DTF transfers: A Bold, Durable Fabric Printing Guide

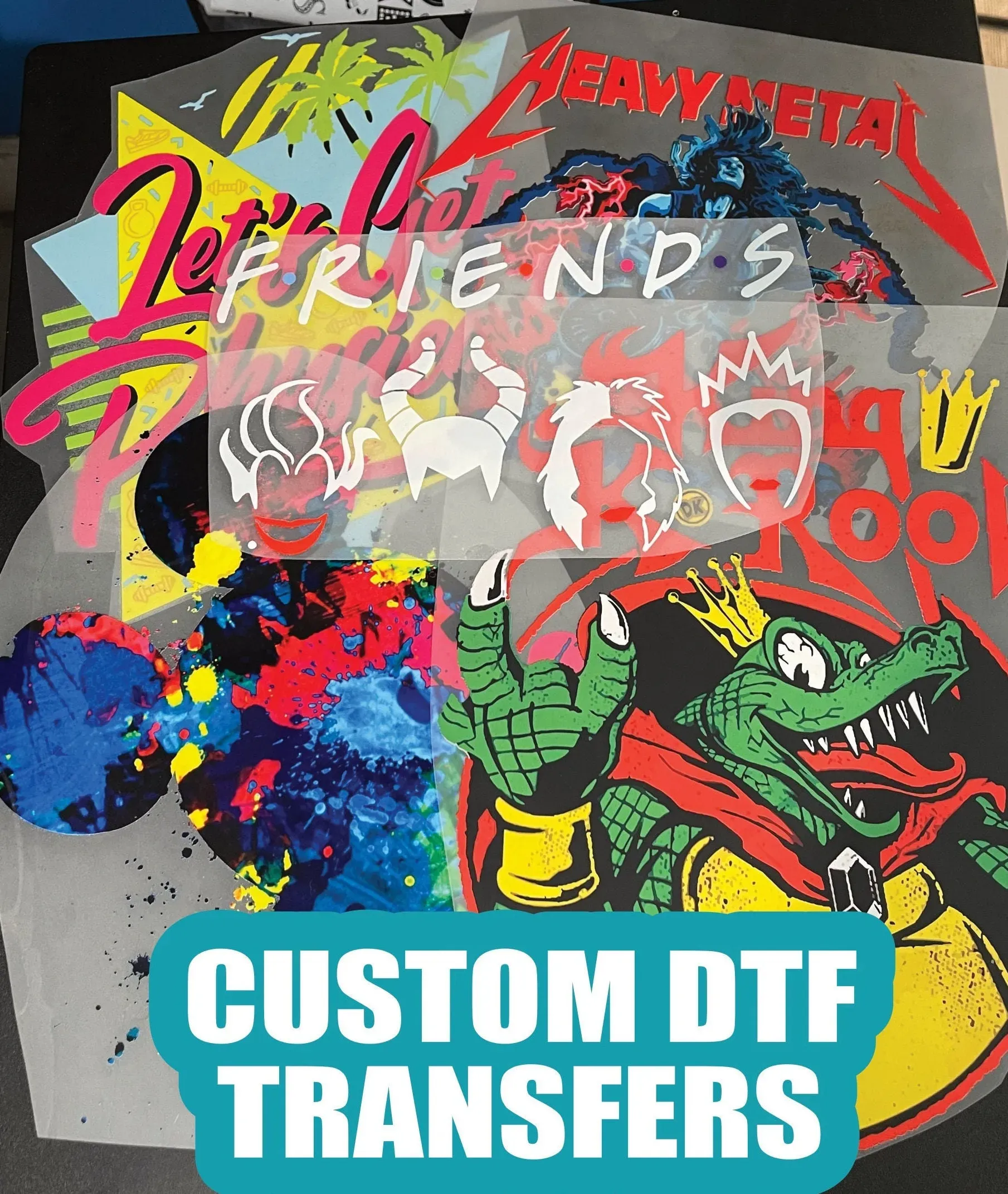

DTF transfers have transformed how creators decorate fabrics, delivering bold, durable designs with vibrant color. For anyone designing custom apparel, bags, or textiles, understanding direct-to-film printing and how to optimize printing DTF on fabrics can unlock new levels of quality. This guide explains what DTF transfers are, the adhesive powder for DTF that helps the bond, and how the workflow compares with other methods. In DTF vs DTG comparisons, transfers offer versatility across fabrics and strong wash-fastness, with vibrant images that stay sharp. With a practical approach to setup and care, you can achieve durable DTF transfers that withstand washing and wear.

From a different angle, this technology can be framed as a film-based textile decoration method that uses a carrier film and adhesive layer. Think of it as a print-on-film workflow where a design is prepared digitally and then transferred onto fabrics through heat and bonding agents. LSI-friendly terms for the same idea include film-transfer printing, substrate-friendly graphics, and decor applied via a digital transfer system. Because the approach emphasizes compatibility with a wide range of materials and rapid production, brands often choose it for prototyping, limited runs, and merchandise.

