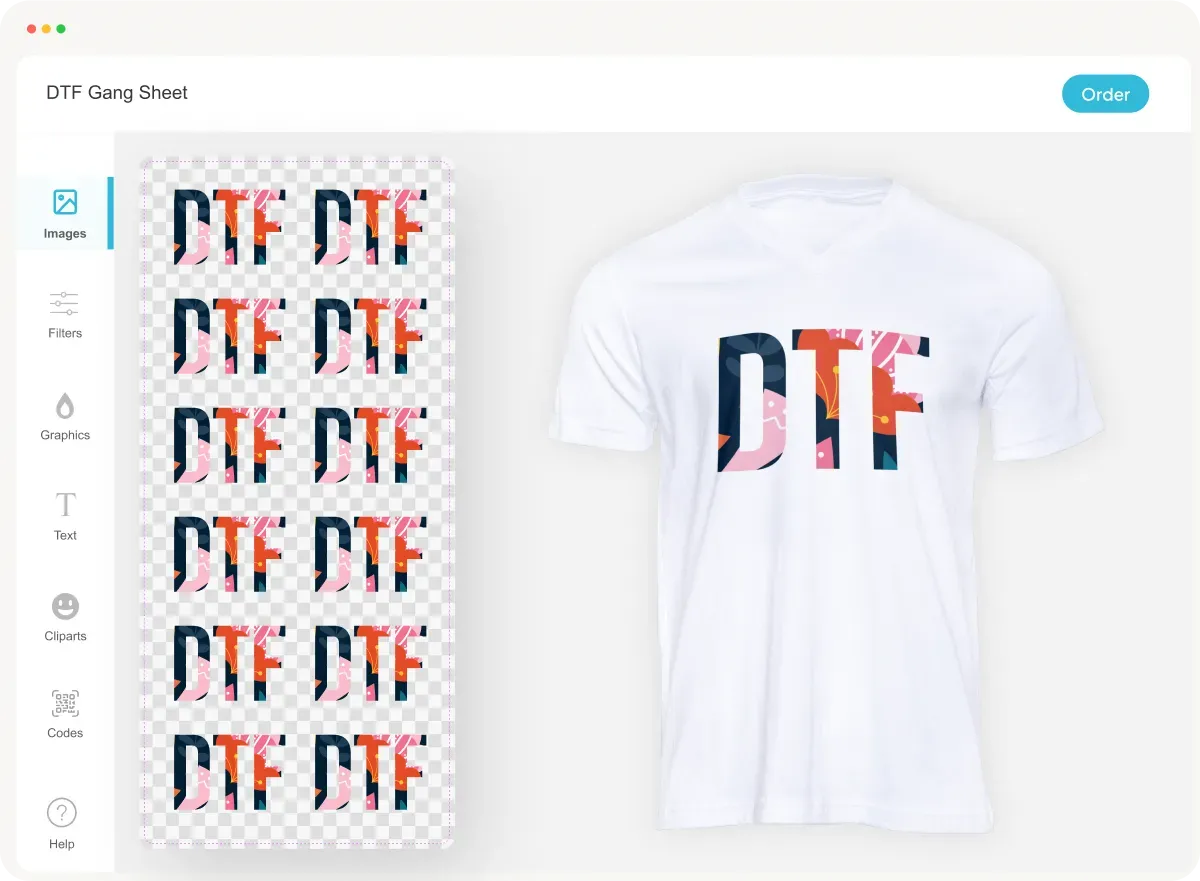

DTF Gangsheet Builder: Master the Step-by-Step Process

The DTF Gangsheet Builder is a groundbreaking tool that is transforming the world of direct-to-film (DTF) printing and textile transfers. This innovative software enables users to efficiently create multi-design gang sheets, allowing for maximum utilization of materials and reduced waste. With the DTF Gangsheet Builder, you can produce striking prints that adhere seamlessly to various fabrics using heat press printing techniques. By mastering the functionalities of this powerful builder, you’ll harness the full potential of DTF printing, leading to vibrant colors and intricate designs. Dive into our comprehensive guide to unlock the secrets of successful gangsheet layout and adhesive powder application, ensuring your textile creations stand out from the rest.

