DTF transfers: Explained, Materials, Process & Substrates

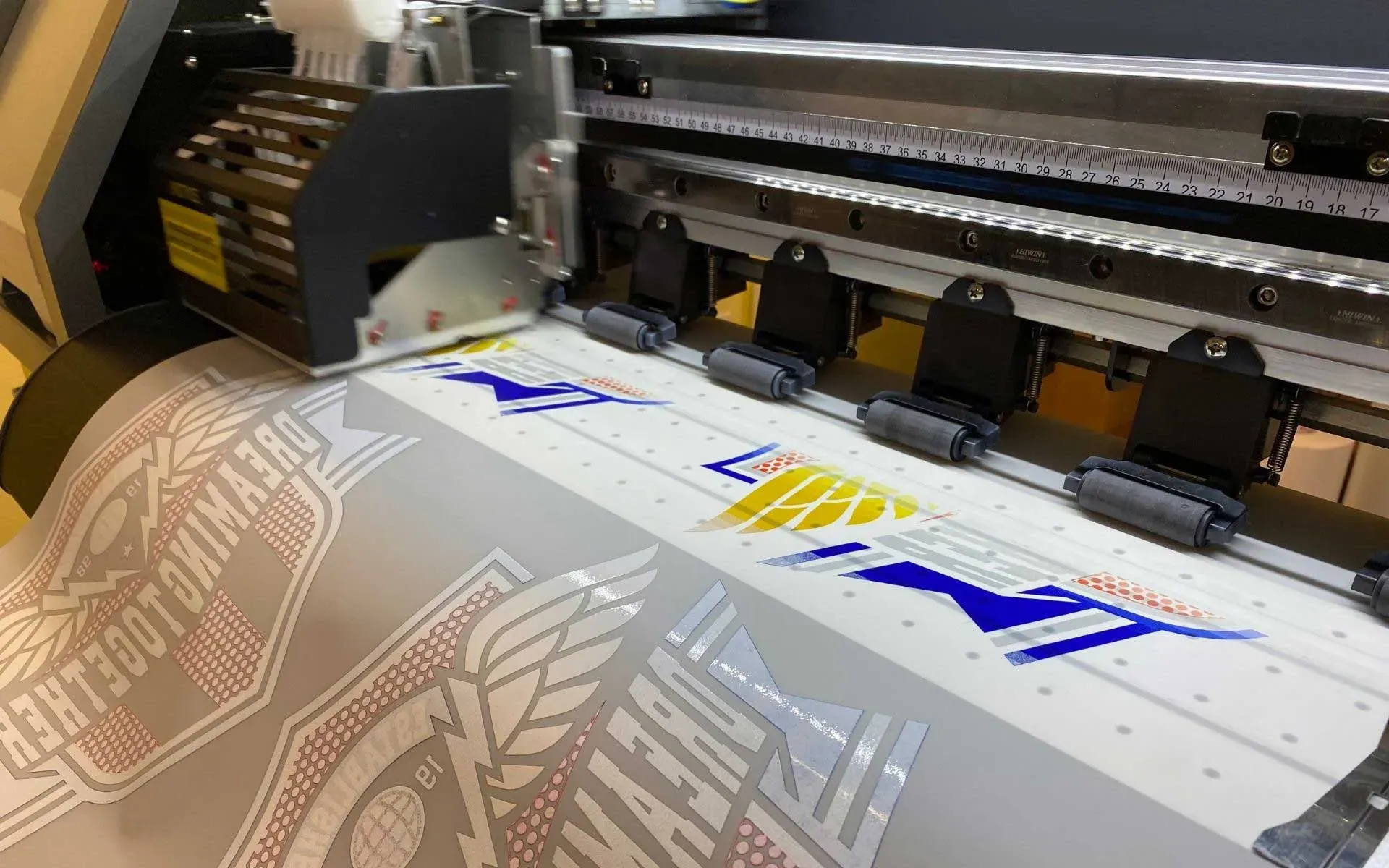

DTF transfers have emerged as a dynamic method for decorating fabrics, offering vibrant color and versatile application. The process involves printing on a specialized film, applying an adhesive layer, and using heat to transfer the design to fabric. This method delivers a soft hand and strong color fidelity across a wide range of substrates. Careful material selection and precise curing are essential for durable results and clean edges. For designers exploring new decoration options, this guide introduces the basics of the workflow and its advantages.

Think of this as a film-to-textile workflow—the DTF printing process that turns digital art into practical graphics applied with heat. Using direct-to-film transfers, artwork is prepared on a PET film, then bonded to fabrics via adhesive powder and heat. Selecting the right materials and substrates is critical, and you’ll want to consider the best substrates for DTF to balance hand feel, color, and wash durability. Equally important are the DTF transfer materials and the curing steps, which influence edge sharpness, adhesion, and longevity after repeated laundering. With this approach, designers gain flexibility across cotton, blends, synthetics, and niche textiles, making it ideal for small runs, custom orders, and multi-fabric projects. By comparing the different substrates and process options, you can tailor your workflow to your budget, timeline, and quality goals.

