DTF Transfers: Material Choices that Enhance Quality and Durability

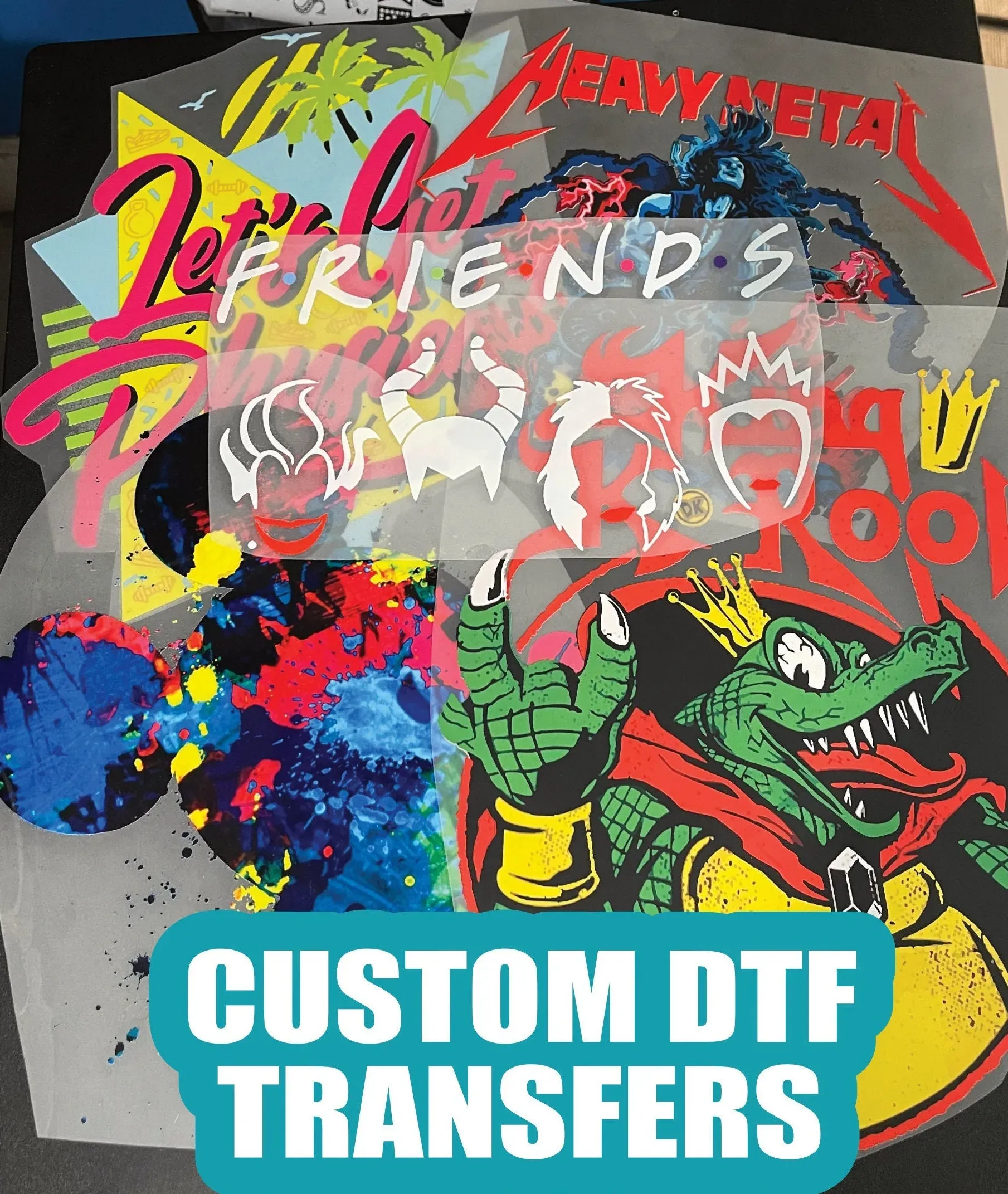

DTF transfers have revolutionized the way designs are applied to fabric, merging precision with creativity. This innovative method allows for vibrant and durable prints on a variety of materials, making it a popular choice in the textile industry. Selecting the right DTF printing materials is crucial, as it directly influences the quality and longevity of the final product. Additionally, understanding fabric compatibility in DTF printing ensures that the designs maintain their integrity and visual appeal, even after multiple washes. With advancements in adhesive powders for DTF and a growing emphasis on sustainable DTF materials, the future looks bright for this printing technique.

