UV DTF Gangheet: Step-by-Step Guide for Stunning Prints

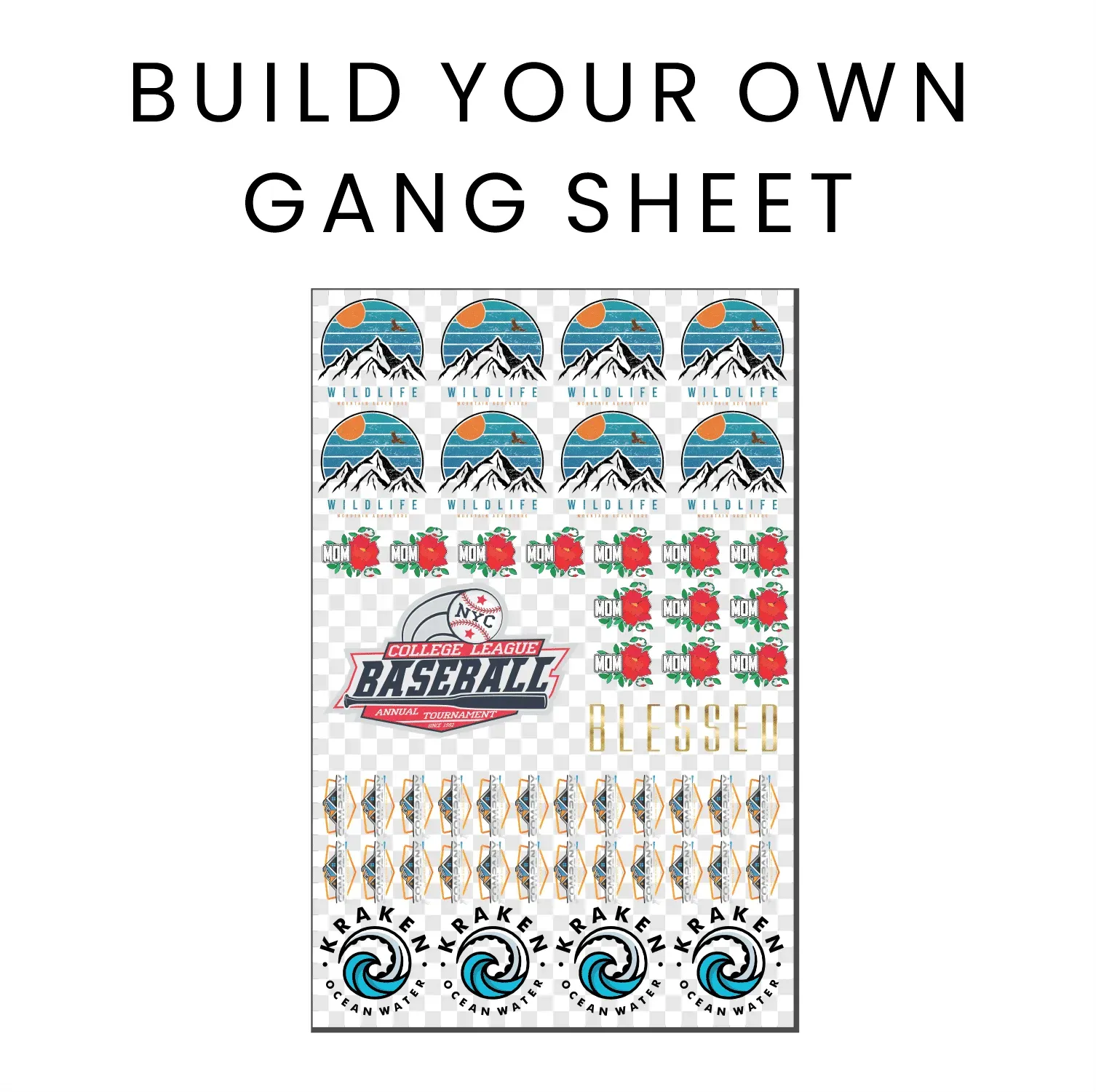

In the ever-evolving landscape of printing, UV DTF gangheet technology has emerged as a game changer, captivating businesses with its remarkable capabilities. This innovative method combines advanced UV printing technology with direct to film (DTF) printing, enabling you to create vibrant and durable prints on a variety of substrates, including textiles and plastics. By leveraging the gangheet approach, users can produce multiple custom prints simultaneously, minimizing waste and maximizing efficiency. Moreover, the UV inks used in this process are renowned for their exceptional longevity, making the resulting prints not only visually striking but also resistant to wear and tear. In this guide, we will delve into the essentials of UV DTF gangheet printing, covering everything from preparation to execution to help you achieve professional-quality results that leave a lasting impression.

