DTF Transfers: Expert Tips for Professional Results

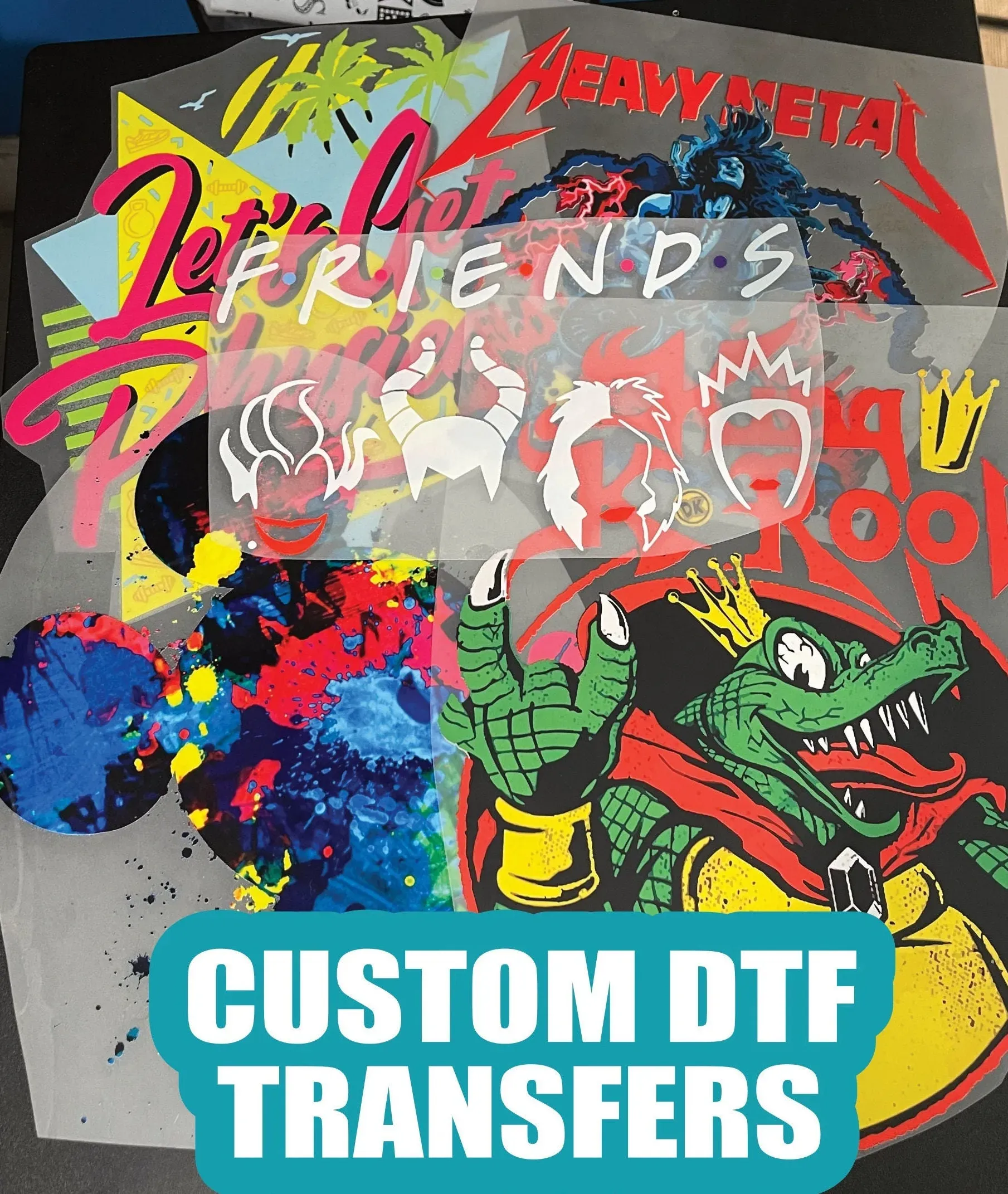

DTF transfers are revolutionizing the world of apparel decoration with their innovative approach to printing. This cutting-edge DTF printing technology offers a reliable and efficient DTF heat transfer solution for producing high-quality garments. As the demand for professional apparel decoration continues to rise, understanding the intricacies of DTF transfers becomes increasingly essential. Whether you’re creating custom designs for a small business or a large-scale operation, mastering this garment printing technology can set you apart from the competition. In this guide, we will share expert tips to help you achieve stunning and durable results using DTF transfers.

