DTF Gangsheet Builder: Tips and Tricks for Stunning Prints

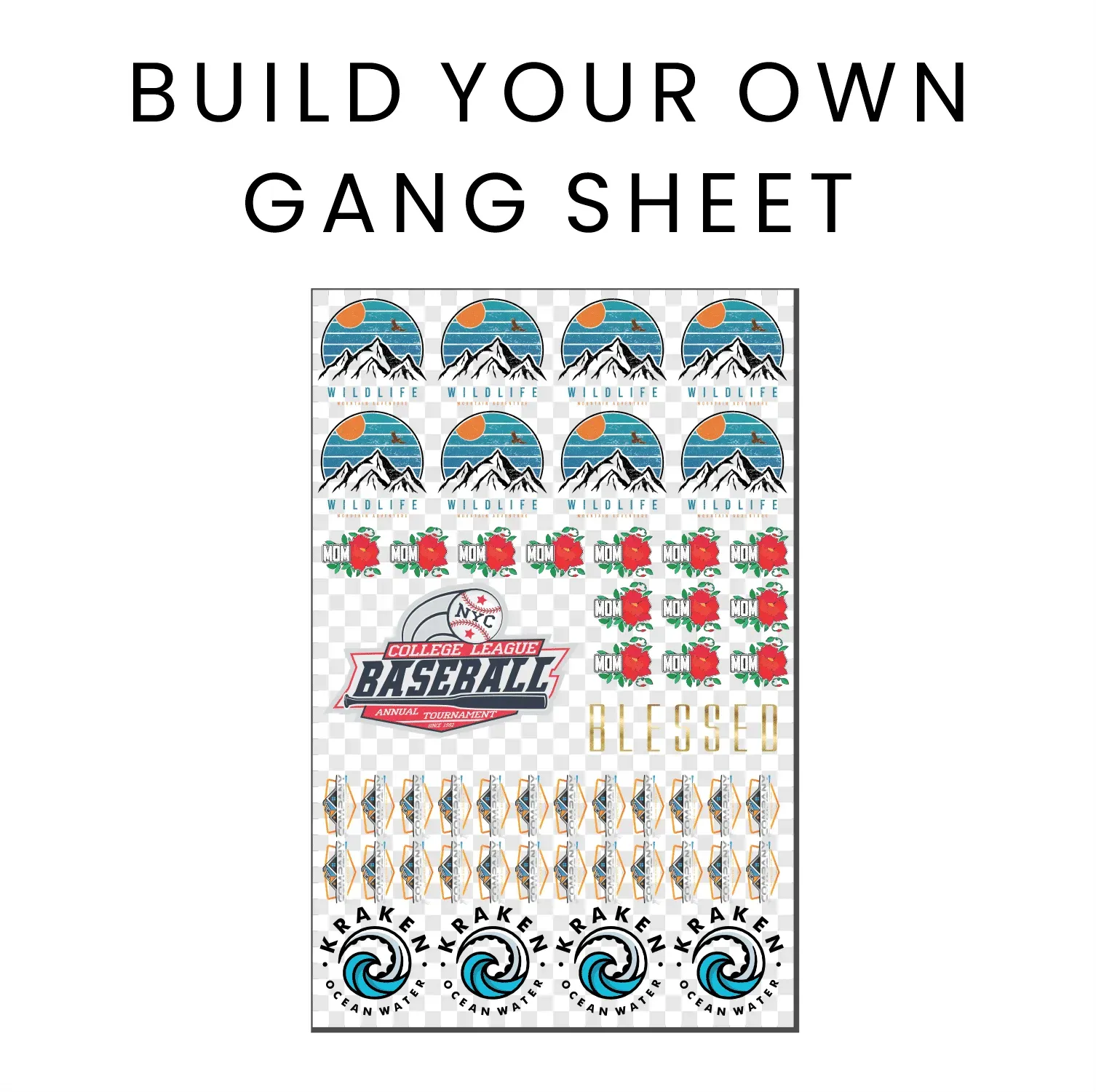

In the world of apparel decoration, the **DTF Gangsheet Builder** stands out as an essential tool for optimizing the process of Direct to Film (DTF) printing. This innovative solution allows users to compile multiple designs onto a single sheet, significantly reducing production time and costs, making it ideal for businesses striving for efficiency. With proper understanding and implementation of DTF printing tips, users can maximize their output quality while maintaining stunning visual results. This guide will not only discuss the DTF Gangsheet Builder, but also explore tips and settings that enhance your printing experience. Discover how this tool can revolutionize your approach to gang sheet printing and ensure your designs shine on every fabric material.

