DTF gangsheet builder: Step-by-Step Setup for Best Results

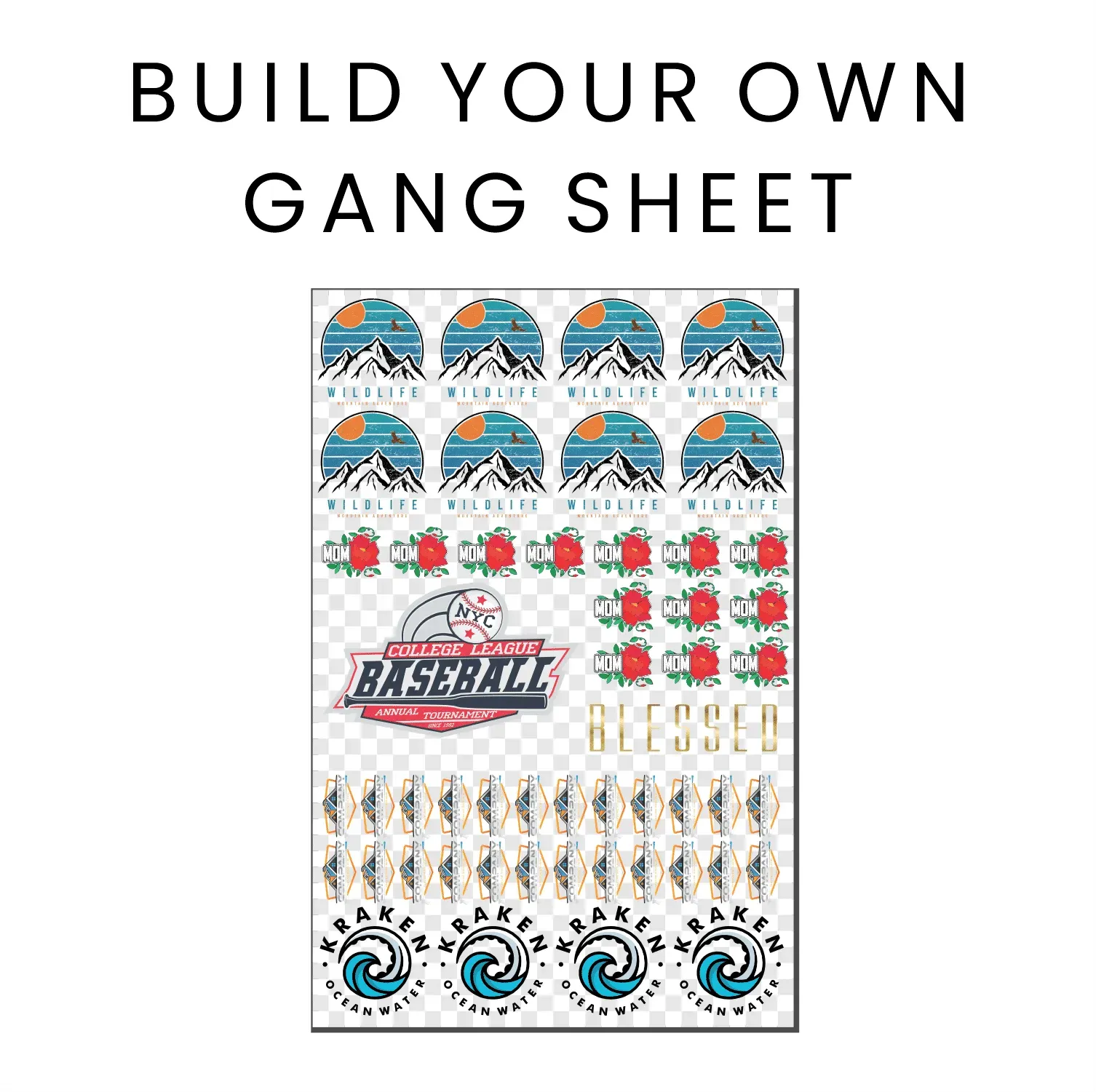

If you are stepping into apparel customization, the DTF gangsheet builder should be on your radar for efficiently coordinating multiple designs on a single transfer. This tool helps maximize production, reduce waste, and speed up your workflow by organizing layouts, spacing, and color management across a multi-design sheet. In this guide, you’ll follow a clear, step-by-step approach for consistent color, accurate placement, and production-ready output. From planning assets to final proofs, adhering to curated best practices keeps designs tidy, reduces misprints, and supports smoother batching across runs. As you work, you can lean on the DTF gangsheet setup tutorial and the how to create gang sheets for DTF guidance to refine your process.

