DTF Printing: The Future of Custom Apparel is Here!

DTF printing, or Direct-to-Film printing, is rapidly revolutionizing the custom apparel industry. This cutting-edge printing technology enables businesses and creators to produce stunning, vibrant designs that can be applied to a diverse range of fabrics, thereby transforming the landscape of apparel customization. With its unique ability to use eco-friendly inks and the popular technique of gang sheets, DTF printing is not just efficient but also cost-effective for small entrepreneurs. The benefits of DTF printing extend beyond mere aesthetics; they offer flexibility and speed that traditional methods like screen printing often struggle to achieve. As the demand for personalized custom T-shirts grows, DTF printing stands out as the innovative solution for bringing creative visions to life.

Referred to as Direct-to-Film printing, this modern technique is quickly gaining traction for producing custom garments with vivid visuals. The advent of direct film technology has opened new avenues for apparel manufacturers to deliver high-quality and distinctive clothing items. By leveraging advanced processes, including the use of eco-solvent inks and gang sheets, this method allows for efficient printing on various materials. As a result, businesses can now meet consumer demands for customized apparel more effectively than ever, satisfying the rising trend towards unique fashion statements. Overall, the evolution of fabric printing methods showcases an exciting future for those involved in the custom clothing market.

Revolutionizing Custom Apparel with DTF Printing

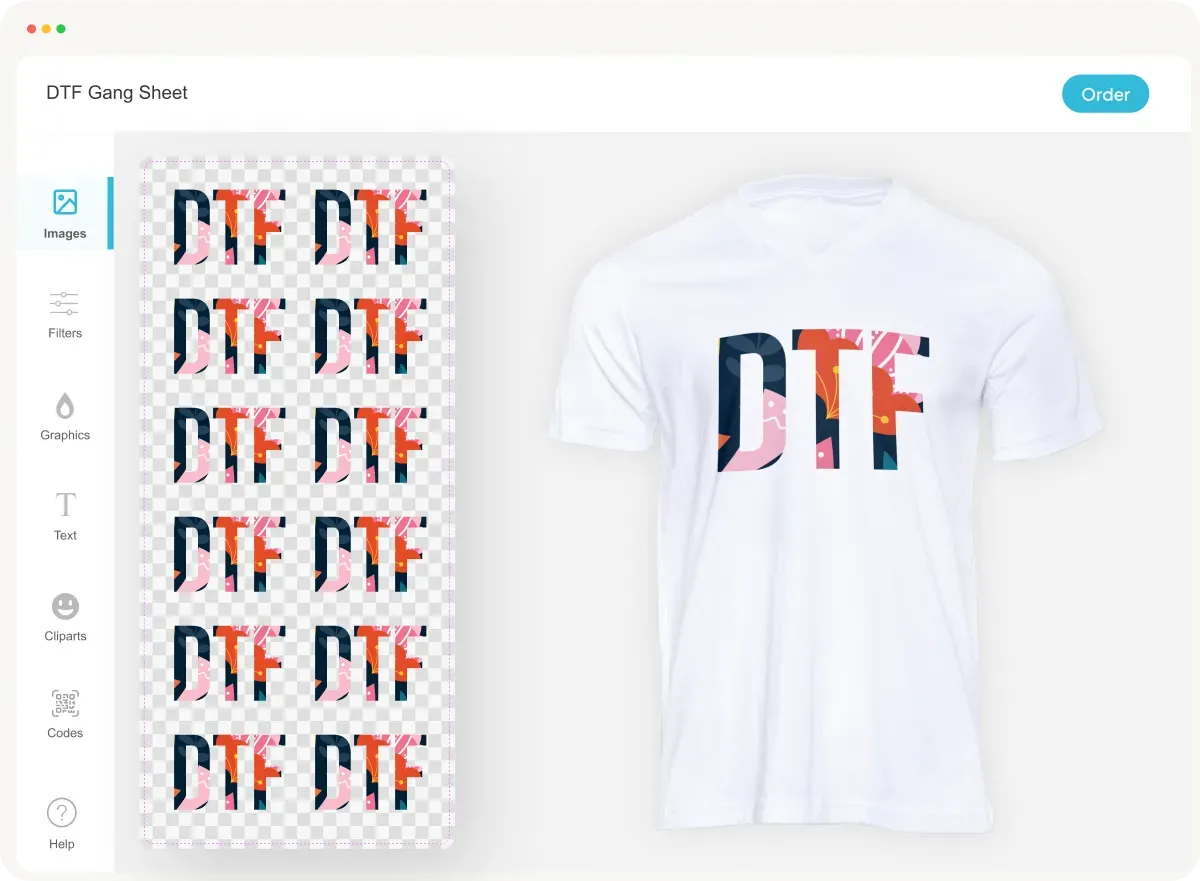

DTF printing has transformed the landscape of custom apparel, offering an unrivaled blend of quality and efficiency. Unlike traditional methods such as screen printing, DTF allows for vibrant colors and intricate designs to be effortlessly transferred onto a variety of fabrics. This capability makes it an essential tool for custom T-shirt creators and designers seeking to elevate their product offerings. The technology operates by printing designs onto a film and then heat-pressing them onto garments, ensuring that even the most delicate details are captured accurately.

Moreover, DTF printing significantly reduces the production time compared to conventional techniques. This rapid turnaround is crucial for businesses aiming to meet the fast-paced demands of the current market. As a result, many small businesses have begun to adopt DTF technology not just to fulfill orders but to experiment with new ideas and expand their creative horizons. By utilizing DTF, entrepreneurs can efficiently produce limited runs or custom orders, catering to the growing trend of personalized apparel.

