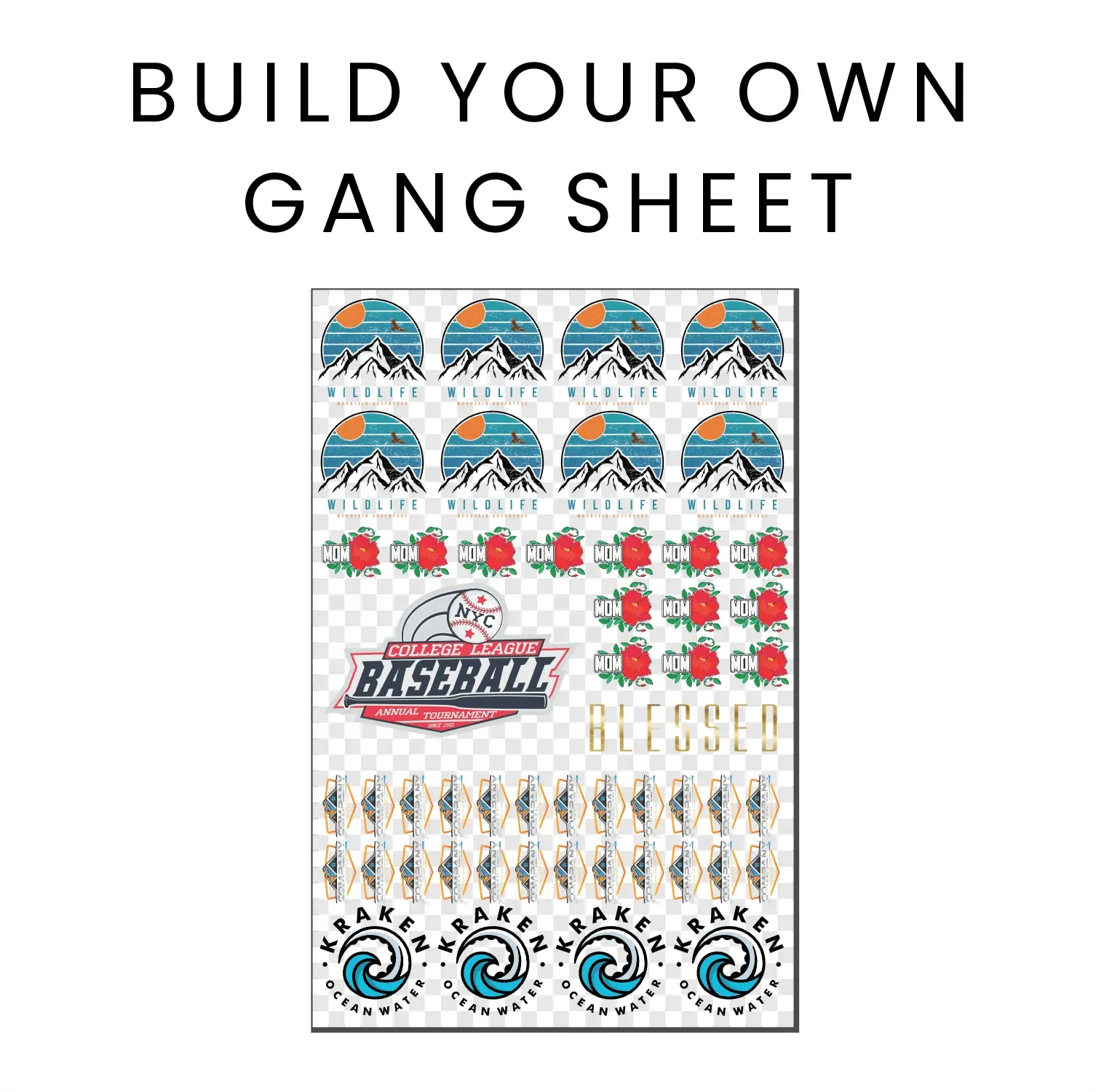

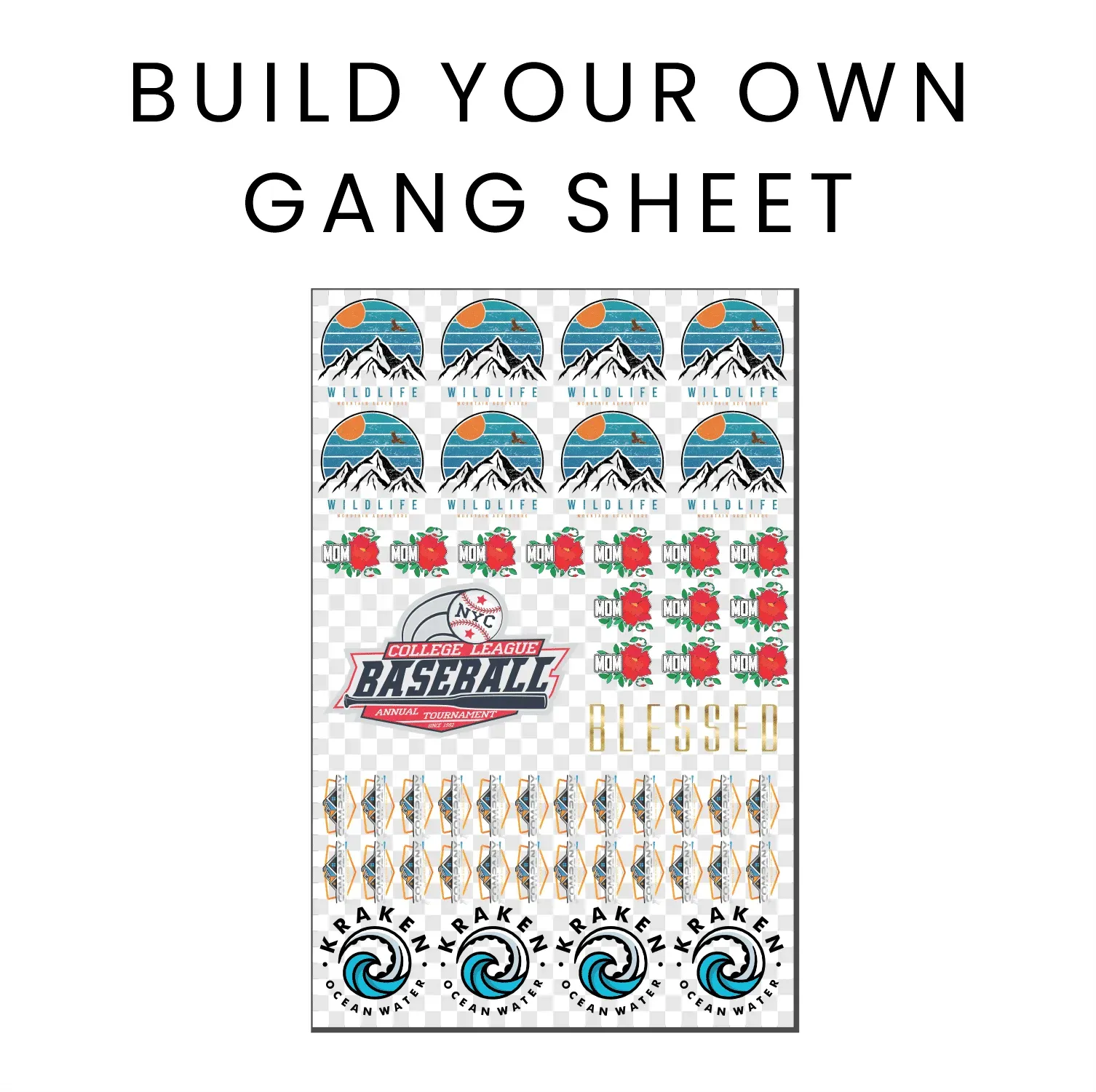

DTF gangsheet layouts unlock efficient, high-volume garment printing by organizing multiple designs on a single transfer sheet. This approach helps minimize waste and keeps color and size accuracy across orders. A dedicated DTF gangsheet builder and a reliable gangsheet template help translate ideas into repeatable, printer-ready layouts. A well-tuned printing workflow reduces misalignment and speeds up production across fabrics. Whether you operate in small batches or scale to high volume, these strategies set the foundation for optimized sheet layouts.

