DTF Gangsheet Builder: Tips for Successful Printing

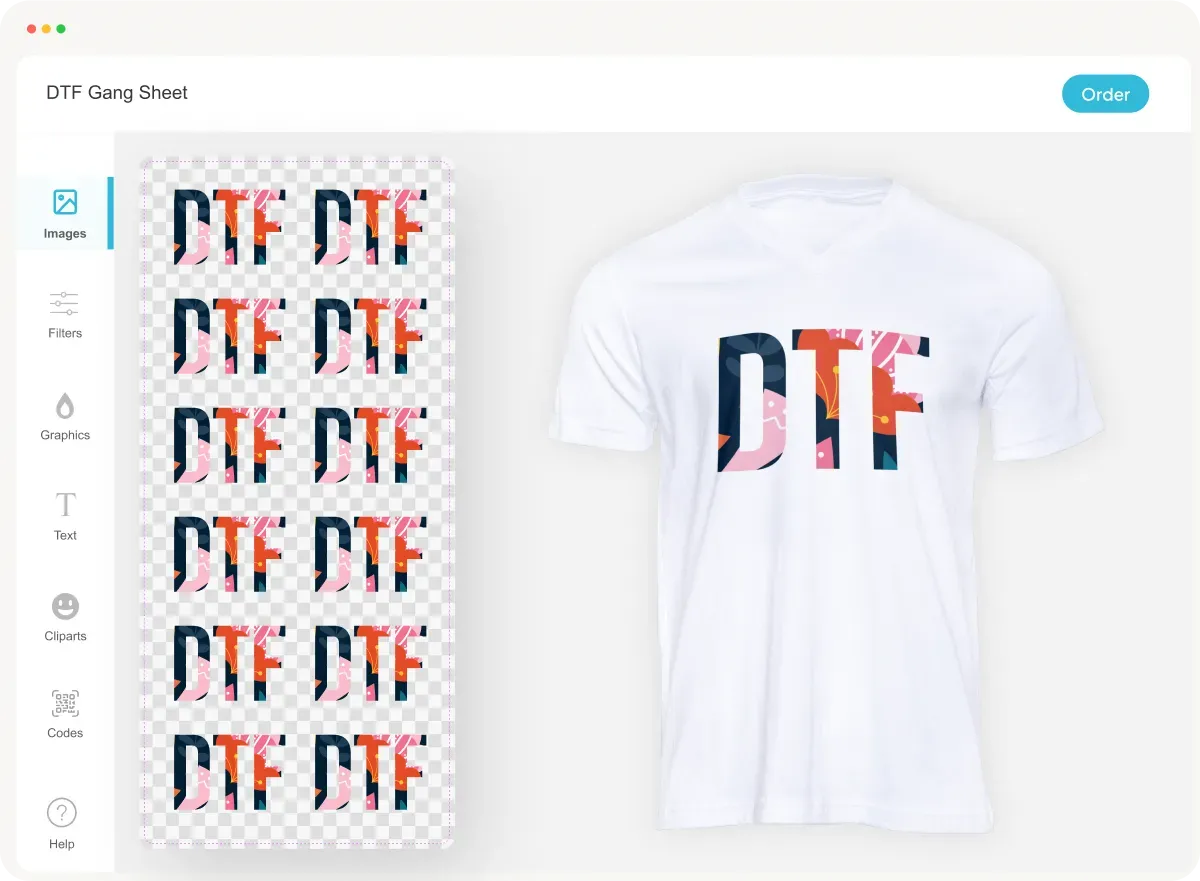

The DTF Gangsheet Builder is revolutionizing the world of Direct to Film (DTF) printing, enabling users to create stunning designs efficiently. By mastering the gangsheet layout, you can optimize each printing session and reduce material waste significantly. Our comprehensive guide offers invaluable DTF printing tips that enhance your skills and elevate your printing success. From selecting the right DTF transfer film to applying proven transfer printing strategies, this resource is tailored for both beginners and experienced professionals. Dive in and discover how to harness the power of the DTF Gangsheet Builder for outstanding results in garment decoration.

The DTF Gangsheet Builder, often referred to as the ultimate tool for efficient transfer printing, simplifies the process of combining multiple designs onto a single sheet. This innovative approach to design layout not only maximizes production efficiency but also ensures high-quality results with minimal waste. By utilizing effective strategies and selecting appropriate transfer materials, users can achieve remarkable outcomes in their garment printing projects. Understanding the nuances of gangsheet creation will not only elevate your printing techniques but also lay the groundwork for enduring success in the competitive world of DTF printing.

Understanding the DTF Printing Process

Direct to Film (DTF) printing revolutionizes the way we create stunning designs on garments. By understanding the DTF printing process, you can maximize your efficiency and output. The process begins with printing your desired artwork onto a special DTF transfer film, which is then coated with adhesive powder. This film allows you to print multiple designs in a single pass, saving time and reducing material waste. Getting acquainted with this process is essential for anyone looking to excel in the DTF printing field.

