DTF transfers and sustainability: Eco-friendly printing

DTF transfers and sustainability are reshaping how brands approach apparel customization, blending vibrant designs with responsible production, smarter material sourcing, and transparent supply chains that can be measured against clear environmental targets. As fashion labels seek durable, eye-catching graphics and fast turnaround, eco-minded operations can cut waste, conserve energy, reduce water usage, and lower emissions across the entire workflow—from design room to finished product—and provide traceable data on energy and water use. Choosing the right inks, films, and powders matters, and deliberate material choices can dramatically reduce environmental footprint while preserving color fidelity, wash durability, and the versatility to decorate a wide range of fabrics across textiles from cotton to performance blends, ensuring compatibility with care instructions and consumer expectations. A proactive focus on end-of-life options, supplier transparency, and certified fabrics helps ensure that the production cycle aligns with broader sustainability goals, while enabling brands to communicate responsible practices to customers without compromising quality. In this evolving landscape, this concept serves as a practical anchor for innovation, accountability, and scalable solutions that translate creative vision into products that respect people and the planet.

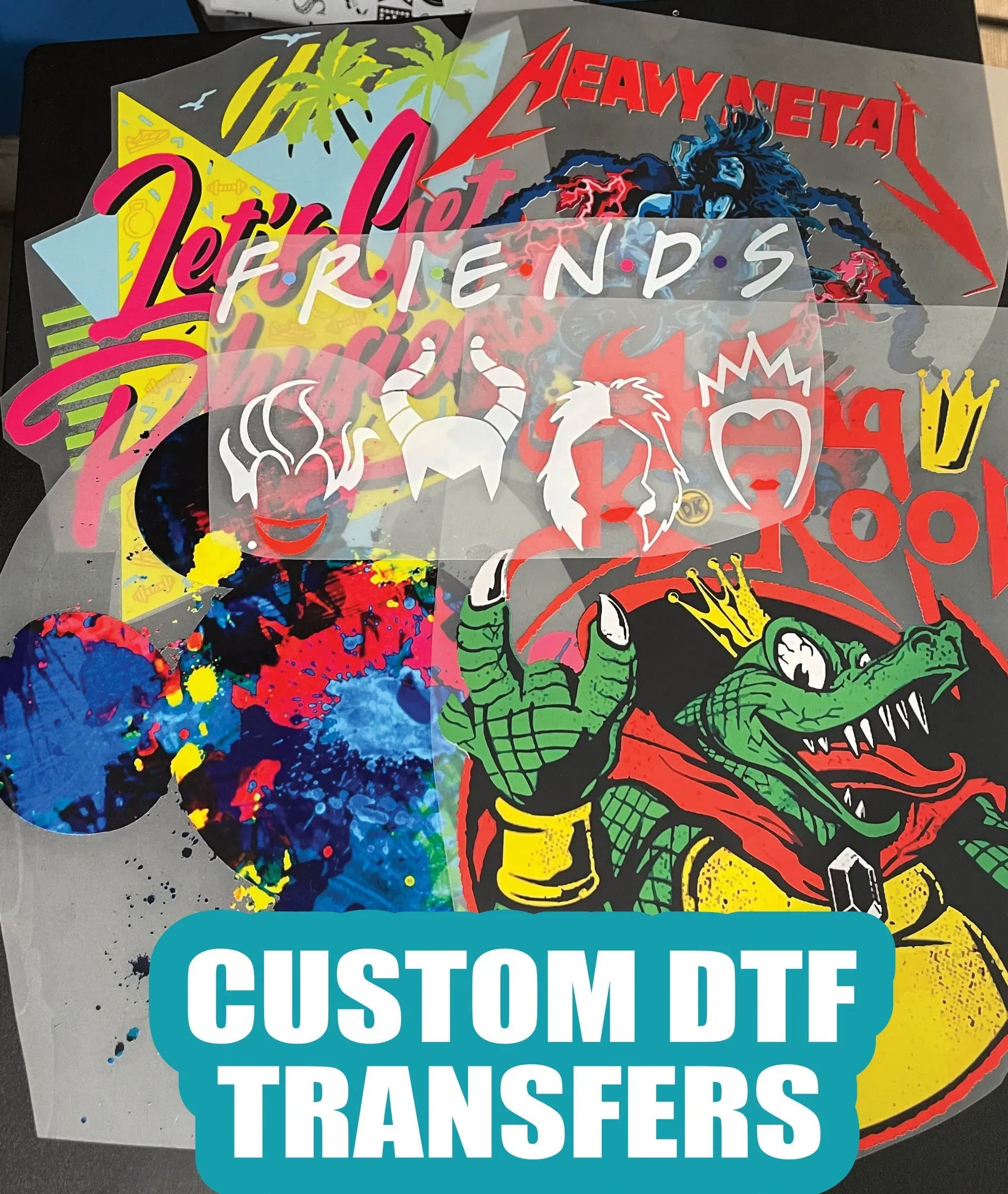

Direct-to-film transfers, also known as film-based textile decoration, offer a flexible pathway for decorating a wide range of fabrics with precise color and texture. In LSI terms, this method relates to digital textile printing and other film-based decoration concepts, helping search engines connect it with sustainability, production technology, and transparent supply chains. Viewed through a sustainability lens, the approach benefits from optimized workflows, careful energy budgeting, and mindful end-of-life considerations for films and powders. As brands compare options, they weigh durability, wash performance, and integration with lifecycle thinking to build trust with customers and partners over time.

DTF transfers and sustainability: Aligning high-quality prints with eco-conscious practices

DTF transfers enable vibrant, durable designs across a wide range of fabrics, offering flexibility for brand customization. However, the environmental footprint of this process hinges on material choices, energy use, and end-of-life options. By embracing eco-friendly printing principles—such as water-based inks where performance permits and energy-efficient curing—brands can preserve print quality while lowering VOC emissions and reducing energy consumption.

Choosing recyclable materials in printing—transfer films, adhesives, and compatible packaging that can be recycled or repurposed—reduces plastic waste and supports circular economy goals. Implementing a lifecycle perspective helps brands assess the entire path from design to end-of-life, identifying opportunities to cut waste, lower emissions, and optimize resource use.

Responsible production fashion emerges when brands demand transparency from suppliers and seek environmental data, certifications, and clear end-of-life options. By prioritizing responsible production fashion, companies align their creative ambitions with ethical practices that protect people and the planet.

