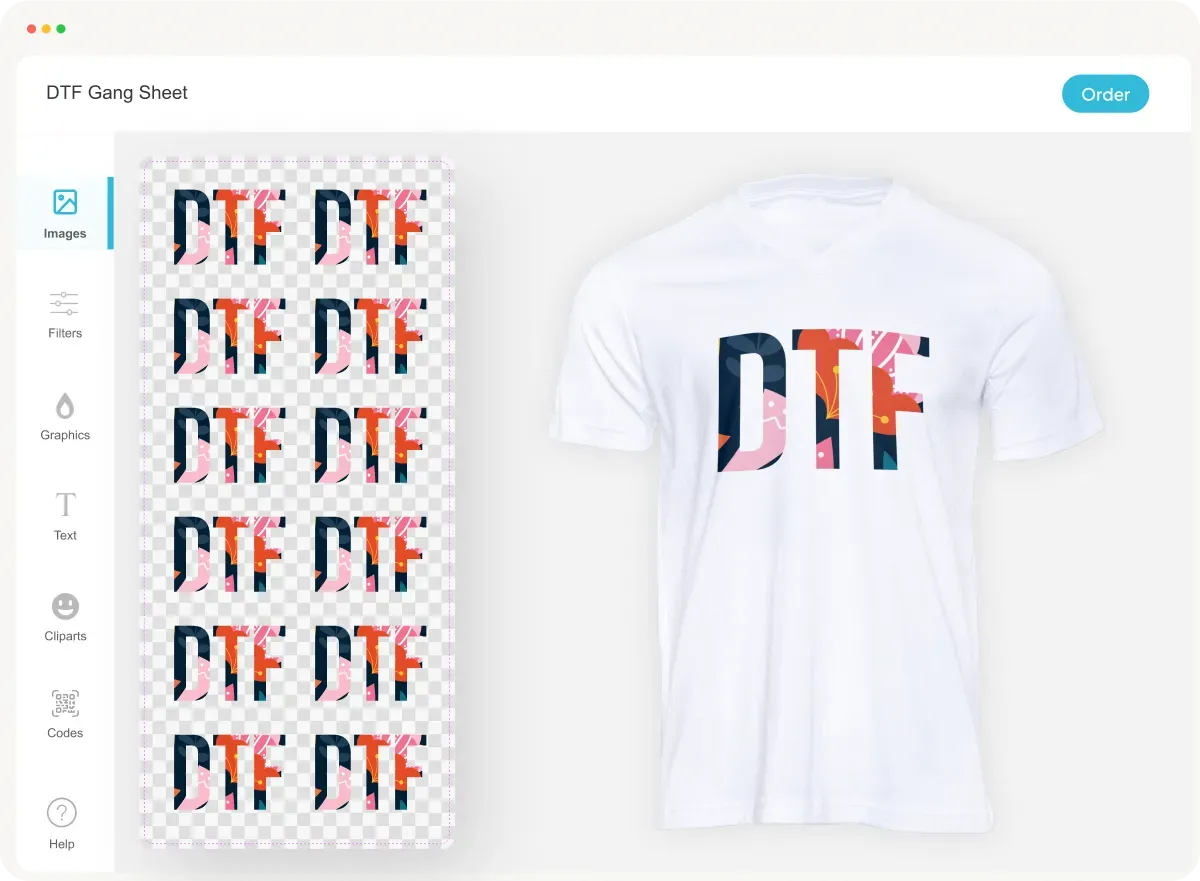

DTF gangsheet builder: Practical bulk textile printing guide

The DTF gangsheet builder is redefining how studios scale garment decoration with speed, consistency, and controlled costs. By planning multiple designs on one sheet, this approach supports bulk textile printing and lowers setup time. A well-designed gangsheet for DTF integrates layout, color management, and transfer readiness, aligning with the DTF printing workflow. A key part of the strategy is gangsheet design for DTF, ensuring consistent margins, spacing, and print alignment. If you’re scaling production, adopting a DTF gangsheet builder can become a cornerstone of cost-saving textile production and faster delivery.

Viewed through the lens of LSI, this sheet-layout system acts as a multi-design planner that groups related graphics on a single media sheet. Instead of treating each design separately, operators optimize color workflows, improve registration, and speed up the transfer process across multiple garments. Think of it as a batch-optimized textile workflow that reduces machine idle time and concentrates effort on repeatable, scalable production. By framing the concept as a sheet-level orchestration tool for garment decoration, teams can align procurement, curing, and quality checks more effectively.

DTF gangsheet builder: Scaling Bulk Textile Printing with a Unified Workflow

A DTF gangsheet builder consolidates multiple designs onto a single sheet, turning a handful of designs into a high-volume production run. By packing several images onto one gangsheet, you minimize printer idle time, streamline file handling, and accelerate the transfer process. This approach is especially powerful in bulk textile printing, where consistency and speed are critical, and it leverages a clear plan for artwork ingestion, layout, and color management to keep output on spec.

With a DTF gangsheet builder, the workflow becomes a repeatable system rather than a series of one-off jobs. The single gangsheet run reduces setup changes, shaves minutes from each batch, and lowers material waste, all of which contribute to a cost-saving textile production model. In practice, you gain predictable throughput, traceable results, and the ability to scale from small orders to catalogs or seasonal collections without sacrificing quality.