As you delve deeper into DTF printing, you’ll discover that nuances in each step can tremendously impact the final product’s quality. It’s crucial to select the right transfer film and ensure your printer is calibrated to the correct settings. Moreover, experimenting with different DTF inks can yield impressive results, bringing vibrancy and longevity to your designs. Understanding these intricacies will empower you to create high-quality prints that are sure to impress.

Key Tips for Successful DTF Printing

To achieve DTF printing success, several key tips should be adhered to. First, always use high-quality DTF transfer film and adhesive powders designed for use with your specific ink type. This synergy between materials is instrumental in ensuring vibrant colors and smooth adherence to fabric. Additionally, accurately setting your printer’s DPI to a minimum of 300 will lead to detail-rich prints that grab attention.

Moreover, remember to utilize precise color profiles tailored to your DTF inks. These profiles can significantly enhance color accuracy, leading to consistent and high-quality results across different printing jobs. Prioritizing these best practices will set a solid foundation for your DTF printing projects, ensuring that you stand out in a competitive market while delivering exceptional designs.

Maximizing Efficiency with Gangsheet Layout

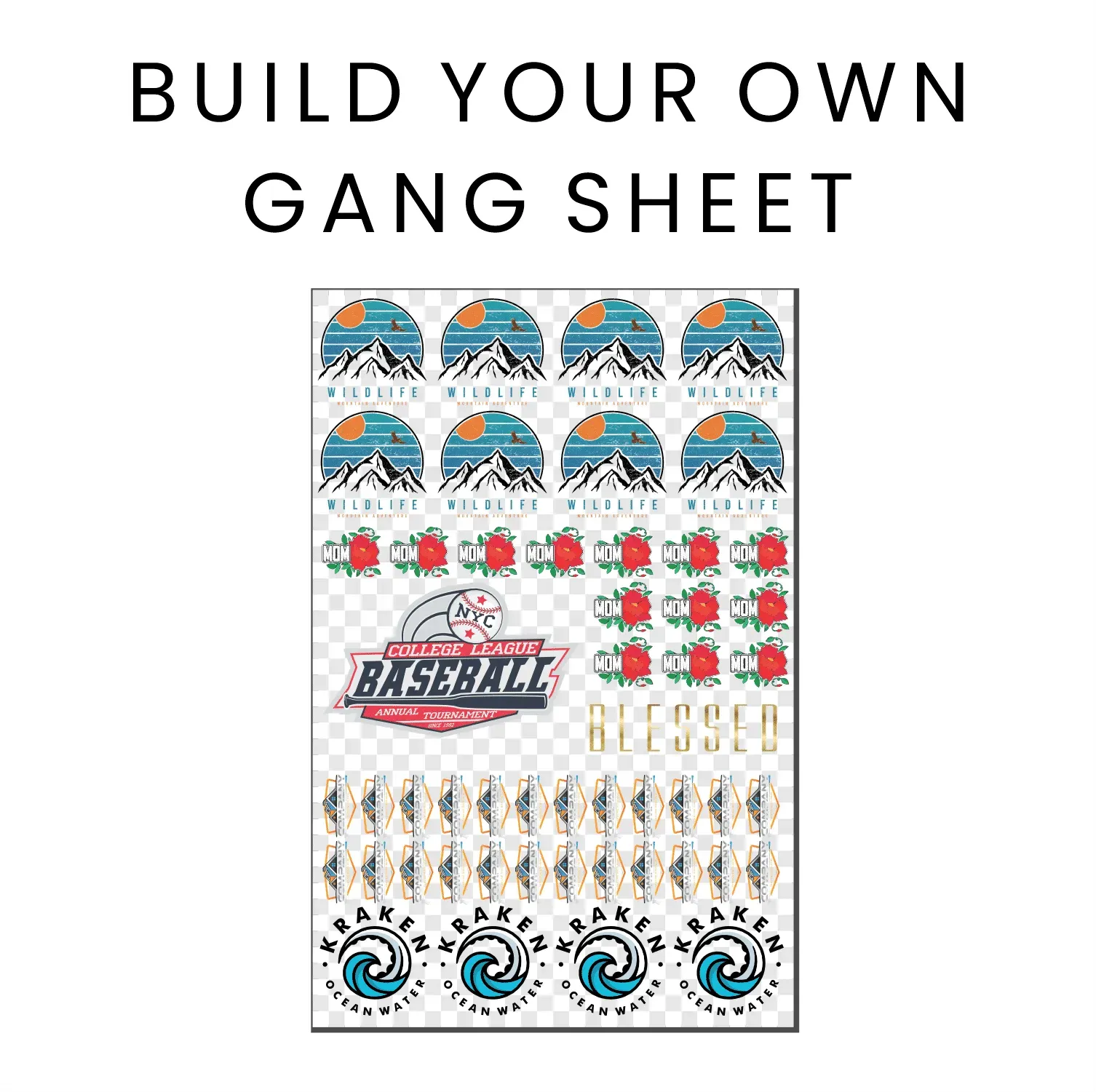

A well-thought-out gangsheet layout is crucial for maximizing your DTF printing efficiency. When arranging multiple designs on a single transfer film, consider the size and shape of each design. Strategically placing larger designs together while clustering smaller ones allows you to save on material costs and optimize print space. Proper spacing between designs is essential to avoid potential overlap issues during the cutting process.