DTF transfers and direct-to-film printing: achieving durable, vibrant graphics across fabrics

DTF transfers have transformed fabric decoration by combining bold color, sharp detail, and long-lasting performance. At the heart of this approach is direct-to-film printing, where artwork is laid down on a PET transfer film and prepared for bonding with an adhesive powder. The powder is melted during heat application to create a strong, durable bond to the fabric, resulting in graphics that resist washing and wear while maintaining color vibrancy.

This workflow supports a wide range of fabrics—from cotton tees to blends and certain synthetics—making it a versatile solution for custom apparel, bags, and textiles. The inclusion of an adhesive powder for DTF is critical to achieving durability, and using a white ink layer for on-dark fabrics helps ensure bright, accurate colors. When designed with care and cured properly, durable DTF transfers can deliver a soft hand and high color fidelity across garments.

In practice, the process emphasizes careful color management and precise transfer parameters to minimize color shifts and ensure consistent results. Whether you’re printing bold graphic tees or intricate multi-color designs, direct-to-film printing provides a practical path to high-impact visuals that stay vibrant through repeated wear and washing.

DTF vs DTG: choosing the right method for durability, color fidelity, and production efficiency

DTF vs DTG represents two distinct approaches to garment decoration, each with its own strengths. DTF transfers prioritize versatility across fabrics, strong adhesion with common care, and robust color performance for multi-color designs without the heavy reliance on pretreatments. Direct-to-film printing enables efficient production for small runs or single-item orders, since you’re not dependent on pre-made garment stock and can apply the transfer to many fabric types.

DTG, by contrast, prints directly onto the fabric and can deliver ultra-soft hand and fine detail on suitable fabrics—especially light-colored cotton. However, DTG sensitivity to fabric type, color, and pretreatment needs can limit its versatility and cost for certain projects. For many designers and printers, DTF transfers offer a practical balance of color fidelity, durability, and cost, making them an excellent choice when you need durable graphics on a variety of fabrics and want to optimize for small runs and rapid prototyping.

When deciding between the two, consider the project’s fabric mix, color complexity, and wash expectations. If you’re aiming for bold, long-lasting graphics across diverse textiles with relatively straightforward production, printing DTF on fabrics can deliver reliable results with a lower risk of color shifting, while adhesive powder for DTF helps secure a durable bond that stands up to washing. In many scenarios, DTF transfers provide the best combination of durability, efficiency, and market flexibility.

Frequently Asked Questions

DTF vs DTG: Which method is better for durable, high-quality graphics on fabrics?

DTF transfers offer versatile use across cotton, blends, and even some synthetics, with durable bonds and strong color vibrancy that hold up to washing. They excel for multi-color designs without extensive color separations and pair well with adhesive powder for reliable transfers. DTG can deliver an ultra-soft hand on compatible fabrics, especially light-colored cotton, but it may require pretreatment and is more sensitive to fabric type. For many brands and designers, DTF transfers provide a practical balance of durability, cost, and production flexibility, especially when printing DTF on fabrics for short runs or bold graphics.

How does adhesive powder for DTF contribute to durable transfers, and what are the essential steps in the direct-to-film printing workflow?

Adhesive powder is the key that melts under heat to bond the ink on the PET film to the fabric, delivering a durable, wash-fast transfer. The direct-to-film printing workflow typically includes design prep, printing on PET film (often with a white ink base for dark fabrics), powder application, curing the powder, transferring with a heat press, and peeling the film after cooling. Proper curing, even powder application, and correct transfer parameters are essential for durable DTF transfers across a range of fabrics.

| Topic | Key Points |

|---|---|

| What are DTF transfers? | Direct-to-film transfers are a textile decoration method where designs are printed on PET film using fabric inks, then bonded to fabric with adhesive powder during heat application. They enable vibrant color, good color accuracy, and a relatively soft hand, even for complex multi-color graphics across many fabrics. |

| Direct-to-Film printing: core technology | Printing is done on a PET film with inks optimized for textiles; a white ink underbase is common for on-dark fabrics. After printing, adhesive powder is applied and melted during heat/press to transfer the image to fabric, yielding a durable bond across a wide range of fabrics. |

| DTF vs DTG: which is right for you? | DTF offers versatility across cotton, blends, and polyesters, a strong durable bond, excellent multi-color performance, and lower minimums for small runs. DTG excels in ultra-soft hand and high detail on light-colored cotton but can be more sensitive to fabric type and pretreatment. For many designers, DTF balances color fidelity, durability, and cost. |

| The DTF printing process: overview | Core steps include design at high resolution, printing onto PET film with a white underbase, powder application and curing, transferring with heat and pressure, and peeling to reveal the final graphic. The process yields a durable, color-stable transfer across fabrics. |

| Materials, equipment, and setup | Key items: DTF-capable printer or pigment system, PET transfer films, textile inks with a white underbase, adhesive powder, heat press, curing setup, and fabrics (cotton, blends, some synthetics) suitable for DTF. |

