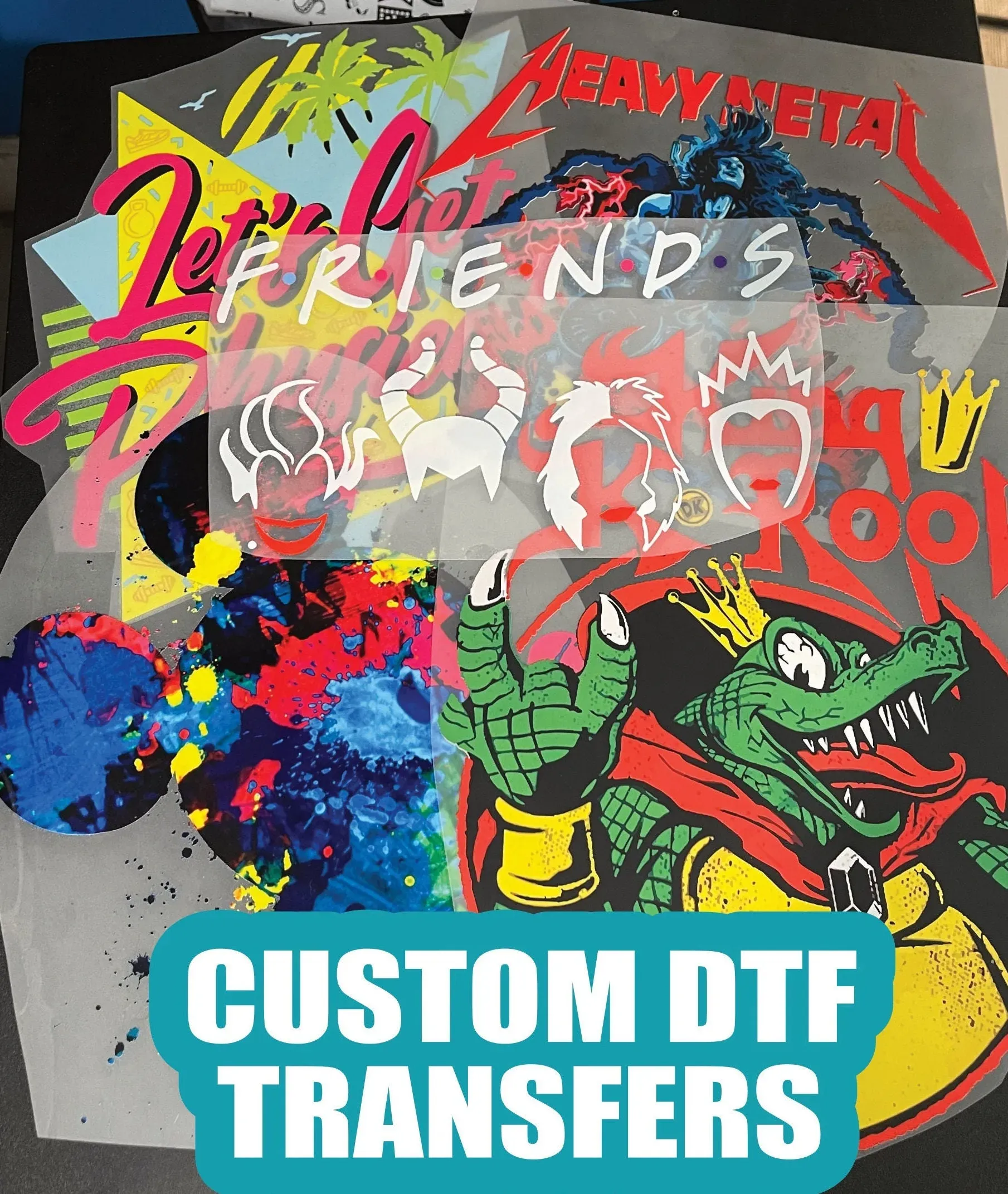

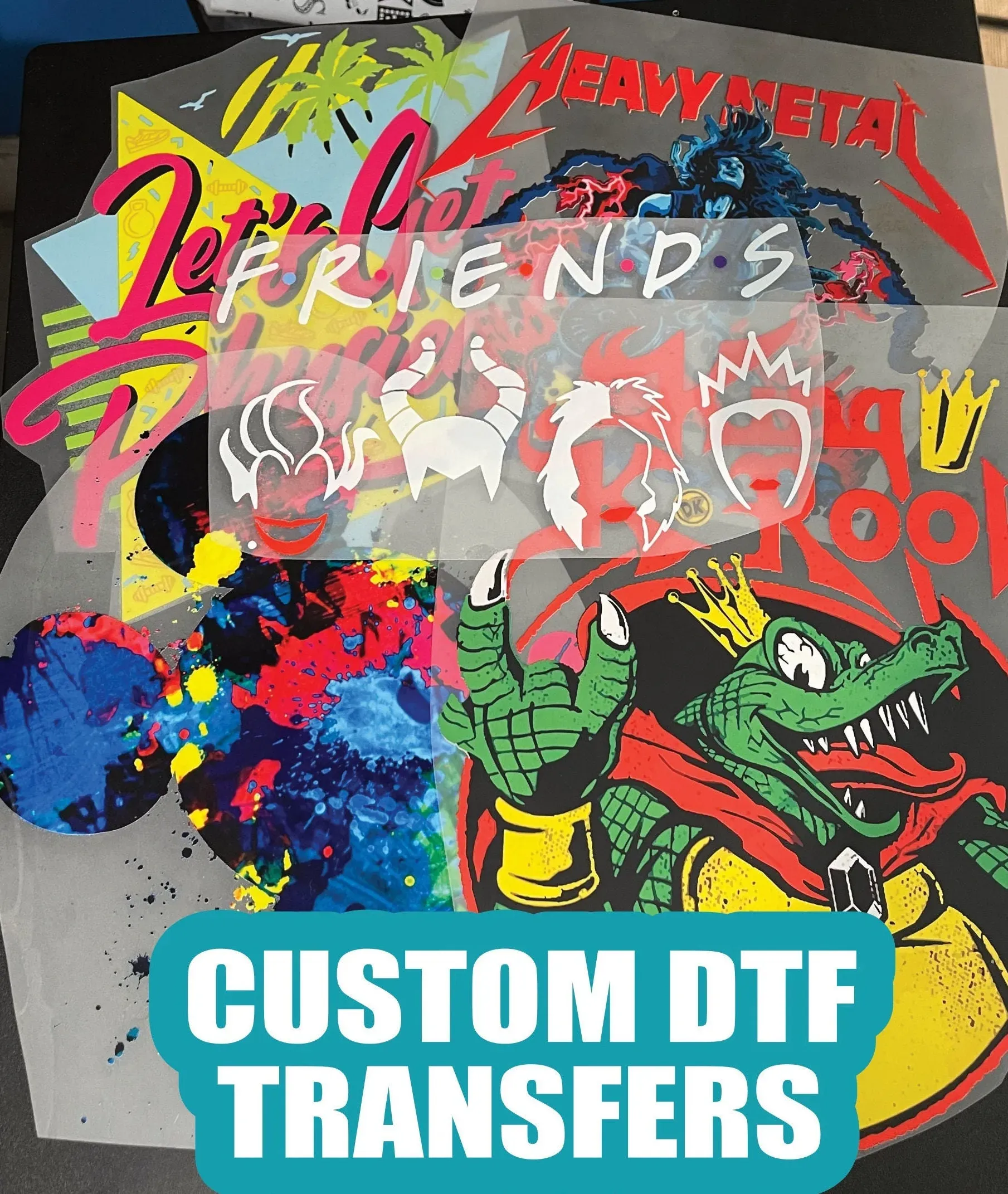

DTF Transfers: Common Myths Debunked You Must Know

DTF Transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel printing landscape with their remarkable efficiency and ability to create vibrant, long-lasting designs. This innovative method allows users to print stunning images onto special film, which can then be transferred onto various fabrics using heat, making it a versatile option for different projects. However, the growing popularity of DTF printing has led to some common myths and misconceptions that often mislead those looking to explore this exciting technology. In this blog, we will debunk these printing myths surrounding DTF technology, ensuring you have the accurate information needed to appreciate its true potential. Understanding the difference between DTF vs. DTG is key in navigating your custom printing options and making informed decisions.