Introducing the DTF Gangsheet Builder, an essential tool for anyone involved in digital textile printing. This sophisticated design software streamlines the creation of gang sheets—layouts that efficiently combine multiple designs on a single print area. As the demand for high-quality textile transfers continues to rise, mastering this tool can significantly enhance your printing outcomes, especially when paired with techniques like heat press printing. Embracing the fundamentals of DTF printing alongside a well-structured gangsheet layout allows for less material waste and improved print quality. Whether you’re new to the world of printing or looking to refine your skills, the DTF Gangsheet Builder is your gateway to an exciting and creative printing experience.

The Importance of DTF Printing in Textile Design

DTF printing is quickly becoming a favorite among textile designers due to its ability to produce intricate designs with vibrant colors. This innovative method goes beyond traditional printing techniques by directly transferring high-quality images from film to fabric. It allows for detailed graphics that can withstand washing and wear, making DTF printing an ideal choice for custom apparel and promotional items. Moreover, the orange peel texture that DTF methods can create enhances the tactile experience of the fabric, adding further value.

Additionally, DTF printing is versatile; it can be applied to a wide range of materials, from cotton and polyester to blends. This adaptability broadens the scope of products designers can offer. With the rise of e-commerce and personalized products, the demand for reliable and high-quality printing processes has never been greater. DTF printing meets this need perfectly, combining creativity with effective production methods.