When exploring modern printing solutions, the UV Direct to Film (DTF) gangheet method stands out due to its seamless blend of efficiency and quality. Often regarded as the pinnacle of direct film printing techniques, this approach allows for the creation of custom designs on a myriad of materials, making it a versatile choice for numerous applications. Using specialized films, producers can achieve durable prints that cater to the unique demands of their projects. The process not only enhances productivity but also embraces the evolving trends in the digital printing sector, ensuring businesses can keep pace with customer expectations. By adopting this innovative technique, print shops can offer distinct, high-resolution canvases that shine in the competitive market of custom merchandise.

Understanding UV DTF Gangheet Technology

UV DTF gangheet technology represents a groundbreaking advancement in the realm of printing, synonymously known for its efficiency and versatility in producing high-quality prints. The process involves using a specialized transfer film, enabling multiple designs to be printed concurrently, making it a highly productive choice for businesses of all sizes. By combining UV printing technology with the DTF method, print providers can create stunning graphics that stand out on various materials, from fabrics to metals.

The uniqueness of UV DTF gangheet lies in its use of UV inks, which are celebrated for their vibrant color output and exceptional durability. These inks, when cured with UV light, result in prints that are not only visually striking but also resistant to fading and wear over time. This attribute makes it an ideal printing solution for custom prints, especially in sectors that demand longevity and resilience, such as fashion and promotional merchandise.

Frequently Asked Questions

What is UV DTF gangheet printing and how does it work?

UV DTF gangheet printing combines UV printing technology with direct-to-film (DTF) capabilities, using a special transfer film known as gangheet. This process allows multiple designs to be printed simultaneously using UV inks, which are cured under UV light for durability and color vibrancy.

What are the key benefits of using UV DTF gangheet technology in printing?

The key benefits of UV DTF gangheet technology include increased efficiency through simultaneous printing of multiple designs, versatility to print on various substrates like textiles and plastics, enhanced durability with resistant prints, and the ability to offer innovative customization options for unique designs.

What types of substrates can I use with UV DTF gangheet printing?

UV DTF gangheet printing can be used on a wide range of substrates, including fabrics, plastics, metals, and more. This versatility makes it an excellent choice for custom prints across different materials and applications.

How do I prepare my printer for UV DTF gangheet printing?

To prepare your printer for UV DTF gangheet printing, ensure you load compatible UV inks, select the appropriate gangheet film, and configure printer settings including ink density and curing time specific to your chosen substrate.

What are the steps involved in the UV DTF gangheet printing process?

The UV DTF gangheet printing process involves several steps: clean and set up the gangheet, load it into the printer and adjust settings, print the designs, cure the UV ink under UV light, and finally transfer the designs to the substrate using heat or pressure.

What safety measures should I take when using UV DTF gangheet technology?

When using UV DTF gangheet technology, ensure proper ventilation in your workspace to avoid UV light exposure and adhere to safety protocols. It’s recommended to wear protective gear such as gloves and goggles during the printing and curing processes to ensure safety.

| Key Point | Details |

|---|---|

| Introduction | UV DTF gangheet technology provides an efficient and versatile printing solution for various substrates. |

| What is UV DTF Gangheet? | A combination of UV printing and DTF, utilizing a special transfer film for printing multiple designs simultaneously. |

| Benefits of UV DTF Gangheet | 1. Efficiency 2. Versatility 3. Durability 4. Innovative Customization |

| Preparing for the Print Job | Ensure proper printer setup and file preparation for successful printing. |

| Step-by-Step Process | 1. Clean and set up gangheet 2. Load gangheet and configure settings 3. Print designs 4. Cure print 5. Transfer designs |

| Tips for Success | Ensure compatibility of substrates, monitor ink levels, and maintain equipment regularly. |

| Recent Trends | Increased use in custom merchandise offerings due to ability to produce intricate designs. |

| Safety Considerations | Use protective gear and ensure proper workspace ventilation to avoid UV exposure risks. |

Summary

UV DTF gangheet offers businesses a powerful solution for creating vibrant, high-quality prints. This innovative printing technique not only maximizes efficiency and versatility but also provides the durability needed for long-lasting designs. By mastering the UV DTF gangheet method, businesses can differentiate themselves in a competitive market, offering customized products that resonate with clients. The step-by-step approach ensures that both novices and experienced printers can successfully adopt this technology, embracing the latest trends in custom merchandise production.