UV DTF vs Traditional Printing: Key Differences Explained

Understanding the differences between UV DTF and traditional printing methods is essential for anyone involved in the printing industry today. With printing technology advancements reshaping the landscape, UV DTF printing emerges as a compelling alternative, boasting several UV DTF printing advantages. This method utilizes UV light to cure inks instantly, resulting in stunning print quality that can sometimes surpass traditional methods. A print quality comparison reveals that while traditional printing techniques like dye sublimation and screen printing have their merits, they often lag in color vibrancy and material versatility. Exploring these printing techniques not only helps businesses make informed choices but also ensures they stay competitive in an evolving market.

In the realm of modern printing technologies, the debate between UV Direct-to-Film (DTF) and conventional printing approaches warrants careful consideration. As businesses strive for excellence in product presentation and durability, the advantages of UV DTF printing stand in stark contrast to established traditional methods like screen printing and dye sublimation. Each technique offers unique processes and output results, catering to specific business needs and project types. A thorough analysis of these printing solutions reveals significant differences in terms of efficiency, speed, and print quality. By weighing these factors, companies can better navigate the choices in printing technology that align with their operational requirements.

Understanding UV DTF Printing Advantages

UV DTF printing stands out in today’s market due to its remarkable advantages over traditional methods. One of the most notable benefits is its ability to produce vibrant and detailed print outputs. The use of ultraviolet light to cure inks almost instantly allows for high-quality graphics with astonishing color richness. Businesses that prioritize print quality and aesthetic appeal find UV DTF especially advantageous, as it can handle intricate designs with precision, far surpassing the capabilities of several traditional printing methods.

Additionally, the speed of UV DTF printing enables companies to respond to market demand swiftly. With the capacity to print multiple designs in a short turnaround time, businesses can efficiently manage their inventory and offer a diverse range of products. This technology eliminates long setup times often associated with traditional printing techniques, making it perfect for short runs or custom orders. The efficiency gained through UV DTF printing means that companies can not only meet consumer expectations but also capitalize on emerging trends more effectively.

Traditional Printing Methods Explained

Traditional printing methods encompass a variety of techniques, each with its unique strengths and weaknesses. From screen printing to offset and dye sublimation, these methods have held a strong presence in the industry for decades. Screen printing, for instance, is often favored for its durability and color vibrancy, especially in apparel. However, it requires a specific setup for each color, limiting its efficiency for multi-color designs unless companies invest in advanced machines.

Dye sublimation, on the other hand, is popular for printing on synthetic fabrics. This method excels at producing vivid colors but is restricted to polyester materials, which can limit product offerings. Additionally, the need for heat to transfer inks can extend production times compared to newer technologies like UV DTF. As businesses increasingly seek to diversify their product lines and meet fast-paced market demands, understanding the limitations of traditional methods becomes essential.

Comparing Print Quality Between UV DTF and Traditional Techniques

When evaluating print quality, UV DTF shines through with intricacies that many traditional methods cannot replicate. The UV curing process ensures that inks are set immediately, which helps maintain sharp details and color integrity even on textured surfaces. This high-resolution output makes UV DTF particularly appealing for businesses seeking to produce promotional materials or product designs that stand out visually, giving them an edge in competitive markets.

In comparison, traditional printing methods can struggle with maintaining print quality, particularly on non-traditional surfaces. While methods like offset printing can produce excellent results, they may fail to capture the same level of detail found in UV DTF prints. Additionally, factors like ink fading and wear can vary, with some traditional inks less resistant to environmental elements. Businesses need to consider such differences when choosing a method that aligns with their desired output quality.

The Impact of Advancements in Printing Technologies

Recent advancements in printing technologies have significantly influenced the landscape of the printing industry. The evolution from conventional methods to modern practices, including UV DTF, highlights a shift towards increased efficiency and quality. With innovations like faster curing times and improved ink formulations, UV DTF printing represents a leap forward that meets the expanding needs of both small businesses and large corporations.

These advancements not only enhance the capabilities of UV DTF printing but also challenge traditional methods to adapt and improve. As more businesses adopt UV DTF technology, the competition encourages ongoing developments in traditional techniques, pushing them to innovate. In the dynamic world of printing, staying updated on these advancements is crucial for companies looking to maintain a competitive edge.

