DTF gangsheet builder vs manual layout: which wins?

DTF gangsheet builder has emerged as a game-changing tool for studios and shops seeking to streamline multi-design production on apparel, delivering consistent layouts, faster approvals, and scalable capability as catalogs grow. By automatically arranging dozens of designs onto a single sheet, it minimizes waste and aligns with your DTF printing workflow, allowing teams to move from concept to production with fewer manual steps. Its core value sits at the intersection of manual layout vs automation, offering the precision of software planning with the flexibility to handle routine reorders, while maintaining visibility into color constraints, margins, and ink waste across multiple SKUs. With intelligent tiling, color management presets, and template libraries, the builder boosts production efficiency in DTF and delivers more consistent results across runs, while supporting better waste tracking, faster changeovers, and tighter control over designer handoffs to the printer. For shops facing growing catalogs and tight deadlines, adopting a gangsheet-based workflow can unlock faster throughput, lower waste, and scalable quality control.

Viewed through an alternative lens, a gangsheet automation tool for DTF shifts emphasis from manual placement to intelligent packing, mirroring efficiency patterns found in modern textile transfer workflows. The concept aligns with Latent Semantic Indexing principles by linking related ideas such as automated layout, sheet tiling, and color-managed production, creating a web of terms like gangsheet layout automation and DTF workflow optimization. For teams deciding between manual layout and automation, the focus becomes predictability, faster changeovers, and measurable production efficiency in DTF. Longer-term benefits include template-driven consistency, testing previews, and cleaner handoffs between design software, RIPs, and printers, all designed to reduce rework and accelerate throughput.

DTF Gangsheet Builder: Automating Layout for Production Efficiency

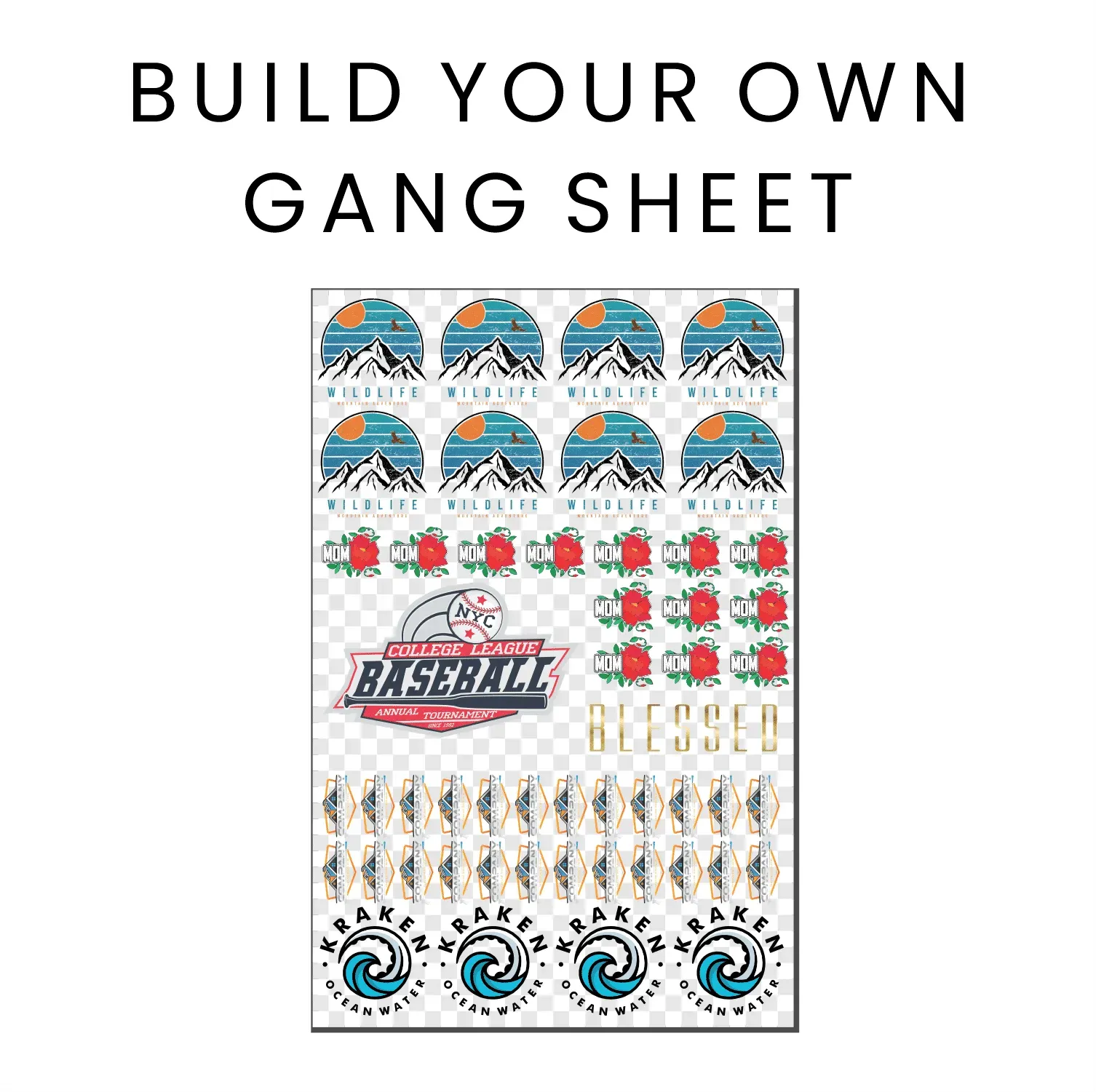

A DTF gangsheet builder is a tool designed to automatically arrange multiple designs onto a single printing sheet, carefully accounting for exact dimensions, margins, bleed, and color constraints within the DTF printing workflow. By replacing manual dragging and dropping with intelligent tiling and size normalization, it delivers significant gains in production efficiency in DTF, especially when you’re handling large catalogs or frequent reorders. This kind of gangsheet layout automation reduces setup time, minimizes human error, and creates a repeatable workflow that scales as demand grows.

