DTF gangsheet builder: Guide to streamline print runs

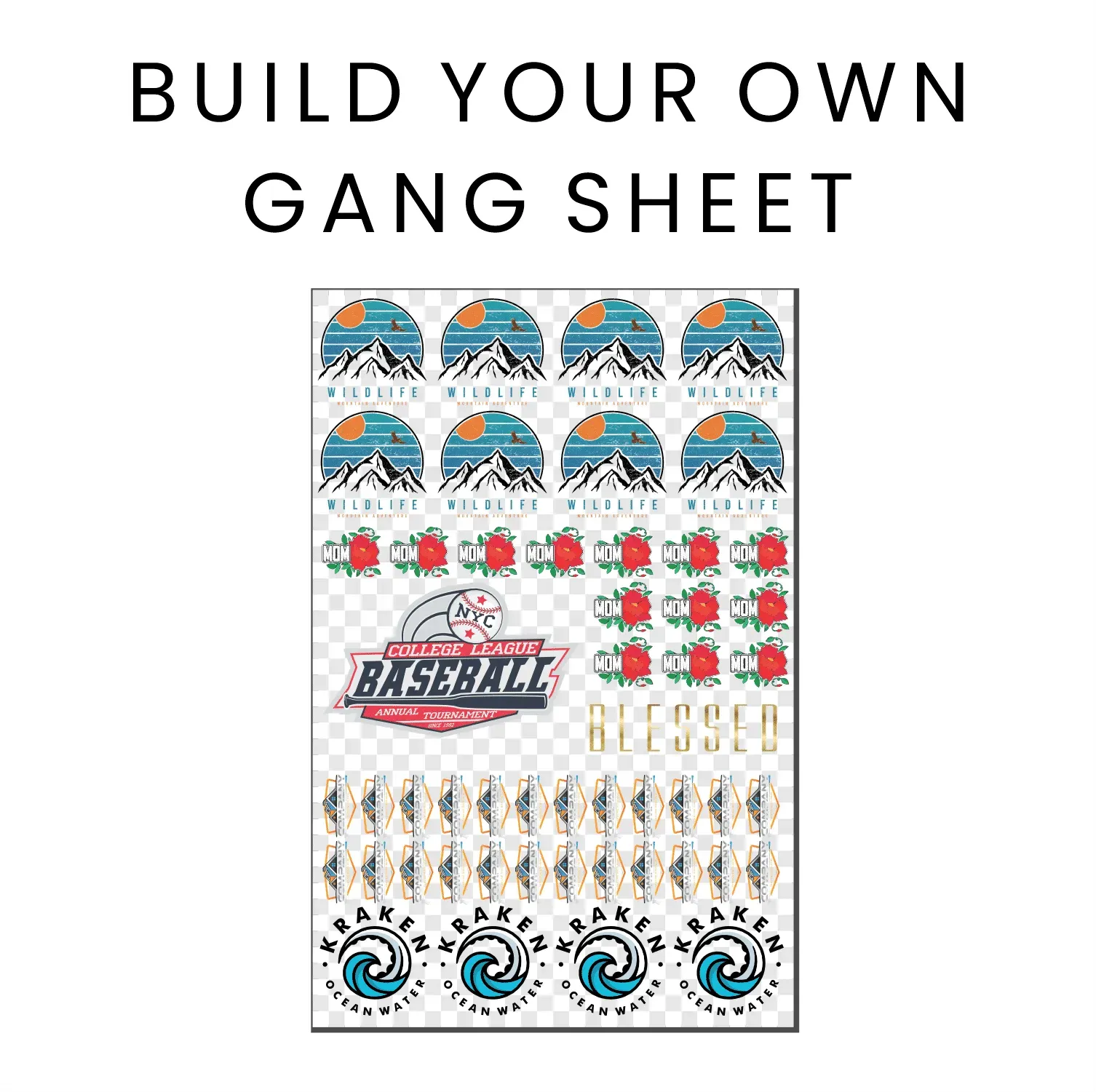

DTF gangsheet builder is transforming how shops approach garment customization by automatically laying out multiple designs on a single transfer sheet. It speeds up the DTF printing workflow by reducing manual pre-press steps and cutting material waste. The tool makes bulk print runs more efficient by stacking designs with precise margins and safe zones. Proper gangsheet design benefits color management and minimizes misalignment, edge artifacts, and reprints. In this guide, we will explore how such tools fit into the broader production workflow and why they matter for scaling up.

Beyond the immediate setup savings, this approach redefines the production pipeline by treating layouts as repeatable templates that travel cleanly from design apps to the printer. By emphasizing precise sheet utilization and consistent color profiles, teams can improve DTF transfer quality across batches while reducing reworks. The concept aligns with broader production goals by tying asset management, ICC settings, and pre-press checks into a single, scalable process. From a design perspective, LSI friendly terms like batch ready templates, automated placement, and color safe previews help organizations communicate value without getting lost in jargon. For shops facing rising demand, such tooling supports bulk orders by reducing setup time, standardizing outputs, and maintaining consistency across shifts. In short, adopting automation for gangsheet layouts can unlock faster turnarounds, better material usage, and predictable results in everyday production.