The Benefits of DTF Printing

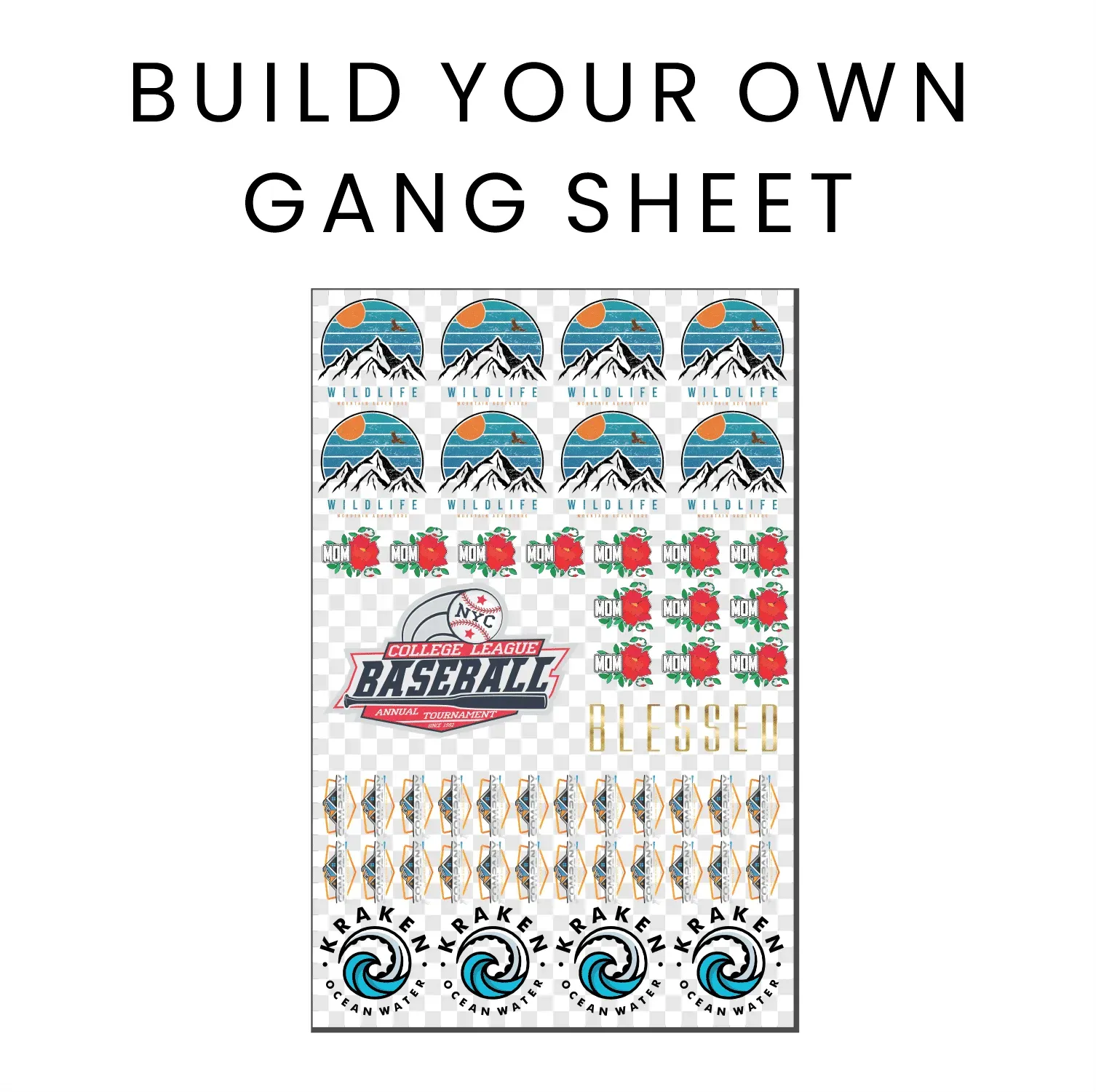

The advantages of DTF printing extend beyond just quality; they also encompass cost-effectiveness. By using gang sheets, businesses can optimize their material usage by printing multiple designs on a single sheet. This method not only minimizes waste but also significantly decreases production costs, making it economically viable for small to medium-sized enterprises. The ability to maximize resources while also offering a diverse range of designs opens up new avenues for creativity and profitability.

Additionally, DTF printing offers a remarkable degree of flexibility. It can seamlessly print on various types of materials including cotton, polyester, and blends, which traditional methods often struggle with. This versatility allows clothing manufacturers to cater to a wider audience, satisfying customer preferences while exploring new fabric options. With DTF, businesses can experiment with different textures and finishes, enhancing their product lines and attracting attention in a competitive market.

Exploring Gang Sheets in DTF Printing

Gang sheets are a game-changer in the world of DTF printing, offering an efficient solution for businesses looking to maximize their production capabilities. By printing several images or designs on a single film sheet, companies can drastically cut down on both time and material costs. This streamlined process allows for greater output with less input, empowering businesses to meet higher demands without sacrificing quality or detail.

Furthermore, the use of gang sheets fosters greater creativity among designers. By allowing multiple designs to be printed simultaneously, artists can experiment and innovate more freely. This aspect not only broadens the range of available products but also encourages a more dynamic creative process. As a result, customers can enjoy a diverse selection of unique apparel, tailored to fit their individual styles and preferences, all thanks to the efficiency that gang sheets provide.

The Accessibility of DTF Printing for Small Businesses