Think of this as a direct-to-film sheet planning tool, or a layout automation solution that groups multiple designs into one transfer for efficient production. From an LSI perspective, it can be described as transfer sheet optimization and print workflow enhancement, with attention to margins, bleed, and color management to ensure consistency. To keep the concept accessible, use terms like dtf gangsheet builder steps and DTF printing best practices so readers and search engines connect related topics naturally.

DTF Gangsheet Builder: Setup, Planning, and Layout for Efficient Printing

When you’re ready to scale your apparel customization, the DTF gangsheet builder becomes a critical tool. It helps you place multiple designs on a single transfer, maximize sheet usage, and streamline the workflow from planning assets to final output. By focusing on sheet size, margins, bleed, and grid alignment, you can drive consistency across designs and reduce waste, all while keeping colors accurate as part of the DTF printing best practices.

Start with a clear plan for your gangsheet: decide how many designs will fit in a sheet, establish standard margins, and set bleed to ensure clean edges after trimming. This phase is foundational to a successful DTF gangsheet setup and translates directly into fewer misprints and tighter color fidelity across all designs, aligning with the dtf gangsheet builder steps you’ll follow in practice.

DTF Gangsheet Builder: Prepare Artwork, Grid Layout, and Production Readiness

With assets ready, the next focus is artwork preparation and color management. Export high-resolution files (vector or 300–600 DPI raster), embed fonts, and convert colors to the appropriate CMYK color space with a defined ICC profile. A well-prepared asset set reduces last-minute edits and helps maintain color integrity across all designs on the gangsheet, which is a core aspect of DTF printing best practices.

Create your gang sheets by configuring the sheet size, bleed, and grid in the builder. A typical setup might be a 12×16 inch sheet with 0.125 inch bleed, accommodating 4–6 designs depending on their size. Use consistent alignment references and smart spacing to account for printer wobble and heat transfer margins. This step hosts the practical core of the dtf gangsheet builder steps and directly informs your ability to execute the how to create gang sheets for DTF workflow.

DTF Gangsheet Builder in Practice: Test, Optimize, and Scale Production

Once you have a draft gangsheet, print a test run on scrap fabric to evaluate color accuracy, spacing, and alignment. The test phase is essential for identifying issues such as color shifts, ghosting, or edge bleed before committing to a full production run. By documenting results and adjusting color management or print settings, you’ll move closer to the DTF transfer sheet optimization you want in real-world production.

Fine-tuning after testing is where real improvements happen. Use the data to tweak exposure, ink density, and adhesive settings for precise transfers, then formalize these adjustments into SOPs. Regular maintenance, firmware updates, and quarterly audits of the DTF gangsheet builder settings ensure ongoing improvements and align with the broader practice of DTF printing best practices and continuous improvement.

Frequently Asked Questions

How do I use a DTF gangsheet builder to create gang sheets for DTF?

A DTF gangsheet builder automates the layout of multiple designs on a single transfer, maximizing material use and speeding production. Start by defining your sheet size and bleed, then plan a grid (for example 2×2 or 3×3) and gather all assets with consistent color palettes. Import designs, place them in the grid with even spacing, and set margins to keep designs within safe print areas. Export the print-ready file with embedded color profiles, run a test print, and adjust spacing or color settings based on results. Document your final setup for future gang sheets.

What are the essential dtf gangsheet builder steps to achieve DTF transfer sheet optimization and follow DTF printing best practices?