DTF Transfers and the DTF Printing Process: Materials, Steps, and Outcomes

DTF transfers are a modern method for decorating fabrics by printing designs onto a specialized PET film, applying an adhesive powder, curing, and then transferring the image to textiles with a heat press. This approach, also known as direct-to-film transfers, enables vibrant color reproduction and a soft hand across a wide range of fabrics. In the DTF printing process, CMYK inks are paired with a white ink layer to ensure opacity on dark substrates, enhancing detail and gradient fidelity.

Because the transfer sits on the surface rather than penetrating fibers, DTF transfers offer flexibility for small runs and multi-fabric projects. The DTF transfer materials—the PET film with a micro-porous coating, white ink, color inks, adhesive powder, and curing equipment—work together to form a durable bond when heat is applied. Mastery of the DTF printing process reduces issues like edge bleeding and powder clumping, contributing to predictable results across substrates.

Choosing the Best Substrates for DTF Transfers and Associated Materials

Selecting fabrics for DTF transfers requires considering fiber content, weight, and end-use care. The best substrates for DTF include 100% cotton for strong color vibrancy and reliable adhesion, as well as cotton/polyester blends that balance hand feel with durability. 100% polyester substrates can yield vivid colors and excellent wash resistance when processed with proper curing and heat settings.

Heavier materials such as canvas and other thick textiles may require adjusted temperature and pressing time to maintain edge sharpness and adhesion. DTF is also versatile across light and dark fabrics; the white ink layer helps with opacity on dark garments, while lighter fabrics can often skip white depending on the design. As always, testing a swatch on your target fabric is essential before committing to a full run, and considering factors like texture and finish will help select the best substrates for DTF and ensure durable results with the chosen DTF transfer materials.

Frequently Asked Questions

What is DTF printing and what are the main steps in the direct-to-film transfers process?

DTF transfers (Direct To Film transfers) are a versatile heat-applied method. In the DTF printing process, designs are printed onto a PET film with CMYK inks plus a white ink layer, then an adhesive powder is applied and cured before heat pressing the design onto fabric. Typical steps: design preparation; printing on film; applying and curing adhesive powder; aligning and heat pressing at the recommended temperature/time; and peeling. This approach relies on DTF transfer materials—PET film with a micro-porous coating, DTF inks, adhesive powder, and curing equipment—to deliver vibrant color, fine detail, and cross-substrate compatibility. Always follow the film manufacturer’s guidelines and test on a sample fabric first.

Which substrates are best for DTF transfers and how should I evaluate DTF transfer materials?

Best substrates for DTF transfers include 100% cotton, cotton blends, 100% polyester, and canvas, which typically deliver strong color, edge detail, and durable adhesion when properly cured. DTF transfers also work on light and dark fabrics, with white ink improving opacity on darks. When evaluating DTF transfer materials, ensure compatibility among the PET film, inks, adhesive powder, and your printer, and test on fabric swatches before a full run. Practical tips: pre-press to remove moisture, follow recommended heat/pressure guidelines, choose the appropriate peeling method (warm or cold), and cure as advised to maximize wash durability. By testing and adhering to the DTF printing process guidelines, you’ll achieve reliable results across diverse substrates.

| Aspect | Key Points |

|---|---|

| What are DTF transfers? | Direct-to-film transfers are heat-applied graphics created by printing designs onto a PET film, coating with adhesive powder, curing, and transferring the image onto fabric; the image sits on the surface for vibrant color, a soft hand, and cross-substrate versatility. |

| DTF printing materials | PET film with micro-porous coating; CMYK inks with white ink for opacity; adhesive powder; curing/conditioning equipment; release liner; finishing products; compatibility with printer, ink system, and substrates. |

| DTF printing process (step-by-step) | 1) Design and prepare artwork; 2) Print on PET film with white ink layer; 3) Apply adhesive powder evenly; 4) Cure the coated film; 5) Place ready-to-transfer film on fabric; 6) Use a heat press to bond; 7) Peel carrier film and finish. |

| Best substrates for DTF transfers | 100% cotton; cotton blends; 100% polyester; canvas/heavy textiles; light, dark, and colored fabrics; non-traditional substrates with prior testing. |

| Application tips and care | Pre-press to remove moisture; align designs precisely; use recommended temperature/time/pressure; follow peeling guidelines (warm or cold); wash/care: turn inside out, cold or warm water, gentle detergents; proper curing for durability. |

| Advantages and limitations | Wide substrate compatibility; high color fidelity; soft hand and good durability; on-demand production and easy design changes; limitations include potential edge issues on very rough fabrics and durability variation; generally more versatile than DTG or screen printing for multi-fabric runs. |

| Common mistakes to avoid | Skipping powder curing or applying too thick a coat; inadequate pre-press or insufficient heat/time; misalignment; using incompatible substrates without testing. |

Summary

DTF transfers offer a flexible, efficient path to vibrant designs across a broad range of fabrics. With the right materials, careful attention to the printing process, and smart substrate selection, you can achieve professional results that withstand washing and wear. Whether producing custom apparel, promotional items, or small-batch fashion, DTF transfers provide a compelling balance of color fidelity, versatility, and cost-effectiveness. By understanding the materials, process, and best substrates for DTF, you can elevate your designs and deliver consistent, high-quality results every time.