DTF Supplies: Top 10 Essentials for Your Printing Business

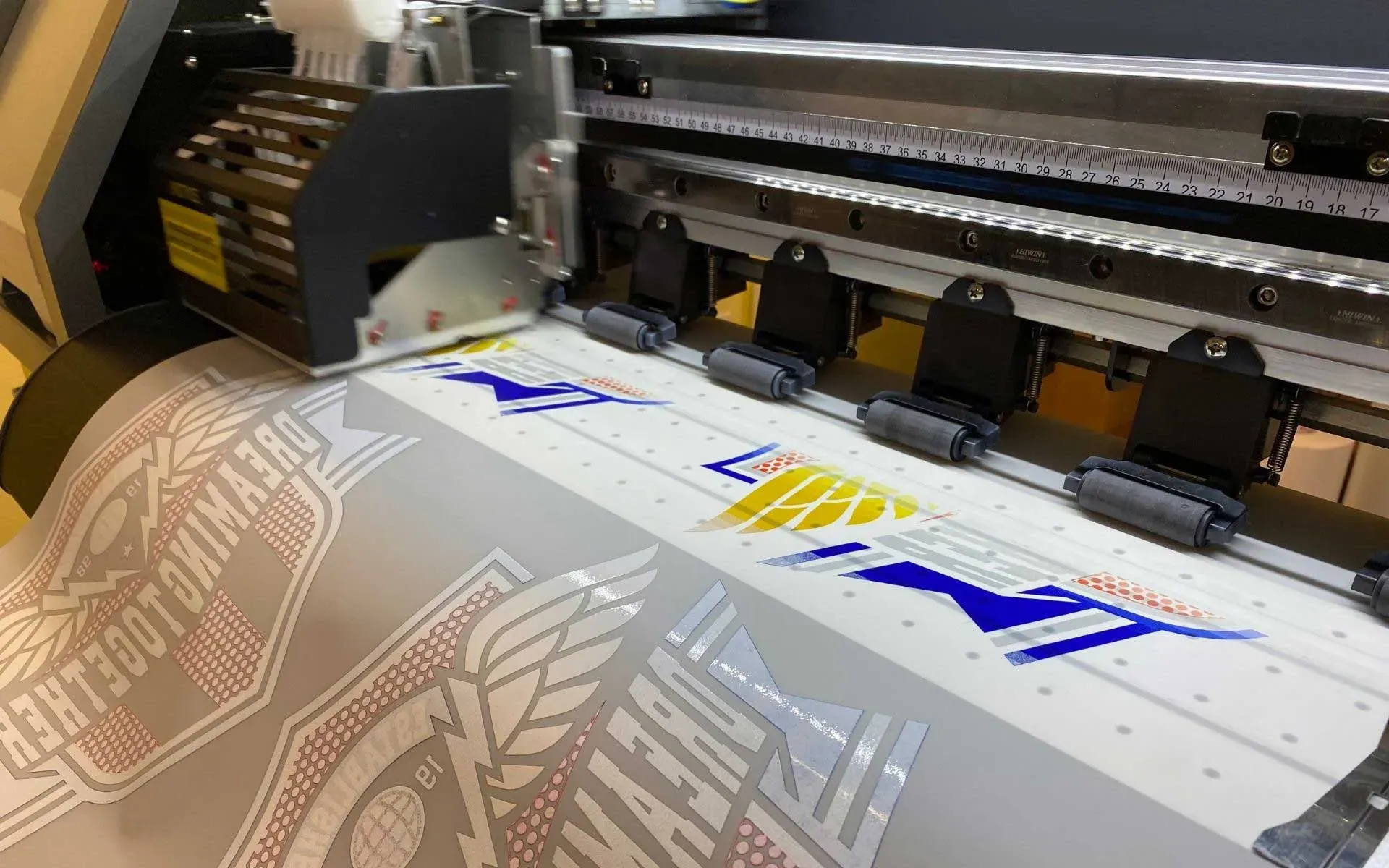

In the world of custom apparel, having the right DTF supplies is crucial to ensuring both quality and efficiency in your printing business. Direct to Film (DTF) printing has revolutionized the way designs are transferred onto fabrics, combining vibrant colors with sharp details to create stunning products. To thrive in this competitive landscape, investing in quality DTF printing supplies is essential, from the best DTF printer to specialized DTF inks and a reliable heat press for DTF applications. This guide will introduce you to the top 10 DTF supplies that not only optimize your printing process but also enhance the longevity and appeal of your finished products. By leveraging these tools, you’ll be equipped to produce impressive prints that will leave your clients coming back for more.

