DTF Printing: Essential Tips and Tricks for Beginners

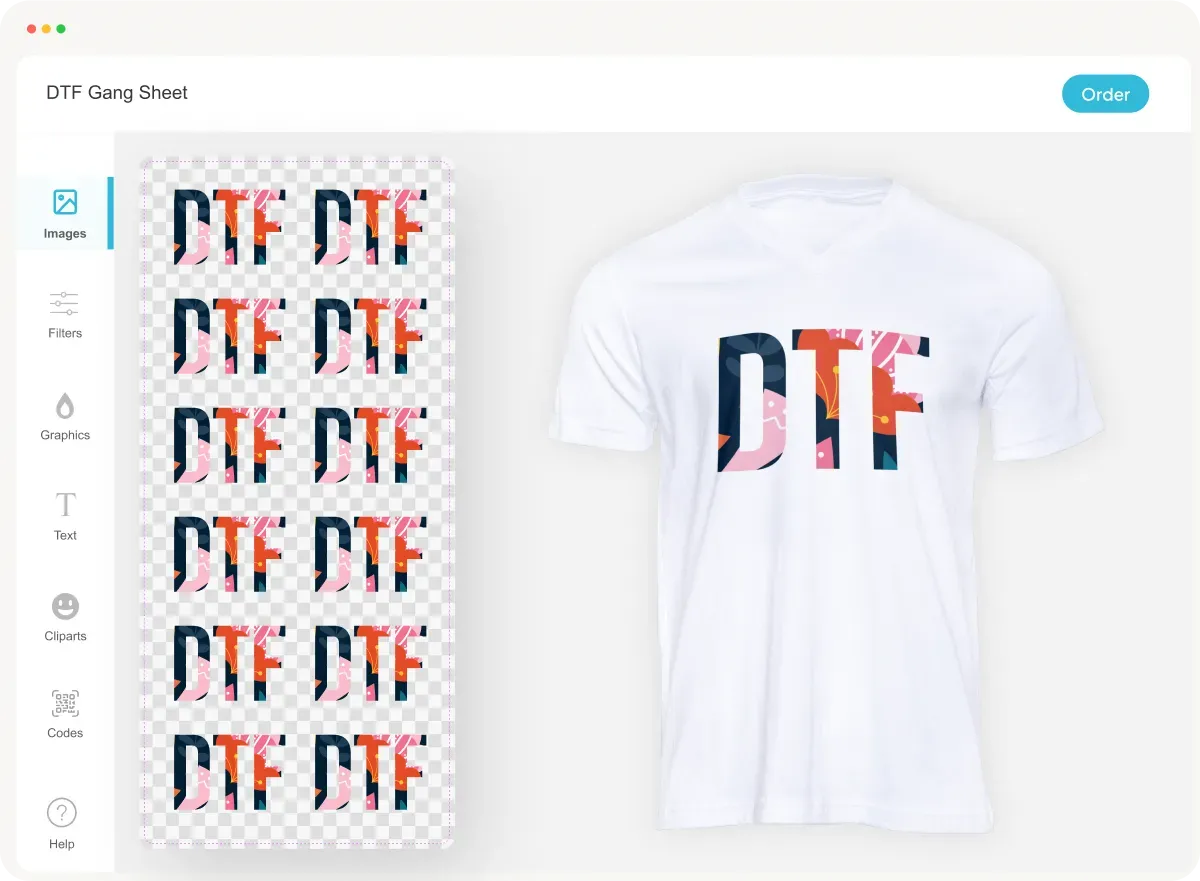

DTF printing, or Direct-to-Film printing, is revolutionizing the way custom designs are transferred onto fabrics. This innovative printing technique uses advanced technology to create high-quality, vibrant prints that are both durable and versatile. For those diving into this art form, understanding the DTF printing process is crucial for achieving the best results. With key tips on using adhesive powder for DTF and avoiding common pitfalls, beginners can quickly enhance their skills. In this guide, we will explore essential DTF printing tips, debunking myths and sharing effective strategies to help you create stunning designs effortlessly.