Think of it as grid-based print planning for heat-transfer films, where multiple designs share a single canvas. By aligning elements in modular blocks and using templates, you can simplify production, reduce setup times, and maintain consistent results across sizes. Alternative terminology like multi-design sheets, transfer sheet planning, and layout optimization helps teams discuss the same workflow without getting bogged down in jargon. LSI-friendly terms such as color separations, margins, and bleed areas map naturally to the same practical steps described above. In practice, adopting a template-driven approach and scalable grid system can improve throughput while preserving detail.

DTF gangsheet layouts: Maximize yield with a dedicated builder and templates

DTF gangsheet layouts organize multiple designs on a single transfer sheet, delivering greater print efficiency and material utilization. By leveraging a dedicated gangsheet builder, you can place designs with precise grid alignment, consistent margins, and reliable color separation, turning complex runs into repeatable processes. This approach naturally supports DTF sheet layout optimization, helping you achieve predictable outcomes across different garment styles while preserving artwork integrity.

A well-planned workflow centers on templates and standardized layouts. Use gangsheet templates to lock in margins, grid spacing, and color configurations, then batch-process incoming designs to populate sheets without guesswork. Integrating a robust DTF printing layout strategy—from bleed management to safe zones—reduces waste, speeds setup, and ensures that each transfer sheet aligns with printer profiles and substrate needs.

DTF printing layout strategies: templates, color management, and preflight for consistency

Optimizing your DTF printing layout starts with scalable templates that accommodate common garment sizes and colorways. A well-designed gangsheet template keeps blocks aligned, preserves color integrity, and simplifies exporting print-ready files. By grouping similar color palettes and arranging designs in predictable zones, you minimize color changes and ink wastage during production, while preserving sharp details on cotton, blends, and synthetics.

To safeguard quality, implement a rigorous preflight and export routine. Validate bleeds, safe zones, and sizing consistency before sending job files to the printer, and consider automated checks that flag overlaps or off-grid placements. This disciplined workflow—supported by DTF transfer sheet layout guidelines and color-managed exports—helps maintain reproducibility across batches and presses, delivering reliable results with less rework.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it enhance DTF printing layout and DTF transfer sheet layout?

A DTF gangsheet builder is a software tool that acts as the nerve center for arranging multiple designs on a single transfer sheet. It offers grid-based placement with snapping, alignment guides, and automated spacing to prevent overlaps, while preserving color information and printer profiles. Key features include template support, batch processing, and export options with bleed, trim, and safe zones. Using a dedicated gangsheet builder improves repeatability, reduces material waste, speeds production, and helps maintain consistent color and size accuracy across orders, aligning with DTF printing layout optimization and DTF transfer sheet layout needs. Practically, you define the canvas (garment size), import designs, place them in a grid, assign bleeds and safe zones, run preflight, and export print-ready sheets for your printer or RIP.

How do gangsheet templates and best practices in DTF printing layout contribute to efficient DTF sheet layout optimization?

Templates are repeatable grid layouts saved for common garment sizes and margins, enabling rapid setup and reducing human error. When paired with a solid DTF printing layout workflow, they help ensure consistent spacing, margins, and color handling across orders. In practice, you define the canvas, import designs, confirm color separations, preview and preflight, then export with proper bleed and trim. Using modular gangsheet templates and color-managed exports improves consistency, minimizes waste, and speeds production, key to DTF sheet layout optimization.

| Aspect | Key Points (Summary) |

|---|---|

| Definition |

|

| Role of the DTF gangsheet builder |

|

| Key features to look for in a gangsheet builder |

|

| DTF printing layout considerations |

|

| Templates for speed and consistency |

|

| Designing layouts: practical workflow |

|

| Optimizing for print quality and production speed |

|

| Quality control: verifying layouts before printing |

|

| Common pitfalls and how to avoid them |

|

| Advanced tips for mastery |

|

Summary

DTF gangsheet layouts empower garment printers by enabling multiple designs to be packed onto a single transfer sheet while maintaining margins, color accuracy, and production efficiency. By applying the strategies outlined—using a capable gangsheet builder, standardized templates, careful preflight, and disciplined export practices—you can achieve reliable transfer results, reduce waste, and accelerate production. This scalable approach supports both small batches and high-volume shops, delivering high-quality, consistent prints across every run.