Exploring the realm of Direct to Film (DTF) technology opens up exciting possibilities for those in the printing industry. This innovative approach to design transfer allows for exceptional detail and durability on various fabric types, making it a favored choice for custom merchandise. To successfully embark on your printing journey, understanding the essential materials required for DTF operations, such as specialized inks and advanced printing equipment, is vital. Furthermore, integrating tools like heat transfer machines tailored for DTF applications can elevate your production efficiency significantly. In this article, we will delve into the must-have tools and materials that will set you up for success in the DTF printing market.

Understanding DTF Printing Supplies

DTF printing, short for Direct to Film printing, has revolutionized the way designs are transferred onto fabrics. This innovative method utilizes unique supplies that are essential for achieving vibrant and durable prints. When establishing your printing business, it’s vital to familiarize yourself with DTF supplies to streamline your production process and enhance the quality of your output. Investing in quality materials, from DTF printers to adhesive powders, can significantly influence the longevity and visual appeal of your products.

One of the key reasons DTF printing has gained traction in the custom apparel industry is its versatility across various fabric types. As such, understanding the distinct roles of each supply is crucial. For instance, using high-quality DTF transfer film and specialized inks can prevent issues like fading and cracking, which are detrimental to customer satisfaction. Overall, being knowledgeable about your DTF supplies is a fundamental step in securing a competitive edge in the printing business.

Choosing the Best DTF Printer

When it comes to DTF printing, selecting the best DTF printer is paramount. Brands like Epson and Mimaki have made a name for themselves by providing printers that cater explicitly to DTF technology. A dedicated DTF printer boasts features that enhance color vibrancy and precision, essential for creating stunning designs. For your printing business, investing in a high-quality printer ensures that your products stand out in a saturated market.

Furthermore, compatibility with DTF inks and transfer films should be a defining factor in your decision-making process. A printer with optimized settings and capabilities can greatly reduce waste and increase productivity, ultimately impacting your bottom line. Be sure to do thorough research and consider reviews from other printing professionals to determine which machine best suits your needs.

Essential DTF Inks for Quality Printing

Specialized DTF inks are crucial for achieving the desired vibrancy and durability in your prints. Unlike traditional inks, DTF inks, particularly water-based options from leading brands like Sawgrass and Epson, are designed to bond seamlessly with the transfer film and fabric. This unique formulation not only ensures vivid colors but also aligns with eco-friendly trends by minimizing environmental impact.

Additionally, the correct choice of DTF inks directly influences the quality of your final product. It’s important to ensure that the inks are fully compatible with your DTF printer and are specifically designed for use with the films in your workflow. This consideration will mitigate the risk of print quality issues, such as smudging or bleeding, which can otherwise undermine your business’s reputation. Regularly experimenting with different ink brands can also help you discover panels that yield superior results.

The Importance of DTF Transfer Film

DTF transfer film is a key component in the Direct to Film printing process, directly affecting the quality of your final printed product. The film must be specially coated to promote optimal ink adhesion and durability. Clear and glossy transfer films are typically recommended for best results, as they contribute to the final vibrancy and clarity of the print.

Investing in high-quality DTF transfer films pays dividends in the long run, as it helps ensure that your designs withstand repeated washes and wear. A reliable transfer film not only enhances the appearance of the printed design but also increases customer satisfaction and repeat business. As the market grows, knowing how to select the right film for different fabric types can significantly elevate your printing capabilities.

Selecting the Right Heat Press for DTF Printing

A top-quality heat press is essential for successfully transferring your DTF prints onto fabric. The heat press not only applies the necessary heat and pressure to bond the design but also contributes to the overall quality of the print. Features such as adjustable temperature, pressure settings, and plate size allow for customization to meet specific production needs, making them invaluable for any printing operation.

