DTF Gangsheet Builder: Pricing, Pros, Cons, Best Practices

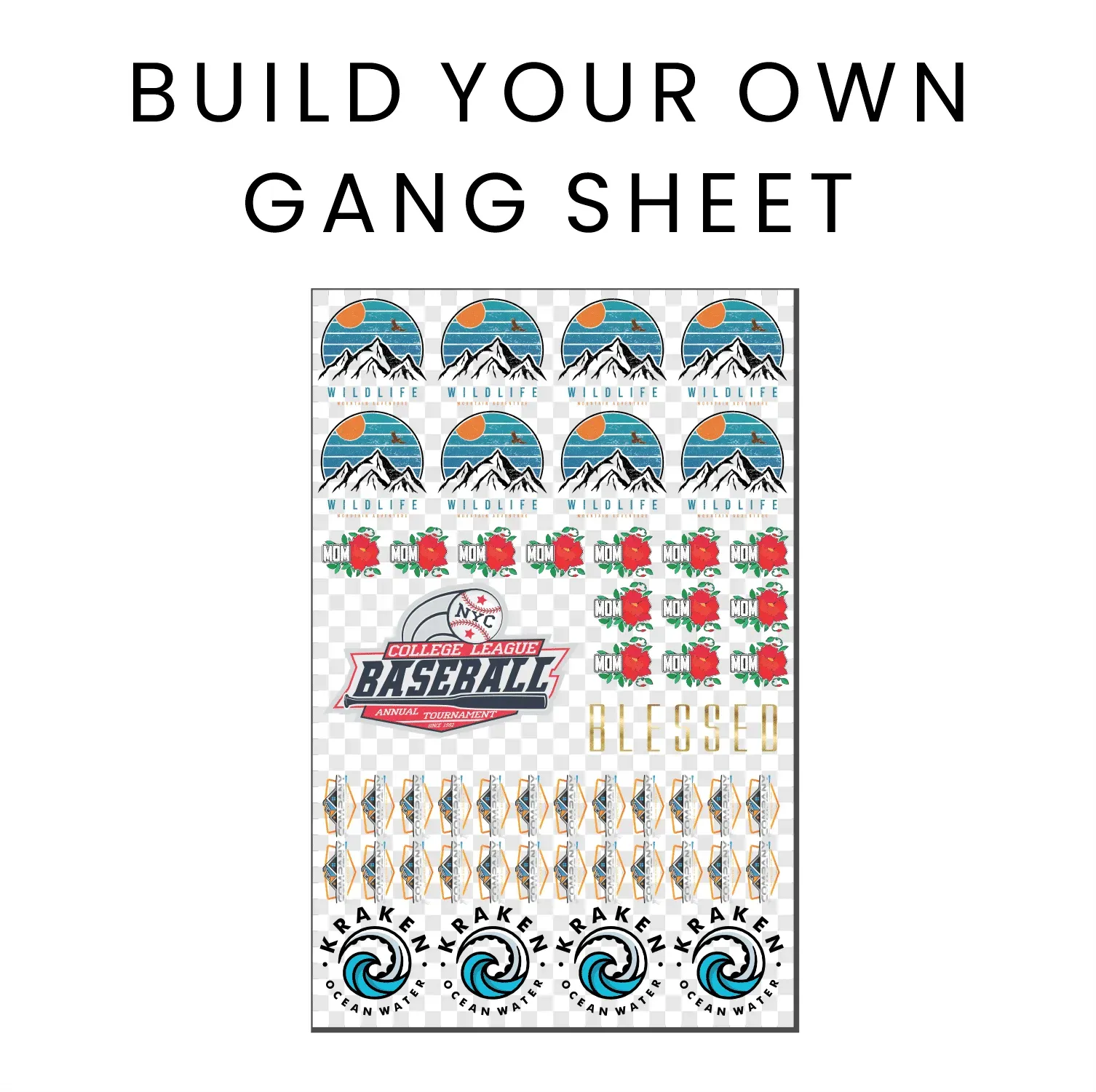

DTF Gangsheet Builder is the headline solution for optimizing multi-design spreads in direct-to-fabric printing, helping shops maximize fabric usage, reduce setup time, and bring order to complex orders. In the fast-paced world of DTF printing, this tool automates layout decisions, streamlines color management, and speeds up the DTF workflow from design to production, supporting both small studios and larger operations. By coordinating multiple designs into multi-design sheets on a single bed, it reduces waste, minimizes misprints, and creates a repeatable process that scales with order volume for teams of all sizes and skill levels. With features like grid-based placement, bleed and margin controls, and batch export options, users can translate a gallery of artwork into production-ready gang sheets, improving predictability and efficiency. As you compare options, understanding gangsheet pricing, return on investment, and best practices for implementation helps explain how this tooling can scale your DTF business while maintaining quality.