Eco-friendly printing strategies for apparel: integrating water-based inks, recyclable materials in printing, and responsible production fashion

Adopting water-based inks where performance permits reduces VOCs, eases disposal, and supports eco-friendly printing. When combined with optimized curing temperatures and shorter cycle times, these choices help lower energy use while maintaining wash durability and color fidelity.

Using recyclable materials in printing for films, powders, and packaging minimizes long-term waste. Implementing take-back programs with suppliers and designing layouts that maximize material efficiency further reduces misprints and scrap, contributing to a more circular production model.

A lifecycle approach, paired with supplier transparency and certifications such as OEKO-TEX or bluesign, supports responsible production fashion. This broader view helps brands balance creative goals with environmental and social performance across the product’s life cycle.

Frequently Asked Questions

How do DTF transfers support sustainability in eco-friendly printing for apparel?

DTF transfers support sustainability when combined with water-based inks and recyclable materials in printing. Use water-based inks to lower VOCs and simplify disposal, choose recyclable transfer films or those with take-back programs to reduce plastic waste, and optimize curing and layouts to minimize energy and material use. A lifecycle approach with transparent supplier data and sustainable fabrics completes the eco-friendly DTF workflow.

What steps can brands take to ensure responsible production fashion when using DTF transfers?

To ensure responsible production fashion with DTF transfers, brands should use water-based inks and low-VOC formulations, favor recyclable or responsibly sourced films, and audit workflows to reduce waste and energy. Partner with suppliers that publish environmental data and third-party certifications (e.g., OEKO-TEX, bluesign), select fabrics with sustainability certifications, and use recyclable packaging. Report progress to customers and pursue continuous improvement through pilot programs and supplier scorecards.

| Key Point | Summary |

|---|---|

| Impact and opportunity | DTF transfers and sustainability shape the future of apparel customization by balancing vibrant designs with reduced environmental impact. |

| Environmental footprint factors | Ink type, transfer film/adhives, energy efficiency, fabric/dye compatibility, and waste handling determine overall footprint. |

| Eco-friendly options | Water-based inks when suitable, recyclable/reusable films, minimizing waste, low-impact adhesives, optimized curing, sustainable fabrics and packaging, lifecycle thinking. |

| Supplier and production responsibility | Seek transparent data and certifications (OEKO-TEX, bluesign); packaging/logistics efficiency; end-of-life options; energy disclosures. |

| Measurement and lifecycle | Track material usage, waste, energy per hour; consider life-cycle assessments for emissions, water use, and resource depletion. |

| Practical steps for brands | Audit processes, supplier scorecards, pilot eco-options, staff training, communicate sustainability, continuous optimization. |

| Future trends | Bio-based films, better water-based inks, improved recyclability; stay informed and collaborate with suppliers. |

Summary

Conclusion: DTF transfers and sustainability guidance