When choosing a heat press, consider the size and functionality that suit your workspace. Brands like Stahls are known for their reliability and are preferred in the DTF printing community. Furthermore, proper use of the heat press will enhance the adhesion between the transfer film and fabric, resulting in long-lasting designs. Conduct accessory checks and test different machines to find the perfect fit for your production process.

A Comprehensive Guide to DTF Supplies Storage Solutions

Proper storage solutions for your DTF supplies can greatly affect their longevity and performance. Factors like temperature and humidity can lead to degradation of inks and transfer films, potentially jeopardizing the quality of your prints. It’s advisable to invest in airtight containers and climate-controlled environments to prevent moisture damage and preserve your materials’ integrity.

Organizing these supplies efficiently not only ensures easy accessibility but also supports streamlined workflow, promoting productivity. Additionally, considering options like shelving units that can accommodate various size containers can help maintain order in your workspace. Good organization practices extend the life of your DTF supplies and contribute to a smoother printing operation.

Frequently Asked Questions

What are the essential DTF supplies for a successful Direct to Film printing business?

To ensure success in your Direct to Film (DTF) printing business, essential supplies include a dedicated DTF printer, high-quality DTF transfer film, specialized DTF inks, adhesive powder, a reliable heat press, and appropriate fabrics like cotton or polyester. These components are crucial for producing vibrant and long-lasting prints.

How do I choose the best DTF printer for my printing needs?

Selecting the best DTF printer involves considering brands like Epson or Mimaki, compatibility with DTF transfer films and inks, and the printer’s ability to produce vibrant colors and detailed images. Research user reviews and specifications to find a model that suits your specific printing needs.

What types of DTF inks should I use for optimal results?

For optimal results in DTF printing, choose water-based DTF inks, such as those from Sawgrass or Epson. These inks provide vivid colors and are environmentally friendly. Ensure compatibility with your printer and check for smooth transfer capabilities onto your chosen fabric for the best outcome.

How important is the adhesive powder in the DTF printing process?

Adhesive powder is crucial in the DTF printing process as it bonds the ink to the fabric, ensuring durability and longevity of prints. Choosing high-grade, heat-activated adhesive powder will enhance the adhesion, making your designs resistant to wear and frequent washing.

What features should I look for in a heat press for DTF printing?

When selecting a heat press for DTF printing, look for features such as adjustable temperature and pressure settings to ensure optimal bonding. Brands like Stahls are reputable; choose a model that fits your workspace and production needs, considering options like swing-away or clamshell designs.

Can I use any fabric for DTF printing, or are specific materials recommended?

Not all fabrics are suitable for DTF printing. Recommended materials include cotton, polyester, or blends, as they adhere well to DTF inks. Testing different fabrics can help you determine which yields the best results in terms of color vibrancy and durability after washing.

| DTF Supply | Description | Recommended Brands |

|---|---|---|

| DTF Printer | Essential for high-quality prints; look for compatibility with DTF film and inks. | Epson, Mimaki |

| DTF Transfer Film | Specially coated to enhance ink adhesion; opt for clear and glossy options. | Various Brands |

| Inks | Water-based, vibrant colors, eco-friendly options available. | Sawgrass, Epson |

| Adhesive Powder | Bonds ink to fabric; choose heat-activated grades. | Various Brands |

| Heat Press | Transfers designs; adjustable settings for optimal results. | Stahls |

| Textile | Fabric type greatly affects print outcome; use cotton, polyester, blends. | Various Fabrics |

| Pre-Treatment Equipment | Enhances adhesion and vibrancy; optional but beneficial. | Various Suppliers |

| Software | Used for design creation and modification; ensure compatibility with DTF. | Adobe Illustrator, CorelDRAW |

| Cleaning Supplies | Essential for maintenance, prolongs printer lifespan. | Printer-Specific Kits |

| Storage Solutions | Ideal for protecting supplies from humidity and temperature effects. | Airtight Containers |

Summary

DTF supplies are essential for ensuring the success of your printing business. By investing in high-quality tools and materials, you can achieve vibrant and durable prints that satisfy your clients’ needs. Each component, from the DTF printer to the adhesive powder and storage solutions, plays a crucial role in the overall quality of your products. Understanding the purpose and ideal use of each supply empowers you to optimize your printing process and stay competitive in the market. In summary, whether you are starting out or enhancing your existing setup, the right DTF supplies will set you on a path to printing excellence.