Mastering the DTF Gangsheet Builder for Efficiency

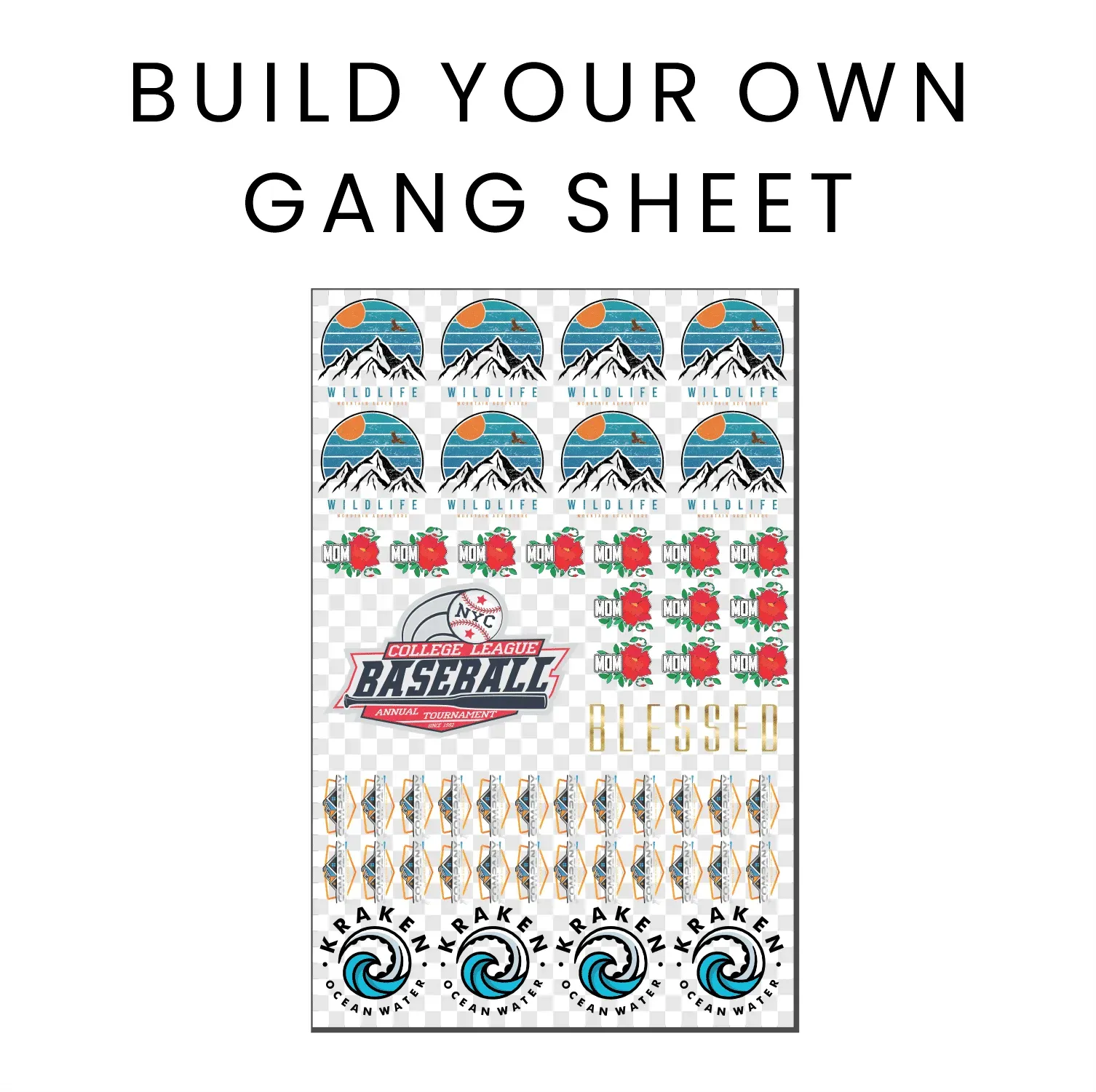

At the core of effective DTF printing is the DTF Gangsheet Builder, a tool designed to optimize the layout of designs on a single sheet. By learning to strategically place multiple designs on one gang sheet, you can minimize waste and improve your production efficiency. This not only saves material and costs but also enhances your ability to produce larger orders swiftly, which is crucial in today’s fast-paced market. An intelligently arranged gang sheet can significantly cut down print time and resources.

Using the DTF Gangsheet Builder effectively requires understanding spacing, alignment, and design flow. Designers should aim for an aesthetically pleasing layout that also maximizes the usage of each square inch of film. With practice, you can create gang sheets that balance function and artistry, ensuring high-quality outputs without excess waste. This skill set is invaluable for any business looking to streamline their printing operations and increase profitability.

Steps to Create a Successful Gangsheet Layout

Creating a gangsheet layout begins with the design phase, which should be approached with care. Start by preparing your designs in graphic design software, ensuring they meet the required resolution and color profiles. Pay particular attention to CMYK settings, as this will affect the final color appearance on fabric. Once your designs are ready, the layout process involves arranging each design thoughtfully on the gangsheet, ensuring adequate spacing between them to prevent any overlaps during the heat transfer.

As you layout your gangsheet, it’s essential to think about the types of fabrics your designs will be printed on. Different materials can absorb ink and adhesive powder differently, so choosing how to position designs can impact the final look and durability of the transfer. Aim to achieve a layout that not only maximizes material usage but also provides aesthetic appeal, making your final product attractive to customers.

Printing Best Practices with DTF Techniques

The printing process in DTF technology requires precision to ensure the best outcomes. It begins by loading your gangsheet onto a DTF printer that is specifically calibrated for this method. Check the media and color settings to match the materials you’re using—a poorly set printer can result in dull colors or inaccurate prints. Furthermore, using high-quality DTF inks formulated for adhesion and flexibility can dramatically enhance the final product quality.

Once printed, it’s vital to immediately apply the adhesive powder while the ink is still wet. This step is crucial, as it fortifies the bond between the fabric and the print once heat applied. After sprinkling the adhesive, make sure to shake off any excess gently, as clumps can lead to subpar transfers. Following this, curing the printed gang sheet under the proper conditions will ensure that the ink sets thoroughly, making the transfer process more effective.

Troubleshooting Common DTF Printing Challenges

Despite the best preparation, challenges in DTF printing can arise. One common issue is poor adhesion of the print to the fabric after transfer. Often, this is a result of insufficient curing time or improper heat settings during the press. Make sure to re-evaluate your equipment settings and ensure that you are heating your press to the recommended temperature and timing specific for the type of material used.