Breaking Down Material Versatility in Printing

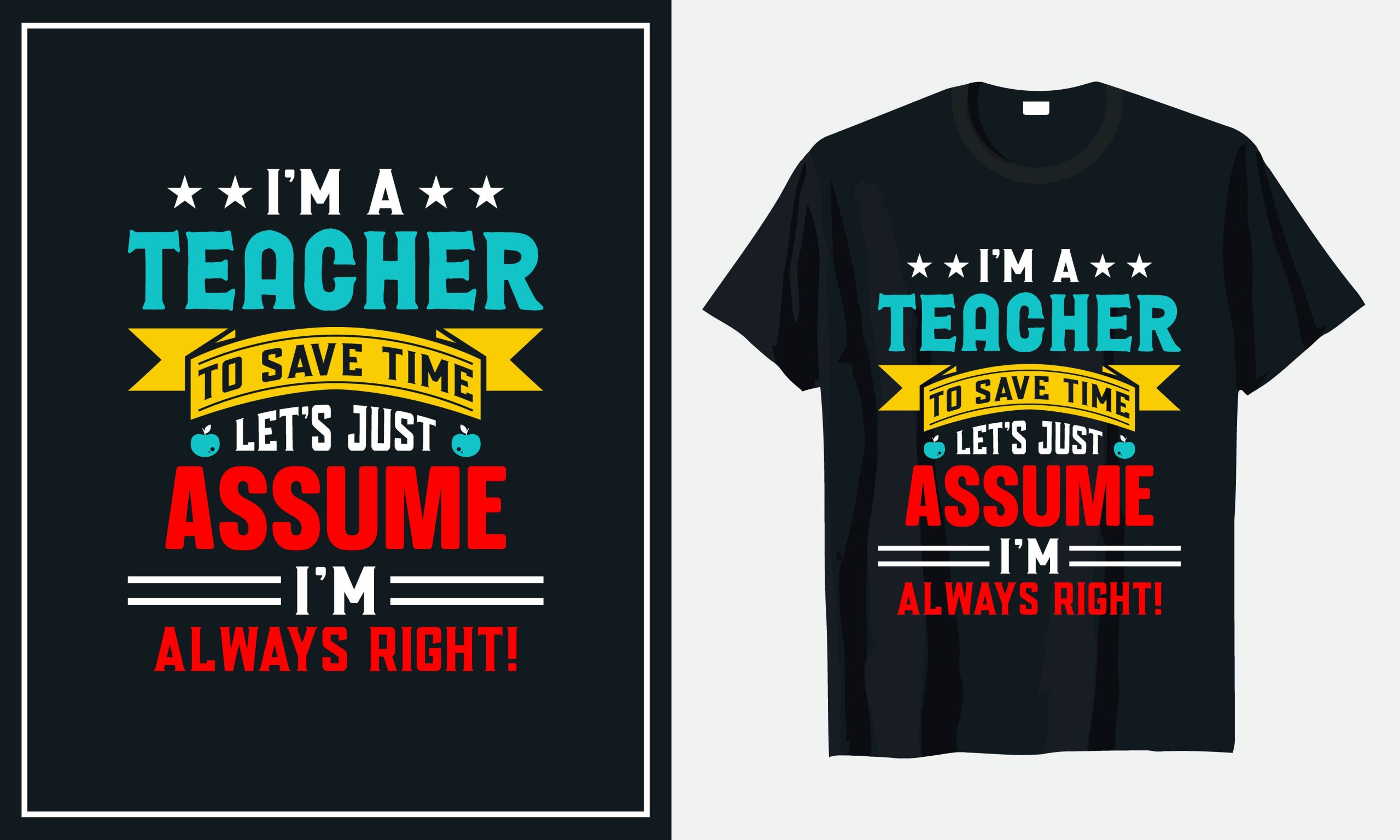

Material versatility is a critical factor when comparing UV DTF and traditional printing methods. UV DTF printing excels by accommodating a wide variety of substrates, from hard surfaces like metal and wood to soft fabrics. This adaptability opens up vast opportunities for businesses to broaden their product ranges, creating unique items for diverse markets. The capability to print directly onto different surfaces expands creative possibilities, making UV DTF particularly appealing to product designers and marketers.

