DTF Transfers: How to Choose the Right Film, Ink, Printer

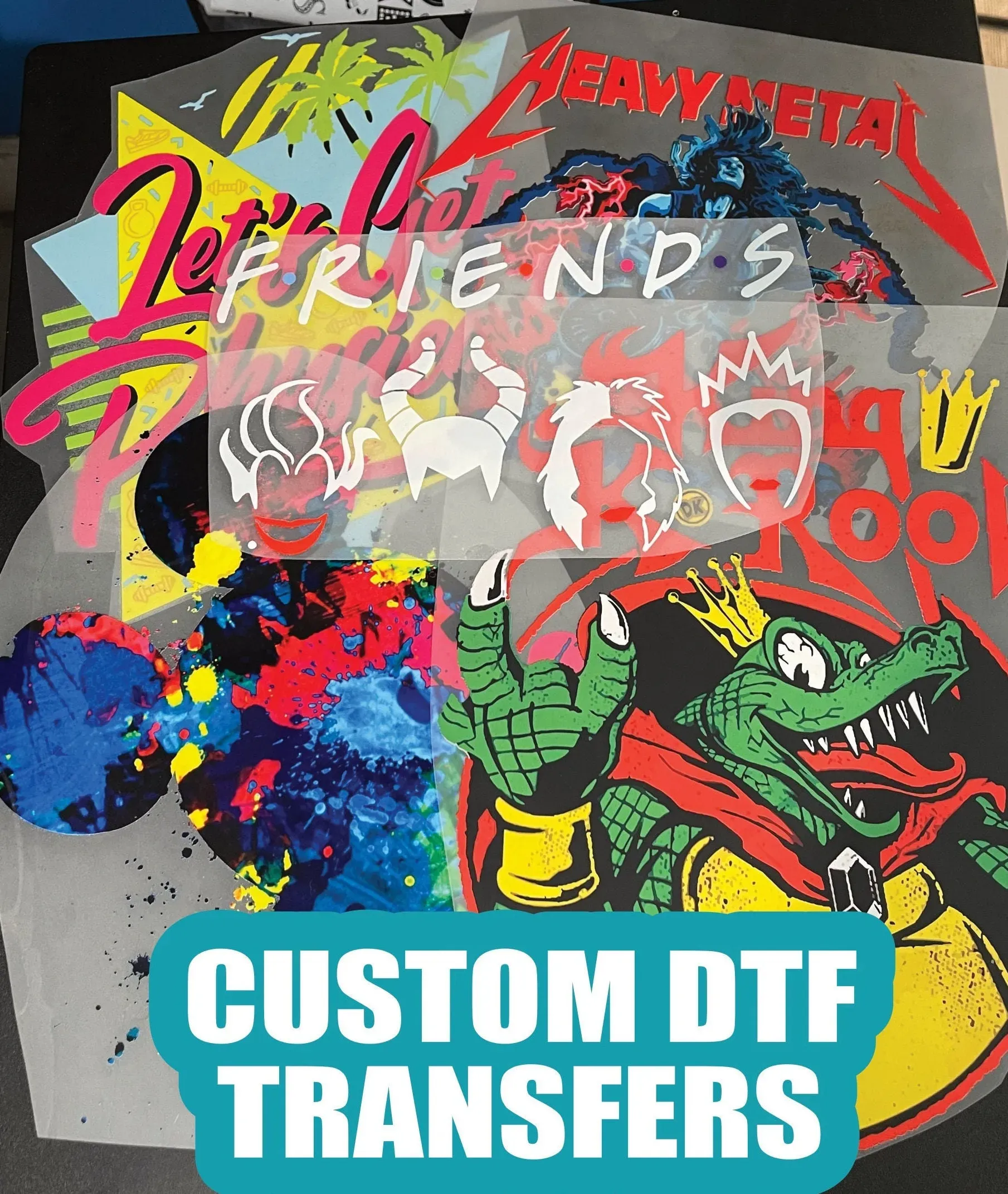

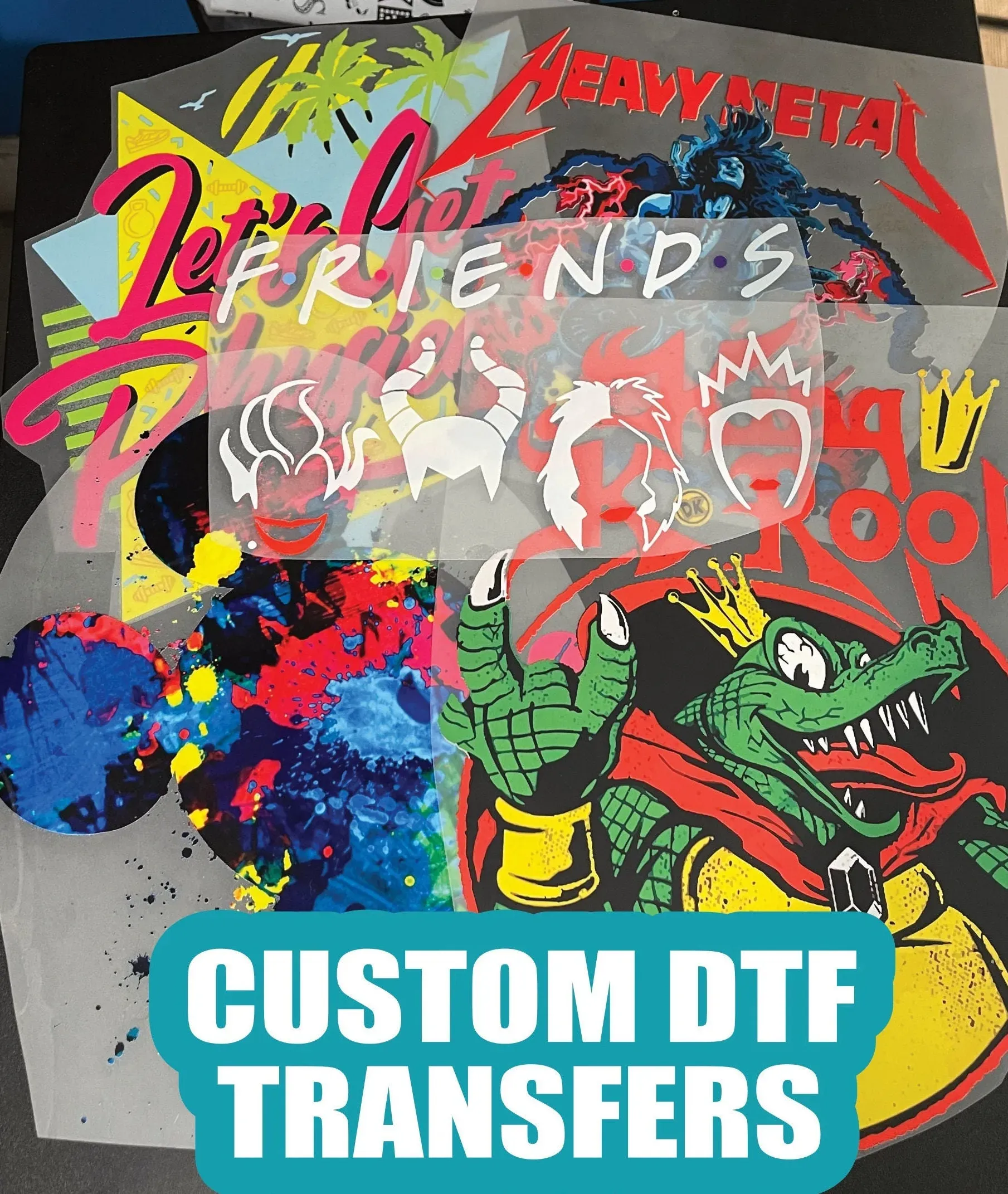

DTF transfers have revolutionized apparel and textile printing, delivering vibrant color, a soft hand-feel, and durable results. This guide shows how a well-balanced workflow can turn creative ideas into reliable, repeatable prints. The right combination of film, ink, and printer influences color accuracy, wash durability, and ease of transfer. Understanding these interactions helps you optimize settings and achieve consistent results across a range of fabrics. Whether you are upgrading an existing setup or starting from scratch, a solid transfer workflow saves time and money.