Gangsheet Design for DTF: Fundamentals, Alignment, and Quality Control

Designing a gangsheet for DTF is both an art and a science. Careful layout choices—consistent margins, safe zones, and deliberate placement—help ensure each design transfers cleanly without misregistration. Grouping related designs, staggering orientation, and aligning designs to the sheet width all support smoother transfer and tighter color control across multiple prints on a single gangsheet.

A well-executed gangsheet design for DTF hinges on robust color management and process discipline. Standardized color profiles, verified proofs, and a documented workflow from artwork ingest to final garment help maintain visual consistency across the batch. This attention to layout and color fidelity translates into fewer reprints, less waste, and a smoother DTF printing workflow that scales with demand while maintaining quality.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it boost efficiency in bulk textile printing?

A DTF gangsheet builder is software plus a defined workflow that lets you arrange many designs on one gangsheet before printing. Instead of sending each design separately, you print the entire gangsheet, then separate the transfers. This approach boosts bulk textile printing efficiency by increasing printer utilization, reducing downtime and setup changes, and minimizing material waste. It also improves color control and consistency across designs on the same sheet, supporting cost-saving textile production. In practice, the builder covers both the design planning stage (gangsheet design for DTF) and the execution stage (printing and transferring efficiently) to speed throughput and scale operations.

What are the essential steps in the DTF printing workflow when using a gangsheet design for DTF?

Key steps in the DTF printing workflow when using a gangsheet design for DTF: 1) Consolidate designs and assets; 2) Create the gangsheet layout with safe zones and margins; 3) Build a print-ready file with correct color space; 4) Print the gangsheet and verify color accuracy with a test strip; 5) Apply and cure adhesive powder; 6) Transfer to fabric with proper dwell time and even heat distribution; 7) Post-process and quality-check; 8) Maintain color management and batch traceability. Following these steps helps minimize waste and downtime, delivering cost-saving textile production at scale in bulk textile printing.

| Topic | Key Points |

|---|---|

| Introduction | DTF tech enables scalable garment printing; a DTF gangsheet builder enables laying out multiple designs on a single gangsheet, boosting throughput, reducing downtime, and cutting waste; essential for scaling bulk textile projects. |

| What is a DTF Gangsheet Builder? | Software + workflow to arrange many designs on one sheet; print together; separate after transfer; increases throughput, reduces downtime, and lowers waste; used for both planning (designing) and execution (printing and transferring). |

| Why GangSheets Matter in Bulk Textile Printing | Maximizes printer utilization; reduces re-calibration and color changes; improves color control across designs on the same sheet; minimizes substrate waste; serves as a scaling blueprint for catalogs, event merchandising lines, or seasonal collections. |

| Gangsheet Design for DTF: The Essentials | Margins/safe zones; optimum placement; color management; size and cadence; reduces post-processing and speeds the transfer phase; improves overall accuracy and efficiency. |

| Choosing Tools and Setting Up Your DTF Printing Workflow | Components: layout software, color management tools, heat-transfer printers, and transfer films. Setup steps: design consolidation, color consistency, print queue management, and transfer management. Goal: repeatability and traceability from artwork ingest to final garment. |

| Step-by-Step: Building and Printing a DTF Gangsheet | 1) Gather designs and asset specs. 2) Create the gangsheet layout with margins and alignment marks. 3) Build a print-ready file with correct color space and embedded assets. 4) Print the gangsheet and verify color accuracy. 5) Apply and cure with adhesive powder. 6) Transfer to fabric with proper dwell time and heat. 7) Perform post-processing and quality checks. |

| Quality Control and Color Management | Standardized color profiles; regular calibration (bed alignment, nozzle checks); proofs/soft-proofs before full runs; batch traceability of lots and curing times to diagnose color drift quickly. |

| Materials, Hardware, and Cost Considerations | Film quality, adhesive powders, curing parameters, and substrate compatibility affect outcomes and cost. Consider higher-gauge films, uniform powders, and documented settings. Bulk runs reduce waste, labor, and improve yield per sheet, lowering unit costs. |

| Common Pitfalls and Troubleshooting | Misregistration, color mismatch, uneven transfer, wasted materials, workflow drift. Fixes: re-check alignment margins, verify color profiles, calibrate equipment, test prints, and maintain procedure logs and staff training. |

| Best Practices for Scalable Production | Maintain a design library; establish a repeatable SOP; monitor throughput and yield; invest in automation where feasible (semi-automatic transfer setups, batch curing racks); plan growth with gangsheet templates for common collections. |

Summary

DTF gangsheet builder is a foundational approach to modern bulk textile printing. By designing efficient gang sheets, managing color with consistent workflows, and aligning materials and equipment with production goals, you unlock higher throughput, better quality, and lower costs. For businesses looking to scale, adopting a DTF gangsheet builder helps manage catalogs, seasonal lines, and large orders with repeatable quality. Implement these practices—design library creation, standardized SOPs, robust color management, and workflow automation—to position your operation for competitive growth in a fast-moving market.