DTF supplies and techniques: From transfer to tees

DTF supplies and techniques are transforming how designers decorate textiles, delivering vibrant, durable graphics with streamlined workflows. Understanding the DTF transfer process, selecting reliable DTF printing supplies, and consulting a direct-to-film printing guide helps you achieve consistent color and bond. Efficient DTF heat press techniques ensure sharp details and a soft hand-feel, even on cotton or blends, making printing on tees with DTF accessible to hobbyists and small studios. A well-planned setup reduces waste, speeds production, and allows repeatable results across batches with careful calibration and testing. Whether you’re just starting or expanding a shop, this guide introduces practical tips to help you grow confidence and deliver quality garments.

DTF supplies and techniques: From film to final tee

DTF supplies and techniques cover the full stack of equipment and know-how you need to turn a concept into a wearable graphic. Essential DTF supplies include film designed for transfer, adhesive powder, a compatible printer with water-based inks, and a reliable heat press. Understanding the DTF transfer process helps set expectations for image fidelity, color density, and bond strength across fabrics.

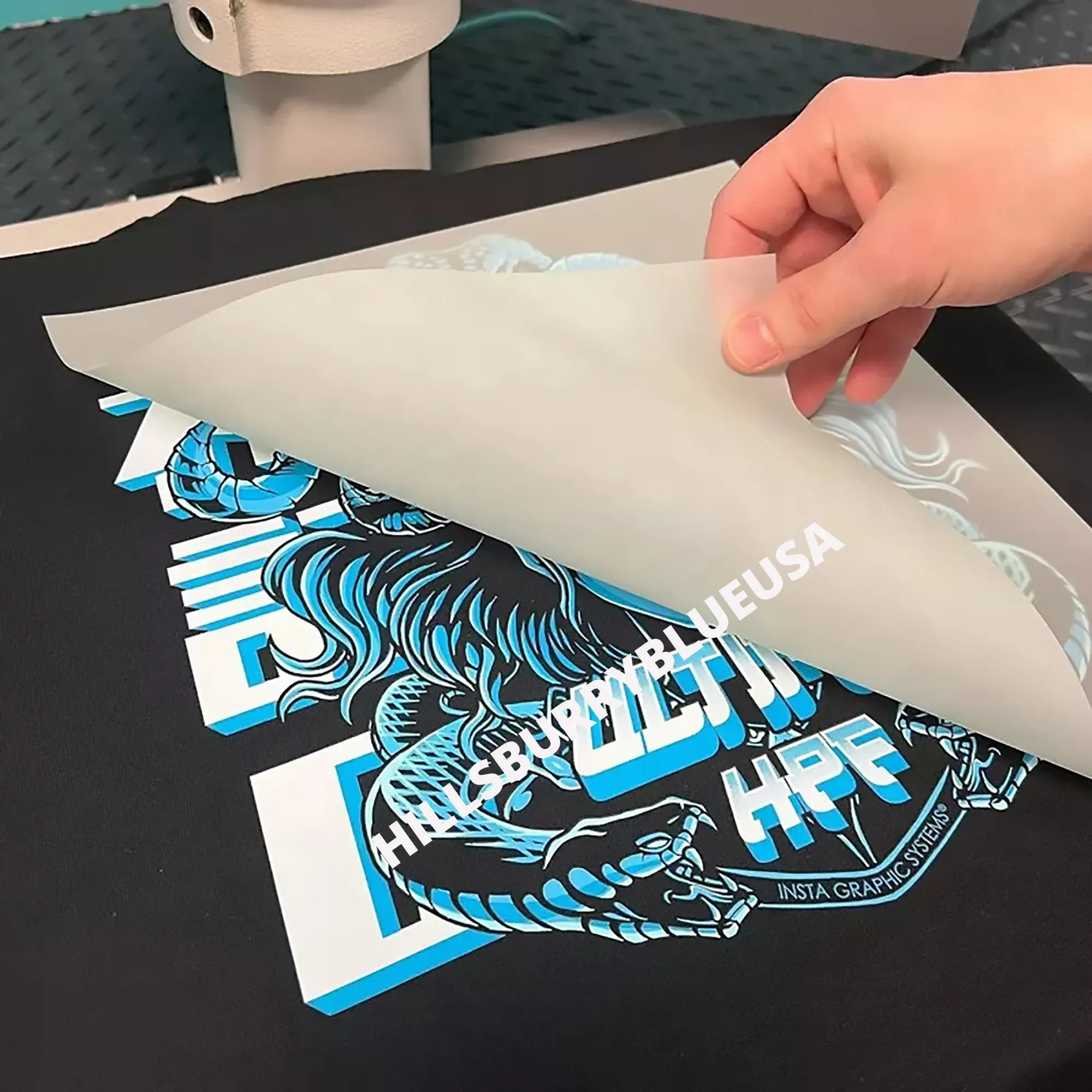

Practically speaking, mastering DTF heat press techniques—temperature, time, and even pressure—directly influences durability and the garment’s feel. As you learn to print on tees with DTF, you’ll develop routines for powder curing, peel methods (hot or cold), and post-press finishing that minimize cracking, peeling, and wash wear. Safety, workspace setup, and dust control are also important parts of a repeatable workflow.

Direct-to-film printing guide: color, materials, and workflow

Direct-to-film printing guide: selecting reliable DTF printing supplies sets the foundation for consistent results. Choose high-release films, uniform adhesive powders, and water-based inks formulated for DTF to maximize color density and white underbase on dark fabrics. Pair your hardware with proper calibration—monitor profiles and printer ICCs—to keep proofs aligned with the final prints.

Beyond gear, a solid workflow emphasizes design prep, precise transfer settings, and ongoing quality control. Documenting settings for each garment type helps with repeatability and troubleshooting, whether you encounter ghosting, color shifts, or tip-of-the-iceberg issues. By following the direct-to-film printing guide and refining your process, you’ll strengthen your ability to deliver professional results for every order.

Frequently Asked Questions

What are the essential DTF supplies and how do they impact the DTF transfer process?