Direct-to-Film transfers, also known as DTF technology, represent a cutting-edge advancement in the realm of apparel customization. As a unique alternative to traditional methods like Direct-to-Garment printing, DTF enables the transfer of intricate designs onto fabric with striking colors and durability. Frequently, people confuse DTF with other printing techniques, potentially overlooking its capabilities. This blog will shed light on the facts behind DTF printing, clarifying misunderstandings and illustrating why it’s an exceptional choice for custom apparel printing. By exploring the advantages and dispelling prevalent myths, we aim to provide clarity and insight into this transformative printing method.

The Advantage of DTF Technology in Custom Apparel Printing

Direct-to-Film (DTF) technology has revolutionized the custom apparel printing industry by providing a method that combines flexibility and efficiency. Unlike traditional methods, DTF transfers can be applied to a wide range of materials, including both light and dark fabrics, thanks to the unique application of a white ink underbase. This versatility allows printers to produce vibrant designs without being limited by the color of the fabric, thereby enhancing the creative possibilities for businesses and designers alike.

Moreover, DTF technology offers significant cost advantages over other printing methods. While the initial investment may seem steep, the ability to print intricate designs quickly and with minimal waste leads to lower costs per item in the long run. As businesses switch to DTF printing, they find themselves not only able to deliver high-quality, durable prints but also meeting the increasing demands of their customers without sacrificing profit margins.

Separating DTF Printing from DTG: What You Need to Know

A prominent misunderstanding in the printing community is that Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing are synonymous. While both techniques are designed for custom apparel printing, their applications and results differ significantly. DTF printing employs a film transfer system, allowing for designs to be printed on various substrates, while DTG directly injects ink onto the garment, primarily favoring lighter fabrics. This distinction is crucial for businesses aiming to optimize their production strategies based on fabric type and design complexity.

Understanding the differences between DTF and DTG also informs the choice of technology for specific print jobs. DTF excels when dealing with intricate artwork or bold designs that require a robust base, regardless of the fabric color. In contrast, DTG may be more suited for simple, high-resolution images on compatible materials. As more companies explore these methods, knowledgeable decisions can lead to improved product offerings and customer satisfaction.

Debunking the Myth: DTF Transfers Are Not Durable

Contrary to popular belief, DTF transfers are remarkably durable when applied properly. Many critics argue that transfers lack longevity, especially when compared to traditional screen printing or DTG printing. However, DTF technology has proven its ability to withstand rigorous washes and everyday wear, providing customers with high-quality prints that maintain their vibrancy and integrity over time. By selecting top-notch materials and following correct application processes, businesses can achieve outstanding durability that aligns with customer expectations for longevity.

The misconception around durability often arises from improper application or low-quality inks. DTF transfers, when executed with care, can rival even the most traditional methods, making them a reliable choice for both personal and commercial applications. This durability not only serves consumer interests but also enhances brand reputation as businesses repeatedly deliver quality products that stand the test of time.

Cost Considerations: Is DTF Printing Worth the Investment?

Many prospective users shy away from DTF printing due to concerns that its implementation may be cost-prohibitive. It is important to recognize that while the initial setup costs may be higher than traditional methods, the long-term savings derived from reduced print costs and increased operational efficiency often justify the expense. DTF printing minimizes waste and maximizes output, providing a financially sensible option as businesses scale their operations and handle bulk orders effectively.

As the technology continues to evolve and the market becomes more competitive, prices associated with DTF equipment and materials are likely to decrease further. This upward trend in affordability makes DTF a more attractive option for new entrants into the custom apparel sector, enabling them to offer high-quality prints without an exorbitant price tag that could deter customers.