In the realm of garment printing, the direct-to-film methodology is gaining traction as a favored choice among professionals. This printing technique, also known as DTF printing, allows for the seamless application of intricate designs onto various fabrics using heat transfer solutions. With the emergence of highly effective products like Insta DTF, creatives can now achieve exceptional vibrancy and detail with their prints, catering to a discerning client base. Whether you’re involved in custom apparel production or promotional merchandise, embracing the advantages of DTF transfers can significantly enhance your capabilities in the competitive landscape of apparel decoration. Get ready to unlock the potential of this innovative technology!

The Significance of Material Selection in DTF Printing

Choosing the right materials is fundamental to achieving superior results in DTF printing. High-quality transfer films and inks directly influence the final product’s vibrancy and durability. For instance, utilizing premium DTF films ensures that the inks adhere properly to various fabric types, providing a consistent finish while avoiding peeling or cracking. Therefore, investing in high-grade materials is not just a recommendation but a necessity for achieving professional apparel decoration.

Moreover, different fabrics behave differently when subjected to DTF transfers. Natural fibers like cotton may require different films than synthetic blends. By tailoring your material selection to the specific needs of your projects, you can maximize the effectiveness of your DTF heat transfer solutions, which ultimately enhances the quality of your finished garments.

Fine-Tuning Printer Settings for Optimal DTF Results

The settings on your DTF printer can drastically affect print quality. Adjusting the resolution to its highest setting captures the fine details of your designs, resulting in vibrant images that effectively reflect your creative vision. Additionally, experimenting with print speed can reveal optimal settings suited for your specific fabrics and designs, particularly for intricate patterns that require more time to print.

Regular maintenance of your printer is equally important to sustain high-quality results in DTF printing. Frequent cleaning and servicing of equipment ensure that print heads perform efficiently, reducing the likelihood of issues like color streaking or incomplete prints. By mastering your printer settings and keeping your equipment in top shape, you can elevate your garment printing technology standards.

Mastering Heat Pressing Techniques for DTF Transfers

Heat pressing is a pivotal stage in the DTF transfer process, dictating how well the film adheres to the fabric. Ensuring the correct temperature and pressure is crucial; deviations can lead to poor adhesion or print quality. Familiarize yourself with manufacturer guidelines tailored to each fabric type—this knowledge is invaluable for consistent and reliable results in your professional apparel decoration projects.

Additionally, pre-heating garments helps in preparing the fibers to bond better with the DTF film. Utilizing protective sheets during pressing prevents damage to the prints and contributes to achieving a flawless finish. Understanding these nuances of heat pressing can significantly enhance your output quality in DTF printing.

The Importance of Proper Curing in DTF Printing

Curing your DTF prints adequately is essential for durability and longevity. If prints aren’t fully cured, they may degrade quickly, especially after washing. Always allow your prints to cool after heat pressing; this cooling period allows the fabric fibers to set around the transfer, solidifying the bond. Some experts recommend a secondary heat cycle for increased security, ensuring that your prints withstand the test of time.

Testing the wash durability of sample garments can validate your curing process. By subjecting your DTF prints to washes, you can gauge their longevity and make necessary adjustments to your techniques. This systematic testing is a great way to ensure that your quality meets professional standards, making your clients happy and securing repeat business.

Staying Ahead with Innovations in DTF Technology

The DTF printing landscape is constantly evolving, with new technologies and solutions being developed regularly. Staying informed about the latest innovations, such as the Insta DTF system, can offer significant advantages, enhancing both quality and efficiency in your printing processes. Regularly engaging with industry resources, including webinars and forums, can help you stay updated and improve your overall operations.

