DTF Transfers Explained: The Key to Vibrant Fabric Printing

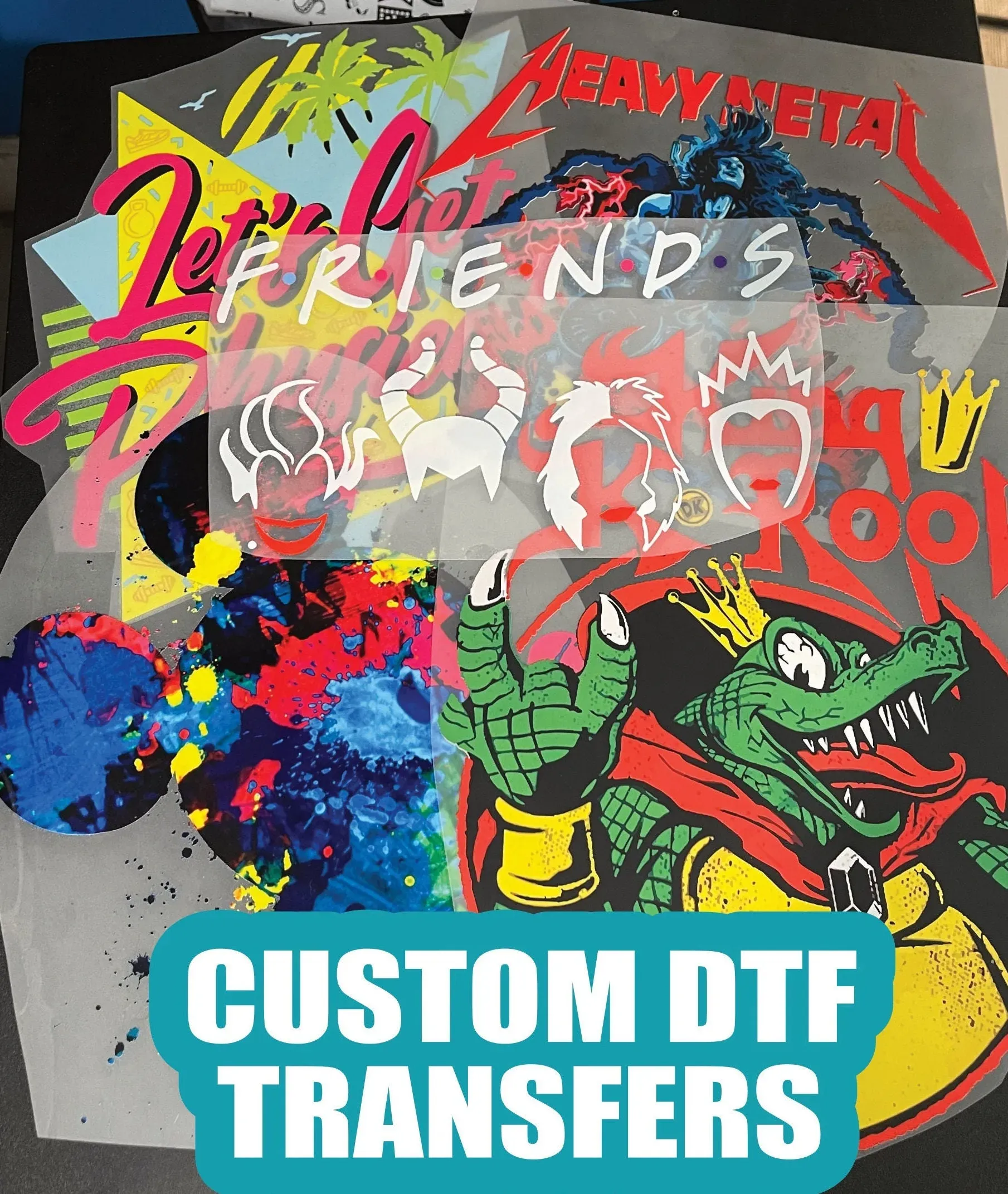

**DTF transfers** are taking the fabric printing industry by storm, offering a remarkable way to apply vibrant designs to various materials. Known as Direct-to-Film transfers, this innovative technology allows for stunning color reproduction and versatility, catering to a diverse range of fabrics. Whether you’re a small business owner looking to enhance custom garment printing or a DIY enthusiast seeking to create unique fabric items, understanding DTF printing technology is essential. This article will explore the multitude of DTF transfer advantages, the printing process, and how it is reshaping the textile market with its durability and ease of application. Dive in to learn how DTF transfers can elevate your printing projects and attract a broader clientele.