Additionally, color discrepancies are another frequent problem that can frustrate many printers. Always double-check that your designs are correctly formatted in CMYK before sending them to print. A simple oversight in color mode can turn vibrant designs into muted representations, disappointing both the printer and the end customer. Further, ensuring that your ink is dry before handling can prevent smudging issues, leading to cleaner transfers.

Enhancing Skills through Community Engagement

Becoming adept at using DTF printing techniques and the Gangsheet Builder requires not just practice but also a continual effort to learn from others in the industry. Engaging with communities focused on textile printing can provide valuable insights, tips, and updates on the latest trends and technologies. Various forums and social media groups are excellent platforms for sharing experiences, asking questions, and receiving guidance from seasoned professionals.

Additionally, participating in workshops or webinars can significantly enhance your skills. Many industry leaders offer training sessions that focus on advanced techniques and troubleshooting common issues within the DTF process. By staying connected with a network of professionals, you can streamline your learning curve, adopt new practices more efficiently, and ultimately enhance your ability to create impressive textile transfers.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool designed for Direct-to-Film (DTF) printing that helps users create a gang sheet layout. This allows for multiple designs to be printed on a single sheet, optimizing material usage and efficiency during the textile transfer process. By arranging designs carefully, users can reduce waste and improve production efficiency.

How do I create a gangsheet layout using the DTF Gangsheet Builder?

To create a gangsheet layout with the DTF Gangsheet Builder, start by designing your images using graphic design software while ensuring they are formatted for high-quality output. Arrange multiple designs on one sheet with proper spacing to prevent overlaps and maximize the use of the printable area. Effective layout design is crucial for achieving efficient textile transfers.

What types of designs can I print with the DTF Gangsheet Builder?

The DTF Gangsheet Builder can accommodate a wide range of designs, including intricate graphics and vibrant colors, thanks to the capabilities of DTF printing. This method is particularly well-suited for detailed textile transfers, allowing printers to achieve high-quality results on various fabrics. Custom designs can be created for garments, accessories, and promotional items.

Why is adhesive powder important in DTF printing with the Gangsheet Builder?

Adhesive powder is essential in the DTF printing process as it ensures that the printed ink properly bonds to the fabric during the transfer. After printing your gang sheet, applying adhesive powder immediately to the wet ink enhances adhesion and durability of the textile transfer. Proper application and curing of the powder play a crucial role in achieving high-quality prints.

What are some common troubleshooting tips for using the DTF Gangsheet Builder?

Common issues when using the DTF Gangsheet Builder include poor adhesion, color discrepancies, and ink smudging. To troubleshoot these issues, ensure that you cure the designs adequately and maintain correct temperature settings on your heat press. Always verify your designs are in CMYK mode before printing to avoid color mismatches, and allow prints to dry fully before applying adhesive powder.

How can I improve my skills with the DTF Gangsheet Builder?

Improving skills with the DTF Gangsheet Builder involves regular practice and experimentation. Test different materials, inks, and adhesive powders to discover optimal combinations for your projects. Additionally, engage with online communities focused on DTF printing for insights and best practices, and maintain your equipment for consistent quality outputs.

| Key Steps | Details |

|---|---|

| 1. Design Creation | Create designs using graphic software in CMYK mode for quality. |

| 2. Gangsheet Layout | Arrange designs to minimize waste and ensure adequate spacing. |

| 3. Printing | Use a DTF printer with proper settings and inks for quality prints. |

| 4. Applying Adhesive Powder | Sprinkle adhesive on wet ink to enhance bonding during transfer. |

| 5. Curing | Cure prints using heat or UV methods to set inks properly. |

| 6. Cutting and Transferring | Cut designs from the gang sheet and apply with a heat press. |

Summary

DTF Gangsheet Builder is a crucial tool for anyone looking to excel in DTF printing. This advanced platform allows you to maximize material efficiency while producing vibrant and high-quality prints. By mastering the step-by-step process outlined in this guide, you’ll be able to create detailed designs that effectively utilize your resources. Engaging with the DTF community can further enhance your skills and keep you informed on best practices in this exciting field. Embrace the full potential of the DTF Gangsheet Builder and let your creativity flow!