DTF Gangsheet Builder: Streamlining the DTF Printing Workflow for Bulk Runs

Using a DTF gangsheet builder aligns with the broader DTF printing workflow by automatically arranging multiple designs on one transfer sheet. It optimizes margins, bleeds, and color separations so that every inch of printable area is used efficiently. This not only speeds up setup but also supports consistent DTF transfer quality across a bulk print run, since each design follows the same layout rules and color management approach.

With centralized gangsheet layouts, operators can export print-ready files that feed directly into RIPs and printers, reducing manual adjustments and potential errors. The result is faster turnaround times for bulk print runs, improved material yield, and more predictable transfer quality from sheet to sheet, which helps maintain brand fidelity across all garments.

Gangsheet Design Best Practices for Consistent DTF Transfer Quality in Bulk Print Runs

Gangsheet design best practices focus on compatibility and reliability. When designs share similar color spaces and resolutions, the layout remains stable across the sheet, minimizing color shifts and edge artifacts. Establish safe zones and margins to prevent important elements from being trimmed, and convert text to outlines as needed to avoid font substitutions, all of which contribute to stronger DTF transfer quality during bulk print runs.

Pair gangsheet design with rigorous quality checks: pilot batches, standardized ICC profiles, and organized asset management. By documenting templates and outcomes, you create repeatable workflows that preserve transfer fidelity across batches, reinforcing the overall DTF printing workflow and ensuring consistent results from one production cycle to the next.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it fit into the DTF printing workflow for bulk print runs?

A DTF gangsheet builder is a software tool that automatically arranges multiple designs on one transfer sheet, optimizing margins, bleeds, color separations, and sheet dimensions. In the DTF printing workflow, it speeds up setups, reduces material waste, and improves transfer quality by keeping layouts consistent across designs, making bulk print runs more scalable and reliable.

What features should I look for in a DTF gangsheet builder to maximize gangsheet design and transfer quality for bulk print runs?

Key features include auto-layout optimization, precise margin and safe-zone control, rotation and arrangement options, color management support with ICC profiles, export formats compatible with RIPs, and batch processing. These capabilities ensure efficient gangsheet design, minimize color shifts, and uphold DTF transfer quality across large print runs.

| Topic | Key Points |

|---|---|

| What is a DTF Gangsheet Builder? | Software tool that intelligently lays out multiple designs on one print sheet, accounting for margins, bleeds, color separations, and sheet dimensions. Maximizes printable area while preserving image integrity; enables faster turnaround by reducing downtime between jobs. |

| Why It Matters for Streamlining Print Runs | Faster setup times: Operators don’t manually position each artwork. Lower material waste: Efficient layouts reduce waste. Consistent transfer quality: Precise layouts reduce alignment errors and color drift. Scalable production: Handles larger runs more efficiently. Better color management: Centralized layouts enable consistent ICC/profile use. |

| Key Features to Look For in a DTF Gangsheet Builder | Auto-layout and optimization; Margin/bleed/safe-zone control; Rotation and arrangement options; Color management support; Export formats (PNG/TIFF/PDF); Batch processing and queue management; Integration with design apps and asset management. |

| How to Use a DTF Gangsheet Builder: Step-by-Step | 1) Gather designs (print-ready: resolution, RGB, size). 2) Set sheet dimensions to match printer/film. 3) Define margins, bleeds, and safe zones. 4) Import/arrange designs (auto placement + manual tweaks). 5) Preview and adjust for conflicts. 6) Apply color profiles. 7) Export print-ready files (PNG/TIFF/PDF) with registration marks. 8) Print and press with standard pre-press checks. |

| Best Practices for Gangsheet Design | Design compatibility (similar color spaces/resolution); Safe zones and margins; Font/vector considerations (outlines where needed); Color management harmony; Layout efficiency; Labeling/metadata. |

| Optimizing the DTF Printing Workflow with a Gangsheet Builder | Centralized control of sheet utilization; Standardized pre-press checks; Consistent transfer results via repeatable layouts/color settings; Faster onboarding with templates; Easier file management. |

| Common Pitfalls and How to Avoid Them | Misalignment/registration errors: calibrate presses and test sheets. Color bleed/edge artifacts: tighten margins; test prints. Inconsistent results across batches: standardized color profiles; consistent substrates. File size/performance: optimize resolution; avoid oversized exports. Poor naming conventions: implement a consistent naming scheme. |

| Case Study: A Small Brand’s Experience | Shifted from manual layout to a gangsheet builder; reduced pre-press time by ~40-50%. Batch of 24-32 designs on a single sheet; scalable for larger batches while maintaining quality. |

| Tips for Getting Started Today | Start with templates for common sizes/colors; Validate with a pilot batch; Maintain clean assets with versioning; Monitor transfer quality and adjust color settings; Document processes and templates for repeatability. |