The realm of garment decoration has been transformed by a technique known as Direct-to-Film printing, or by its commonly used acronym, DTF printing. This method harnesses advanced printing technologies to create long-lasting, high-resolution images that adhere seamlessly to fabric surfaces. As more businesses seek to personalize their offerings, understanding the nuances of this transfer application method becomes crucial in today’s competitive market. By utilizing the benefits of DTF films, creators and brands can streamline their production processes while achieving vibrant, eye-catching results on a variety of textiles. In this piece, we will delve into the essential features, benefits, and recent advancements that make DTF printing a preferred choice for custom garment decorators.

Understanding DTF Printing Technology

DTF printing technology, short for Direct-to-Film, represents a remarkable evolution in the world of fabric printing. This innovative method begins with high-quality designs being printed on a specialized film using advanced DTF inks. Unlike traditional printing methods, DTF printing ensures that colors are not only vibrant but also well-defined, allowing intricate designs to be accurately represented on fabric. The entire process is designed to create stunning and durable prints that can withstand regular wear, making it a preferred choice for garment decorators and fashion designers.

The beauty of DTF printing lies in its versatility. This process can be applied to a wide variety of fabrics, including cotton, polyester, and blends. As a result, businesses can cater to diverse customer preferences, producing everything from eye-catching t-shirts to bespoke home textiles. With continual advancements in DTF technology, including improvements in ink formulation and adhesive bonding, the possibilities for creative applications in fabric printing are virtually endless.

Frequently Asked Questions

What are DTF transfers and how do they work?

