DTF Gangsheet Builder Best Practices for Perfect Designs

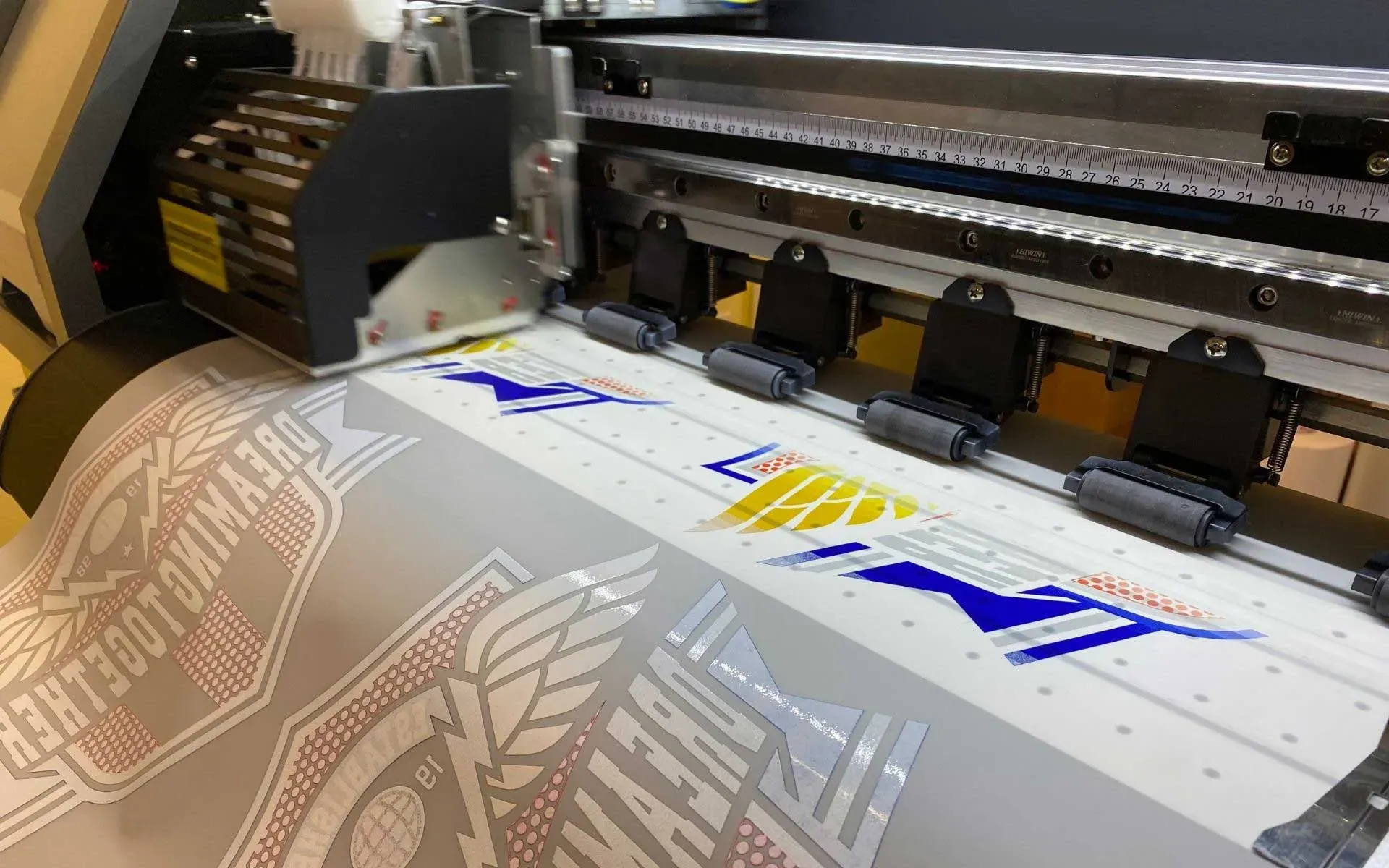

When it comes to the world of textile printing, understanding DTF Gangsheet Builder Best Practices is essential for achieving high-quality results. DTF printing, or direct to film printing, offers vibrant colors and complex designs, making it a favorite among apparel printers. However, success in this field hinges not just on having the right technology but also on mastering gangsheet design techniques. Proper DTF artwork preparation and knowledge of the DTF transfer process can significantly enhance the efficiency and quality of your final products. By focusing on these best practices, you can optimize your workflow and elevate your brand’s presence in the competitive market of textile decoration.