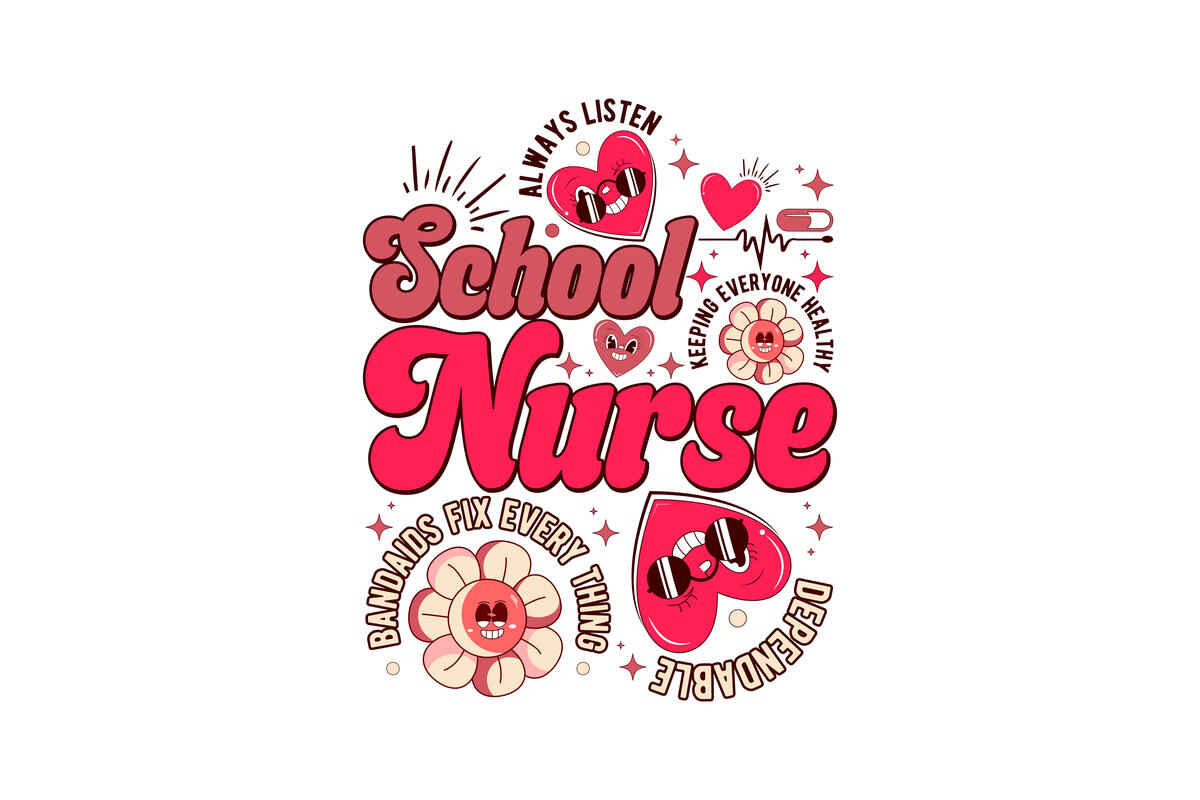

| Best practices for bold, durable graphics | Design at high resolution (300–600 dpi); use a white layer on dark fabrics; apply adhesive powder evenly; cure powder properly; use correct transfer parameters for the fabric; align the print accurately; allow the bond to set after transfer. |

| Care and maintenance | Turn garments inside out, wash on gentle cold/warm cycles, avoid high heat and harsh detergents, line-dry when possible, and follow manufacturer guidance for drying and ironing to maximize longevity of the print. |

| Common issues and troubleshooting | Cracking/peeling: verify curing and heat times; dull colors: check white underbase and color calibration; sticky feel: adjust adhesive powder; inconsistent adhesion on dark fabrics: adjust underbase and transfer parameters. |

| Applications and real-world use cases | DTF transfers are used for custom apparel, promotional items, and event merchandise—T-shirts, hoodies, bags, athletic wear—offering rapid prototyping, cost-effective short runs, and bold, durable graphics across fabrics. |

Summary

This HTML table summarizes the core concepts of DTF transfers, the technology behind direct-to-film printing, how DTF compares with DTG, the step-by-step workflow, required materials, best practices, care tips, common issues, and practical applications for bold, durable graphics on fabrics.