DTF Transfers Explained: Create Vibrant Designs with Ease

DTF Transfers have emerged as a groundbreaking technique in the realm of custom apparel, providing a seamless solution for achieving vibrant designs that capture attention. This innovative process, known as Direct-to-Film transfers, has transformed how designers and entrepreneurs approach fabric printing. By using advanced DTF printing technology, creators can easily apply intricate and colorful graphics onto various materials, making it an ideal choice for businesses seeking high-quality outputs. The versatility of DTF heat transfer not only enhances creativity but also ensures durability, making prints that last through multiple washes. If you’re in the market for a reliable printing solution, the Procolored DTF Printer P13 stands out as an excellent option for producing professional-grade designs right from your home.

The world of fabric printing is witnessing a dynamic shift with the introduction of DTF Transfers, also known as Direct-to-Film transfers. This advanced method allows for the direct application of bright, eye-catching graphics onto textiles, ensuring that custom apparel stands out in a competitive market. Unlike traditional methods, the DTF printing process is efficient and adaptable, specifically designed to produce stunning visuals that are both long-lasting and vibrant. The recent advancements in technology, including the Procolored DTF Printer P13, have made it easier than ever for both experienced professionals and newcomers to create high-quality prints that meet diverse needs. Whether you’re launching your own clothing line or enhancing branding efforts, DTF heat transfer techniques offer an exciting way to elevate your designs.