In the realm of fabric decoration, Direct to Film printing stands out as a game-changing technology that elevates the aesthetic and functional qualities of textile products. This technique empowers creators to transfer intricate designs onto various fabrics, combining versatility with high-impact visuals. It’s essential to explore options like film substrates, adhesive products, and environmentally friendly choices that enhance overall print durability and appeal. As brands prioritize fabric performance and sustainability, the evolution of materials available for this printing method will likely shape its future impact in the fashion landscape. Ultimately, optimizing material selection is key to achieving superior outcomes in DTF print projects.

Innovative DTF Printing Materials

The world of Direct to Film (DTF) printing has evolved significantly as new materials are introduced to enhance quality and performance. Key among these are the advanced DTF printing materials such as high-resolution films and specialized inks designed for a variety of fabrics. These materials are engineered to offer compatibility with both synthetic and natural fibers, enabling vibrant applications across clothing types. Furthermore, advancements in these materials often lead to prints that withstand multiple washes and retain their color integrity, which is critical for businesses seeking long-lasting solutions.

In addition to films, the choice of DTF printing materials also includes innovative inks that contribute to the final output’s vibrancy and quality. Many manufacturers now utilize water-based inks that are not only effective in achieving bright colors but are also safer for the environment. As the demand for high-grade DTF printing increases, exploring these innovative materials allows print shops to remain competitive while meeting a diverse range of customer expectations.

The Role of Adhesive Powders in DTF Transfers

Adhesive powders play a pivotal role in the success of DTF transfers, acting as the linking element that secures the print to the fabric. Selecting the right adhesive powder is crucial as it can significantly influence the flexibility, softness, and overall durability of the transferred designs. Recent innovations have led to the development of adhesive powders that not only improve the bond strength but also enhance the washability of printed items, making them ideal for various applications. This ensures that the vibrant designs remain intact despite repeated washing and wearing, promoting customer satisfaction.

With a variety of options available on the market, choosing the right adhesive for DTF printing is essential to achieve optimal results. High-performance adhesive powders are increasingly recognized for their ability to maintain print integrity under vigorous conditions. By preventing cracking or peeling, these advanced adhesives guarantee that your DTF transfers will look as good as new for much longer, highlighting their essential role in the production process.

Fabric Compatibility in DTF Printing

Successful DTF printing hinges on the relationship between the selected fabric and the print materials. Understanding fabric compatibility is imperative as certain textiles display enhanced adhesion and vibrant color reproduction compared to others. Typically, polyester and poly-cotton blends yield excellent results for DTF transfers due to their ability to hold inks effectively without absorbing excess. This compatibility not only ensures clarity in designs but also extends the life of the prints, which is a crucial consideration for businesses.

Moreover, fabric texture and pre-treatment processes can significantly affect DTF printing outcomes. Fabrics specifically designed for DTF applications often provide superior performance due to their engineered surfaces which facilitate better ink adhesion. Conducting comprehensive trials on different fabric combinations is advisable to select the best pair to achieve the desired visual appeal and durability in the final product.

Sustainable Options in DTF Transfers

As sustainability becomes a central focus in manufacturing, the DTF printing industry is increasingly adopting eco-friendly practices. This transition involves utilizing sustainable DTF materials such as biodegradable films and non-toxic adhesive powders. Not only do these materials lessen environmental impact, but they also meet the quality expectations of quality-driven consumers. The pursuit of sustainability ensures that the printing processes align with the values of modern-day shoppers who prefer brands that consider environmental responsibility.

