DTF gangsheet builder vs manual layout: Key insights

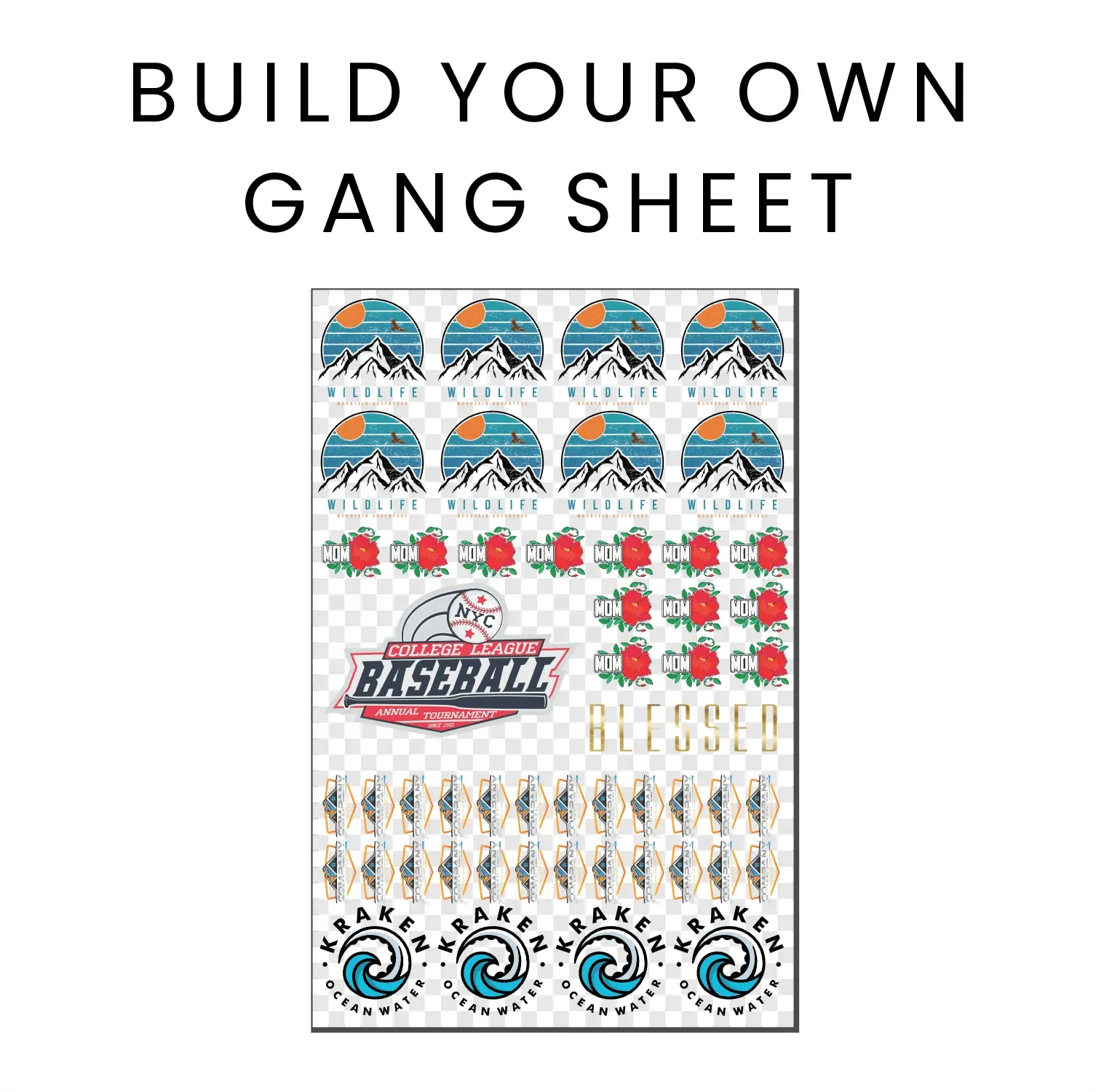

DTF gangsheet builder is transforming how shops plan designs, delivering faster, more precise transfers for a wide range of fabrics. This powerful tool works hand in hand with your DTF printing workflow to optimize layouts and reduce waste. Compared with DTF manual layout, it helps you nest multiple designs on each transfer sheet, saving time on setup. For designers and operators, the software integrates with DTF layout software and generates print-ready files that respect DTF transfer sheets. As a result, your production becomes more scalable, predictable, and cost-efficient across runs.