Viewed through an alternative lens, this tool acts as a sheet-layout optimizer for direct-to-fabric projects, organizing artwork into efficient print sets rather than a jury-rigged collage. Other terms you might encounter include gang-sheet planning software, print-bed layout engine, and batch-export workflows—each geared toward maximizing fabric usage and ensuring consistent results. Practical DTF transfer tips emphasize color budgeting, reliable ICC profiles, and proofing steps to minimize repeats and misregistration. By presenting the same concept with these related terms, you improve search visibility while guiding readers through the core idea of a production-ready sheet system.

DTF Gangsheet Builder: Optimizing Multi-Design Sheets for a Lean DTF Workflow

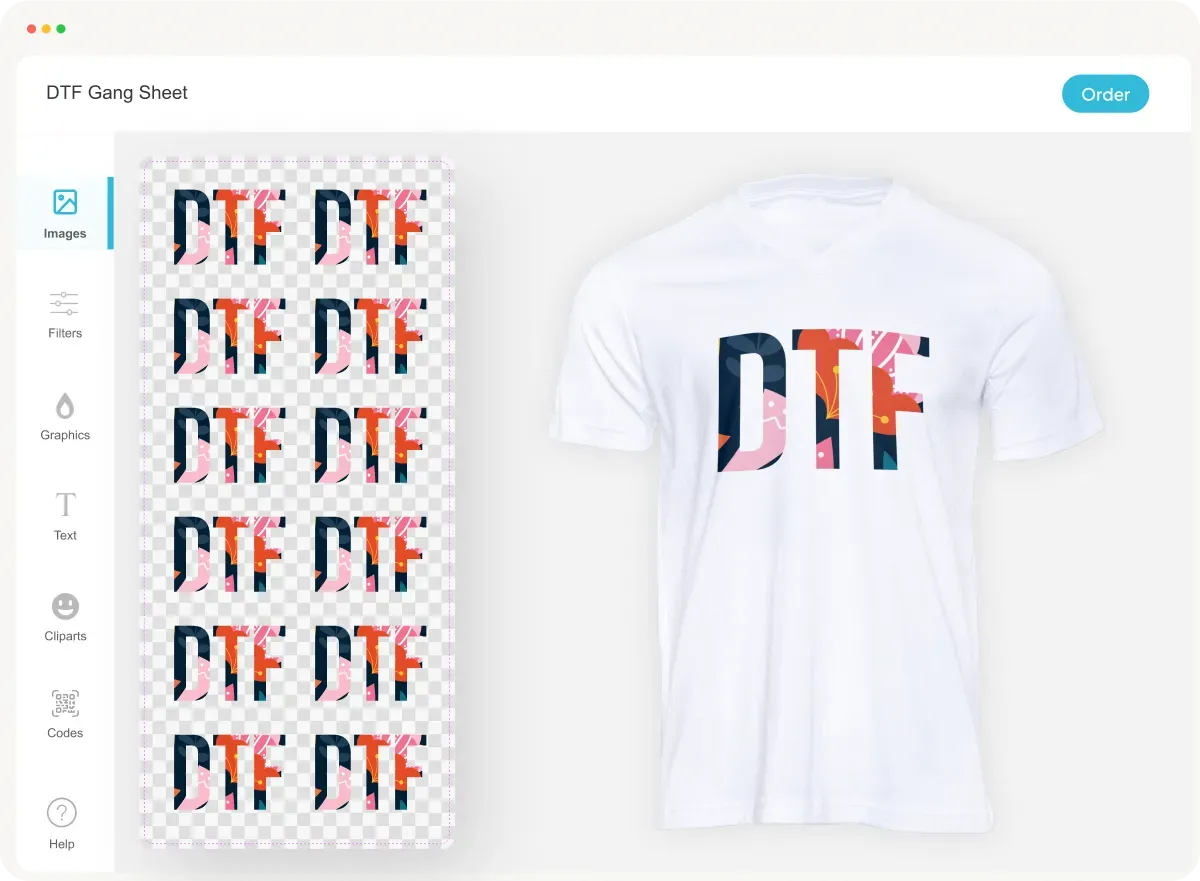

The DTF Gangsheet Builder is designed to orchestrate the layout of multiple designs on a single print sheet, turning a potentially chaotic batch into a repeatable workflow. By automating placement decisions, it helps maximize fabric usage per run, reduce misprints, and standardize how artwork transfers to garments across sizes. With export-ready files and built‑in color management, shops can streamline the DTF printing process and scale operations from small studios to larger print shops.

Key features include grid-based layout, automatic placement, bleed and margin controls, batch export options, and compatibility with common RIP software. In practice, these capabilities simplify the handoff from design to production, enabling designers and operators to produce consistent outputs across multiple garments and sizes. This supports a data-driven DTF workflow and can positively impact ROI by cutting setup time and material waste.

