DTF transfers for small businesses: essential start-up tips

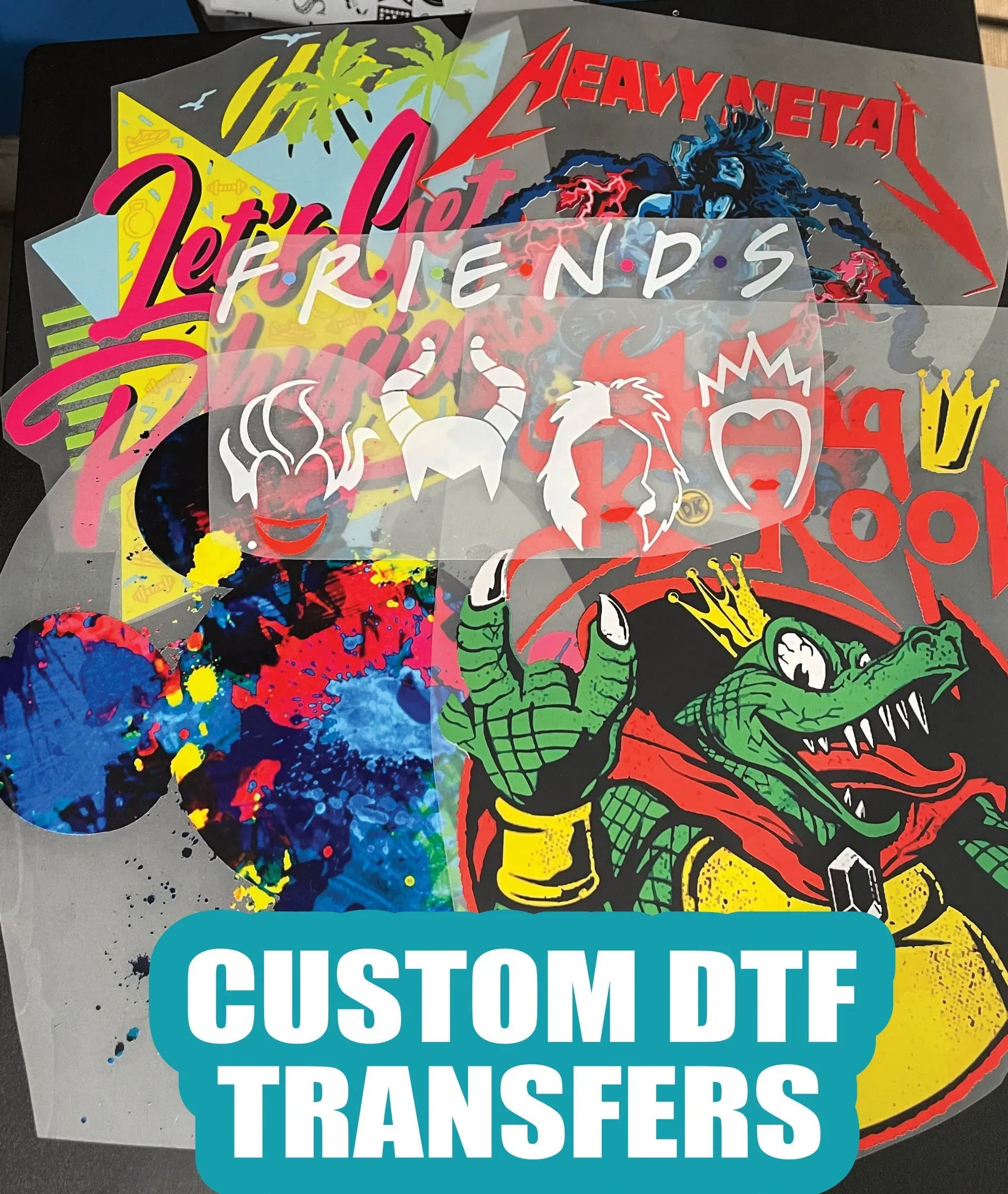

DTF transfers for small businesses deliver a flexible, high-quality entry point for apparel brands, custom shops, and entrepreneurs looking to expand offerings without a heavy upfront investment. This approach blends vibrant color reproduction and fabric compatibility with a straightforward workflow that suits lean teams and quick turnarounds. Understanding the DTF transfer process helps you compare results, costs, and timelines with alternative methods. For those starting a DTF business, practical steps include selecting DTF printing equipment and planning for DTF transfer costs, while weighing DTF vs screen printing to choose the best fit. With a clear product scope and solid quality controls, you can build a scalable model that meets demand and protects margins.

Viewed from another perspective, this approach is a film-based garment decoration method that relies on digital-to-fabric transfer rather than traditional screen templates. Designs are printed onto a special PET film, then heat-pressed onto fabrics to create durable, vibrant images. This technology is well suited for on-demand apparel, small brands, and event merchandise, where fast prototyping and minimal inventory matter. Key considerations include choosing compatible printing hardware, heat press setups, and the right consumables to optimize cost per unit for short-run production. By framing the topic with related concepts such as transfer workflow, fabric decoration, and cost structure, you align content with common industry searches and guide readers toward practical steps.

DTF transfers for small businesses: mastering the transfer process and launching your DTF business

DTF transfers for small businesses start with a clear understanding of the DTF transfer process. This end-to-end workflow runs from artwork preparation and color management to printing on a PET film, applying adhesive powder, curing, and finally heat-pressing the transfer onto the garment. By focusing on consistent color accuracy, clean edges, and reliable adhesion, small shops can achieve professional results even with limited staff. Establishing robust quality controls at each stage reduces misprints and reworks, which helps maintain on-time delivery and customer satisfaction.