Essential DTF supplies include DTF film and adhesive powder, a compatible DTF printer with water-based inks, curing/drying equipment, a reliable heat press, and basic PPE. The right combination affects image quality, bond strength, and durability during the DTF transfer process, and proper powdering, curing, and pressing steps ensure a clean, long-lasting result.

How can I optimize DTF heat press techniques for printing on tees with DTF?

To optimize DTF heat press techniques, set temperature, time, and pressure to your fabric (e.g., 300–320°F for 10–20 seconds), include a pre-press to remove moisture, and follow the recommended peel method. Use test prints on different tees to verify bond strength, adjust settings for blends or dark fabrics, and apply a brief post-press cure for durability.

| Topic | Key Points | SEO & Notes |

|---|---|---|

| DTF Essentials (Supplies & Equipment) | – DTF film, adhesive powder, release powder, powder shaker – DTF printer with water-based pigment inks (or a conversion kit) – Inks with white base for dark fabrics; curing/drying step – Drying/curing equipment (heat source, oven, or dryer) – Heat press with appropriate sheets; PPE and clean workspace |

Keywords: DTF printing supplies; DTF heat press techniques; printing on tees with DTF |

| DTF Transfer Process (Step by Step) | – Design & prepare (white underbase, mirror) – Print on PET film – Apply adhesive powder – Cure powder – Weed and prep – Pre-press garment – Transfer to fabric (approx. 300–320°F / 150–160°C, 10–20s) – Post-press – Care instructions |

Keywords: DTF transfer process; direct-to-film printing guide |

| Material Selection & Color Management | – Film quality; adhesive powder quality – Inks & color management; color profiles – Substrates (cotton, blends, synthetics) and starting tests – Heat press settings; keep a settings log |

Keywords: DTF printing supplies; color management |

| Applying Design on Garments | – Pre-press for moisture removal and smooth surface – Alignment using registration tools – Even heat/pressure during press – Peel method guidance (hot vs cold) – Post-press care to prevent smudging |

Keywords: printing on tees with DTF |

| Color Control, QC & Troubleshooting | – Calibrate displays and prints; use color profiles – Run test prints for color/bond tests – Check bonding across fabrics; document settings – Common fixes: powder adhesion, ghosting, wash durability |

Keywords: DTF transfer process; direct-to-film guide |

| Maintenance, Safety & Sustainability | – Clean workspace; routine printer/press maintenance – PPE and ventilation as needed – Consider eco-friendly powders/inks to reduce waste |

SEO: DTF printing supplies; DTF heat press techniques |

Summary

HTML table provided above summarizes key points about DTF supplies and techniques, including essential equipment, transfer steps, material selection, garment application, color management, troubleshooting, and safety. A descriptive conclusion follows to reinforce the topic.