DTF Printing Efficiency: Pricing, Workflow, and Tips for Multi-Design Sheets

Understanding gangsheet pricing helps forecast ROI and informs long‑term planning. Pricing models vary from free tiers and monthly subscriptions to per-sheet charges and enterprise options. Evaluating these against anticipated production volumes—especially for multi-design sheets—helps shops estimate total cost of ownership and the payback from faster layouts, reduced waste, and fewer misprints. A well-chosen DTF gangsheet tool can lower cost per print and improve margins as design variety expands.

To maximize value, adopt best practices such as standardized templates, early color management, and a workflow that integrates smoothly with your RIP and printer. Use batch exports and proofs to validate color accuracy and layout before committing to a full run, and apply DTF transfer tips like testing color fidelity on sample fabrics, checking registration, and monitoring ink usage. Prioritize optimizing multi-design sheets to minimize tool changes and handling, while maintaining revision control so you can re-run proven layouts without starting from scratch.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it support the DTF workflow for multi-design sheets?

A DTF Gangsheet Builder is software (desktop or cloud) that lets you design, arrange, and optimize multi-design sheets for DTF printing. It automates layout decisions, color management, and export of print-ready files, improving the DTF workflow. By packing multiple designs onto a single sheet, it enables multi-design sheets, minimizes material waste, and speeds up production consistency across runs. This tool scales from small studios to larger shops and helps you maximize fabric usage and output quality.

How should I evaluate gangsheet pricing when choosing a DTF Gangsheet Builder for my shop?

Gangsheet pricing varies by vendor, with free or entry tiers, monthly subscriptions, per-sheet or usage-based fees, and enterprise options. Consider total cost of ownership and ROI: savings from reduced layout time, less waste, and faster production can offset ongoing costs. Look for templates, robust color management, and strong integration with your RIP and printer as part of the value. Also follow practical guidance like DTF transfer tips—test proofs, ensure proper curing, and maintain alignment—to protect print quality while scaling.

| Topic | Key Points |

|---|---|

| What is a DTF Gangsheet Builder? | Software (often desktop or cloud-based) that designs, arranges, and optimizes multi-design sheets for direct-to-fabric printing; aims to maximize fabric usage, minimize misprints, and streamline handoffs; features include grid-based layout, automatic placement, bleed and margin controls, color management helpers, batch export options, and RIP compatibility. |

| Pricing and ROI | Pricing models vary considerably: free/entry-level tiers; monthly subscriptions; per-sheet or usage-based pricing; and enterprise or on-prem options. ROI comes from reduced layout time, less waste (fabric and ink), fewer misprints, and faster design-to-production cycles. |

| Pros | Faster layout and planning; better material efficiency; improved consistency; simplified file management; collaboration and multi-user access; data-driven decision making. |

| Cons and Trade-offs | Learning curve; upfront or ongoing costs; limitations in design complexity; dependency on the tool’s roadmap; potential file size and performance issues. |

| Best Practices | 1) Start with standardized templates; 2) Define color management early; 3) Plan layout for production reality; 4) Optimize for multi-design sheets; 5) Validate with proofs; 6) Manage fonts and artwork; 7) Use batch exports and presets; 8) Integrate with your DTF workflow; 9) Plan for revision control; 10) Back up assets. |

| Choosing the Right Builder | Printer and RIP compatibility; design capacity; collaboration features; export options; color and ink management; ease of use and support; cost of ownership. |

| Use Cases | Small design studios offering on-demand apparel; print-on-demand shops with varied designs; event merch and custom batches. |

| Step-by-Step Getting Started | 1) Gather designs and assets; 2) Define product templates; 3) Set up a layout strategy; 4) Import designs and auto-place; 5) Verify color and print parameters; 6) Export print-ready files; 7) Run a proof print; 8) Launch production; 9) Review and iterate. |

| Common Pitfalls and Troubleshooting | Mismatched color expectations; overcrowded sheets; large file bloat; inconsistent bleed and margins; disconnected workflows. |

Summary

DTF Gangsheet Builder is a powerful tool for optimizing multi-design runs in modern DTF printing. It helps maximize fabric usage, minimize waste, and streamline the handoff from design to production. By choosing the right tool, applying best practices, and monitoring layout efficiency and production metrics, shops can reduce setup time, improve color consistency, and scale effectively. When evaluating options, consider pricing models, supported workflows, and the tool’s ability to integrate with your RIP, printer, and heat-press processes. With careful implementation, a DTF Gangsheet Builder enables faster turnarounds, better batch consistency, and a more predictable production pipeline, supporting growth and profitability for teams of any size.