In other words, a nesting tool or batch-packing solution for direct-to-film production groups several designs on one sheet to maximize material usage. This approach follows LSI principles by using related terms like auto-nesting, multi-design packs, and print-ready templates to reinforce the topic. Beyond automation, it supports accurate bleed control, color management, and seamless integration with printers and DTF transfer sheets. When paired with manual layout for edge cases, it helps studios scale operations without sacrificing detail or speed.

DTF gangsheet builder: Accelerating efficiency, reducing waste, and ensuring color consistency

Adopting a DTF gangsheet builder dramatically changes how designs are laid out by auto-nesting multiple art files onto a single transfer sheet. This approach minimizes material waste, shortens setup times, and creates a predictable print file that aligns with your printer, transfer sheets, and color management pipeline. By standardizing margins, bleed, and alignment, you gain consistency across runs and simplify the DTF printing workflow from design to production to final transfer.

Beyond speed, the gangsheet builder supports cohesive color management and smoother integration with DTF transfer sheets, helping shops achieve reliable results across batches. When paired with robust DTF layout software and properly calibrated ICC profiles, automated layouts reduce rework and improve throughput—critical for scaling up operations while maintaining quality and cost control.

DTF manual layout vs. automated nesting: practical guidance for balancing efficiency and customization

DTF manual layout offers granular control for high-detail artwork, unusual garment shapes, and niche placements where precision margins and orientation matter. This method shines when you need bespoke tweaks on the fly or when a complex design requires bespoke placement that automated nesting might compromise. However, it is inherently labor-intensive and more prone to human error, especially when managing large runs.

A practical path blends both approaches to maximize efficiency without sacrificing customization. Start with a baseline DTF gangsheet workflow for bulk orders, then reserve manual layout for exceptions or special projects. Use DTF layout software to switch between modes, maintain color accuracy, and ensure compatibility with transfer sheets, all while keeping the overall DTF printing workflow streamlined and scalable.

Frequently Asked Questions

How can a DTF gangsheet builder improve my DTF printing workflow for high-volume runs?

Using a DTF gangsheet builder speeds up the DTF printing workflow by automatically nesting multiple designs on a single transfer sheet, reducing material waste and setup time. It helps maintain consistent margins and color alignment across batches when paired with proper transfer sheets and color management. For edge cases or custom orders, you can still rely on manual layout, blending automation with hands-on adjustments as needed.

What features should I prioritize in DTF layout software to optimize gangsheet layouts and maximize use of DTF transfer sheets?

Look for DTF layout software that supports auto-nesting, bleed and margin control, color management with ICC profiles, and flexible layout options (rotation, mirroring). Ensure it integrates smoothly with your printer and DTF transfer sheets, and supports common file formats for a seamless DTF printing workflow. If a design is complex or unusual, the option to switch to manual layout can help preserve detail without slowing down standard gangsheet workflows.

| Topic | Summary |

|---|---|

| What is a DTF gangsheet builder? | Specialized software that arranges multiple designs on a single transfer sheet before printing; optimizes layout to save material, speed up prepress, and standardize color management. |

| What is a manual layout in DTF printing? | Manual arrangement of designs on transfer sheets; offers granular control for unusual shapes or high-detail artwork but is labor-intensive and prone to human error. |

| Why the comparison matters | Not binary; the best workflow blends both: use gangsheet for bulk straightforward orders and manual for special projects. |

| Efficiency, accuracy, and cost (three-way lens) | Efficiency: nested designs reduce waste and setup time; Accuracy: standardized margins improve alignment; Cost: potential savings from automation; Manual layouts may incur higher labor costs on large projects. |

| Key factors to consider | Run size, design complexity, equipment/workflow compatibility, color management, and training/staffing. |

| DTF layout software features | Auto-nesting, bleed/gaps control, color management, layout flexibility, file compatibility, and printer/transfer-sheet integration. |

| Practical path forward: blending approaches | Baseline gangsheet workflow for standard/high-volume runs; manual layout for specialized jobs; QA, waste/throughput monitoring, and templates. |

| Practical tips to optimize workflow | Calibrate printers; color-proofing; design templates with safe zones; maintain a color-safe workspace; document processes. |

| Case studies and scenarios | Examples show reduced prep time and waste with gangsheet, while manual layouts support unique garments and customization as needed. |

| Choosing the right balance | Aim for a reliable, scalable, and cost-effective workflow; use gangsheet for bulk orders and reserve manual for exceptions. |