When discussing custom printing methods, Direct to Film (DTF) printing stands out as a game-changing option for many creators. This technology simplifies the transfer of intricate designs onto various materials, making it an appealing choice for small businesses and hobbyists alike. This guide will not only outline the fundamental aspects of direct-to-film techniques but will also delve into alternative terminology related to DTF. By understanding the components involved in the DTF printing process, beginners can avoid common mistakes and streamline their workflow. Join us as we explore tips that cater to both novice and experienced printers looking to elevate their crafting endeavors.

Getting Started with DTF Printing Gear

When embarking on your DTF printing journey, investing in the right equipment is crucial to achieving outstanding results. Essential tools include a DTF-compatible printer and specialized DTF transfer film. A reliable printer, often a modified inkjet model, is necessary to process DTF inks effectively. Additionally, ensure you have a heat press to transfer your designs accurately onto fabrics. Beyond just these essentials, consider sourcing high-quality inks and films; they play a significant role in the vibrancy and durability of the final prints.

Moreover, don’t overlook the importance of adhesive powder in the DTF printing process. This powder bonds the ink to the fabric when heat is applied, ensuring that your designs don’t fade or peel after washing. It’s advisable to invest in a high-quality hot-melt adhesive powder specifically formulated for DTF applications. These components not only enhance the quality of your prints but also streamline the workflow, making the printing process much simpler for beginners.

The Art of DTF Printing Process

Understanding the DTF printing process is vital for producing stunning prints. The first step involves creating a design using graphic software such as Adobe Illustrator. Be sure to use the appropriate color profile to ensure that the printed colors match your design. Once your artwork is ready, it is printed onto DTF transfer film. The choice of film impacts the quality of the prints, so selecting high-grade, compatible films is essential.

After printing, the next critical step is applying adhesive powder. This step is often overlooked by beginners, yet it’s necessary for achieving adhesion between the ink and the fabric. Once sprinkled on the wet ink, a heat source should be utilized to cure the adhesive. This preps the design for transferring it onto a fabric of choice. Each step in the DTF printing process requires attention to detail and practice, but it paves the way to producing high-quality prints.

Tips for Successful DTF Printing

As a beginner in DTF printing, certain tips can significantly enhance your printing outcomes. Firstly, always perform test prints before executing large orders to ensure your settings are optimized. This practice not only helps in checking colors but also in fine-tuning the heat press settings for perfect adhesion. Quality of ink is another cornerstone of successful DTF printing; thus, consider investing in quality inks that offer better color vibrancy and wash durability.

Furthermore, it’s beneficial to pre-treat your fabrics to improve the adherence of the DTF prints. Different fabrics can react differently to DTF techniques, and pre-treatment can help mitigate adhesion problems. Lastly, as you complete the printing process, provide care instructions that reflect best practices to your customers. Ensuring they understand how to wash and care for DTF printed items can greatly increase customer satisfaction and retention.

Addressing Common DTF Printing Challenges

DTF printing, like any other technique, has its unique challenges. Beginners may encounter issues such as adhesion problems, where prints may not stick properly to the fabric. If this occurs, it’s important to reassess your heat press settings, ensuring that both the temperature and pressure are adequate for your specific materials. Often, manufacturers have guidelines for ideal settings, so consulting those can be incredibly helpful.

Another common issue is inconsistent colors which can arise from variations in fabric and ink quality. Performing thorough tests with different fabric samples can help you identify how colors transfer and adjust accordingly. Keeping a close eye on print quality during the process can help catch these issues early, enabling you to make necessary adjustments before managing bulk productions.

Expanding Your Knowledge with DTF Resources

For those enthusiastic about mastering DTF printing, ongoing education can offer tremendous benefits. Numerous YouTube channels provide practical tutorials, showcasing hands-on techniques that can illuminate complex aspects of DTF printing. Engaging with these resources not only fills gaps in knowledge but also introduces creative ideas that can enhance your designs.