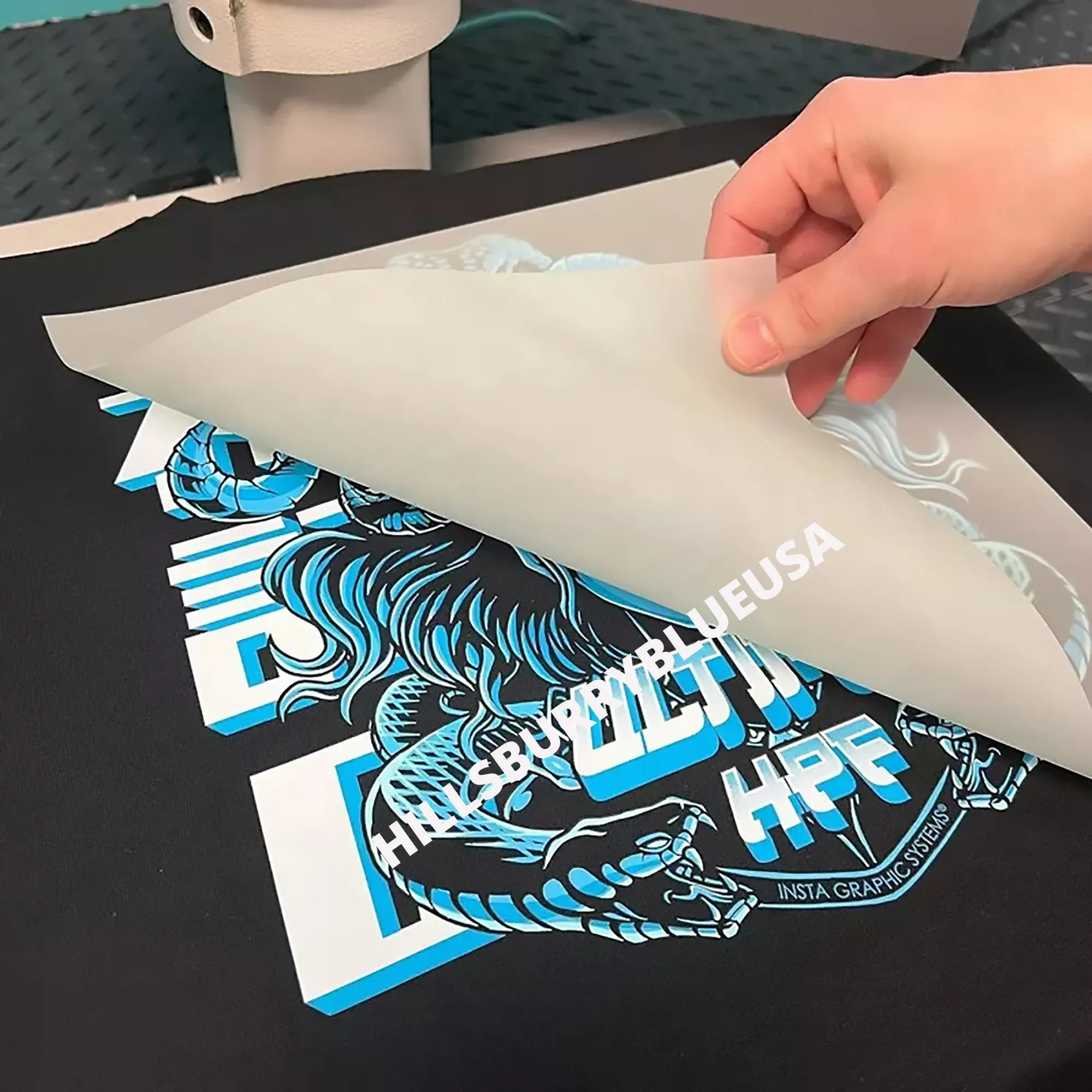

DTF transfers, or Direct-to-Film transfers, involve a printing process where designs are printed onto a specialized film using DTF inks. This film is then used to apply the design to fabric through heat and pressure. The process ensures vibrant colors and high-quality prints on various materials.

What are the advantages of using DTF printing technology?

DTF printing technology offers several advantages: it produces vibrant colors, works on a wide range of fabrics including blends, provides durable prints resistant to cracking and fading, and is easy to apply using a heat press, making it accessible for both businesses and DIY enthusiasts.

Can DTF transfers be used on all types of fabric?

Yes, DTF transfers are versatile and can be applied to many fabric types, including cotton, polyester, and specialty blends. This flexibility allows businesses to create custom garments and products but ensures vibrant results across different materials.

How do DTF transfer prints compare in durability to other fabric printing methods?

DTF transfer prints are designed to be long-lasting, resisting fading, cracking, and deterioration even after multiple washes, making them more durable than some traditional printing methods. This quality helps create products that maintain their appearance over time.

Are there eco-friendly options available in DTF printing?

Yes, the DTF printing market is evolving to include eco-friendly options. Many manufacturers are now offering sustainable inks and materials, allowing businesses to meet the growing consumer demand for environmentally responsible printing practices.

What recent developments can we see in DTF transfer technology?

Recent developments in DTF technology include improved ink formulations for better adhesion and flexibility, the introduction of eco-friendly products, and a growing market for custom garment printing, driven by increased demand for personalized products.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A printing process where designs are printed on a specialized film and transferred to fabric through heat application. |

| Advantages | 1. **Vibrant Colors**: Exceptional color integrity on various fabrics. 2. **Versatility**: Works on a wide range of materials. 3. **Durability**: Resistant to cracking and fading. 4. **Ease of Application**: Straightforward process requiring a heat press. |

| Recent Developments | 1. **Improved Inks**: Higher adhesion and flexibility. 2. **Eco-Friendly Options**: Sustainable choices available. 3. **Market Growth**: Increasing demand for customized products. |

| Industry Insights | Cost-effective and high-profit margins make DTF attractive for businesses and hobbyists alike. |

Summary

DTF transfers have emerged as a transformative technology in the world of fabric printing, enabling creatives to execute vibrant, high-quality designs on various materials. By leveraging the innovative process of Direct-to-Film transfers, businesses can enjoy the benefits of stunning color reproduction, versatility across fabric types, durability for everyday use, and ease of application. As market demand for personalized products continues to grow, staying abreast of the advancements in DTF transfers will undeniably give print professionals a competitive edge in this dynamic industry.