In practical terms, this approach uses the DTF film, DTF ink, and a compatible DTF printer to transfer vibrant designs onto fabrics. If you’re evaluating options, learning how to choose DTF film for your typical materials is essential to long-term quality. Evaluating DTF transfer quality means considering how the ink and film interact under heat and pressure, not just the printer alone. A holistic setup—where the film, ink, and printer are matched to your workflow—tends to yield stronger color, smoother textures, and better wash durability.

DTF transfers: Aligning film, ink, and printer for consistent results

DTF transfers rely on a cohesive trio: the DTF film, the DTF ink, and the DTF printer that drives the process. The interaction among film surface (thickness, finish, texture), ink formulation (color gamut, curing behavior), and printer capabilities (printhead technology, nozzle count) determines color vibrancy, transfer yield, and wash durability. When these elements are matched—smooth film with a compatible ink and a properly calibrated printer—you unlock reliable results across fabrics and designs.

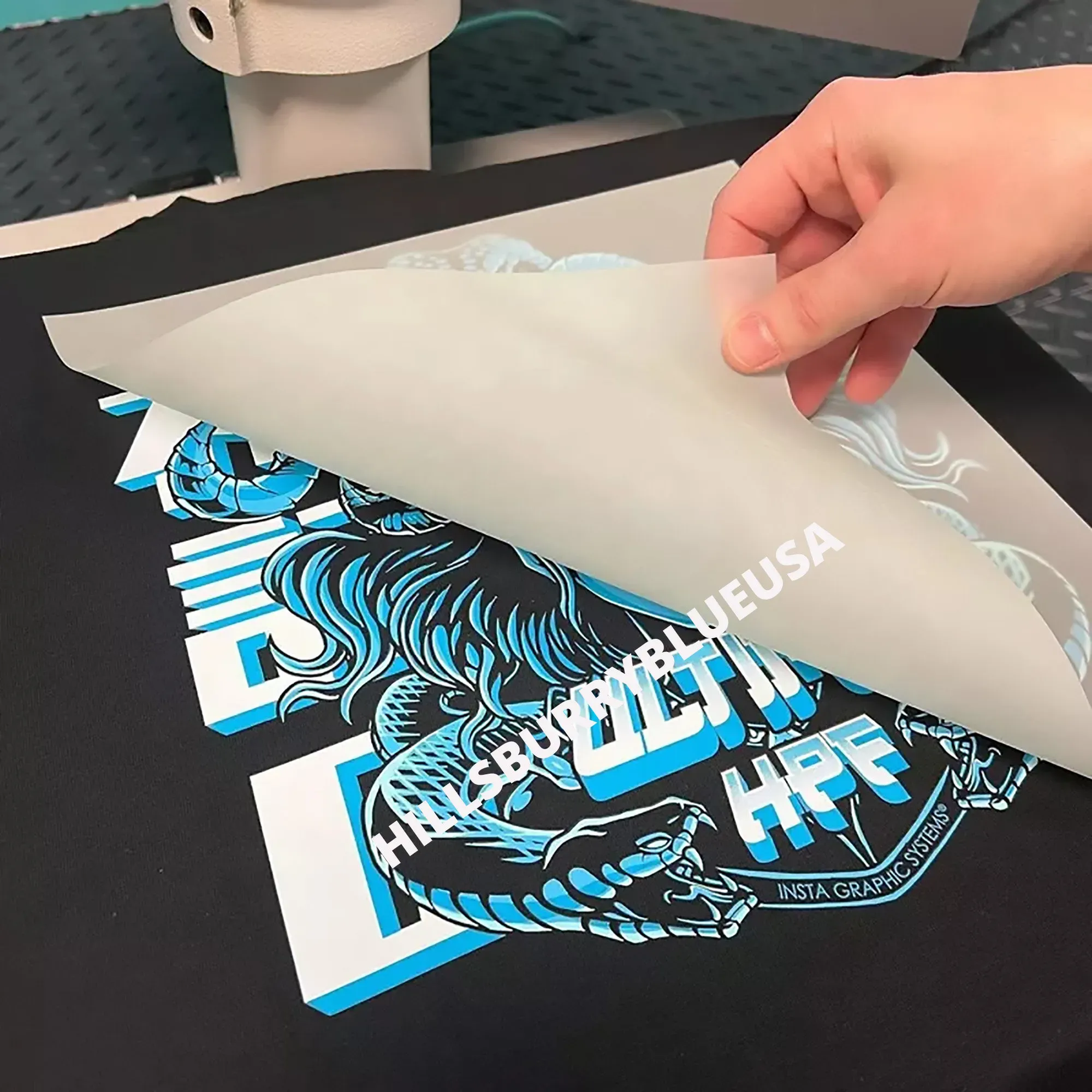

To achieve this alignment, start by evaluating how the film’s thickness and gloss affect ink deposition and transfer adhesion. Test different film types (white base vs clear base) and run sample prints on common fabrics like cotton and poly blends. Then calibrate color profiles, optimize curing, and adjust powdering to minimize ghosting and edge cracking. This structured testing reduces color shifts and ensures consistent DTF transfer quality across batches.

How to Choose DTF Film: A Practical Framework for Your DTF Printer and Ink to Maximize DTF Transfer Quality

The choice of DTF film sets the foundation for color accuracy and adhesion. Film thickness, surface texture, and gloss influence how well the ink lays down and how the transfer peels and cures on fabric. Consider compatibility with your chosen DTF ink and printer—some films cure best with pigment inks on specific gloss levels. Understanding the nuance of film types, including white base films and clear base films, helps you target fabrics from cotton to synthetics.