Adopting sustainable material choices for DTF printing can also enhance a brand’s marketability. By promoting the use of eco-friendliness in production, companies can appeal to a growing demographic demanding transparency and ethical practices. As innovations continue to emerge, the integration of sustainable materials in DTF transfers is poised to revolutionize the industry, enabling businesses to thrive while committing to a healthier planet.

Trends Shaping the Future of DTF Materials

The future of DTF printing is bright as ongoing research leads to innovative materials that do not only meet performance requirements but also address sustainability in a multifaceted way. Emerging technologies in ink formulations and film characteristics are poised to transform how designs are printed and retained on various fabrics. This transition is expected to empower brands to experiment with new textures and vibrant colors while maintaining product quality standards that consumers demand.

Likewise, the potential integration of hypoallergenic and natural polymer-based adhesives marks a significant milestone in DTF printing’s evolution. These advancements not only broaden the compatibility range with different fabric types but also ensure that printed products are safe for sensitive skin. As both consumer preferences and environmental concerns continue to evolve, staying ahead of these trends will be vital for businesses looking to leverage DTF printing capabilities effectively.

Optimizing DTF Transfers for Better Performance

To achieve superior DTF transfers, it’s essential to focus on optimizing print conditions alongside material choices. Temperature and pressing times during the transfer process must be carefully calibrated to minimize issues such as bubbling or lifting of the design. Understanding each material’s specific requirements can significantly enhance the final outcome, resulting in more vibrant and durable prints.

Furthermore, investing in high-quality printers and ensuring regular maintenance can contribute significantly to the overall efficiency and performance of DTF operations. By optimizing every aspect of the DTF transfer process from materials to machinery, businesses can ensure high-quality outputs that meet customer demands for both aesthetics and durability.

Frequently Asked Questions

What are the best material choices for DTF transfers?

The best material choices for DTF transfers include specialized polyester films for printing, which provide excellent adhesion and vibrant colors. Cotton blends are also compatible, but the fabric’s finish and texture play a crucial role in achieving high-quality output.

How does fabric compatibility affect DTF printing results?

Fabric compatibility is vital for DTF printing, as different materials react differently to the print process. Polyester blends typically yield brighter and more durable prints, while untreated natural fibers might absorb more ink, leading to less vibrant results.

What types of adhesive powders are used in DTF transfers?

In DTF transfers, high-performance adhesive powders are crucial for binding ink to fabric. Advanced formulations enhance stretchability and softness while preventing issues like cracking and peeling, ensuring a longer-lasting print.

Are there sustainable DTF materials available on the market?

Yes, the market for DTF printing is seeing a rise in sustainable materials, such as biodegradable films and non-toxic adhesive powders, catering to eco-conscious consumers while maintaining high-quality print standards.

What are the advantages of using specialized DTF printing materials?

Specialized DTF printing materials, including high-quality films and tailored adhesives, enhance the vibrancy and durability of prints, improving wash resistance and overall longevity, leading to better customer satisfaction.

How can I ensure the durability of DTF transfers on different fabrics?

To ensure durability, it’s important to test DTF transfers on various fabric types. Using fabrics specifically designed for DTF printing, like polyester or treated cotton blends, can optimize print quality and resistance to wear and tear.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF printing revolutionizes the apparel industry with high-quality and durable designs. |

| Material Composition | Specialized polyester films enhance adhesion, color vibrancy, and wash durability. |

| Role of Adhesive Powders | New adhesive formulations improve stretchability and prevent cracking and peeling. |

| Fabric Compatibility | Coated or treated fabrics yield superior adhesion and print quality. |

| Sustainable Material Choices | Eco-friendly materials such as biodegradable films are gaining popularity. |

| Future Trends | Innovations in inks and hypoallergenic adhesives are expected to shape the market. |

Summary

DTF Transfers represent a transformative approach towards high-quality garment printing. By focusing on material choices such as specialized films, advanced adhesive powders, and sustainable options, DTF printing enhances not only the aesthetics but also the durability of printed designs. As consumer demand leans towards environmentally-friendly options, innovation in materials is expected to ensure that DTF transfers meet both performance and sustainability standards. This trend will likely define the future of DTF printing, allowing brands to achieve superior results while remaining eco-conscious.