Exploring Complex Designs: The Strength of DTF Transfers

One of the strongest selling points of DTF printing lies in its exceptional ability to reproduce complex designs with intricate details and vivid colors. Many assume that only simple graphics can be executed well through this method, but DTF technology has advanced to a point where it can handle everything from detailed logos to fine photographic images. This capability makes it a prime choice for designers seeking to push creative boundaries and make a lasting impression.

Furthermore, DTF transfers can produce unique textures and finishes that are often unattainable through other methods. By utilizing the right inks and films, businesses can create stunning visual effects that enhance the overall appeal of their products, setting them apart in a saturated market. The possibilities and creative power offered by DTF printing represent a significant opportunity for any company looking to raise its profile through custom apparel.

Common DTF Printing Myths: Setting the Record Straight

In the realm of DTF printing, a slew of misconceptions persists that can cloud potential users’ understanding of its capabilities. One such myth is the belief that DTF is unsuitable for all types of fabric, particularly darker colors. In fact, DTF technology utilizes a white ink underbase to achieve stunning color vibrancy on any material. By dispelling this myth, printers can better appreciate the versatility that DTF offers for both bold and subtle designs across various fabric types.

Another myth that needs to be addressed is the belief that DTF transfers are not cost-effective compared to other printing methods. In reality, when considering the efficiency and longevity offered by DTF printing, businesses often find that they can maintain better margins while delivering high-quality products. By examining these prevalent myths, those interested in custom apparel can make more informed choices and understand the full potential of DTF technology.

Frequently Asked Questions

What is the difference between DTF transfers and DTG printing?

DTF transfers, or Direct-to-Film printing, differ from DTG (Direct-to-Garment) printing in that DTF involves printing designs onto a film which is then heat transferred to fabric, while DTG prints directly onto the garment. DTF is versatile and suitable for a wider range of fabrics and colors.

Can DTF transfers be applied to dark fabrics?

Yes, DTF transfers can be applied to both light and dark fabrics thanks to the incorporation of a white ink underbase. This feature ensures vibrant colors are achievable on all fabric types, expanding the creative possibilities for custom apparel.

Are DTF transfers durable for long-term wear?

DTF transfers can be highly durable when applied correctly. They are designed to withstand multiple washes without fading or cracking, making them a reliable choice for both personal and commercial custom apparel printing.

Is DTF printing more cost-effective than other printing methods?

While the initial investment in DTF printing equipment may be higher than some methods, it offers long-term cost efficiency. DTF printing reduces waste and provides lower costs per print, especially as technology improves and prices decrease.

Can DTF printing handle complex designs effectively?

Absolutely! DTF printing excels in reproducing intricate details and vibrant colors, making it ideal for complex designs such as photographs and detailed logos. This capability sets it apart as a preferred choice for custom apparel.

What are some common myths about DTF technology?

Common myths about DTF transfers include the beliefs that they are only for light fabrics, lack durability, or are too expensive. In reality, DTF printing is versatile enough for various fabric types, offers durability, and can be cost-effective in the long run.

| Myth | Explanation | Truth |

|---|---|---|

| DTF Printing is the Same as DTG Printing | DTF and DTG are different processes. | DTF uses a film for transfers, accommodating various fabric types. |

| DTF is Only for Light-Colored Fabrics | DTF cannot be used on dark fabrics. | DTF technology can print vibrant designs on both light and dark textiles. |

| DTF Transfers are Not Durable | DTF prints fade easily after washes. | DTF transfers are durable and withstand multiple washes. |

| DTF is More Expensive Than Other Methods | DTF printing has higher initial costs. | Long-term efficiency in DTF reduces overall costs. |

| Complex Designs are Not Possible | DTF cannot reproduce intricate designs. | DTF excels in printing detailed graphics and photographs. |

Summary

DTF Transfers have revolutionized the custom apparel printing industry, providing a powerful method for creating vibrant and durable designs. By debunking the myths surrounding DTF transfers, we highlight their unique advantages over traditional methods, such as their ability to print on both light and dark fabrics, the durability of prints, and the accommodating nature of intricate designs. As more businesses and individuals explore the possibilities offered by DTF technology, it’s clear that these transfers are a forward-thinking choice for innovative design in custom apparel.