Beyond basic tiling, the builder leverages color management and separation presets to preserve color intent across gang sheets, supports test sheets and previews to catch overlaps before printing, and offers template libraries for common products and repeat orders. Integrated workflow hooks connect design software, RIPs, and printer firmware to streamline handoffs from concept to print, making automation a practical backbone for both speed and consistency. While there are upfront costs for licenses and potential hardware upgrades, the payoff often shows up as faster turnarounds, lower material waste per sheet, and a more adaptable operation for evolving product lines.

Manual Layout vs Automation: Balancing Flexibility and Efficiency in DTF

Manual layout remains a valuable approach for highly customized orders, irregular garment shapes, or designs that demand unconventional placements. It offers maximum creative control and flexibility, allowing operators to optimize each sheet for a one-off request without being constrained by templates. However, this flexibility comes with higher labor costs and the risk of human variability, which can impact color accuracy and packing efficiency when catalogs grow.

A practical path often combines both methods: use automation to handle the bulk of routine layouts and deploy manual layout for exceptions or bespoke jobs. Emphasize solid template management, consistent color management, and training so operators understand when to lean on automation and when to intervene manually. This balanced approach aligns with the principles of the DTF printing workflow, improves production efficiency in DTF, and helps maintain brand-consistent output across a mixed catalog.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it optimize the DTF printing workflow?

A DTF gangsheet builder is software that automatically arranges many designs onto a single printing sheet, accounting for exact dimensions, margins, bleed, and color constraints within your DTF printing workflow. It features automated tiling and spacing, size normalization, color management presets, test sheets and previews, template libraries, and seamless workflow integration. This gangsheet layout automation reduces manual layout time, improves packing density, lowers the risk of misalignment, and enhances production efficiency in DTF, especially for shops running dozens to hundreds of items per batch.

Manual layout vs automation: which approach yields better production efficiency in DTF for large catalogs, and when should you rely on automation?

For large catalogs, automation typically delivers higher production efficiency in DTF by speeding up setup, improving sheet packing, and delivering consistent color and layout across orders. A DTF gangsheet builder is especially effective for standard templates and repetitive designs. Manual layout remains valuable for highly customized placements or nonstandard products. A practical approach is to use automation for the bulk of layouts and reserve manual layout or a hybrid workflow for exceptions, while investing in solid template management, color profiles, and test runs to maximize efficiency.

| Topic | Key Points |

|---|---|

| What is a DTF gangsheet builder? | – Automates arrangement of multiple designs on a single printing sheet; – Considers exact dimensions, margins, bleed, and color constraints; – Produces efficient, low-waste gang sheets; – Reduces manual layout time; – Supports test previews, templates, and integrated workflow access. |

| Manual Layout vs Automation | – Manual layout requires a human operator to position designs with precise margins and spacing; – Automation (DTF gangsheet builder) tiles designs efficiently, normalizes sizes, and manages colors; – Hybrid approaches combine both for flexibility. |

| Pros and Cons | – Pros (automation): faster setup, better consistency, reduced waste, scalable; – Pros (manual): maximum flexibility for unique placements; – Cons (automation): may need templates and initial setup; – Cons (manual): more time per sheet and potential human error. |

| Production Efficiency & ROI | – Time savings, material savings, and consistent output with automation; – ROI improves with large catalogs and repetitive designs; – Upfront costs include software/licenses and potential hardware; – Manual layouts incur ongoing labor costs but lower initial spend. |

| Guidelines for Choosing | – Volume/catalog size: large, similar artwork favors automation; small or bespoke runs favor manual or hybrid; – Design complexity: highly customized layouts benefit from manual input; – Quality control: strong color management supports automated workflows; – Training: assess onboarding time and team readiness. |

| Best Practices | – Define standard sheet sizes and templates; – Align with printer color profiles and RIP settings; – Validate with test runs and previews; – Implement clear naming/metadata for tracing; – Train operators for both automation and manual layout; – Monitor waste and cycle times. |

| Practical Scenarios | – Scenario A: 20–40 designs, 200–500 prints/week; automation reduces setup time and waste. – Scenario B: Bespoke orders with unique placements benefit from manual or hybrid approaches. – Scenario C: High-volume, strict color standards thrive with mature automation and solid templates. |

| Common Pitfalls | – Overreliance on automation without validation; – Poor template management; – Inadequate color management; – Underestimating training needs. |

| Trends & Future | – AI-assisted layout, smarter color matching, deeper integration with RIPs and textile printers; – Ongoing improvements narrow the gap between manual and automated layouts; – Early pilots help stay competitive. |