Direct to film methods, or DTF approaches, have changed the landscape of printing, particularly with the use of gangsheet builders for efficient design layouts. By leveraging the art of gangsheet design, printers can print multiple designs simultaneously, maximizing material use and saving costs. To truly excel in DTF artwork preparation, understanding the intricacies of the transfer process is paramount. This comprehensive guide serves to demystify the best practices associated with this innovative printing technology, ensuring that even newcomers can create eye-catching, high-quality prints. Join us as we dive deeper into these essential techniques for a successful printing experience.

Mastering DTF Gangsheet Builder Best Practices

When it comes to maximizing the effectiveness of the DTF gangsheet builder, one must adopt best practices that align with the overall objectives of DTF printing. Start by ensuring that your gangsheet is designed with attention to detail, being mindful of elements like spacing, layout, and artwork positioning. Proper arrangement not only helps in achieving a cohesive look but also conserves materials, making your production process more efficient. A thoughtful gangsheet layout can accommodate various designs, suitable for different apparel, while also ensuring high-quality transfers.

Moreover, familiarize yourself with the specific requirements of your DTF equipment and the materials you are using, such as the heat press and the inks. Using the right settings for temperature and time is crucial; for example, temperatures around 300°F for 10-15 seconds are standard. Likewise, knowing when to employ a hot peel or cool peel technique significantly affects the outcome. These insights can substantially improve the quality and durability of the prints produced from your gangsheet.

The Importance of Artwork Preparation for DTF Printing

Artwork preparation is a fundamental phase that directly influences the outcome of DTF printing. The clarity and quality of design work play an essential role. As mentioned earlier, ensure your images are high resolution, ideally at 300 DPI, and saved in formats such as PNG or TIFF, which help maintain the integrity of color and transparency. This preliminary step is vital as poorly prepared artwork may lead to muddled or distorted prints, resulting in wasted resources and time.

In addition to resolution, selecting the right color profiles cannot be overstated. DTF printing typically benefits from designing in RGB mode for digital displays, while converting to CMYK for printing purposes achieves better color fidelity. Engaging in rigorous artwork preparation can significantly enhance the vibrancy and sharpness of the final printed items, directly impacting customer satisfaction and brand reputation.

Design Layout Tips for Efficient DTF Gangsheet Printing

An efficient design layout is critical when utilizing the DTF gangsheet builder. Start with the concept of gangsheet design, which enables you to print multiple graphics on one sheet, thereby reducing waste and costs. Arrange your designs logically, considering the size and orientation needed for each piece. Overlapping or improper placement can lead to unintended consequences during the transfer process, such as print distortion or misalignment.

The spacing between designs is another crucial aspect; maintaining a minimum of half an inch distance can prevent overlap during heat application. This spacing allows for clean lines in your prints and minimizes the risk of ink bleed. By carefully planning your gangsheet layout, you ensure better control over prints, optimize the production workflow, and significantly improve the output quality.

Choosing Suitable Materials for DTF Printing

Selecting the right materials is vital in ensuring that DTF transfers perform optimally. Start with high-quality DTF films that are specifically designed to enhance adhesion and clarity in prints. The choice of material not only influences the transfer quality but also the durability of the final product. Inferior quality films can lead to peeling or fading, which hampers the look and longevity of the designs.

In addition to film quality, using DTF-compatible inks is essential for vibrant and lasting colors. Unlike regular inks, DTF inks are formulated to bond effectively with textiles during the transfer process, resulting in brighter colors and improved washability. Investing in the right materials contributes to the overall success of your DTF printing operations and ensures that you meet customer expectations regarding design quality and durability.

Optimizing the Transfer Process for DTF Printing

Executing the DTF transfer process meticulously is crucial for achieving successful prints. Pay close attention to the heat press settings as provided by the manufacturers of your films and inks. Common practice suggests a temperature around 300°F for 10-15 seconds, but specific instructions might vary based on the materials you are using. Understanding and adhering to these guidelines will help prevent issues such as incomplete transfers or incorrect adhesion.