In today’s economy, accessibility to advanced printing technology like DTF is a critical factor for small businesses and individual entrepreneurs. This technology has become increasingly affordable and attainable, allowing even the most modest operations to implement professional-grade printing. This accessibility helps democratize the custom apparel market, empowering small businesses to compete against larger corporations by offering unique, high-quality products without the need for hefty upfront investments.

As more creators harness the power of DTF printing, we are witnessing a boom in personalized fashion products. Whether it’s a local artist or a budding entrepreneur, the barrier to entry has been lowered, leading to a surge in creativity and innovation. As a result, consumers can enjoy a wide variety of custom T-shirts and other apparel that cater specifically to their tastes, paving the way for a thriving ecosystem of individual expression and entrepreneurship.

Future Trends in Custom Apparel with DTF Printing

Looking ahead, DTF printing is set to redefine the future of custom apparel in several exciting ways. First and foremost, we can anticipate an increase in the diversity of product offerings. As technology evolves, production capabilities will grow, enabling businesses to push boundaries and introduce a wider array of unique designs. This diversification will not only satisfy consumer demand for personalization but also encourage continuous innovation within the industry.

Moreover, sustainability will likely become a significant focus. DTF’s ability to minimize waste through practices such as gang sheet printing aligns well with the growing demand for eco-friendly solutions in fashion production. As consumers become more environmentally conscious, companies that embrace sustainable practices while utilizing DTF printing will position themselves favorably within the market. This trend not only enhances brand reputation but also contributes positively to the industry’s overall environmental footprint.

Integrating DTF Printing with E-commerce Strategies

The integration of DTF printing with e-commerce platforms is poised to shape the future of retail in the custom apparel sector. As online shopping continues to surge, businesses equipped with efficient DTF printing technology can quickly scale their operations to meet consumer demand. The agility provided by DTF allows these businesses to launch new designs without significant lead time, ensuring they remain competitive in a fast-moving marketplace.