In contrast, traditional methods often limit material options. For instance, dye sublimation is restricted to polyester fabrics, while screen printing focuses primarily on apparel. Such limitations can hinder companies from exploring new markets or catering to specific customer demands. As customization and personalization continue to trend, the versatility of UV DTF allows businesses to stay competitive by offering varied and unique printed products.

Evaluating Cost Effectiveness: UV DTF vs Traditional Printing

When assessing cost effectiveness, both UV DTF and traditional printing methods present unique advantages and challenges. Initially, UV DTF equipment may require a higher investment, but the operational savings gained from faster print times and reduced labor needs can lead to lower overall costs in the long run. For small to medium-sized businesses with diverse product offerings, the efficiency of UV DTF often translates to greater profitability.

On the other hand, traditional printing methods might have a lower upfront cost but can rack up expenses over time due to labor-intensive setups and additional equipment needs for larger runs. Businesses that primarily focus on high-volume production can sometimes find cost advantages in traditional methods, as bulk printing can reduce per-unit costs. Ultimately, assessing cost effectiveness requires a thorough examination of each printing method’s specific needs and business objectives.

Frequently Asked Questions

What are the advantages of UV DTF printing compared to traditional printing methods?

UV DTF printing offers several advantages over traditional printing methods, including faster production times, high-quality outputs with vibrant colors, and the ability to print on a wide range of substrates such as plastics, metals, and textiles. Unlike traditional methods that may require multiple setups, UV DTF can produce multiple designs in one batch, enhancing efficiency.

How does the print quality comparison between UV DTF and traditional printing methods stand?

When comparing print quality, UV DTF often outshines traditional printing methods. It produces high-resolution images with fine details and vibrant colors that remain durable and resist fading. In contrast, some traditional methods might compromise on detail and longevity, especially under harsh conditions.

What is the role of printing technology advancements in favor of UV DTF printing?

Advancements in printing technology significantly favor UV DTF printing, making it a preferred choice for many businesses. Innovations in UV ink formulations and curing technologies have improved color fidelity, durability, and curing speed, allowing for quicker turnarounds and high-quality outputs compared to traditional methods.

In what scenarios might traditional printing methods still be preferred over UV DTF printing?

Traditional printing methods, like screen printing or dye sublimation, might be preferred in high-volume production scenarios where initial setup costs are lower. They can also be beneficial for specialized applications, like large fabric runs where dye sublimation excels. However, for versatility and speed, UV DTF is typically the better option.

What are the cost considerations when choosing between UV DTF printing and traditional methods?

While the initial investment for UV DTF printing may be higher, the overall operational costs can be lower due to reduced labor and setup times. Traditional methods might appear more cost-effective initially but can lead to higher long-term expenses due to additional equipment and labor costs, especially for smaller runs.

How does UV DTF printing compare to dye sublimation printing?

UV DTF printing and dye sublimation printing are distinct processes with specific strengths. UV DTF can print on a variety of surfaces, including non-fabric materials, while dye sublimation is limited to polyester fabrics and relies on heat transfer. UV DTF generally provides more versatility and speed, making it suitable for diverse applications, unlike dye sublimation which is more specialized.

| Key Points | UV DTF Printing | Traditional Printing Methods |

|---|---|---|

| Technology and Process | Uses UV light to cure inks instantly for vibrant prints. | Includes techniques like screen printing and dye sublimation, often slower and more labor-intensive. |

| Speed and Efficiency | Fast production with multiple designs in one setup. | Longer setups and less efficiency for smaller runs. |

| Material Versatility | Prints on various surfaces: plastics, textiles, metals, wood. | Limited to specific materials: best for garments or polyester fabrics. |

| Cost Considerations | Higher initial investment, lower operating costs overall. | Lower upfront costs but can be expensive in the long run. |

| Quality and Longevity | Produces durable, high-resolution prints resistant to fading. | Quality can be good but often less durable than UV DTF prints. |

Summary

UV DTF vs Traditional Printing is a crucial comparison for businesses in the printing industry, as the differences can significantly impact operational efficiency and product quality. UV DTF printing stands out for its speed, versatility, and durability, making it a compelling choice for modern commercial applications. Conversely, traditional printing methods might be suitable for specific use cases that require lower initial investments but may incur higher costs in the long run due to inefficiencies. Ultimately, understanding these differences will enable businesses to choose the most appropriate printing method that aligns with their goals and customer needs.