Furthermore, knowing whether your design requires a cool or hot peel process can greatly impact the final product’s appearance. Cool peel allows the design to settle before removal, often resulting in a smoother finish, while using a hot peel can enhance brightness but requires careful handling. Mastering these elements of the transfer process is vital for ensuring the aesthetic quality and longevity of printed items.

Post-Production Tips for DTF Printed Garments

Post-production practices are often overlooked, yet they hold immense value in extending the life of your DTF printed garments. Providing detailed washing instructions to customers can improve the durability of the prints. Ideally, recommend washing items inside out in cold water, which protects the design while maintaining appearance and quality over time. By educating customers on proper care, you not only ensure the longevity of the garments but also enhance customer satisfaction, potentially leading to repeat business.

Additionally, conducting durability tests on samples can yield valuable insights into how well your transfers hold up over time. This could involve washing items multiple times to gauge their resistance to fading, peeling, and overall quality retention. Results from such testing provide confidence to both you and your customers about the reliability of your prints, reinforcing your brand’s commitment to quality.

Frequently Asked Questions

What are the key DTF Gangsheet Builder best practices for artwork preparation?

When creating designs for DTF printing using a gangsheet builder, prioritize high-resolution images (300 DPI recommended) and save them in suitable formats like PNG or TIFF. Additionally, ensure color profiles are correctly set—use RGB during design and convert to CMYK for printing to achieve optimal color accuracy.

How can I optimize gangsheet design layouts in DTF printing?

Maximize efficiency when using a DTF gangsheet builder by thoughtfully arranging multiple designs on a single sheet. Maintain appropriate spacing, typically half an inch, between designs to prevent overlaps during the transfer process. This layout consideration not only saves materials but also enhances print quality.

What software tools are best for designing DTF artwork for gangsheet builders?

Use industry-standard software such as Adobe Illustrator or CorelDRAW for creating DTF designs. These programs offer robust features for detailed editing. Alternatively, beginner-friendly online platforms with pre-made templates can simplify the design process for those new to DTF printing.

What materials should I choose for effective DTF printing?

The selection of materials is crucial in DTF printing. Opt for high-quality DTF films specifically treated for optimal adhesion and vibrant colors, and use DTF-specific inks to ensure effective transfers and long-lasting prints.

What temperature and timing settings should I use during the DTF transfer process?

For successful DTF transfers, follow the manufacturer’s guidelines for heat press settings. Generally, set the temperature around 300°F and the time for 10-15 seconds. Always refer to specific product instructions for the best results.

How can I ensure the durability of prints made with a DTF Gangsheet Builder?

To ensure the longevity of DTF prints, provide customers with clear washing instructions, ideally recommending washing inside out in cold water. Conduct durability tests on samples to evaluate how well designs hold up after multiple washes, instilling customer confidence in the quality of your products.

| Key Point | Description |

|---|---|

| Understanding DTF Technology | DTF printing is a method that allows vibrant colors and detailed designs to be transferred onto various materials using heat, optimizing efficiency and reducing costs. |

| Artwork Preparation | This involves ensuring images are high-resolution (300 DPI), saved in suitable formats (PNG, TIFF), and using proper color profiles for accuracy (RGB for digital, CMYK for printing). |

| Design Layout | Using gangsheet builders effectively allows multiple designs on a single sheet, saving materials and optimizing print processes by considering spacing and design orientation. |

| Software and Tools | Utilizing industry-standard software (Adobe Illustrator, CorelDRAW) and online platforms for design can significantly enhance capabilities and streamline workflows. |

| Material Selection | Choosing high-quality DTF films and compatible inks is crucial for adhesion and color vibrancy in the final prints. |

| Transfer Process | Accurate execution during transfer is vital; follow recommended temperature and time settings and understand the differences between cool peel and hot peel methods. |

| Post-Production | Providing customers with washing instructions and conducting durability tests on prints enhances customer satisfaction and trust in the product quality. |

Summary

DTF Gangsheet Builder Best Practices are essential for anyone looking to optimize their design and printing process in textile applications. By focusing on detailed artwork preparation, proper layout, software usage, and material selection, businesses can achieve high-quality prints that stand the test of time. Implementing precise transfer processes and maintaining superior post-production care not only enhances the finished product but also boosts customer satisfaction and brand reputation. Thus, mastering these best practices allows for an effective and efficient DTF printing experience, elevating creative possibilities in the textile design industry.