Next, align this film decision with ink and printer capabilities. When evaluating DTF film, test at least a couple of film options with your preferred ink set and perform small-scale washes to check color retention and adhesion. Document results with color profiles and curing temps. This approach supports a stable, repeatable process and helps maintain high DTF transfer quality across runs and fabrics.

Frequently Asked Questions

What factors should I consider when setting up DTF transfers to maximize DTF transfer quality with my DTF printer, DTF ink, and DTF film?

To optimize DTF transfer quality, align your DTF printer, DTF ink, and DTF film as a cohesive system. Choose a film that is compatible with your ink and printer, paying attention to thickness, finish, and adhesion on your target fabrics. Calibrate color profiles and run swatches on representative fabrics, then fine-tune curing, powdering, and heat/pressure settings to minimize ghosting and color shifts. Regular tests across different fabrics help maintain consistent results over time.

How to choose DTF film and DTF ink for a DTF transfers workflow and DTF printer setup to ensure consistent quality across fabrics?

When choosing DTF film and DTF ink, start by matching film surface and thickness to your ink chemistry and printer capabilities. Consider fabric type (cotton, blends, synthetics), color needs, and wash durability to select pigment- or dye-based inks and the corresponding film. Validate compatibility with small batches, calibrate color profiles, and perfect curing, powdering, and transfer timing. With careful testing and routine maintenance, you can achieve reliable, high-quality DTF transfers across products.

| Aspect | Key Points |

|---|---|

| Introduction |

|

| Core Components |

|

| DTF Film |

|

| DTF Ink |

|

| DTF Printer |

|

| Practical Framework to Choose Setup |

|

| Choosing by Fabric Type & Use Case |

|

| Practical Tips for Consistency |

|

| Common Pitfalls & Fixes |

|

Summary

DTF transfers offer a flexible and cost-effective route to high-quality garment printing when you choose the right combination of film, ink, and printer. This balance drives color vibrancy, durability, and wash performance across fabrics and designs. By aligning the three core components—film, ink, and printer—you optimize consistency from run to run. With testing, proper curing, and a repeatable workflow, you can achieve reliable results for a wide range of apparel applications and production scales.