Key dtf gangsheet builder steps start with planning your workflow: decide how many designs per sheet, the spacing, and alignment. Prepare artwork at the correct resolution and color space (CMYK with a defined ICC profile) and ensure fonts are embedded. Create the gang sheet layout with proper grid, bleed, and margins, then configure printer and transfer settings. Export a print-ready file, perform an integrity check, and run a test print to verify color accuracy and alignment. Use test results to fine-tune impressions and adhesive settings, and standardize the process with documentation to support DTF transfer sheet optimization and overall DTF printing best practices.

| Topic | Key Points |

|---|---|

| What is a DTF gangsheet? | A single transfer containing multiple designs arranged in a grid. Efficiency: more designs per print run lowers material cost per piece and speeds production. A DTF gangsheet builder automates layout, spacing, bleed, and color consistency to save time. |

| Why use a DTF gangsheet builder? | Automates layout, spacing, bleed, and color management; reduces manual tweaking; improves consistency; helps scale production. |

| Getting ready: focus, planning, and the right mindset | Gather all design assets; confirm color palettes; decide max sheet size; set standard margins and bleed; foundation for fewer misprints and better color fidelity. |

| Step 1 — Define your workflow and goals | Decide how many designs per gangsheet, minimum spacing, and the alignment method. Start with a smaller gangsheet (4–6 designs) and scale up as you gain confidence. Note design constraints (largest print area, avoid color overlaps, seam-line considerations). |

| Step 2 — Prepare artwork and color management | Export-ready designs (vector or 300–600 DPI raster); convert colors to CMYK with an ICC profile; embed fonts; calibrate monitor and printer profile for reliable color reproduction. |

| Step 3 — Create your gang sheets (layout and grid) | Configure sheet size, margins, bleed, and grid. Example: 12×16 inch sheet with 0.125 inch bleed and a 4–6 design grid. Maintain consistent alignment and spacing; start with 2×2 or 3×3 layouts. |

| Step 4 — Optimize for production (bleed, margins, tolerances) | Bleed ensures edges print cleanly; set margins to prevent edge issues; manage tolerances to reduce misalignment and waste. |

| Step 5 — Prepare printer and transfer settings | Configure printer and transfer material; ensure printable area matches layout; select correct media type; set heat-press temps, dwell time, and pressure; ensure correct film and adhesive settings for DTF. |

| Step 6 — File export and integrity checks | Export print-ready file with embedded color profiles; verify all designs are present and correctly scaled; check safe margins; flatten layers if required by RIP. |

| Step 7 — Print a test run and evaluate | Print a test gangsheet on scrap fabric; evaluate color accuracy, spacing, alignment, and transfer results; adjust color management or layout if needed. |

| Step 8 — Fine-tune based on results | Tweak exposure, ink density, or adhesive settings; document what worked for future projects; refine steps to improve consistency. |

| Step 9 — Documentation and SOP | Create an SOP with file naming, color profiles, grid presets, bleed/margin values, and printer settings; improves training and consistency. |

| Step 10 — Maintenance and continuous improvement | Regularly review setup; track software/firmware updates; quarterly audits; maintain a log of changes and outcomes. |

| Practical tips and common pitfalls | Back up layouts and assets; separate designs with different color profiles to minimize color shifts; maintain a color management log; keep printer heads and films clean; check copyrights and usage rights. |

| Putting it all together: benefits of a well-executed DTF gangsheet workflow | Higher production efficiency, reduced waste, consistent color reproduction, faster turnaround, and clearer documentation for future projects. Integrating keywords like DTF gangsheet setup tutorial and how to create gang sheets for DTF helps build a scalable system. |

Summary

DTF gangsheet builder is a practical strategy for coordinating multiple designs on a single transfer, enabling efficient production in apparel customization. This descriptive conclusion synthesizes the topic, emphasizing planning, precise layout, color management, and disciplined production settings. By following the workflow steps and maintaining clear documentation, you can achieve consistent quality, higher throughput, and better profitability in your DTF printing operations.