Furthermore, the ability to create tailored apparel on demand means that e-commerce brands can offer unique customer experiences. Personalized items, like custom T-shirts featuring individual designs, become viable options for online retailers. This not only enhances customer satisfaction but also cultivates brand loyalty, making it imperative for businesses to adopt DTF printing as they develop their e-commerce strategies.

Frequently Asked Questions

What are the benefits of DTF printing for custom apparel?

DTF printing, or Direct-to-Film printing, offers numerous benefits for custom apparel, including high-quality and vibrant designs that adhere well to various fabrics like cotton and polyester. This technology allows for quicker production times and is cost-effective, particularly when using gang sheets, which maximize material use by printing multiple designs on a single sheet. Additionally, DTF printing is more accessible for small businesses and individual creators, making it easier to produce unique and personalized apparel.

How does DTF printing work compared to traditional methods like screen printing?

DTF printing works by printing digital images onto a special film using eco-solvent or water-based inks. The film is then coated with a powdered adhesive that bonds the design to fabric when heat-pressed. Unlike traditional screen printing, which often requires multiple steps and setups for different colors, DTF printing simplifies the process and can print on various materials efficiently, offering more versatility for custom T-shirts and other apparel.

Can DTF printing be used on dark fabrics?

Yes, DTF printing can effectively be used on dark fabrics. The technology’s ability to produce vibrant colors and detailed designs means that it can be applied to a variety of textiles, including darker materials. With the right ink and adhesive, DTF printing ensures that the designs remain bright and durable, making it an excellent choice for custom apparel that stands out.

What are gang sheets in DTF printing, and how do they benefit businesses?

Gang sheets in DTF printing are used to print multiple designs on a single sheet of film, optimizing material usage and production costs. This feature greatly benefits apparel businesses by reducing waste and saving money while allowing for a diverse range of designs. Using gang sheets can enhance profit margins and creativity, enabling smaller print runs without sacrificing quality or variety.

Is DTF printing environmentally friendly compared to other printing methods?

DTF printing has the potential to be more environmentally friendly than traditional methods, such as screen printing, due to its minimized waste production when using gang sheets. The technology often employs water-based and eco-solvent inks, which can be less harmful to the environment. Furthermore, DTF printing reduces the need for plastics and large volumes of inks, contributing to a more sustainable approach in the custom apparel industry.

What makes DTF printing accessible for small businesses and individual creators?

DTF printing is accessible for small businesses and individual creators due to the availability of more compact and affordable printers, such as the A3 DTF printer from AM.CO.ZA. This technology allows even hobbyists to invest in professional-grade equipment without significant costs, making it easier to enter the custom apparel market. As a result, more creators can produce high-quality, customized items that cater to niche markets.

| Key Point | Description |

|---|---|

| Introduction | Direct-to-Film (DTF) printing is a revolutionary method for custom apparel that produces high-quality designs on various fabrics. |

| Understanding DTF Printing | DTF printing uses digital images on a film with eco-solvent inks and a powder adhesive, making it versatile across materials. |

| Market Growth and Investments | High market growth and investment in DTF technology indicate its increasing demand and importance in apparel manufacturing. |

| Technological Advances | Advancements have made DTF printers available for small businesses, allowing for professional-grade output at lower costs. |

| Efficiency Through Gang Sheets | Gang sheets enable cost-effective printing of multiple designs, optimizing material use and improving profit margins. |

| Consumer Accessibility and Trends | DTF technology empowers diverse creators, enabling them to produce unique and appealing clothing at lower costs. |

| The Future of Custom Apparel | DTF’s scalability and sustainability focus are set to influence the future of the custom apparel market significantly. |

Summary

DTF printing is transforming the landscape of custom apparel by providing a highly efficient and versatile method for producing vibrant designs on a variety of fabrics. This innovative technology has not only proven its capability to meet the growing demand for personalization in clothing but has also made it more accessible to small businesses and individual creators. As advancements in DTF printing technology continue to evolve, we can expect an increase in unique product offerings and a stronger focus on sustainability, which are crucial elements in today’s market. Thus, DTF printing stands not just as a trend but as a cornerstone in the future of apparel design and production.