Adopting cutting-edge solutions and techniques not only boosts the quality of your apparel decoration but also positions your business as a leader in the DTF printing market. Embracing technology ensures that your skills and processes remain relevant and can help in expanding your service offerings, appealing to a wider audience.

Getting the Most from Your DTF Heat Transfer Solutions

To maximize the efficacy of your DTF heat transfer solutions, understanding the interplay between inks and substrates is pivotal. Certain inks perform better on particular materials; for example, water-based inks might yield better results on cotton than on polyester. Testing different combinations can lead to discovering optimal settings that let you achieve remarkable clarity and brilliance in your designs.

Regular assessment of ink compatibility and output quality also keeps your production standards high. Many users of Insta DTF products report enhanced satisfaction due to its versatility across fabric types, broadening the scope for creative applications. Leveraging these insights can lead to effective use of your resources, enabling you to create striking prints that stand out in a competitive market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a popular method in professional apparel decoration where designs are printed onto a special transfer film using DTF printing technology. These films are then heat-pressed onto fabrics, allowing for vibrant colors and detailed designs that adhere well to various materials.

What makes DTF printing a preferred choice for garment decoration?

DTF printing is favored for its ability to produce high-quality, durable prints that maintain their vibrancy through multiple washes. This DTF heat transfer solution provides flexibility across different fabric types and is easier to use compared to traditional methods such as screen printing.

How can I achieve professional results with DTF transfers?

To achieve professional results with DTF transfers, focus on selecting high-quality films and inks, fine-tuning your printer settings, and optimizing your heat pressing technique. Ensuring proper curing of the prints after application is also crucial for durability.

What are the key factors in selecting materials for DTF transfers?

When selecting materials for DTF transfers, it’s essential to choose compatible films and inks that meet professional standards. High-quality materials enhance adhesion, reduce issues like peeling or fading, and ultimately influence the longevity of your prints in garment printing technology.

How does the Insta DTF heat transfer solution improve the printing process?

The Insta DTF heat transfer solution enhances the DTF printing process by providing advanced compatibility with various fabric types, resulting in better print quality and efficiency. It simplifies the process for users, allowing for seamless application in professional apparel decoration.

What maintenance is required for printers used in DTF printing?

Regular maintenance for printers used in DTF printing includes cleaning the print heads, adjusting printer settings for optimal resolution and speed, and performing routine checks to ensure consistent quality. Proper maintenance is essential for achieving the best results with DTF transfers.

| Key Aspect | Description |

|---|---|

| Introduction | DTF transfers are revolutionizing the apparel decoration industry, making professional results accessible. |

| Understanding DTF Transfers | DTF involves printing designs on a transfer film that is then applied to fabric with heat and pressure, enabling vibrant colors and details. |

| Expert Tips | Key recommendations include: material selection, fine-tuning printer settings, optimizing heat pressing, ensuring proper curing, and keeping up with innovations. |

| Material Selection | Choose high-quality films and inks to enhance durability and avoid issues like peeling or fading. |

| Printer Settings | Adjust the resolution and speed settings; clean printer regularly for consistent quality. |

| Heat Pressing Technique | Set accurate temperature and pressure, pre-heat garments, and use sheets to protect prints. |

| Proper Curing | Allow prints to cool and test durability through washing. |

| Stay Updated | Regularly learn about new DTF technologies and techniques to improve production quality. |

Summary

DTF transfers are a transformative method in the garment printing industry, allowing for high-quality and durable prints with ease. By meticulously choosing materials, fine-tuning your equipment, and following best practices such as proper heat pressing and curing, you can achieve professional results. The rapid evolution of DTF technology continues to enhance the capabilities of printers across the industry. For garment decorators looking to stay competitive, embracing innovations like the Insta DTF heat transfer solution is critical for maximizing quality and efficiency. By applying these expert tips, anyone can elevate their printing process to achieve remarkable DTF transfers.