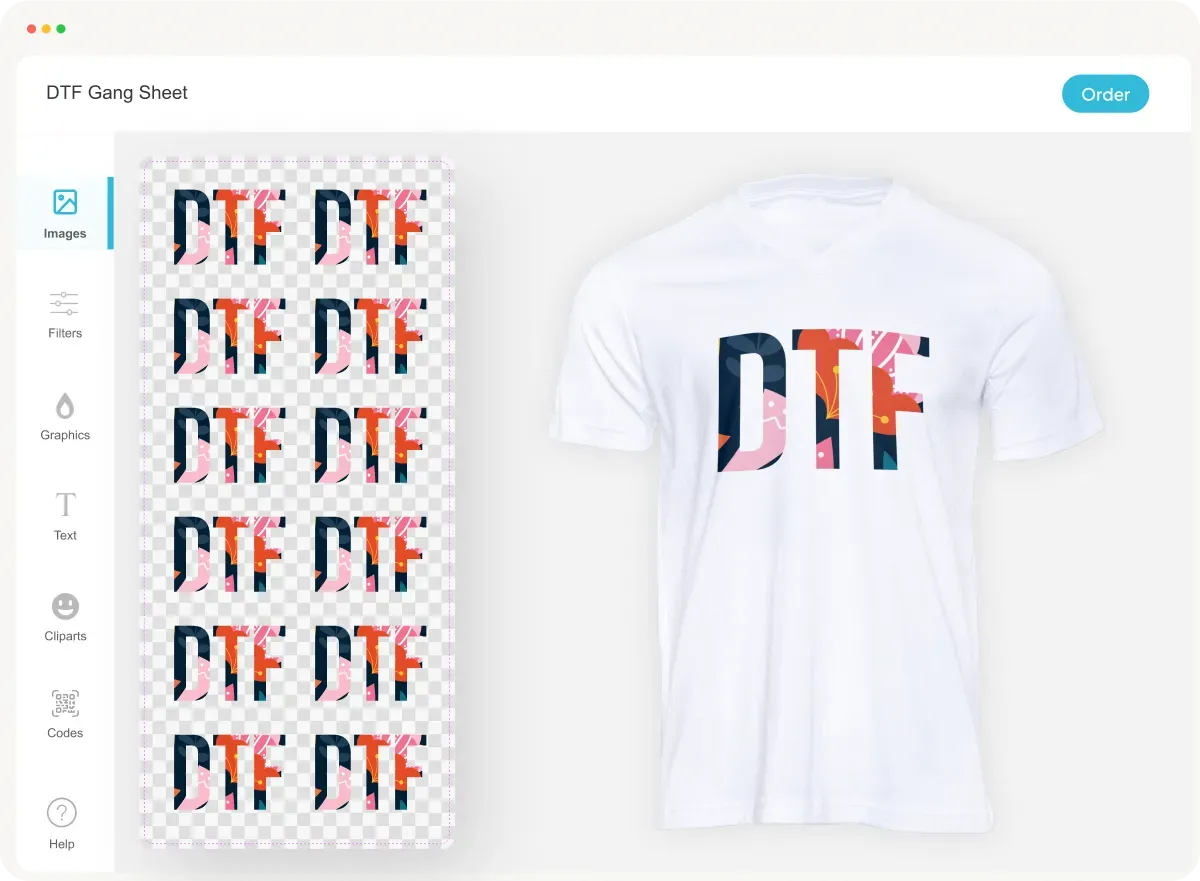

1. Understanding the DTF Printing Process

DTF printing is a groundbreaking technique that simplifies the transfer of vibrant designs onto various fabric types. The process begins with creating a digital design that can captivate anyone’s attention. High-resolution graphics are crucial here, as they determine the overall quality of the final print. Utilizing programs like Adobe Illustrator or CorelDRAW allows creators to manipulate colors and details effectively. Once your design is complete, it’s printed onto a special film, which is critical in transferring those intricate details to fabric.

After printing, the design undergoes a process where adhesive powder is applied to the wet ink on the film. This adhesive helps the design to bond firmly with the fabric when heat is applied. The entire procedure is not only straightforward but also highly effective, enabling the production of durable, vibrant prints. Hence, understanding each step of DTF printing is essential for achieving stunning results and elevating the quality of custom apparel.

2. The Advantages of Using DTF Transfers for Custom Apparel

DTF transfers present several advantages that make them ideal for custom apparel production. First and foremost, the vibrant colors achievable through DTF printing stand out significantly in the marketplace. Unlike traditional methods, DTF technology allows for deep, rich colors and detailed designs that appeal to customers. This vibrant output makes it a popular choice for merchandise, promotional items, or personal projects, ensuring that they grab attention.

Besides aesthetic appeal, DTF transfers are celebrated for their durability. Prints resist fading and maintain their integrity after multiple washes, making them perfect for everyday wear. This durability guarantees customer satisfaction and returns on investment for businesses, as they can trust the quality of their products. With DTF printing, the combination of vibrant designs and long-lasting results cements its place as a go-to option for custom apparel.

3. Innovations in DTF Technology: The Procolored DTF Printer P13

The recent surge in DTF technology has led to innovative products like the Procolored DTF Printer P13, specifically designed for both home-based entrepreneurs and established businesses. Launched recently, this printer enhances the capabilities of users to produce stunning and vibrant prints with ease. The Procolored DTF Printer P13’s user-friendly features make it an attractive option for those new to DTF printing, while its efficiency caters to seasoned creators seeking high-quality results.

Moreover, the Procolored DTF Printer P13 highlights the growing trend towards accessible, high-quality printing solutions. It combines affordability with performance, making it an invaluable tool for anyone looking to create bespoke designs. Users can efficiently produce a variety of prints, driving creativity in the custom apparel market. Innovations like this pave the way for even broader applications of DTF transfers across different sectors.

4. Cost-Effectiveness of DTF Transfers Compared to Traditional Methods

One of the most significant advantages of DTF transfers is their cost-effectiveness, especially when comparing them to traditional screen printing techniques. Traditional screen printing often involves high setup costs, which can become a barrier for small businesses and home-based creators. In contrast, DTF printing minimizes these upfront costs, allowing more creators to enter the market and produce custom pieces without a substantial financial burden.

Additionally, DTF technology reduces waste associated with printing, enabling one-off or small runs without needing extensive ink and materials. This efficient utilization of resources appeals not just to cost-conscious creators but also to those who prioritize sustainability in their work. By adopting DTF transfers, businesses can achieve vibrant designs while maintaining profitability and reducing their environmental impact.

5. The Versatility of DTF Transfers Across Fabric Types

DTF transfers excel in their versatility, as they can effectively be applied to a wide range of fabric types. Unlike other printing methods that may be limited to cotton or certain blends, DTF technology allows for successful applications on materials like polyester, silk, denim, and more. This diversity opens up numerous opportunities for creators looking to explore various fashion markets or promotional products.