Starting a DTF business requires practical planning that balances product variety with cash flow. Practical steps include researching niche demand (apparel brands, clubs, schools), defining your product scope (shirts, hats, bags), sourcing credible supplies, and building a scalable production plan. A clear proof-and-ship workflow, simple inventory management, and transparent pricing are essential to manage growth and maintain margins as you test different designs and markets.

DTF printing equipment and cost strategies for startups: choosing gear, managing costs, and comparing with screen printing

Equipment considerations form the backbone of a successful DTF operation. A typical setup includes a DTF printer, a heat press, adhesive powders, and specialty transfer films, with optional curing equipment depending on your workflow. Selecting reliable DTF printing equipment that handles white ink and vibrant color reproduction is crucial for achieving high-quality transfers across diverse fabrics. Additionally, investing in a well-organized workspace with proper ventilation and safety measures supports consistent results and smoother operations.

Understanding DTF transfer costs and how they compare with alternative methods helps you price for profitability. Track per-unit material costs (film, ink, powder), monitor equipment depreciation and maintenance, and look for bulk-purchasing opportunities to reduce expenses. When evaluating methods, consider DTF vs screen printing: DTF offers flexibility for short runs, faster prototyping, and easier color variation, while screen printing can be more cost-effective for large, identical orders. This analysis informs decisions about when to scale up, upgrade presses, or add automation to meet growing demand.

Frequently Asked Questions

DTF transfers for small businesses: what is the DTF transfer process and how does it support startups?

The DTF transfer process starts with artwork prep and color management, then printing onto a PET film with water-based inks. After printing, adhesive powder is applied and cured, the film is aligned with the garment, and a heat press transfers the design, followed by finishing to improve wash durability. For small businesses, mastering this process enables short runs, fast prototyping, and flexible product mixes with lower upfront capital than traditional screen printing. Maintain quality through standardized settings, color-proofing, and post-transfer checks to ensure consistent results.

DTF transfers for small businesses: what are the key components of DTF transfer costs and how should I budget when starting a DTF business?

Major cost components include materials (films, inks, powders), equipment depreciation, maintenance, utilities, and labor. To budget effectively, track per-unit material use, optimize workflow to reduce waste, and consider bulk purchases of consumables to lower ongoing costs. Invest in reliable DTF printing equipment and a suitable heat press to ensure consistent quality, and price products to reflect durability and fabric compatibility. Plan for scale: longer runs lower per-unit costs, while on-demand items can sustain margins with appropriate pricing.

| Key Point | Summary |

|---|---|

| What DTF transfers are and why they matter for small businesses | DTF transfers are a digital-to-fabric method that prints designs on PET film, then heat-presses them onto fabrics. They offer high-resolution results on many fabrics, flexible color handling, and faster, lower-setup production for small teams compared with traditional screen printing. |

| DTF transfer process (overview) | End-to-end workflow: artwork prep and color management, printing on PET film with water-based inks, applying adhesive powder, curing, heat-press transfer to fabric, and a finishing step for durability and wash-fastness. |

| Starting a DTF business: practical steps for startups | Develop a plan focused on market demand, define product scope, source reliable equipment and materials, build a scalable production plan, price strategically, and establish a proof-and-ship workflow to avoid delays. |

| Equipment considerations: choosing the right DTF printing equipment | Key setup includes a DTF printer, heat press, adhesive powder, and films, plus curing equipment. Look for high-resolution printing, reliable white ink, adjustable heat/pressure, and a safe, organized workspace. |

| Understanding costs: DTF transfer costs and pricing strategies | Costs come from films, inks, powders, equipment, maintenance, utilities, and labor. Track per-unit material use, optimize workflow, consider bulk purchasing, balance customization with volume, and price based on perceived value. |

| Quality and sustainability considerations | Maintain consistent color and adhesion across fabrics with calibrated printer profiles and curing. Implement pre-production checks, test prints, standardized temperature/pressure, and clear care instructions for customers to extend transfer life. |

| DTF vs screen printing: choosing the right method | DTF excels in short runs, rapid prototyping, and design variation with less setup; screen printing can be more cost-effective for large, identical runs. Align method with your business model and margins. |

| Best practices for startup success with DTF transfers | Document SOPs, implement strict QC, maintain supplier relationships, train staff, offer proofs, target niche markets, and plan for scale with automation or more efficient curing as orders grow. |

| Operational best practices and customer experience | Communicate lead times and order status clearly, provide a user-friendly catalog and transparent pricing, and ensure reliable support to encourage repeat business and referrals. |

Summary

Conclusion: DTF transfers for small businesses offer a versatile path to expand product lines, speed up orders, and maintain high design quality with a lean setup. By understanding the transfer process, selecting the right DTF printing equipment, managing transfer costs, and applying startup-focused best practices, you can build a resilient operation that scales with demand. Whether launching a new venture or growing an existing shop, embracing the DTF approach with clarity and discipline helps deliver durable transfers that satisfy customers and support long-term growth. Start small with a pilot run, document your workflow, and continually monitor performance to drive ongoing improvements. This approach illustrates why DTF transfers for small businesses are a strategic choice for modern print entrepreneurs.