In addition to layout considerations, factor in the type of fabric on which your designs will be printed. Different fabrics absorb ink and adhere to adhesive powder differently, which may affect your gangsheet’s overall performance. Testing various gangsheet layouts on sample fabrics will provide insights that refine your printing approach and lead to more effective production strategies.

Effective Adhesive Powder Application

Applying adhesive powder correctly after printing is critical for ensuring that your designs adhere well to fabrics during the heat transfer process. An even distribution of adhesive powder helps guarantee that every part of your printed design receives adequate bonding capability. Avoid clumping, as this can lead to uneven transfers and compromised print quality.

Additionally, carefully removing excess adhesive powder is just as important. Too much adhesive can result in a crunchy texture or discoloration on the final garment. Utilize a steady hand to shake off excess powder and ensure a professional finish. By mastering this step, you not only enhance design longevity but also contribute to the overall aesthetic quality of your prints, which ultimately reflects your brand’s reputation.

Curing Techniques for Longevity

Curing your DTF prints is essential for ensuring their durability and vibrancy over time. Proper curing ensures that the ink bonds well with the fabric, preventing fading, peeling, or cracking. Follow the manufacturer’s guidelines regarding heat settings and timing, as over or under-curing can significantly affect the final product’s quality.

Before committing to a full production batch, conducting test transfers is advised. This practice allows you to adjust temperature and pressure settings specific to different fabric types, enhancing your success rate. By refining your curing techniques, you’ll provide customers with high-quality apparel that withstands washing and wear, thereby elevating your business’s credibility.

Regular Maintenance for Consistent Results

Maintaining your DTF printer is critical for achieving consistent results in your printing endeavors. Regular cleaning of the printer heads and components helps to prevent clogs and ensures that your prints maintain their quality over time. Neglecting maintenance can lead to subpar prints that don’t meet your standards.

In addition to routine cleaning, checking the hardware and software components of your printer frequently can prevent unexpected breakdowns and keep your output at a professional level. Keeping documentation of maintenance schedules will aid in ensuring that your equipment is always in top shape, allowing you to focus on creativity rather than on troubleshooting technical issues.

Frequently Asked Questions

What is the purpose of a DTF Gangsheet Builder?

The DTF Gangsheet Builder is designed to maximize the efficiency of DTF printing by allowing multiple designs to be printed on a single sheet. This approach minimizes waste while streamlining the transfer process, ultimately improving DTF printing success.

How can I maximize space in my gangsheet layout?

To maximize space in your gangsheet layout, arrange larger designs together and cluster smaller designs closer. Ensure adequate spacing between designs to prevent overlap and cutting issues, following effective transfer printing strategies.

What are the best DTF transfer films for printing?

The best DTF transfer films should be compatible with your printer and promote ink adhesion. Look for films with a strong coating that enhances vibrancy and durability of prints, which is crucial for DTF printing tips.

How do I ensure the quality of my DTF inks?

To ensure quality, use certified DTF inks and conduct tests with samples on your specific transfer films. This will help guarantee optimal color fidelity and adherence, which are essential for DTF printing success.

What are key temperature and pressure settings for effective DTF transfers?

Key temperature and pressure settings can vary, so it’s important to experiment with different levels based on the fabric type. Monitoring these conditions during the heat press process is crucial for perfecting your DTF transfer printing strategies.

What maintenance is necessary for my DTF printer?

Regular maintenance for your DTF printer includes cleaning the printer heads, checking software and hardware for updates, and ensuring all components are functioning properly. This helps maintain consistent quality and prevents issues during DTF printing.

| Key Points | Details |

|---|---|

| What is a DTF Gangsheet? | A DTF gangsheet is a film that combines multiple designs for efficient printing. |

| Choosing Transfer Film | Select high-quality films that are compatible with your printer and enhance ink adhesion. |

| Printer Setup | Set DPI to 300 and use correct ICC profiles for accurate colors. |

| Selecting DTF Inks | Use certified inks and always test new samples. |

| Design Considerations | Use transparent backgrounds and select visible colors for your designs. |

| Gangsheet Layout | Arrange designs wisely with enough spacing to prevent overlaps. |

| Applying Adhesive Powder | Ensure even powder distribution and remove excess. |

| Curing Prints | Follow heat specifications and conduct tests for quality. |

| Temperature and Pressure | Experiment with settings for fabric types and monitor conditions. |

| Fabric Testing | Run tests on various fabrics and document successful combinations. |

| Printer Maintenance | Regularly clean your printer and inspect components for consistent results. |

Summary

The DTF Gangsheet Builder is pivotal for anyone looking to excel in DTF printing. By mastering the essential aspects of design setup, film selection, and technical adjustments, you can ensure high-quality outputs consistently. This comprehensive approach not only optimizes printing efficiency but also enhances the durability and vibrancy of your designs. Embrace these best practices and witness improved results in your DTF printing projects. Happy printing!