Moreover, joining online communities dedicated to DTF printing can facilitate valuable connections with fellow enthusiasts and professionals. These forums and social media groups often share troubleshooting tips, feedback on techniques, and project showcases that can inspire your growth in the field. Leveraging these resources helps you stay informed of the latest advancements and trends in DTF printing, ensuring you remain competitive in the market.

The Future of DTF Printing in Custom Apparel

DTF printing is increasingly being recognized for its potential in the custom apparel industry. As more individuals pursue personalized clothing and niche fashion items, DTF provides an attractive solution thanks to its versatility and capacity for intricate designs. This technology allows for cheaper setup costs compared to traditional methods, making it a favorable choice for small businesses and home entrepreneurs looking to enter the market.

Furthermore, as the technology continues to evolve, the color quality, ink formulations, and equipment options are rapidly improving. Beginners entering the DTF printing space can leverage these advancements for high-quality outputs that rival more established printing methods. This innovation not only enhances the quality of printed designs but may also expand the range of materials DTF can successfully print on, paving the way for endless creative possibilities.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a process where designs are printed onto a special film that serves as a carrier. The printed film is then transferred onto fabric using heat and pressure, allowing for high-quality, vibrant designs suitable for various materials.

What are the essential tips for beginners in DTF printing?

Beginners in DTF printing should start by performing test prints, using quality DTF inks, pre-treating fabrics for better adhesion, and ensuring proper heat press settings to achieve the best results. Joining online communities can also provide valuable support and tips.

What equipment do I need for DTF printing?

To begin DTF printing, you need a DTF-compatible printer, DTF transfer film, adhesive powder for DTF printing, and a reliable heat press. Ensuring you have quality tools will enhance your printing experience and output quality.

How do I apply adhesive powder for DTF printing?

After printing your design on the DTF film, immediately sprinkle the adhesive powder over the wet ink. Subsequently, use a heat source like a heat gun to cure the adhesive, enabling it to bond effectively with the ink.

What common challenges do beginners face in the DTF printing process?

Beginners often encounter challenges such as adhesion problems, where prints peel off due to incorrect heat settings, and color inconsistencies, which can arise from fabric variations. Testing and adjusting your settings can help mitigate these issues.

Can I use DTF printing on different fabrics?

Yes, DTF printing is versatile and can be used on a wide range of fabrics, including cotton, polyester, and blends. This makes it an excellent choice for customized apparel across various materials.

| Key Point | Description |

|---|---|

| Introduction to DTF Printing | DTF printing is a emerging method that involves printing designs onto a film that can be transferred to fabric, offering vibrant designs. |

| Benefits of DTF Printing | Versatile across materials, provides high-resolution and vivid color prints, and requires fewer equipment compared to screen printing. |

| Essential Equipment | A compatible printer, DTF transfer film, adhesive powder, and a heat press are crucial for successful DTF printing. |

| DTF Printing Process Steps | 1. Create Design 2. Print on Film 3. Apply Adhesive 4. Transfer to Fabric 5. Peel and Finish. |

| Tips for Success | Perform test prints, use quality inks, pre-treat fabrics, and provide post-care instructions for longevity of prints. |

| Challenges and Solutions | Common issues include adhesion problems and color inconsistencies, solvable by adjusting temperature/pressure and testing colors. |

| Continuous Learning Resources | Utilize YouTube tutorials and participate in online communities for further insights and troubleshooting. |

Summary

DTF printing is a revolutionary method that simplifies the process of creating custom designs on fabrics. By harnessing the capabilities of DTF printing, beginners can explore endless creative possibilities while learning about essential tools and techniques. The versatility and quality of prints achievable with DTF printing make it a preferred choice among entrepreneurs and hobbyists alike. With a proper understanding of the printing process, high-quality equipment, and consistent practice, anyone can produce stunning designs that stand out in the market. Embrace DTF printing as your go-to solution for custom apparel and watch your ideas transform into tangible art.