The ability to easily adapt DTF transfers to different fabrics makes it a game-changer for custom apparel. Entrepreneurs can tap into niche markets by offering personalized designs on unique substrates, catering to diverse consumer demands. This adaptability not only enhances creativity but also establishes a broader market presence for brands, making DTF transfers a preferred choice in today’s competitive fashion landscape.

6. Essential Tips for Mastering DTF Printing

To master DTF printing and ensure successful outcomes, there are several essential tips to keep in mind. Firstly, always prioritize high-quality materials for your prints, including transfer films and eco-solvent inks. Utilizing quality substrates ensures that the final products are both vibrant and durable, enhancing customer satisfaction and encouraging repeat business.

Additionally, performing test prints before committing to large orders can save time and resources. Testing allows creators to adjust colors and settings, ensuring that the final product meets expectations. Furthermore, understanding and setting the correct temperature and pressure for the heat press is crucial for optimal adhesion. By adhering to these tips, creators can maximize the potential of DTF transfers, producing stunning and reliable custom apparel.

Frequently Asked Questions

What are DTF Transfers and how do they compare to traditional printing methods?

DTF transfers, or Direct-to-Film transfers, utilize a unique heat transfer process to create vibrant designs directly on fabrics. Unlike traditional methods like screen printing or direct-to-garment (DTG) printing, DTF provides vibrant colors and durable prints that adhere well to various materials, making it a versatile and cost-effective option for custom apparel production.

How does the Procolored DTF Printer P13 enhance DTF printing capabilities?

The Procolored DTF Printer P13 is designed for home-based creators and entrepreneurs, allowing for efficient production of high-quality prints. Its advanced technology ensures vivid colors and sharp details, making it an excellent choice for those looking to produce custom apparel with DTF transfers.

What are the key benefits of using DTF heat transfer for custom apparel?

DTF heat transfer offers numerous benefits, including vibrant colors, durability, versatility across different fabric types, and cost-effectiveness for short production runs. This makes DTF an attractive option for custom apparel businesses, enabling them to create detailed designs that last.

What types of fabrics can I use for DTF transfers?

DTF transfers work effectively on various fabric types, including cotton, polyester, and blends. This versatility allows designers to apply vibrant DTF printing techniques to a wide range of custom apparel products, expanding their creative possibilities.

How can I ensure the best results with DTF printing?

To achieve the best results with DTF printing, use high-quality substrates, inks, and films. Conduct test prints to verify color accuracy, adjust heat press settings based on fabric type, and consider post-pressing for enhanced print durability.

What recent advancements in DTF printing technology should I be aware of?

Recent advancements in DTF printing technology include the release of the Procolored DTF Printer P13 and new DTF products from companies like Insta Graphic Systems. These innovations are focused on improving print quality, durability, and efficiency, enhancing the overall custom apparel production process.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A new technique for directly applying vibrant designs onto fabrics, using a film and heat transfer process. |

| Recent Developments | Insta Graphic Systems’ new DTF product and Procolored DTF Printer P13 enhance branding and home-based crafting. |

| How DTF Transfers Work | Involves design creation, printing on film, applying adhesive powder, curing the design, and heat transferring to fabric. |

| Benefits of DTF Transfers | Offers vibrant colors, durability, versatility, cost-effectiveness, and is ideal for home-based creators. |

| Tips for Successful DTF Printing | Use quality materials, perform test prints, adjust heat settings, and consider post-processing. |

Summary

DTF Transfers are revolutionizing the custom apparel industry by allowing creators to make vibrant designs with unmatched ease. This innovative printing method offers a blend of high-quality, durable prints and affordability, making it accessible to both professional businesses and individual creators. As DTF technology continues to evolve with new advancements, such as the latest printers enabling home-based production, the potential for stunning artistic expression is limitless. Embracing DTF Transfers can significantly enhance creative possibilities in apparel design while ensuring that designs stand the test of time in durability and visual appeal.