The **DTF Gangsheet Builder** is a game-changing resource for those engaged in direct film transfer processes, making it easier to produce multiple graphics on one sheet. This technique, often referred to as gang sheet creation, significantly cuts down on material waste and production costs, catering to various sectors within the garment industry. By adopting the practice of consolidating designs into a single printable sheet, businesses not only streamline their workflow but also boost efficiency in their direct-to-film printing adventures. Additionally, understanding the nuances of DTF print settings and materials is crucial to achieving exceptional results. As the demand for high-quality prints grows, utilizing tools like the DTF Gangsheet Builder becomes increasingly vital for staying competitive in the market.

Understanding DTF Printing Basics

Direct to Film (DTF) printing has revolutionized the apparel decoration industry, allowing for intricate designs to be transferred onto various materials with ease. At its core, DTF printing involves printing designs onto a special film which is later transferred onto the garment using heat and pressure. This method not only offers vibrant colors but also allows for printing on both light and dark fabrics without compromising quality. Understanding these basics is essential for anyone entering the world of garment printing.

Moreover, the versatility of DTF printing extends beyond traditional clothing. It supports diverse applications across different merchandise such as tote bags, hats, and even leather products. This flexibility empowers businesses to cater to a broader audience, increasing market potential. Thus, comprehending the foundational aspects of DTF printing is crucial in developing effective strategies for a successful printing business.

The Importance of Proper DTF Print Settings

Achieving stunning prints using DTF printing requires meticulous attention to print settings. The correct calibration of temperature, pressure, and duration during the heat press process is vital. Setting your heat press between 325°F and 350°F for 8 to 15 seconds not only ensures proper adhesion of the transfer to the substrate but also enhances the overall vibrancy of the print. Incorrect settings could lead to faded designs or ineffective transfers, significantly impacting product quality.

Equally important is the consideration of the type of fabric being used, as different materials may require slight adjustments in print settings for optimal results. By testing the settings on sample fabrics before scaling up production, print professionals can fine-tune their processes, resulting in higher quality prints and satisfied customers. Thus, investing time in understanding and applying the correct DTF print settings is essential in achieving professional-grade outputs.

Maximizing Efficiency with the DTF Gangsheet Builder

The DTF Gangsheet Builder is integral for optimizing print organization. By consolidating multiple designs into a single printable sheet, it reduces both production time and material waste significantly. This not only streamlines the workflow but also enhances cost-efficiency, allowing businesses to increase profitability. Implementing this tool can transform the printing process, offering a competitive edge in a crowded marketplace.

Furthermore, with the DTF Gangsheet Builder, users can carefully arrange each design to maximize the use of print area while maintaining the necessary space to prevent designs from blending during the transfer process. This careful arrangement allows for more products to be printed in a single run, which saves on time and resources. Thus, mastering the DTF Gangsheet Builder is a pivotal step in building a sustainable and successful print business.

Testing and Quality Control in DTF Printing

Quality control is a non-negotiable aspect of any printing process, including DTF printing. Conducting test prints ensures that designs appear as intended on the final products and allows an opportunity to assess the effectiveness of your DTF print settings. It’s during these preliminary tests that issues such as color mismatches, poor adherence, or alignment problems can be identified and corrected before commencing full production.

Additionally, incorporating routine quality checks during production can help maintain a high standard of output. Establishing SOPs (Standard Operating Procedures) for testing each batch of prints can prevent costly errors and reduce the likelihood of customer complaints. Quality control not only preserves the reputation of your business but also instills confidence among customers in the reliability of your printing services.

Exploring DTF Printing Materials

The choice of materials in DTF printing directly impacts the final quality of the prints. Printing on diverse fabrics like cotton, polyester, or blends requires a thorough understanding of the material characteristics to achieve optimal results. Each type of fabric may respond differently to heat transfer, so it’s essential to select the right printing material to ensure durability and vibrancy in the final product.

Moreover, utilizing high-quality inks and adhesives designed specifically for DTF applications enhances the longevity of prints. The proper bonding of inks to the substrate is crucial in preventing issues like cracking or fading over time. Therefore, familiarizing oneself with various DTF printing materials is fundamental for any business aiming to deliver exceptional and lasting printed products.

Looking Forward: The Future of DTF Printing

As the landscape of DTF printing continues to evolve, staying informed about industry developments and advancements in technology is crucial. Events like the DTF Expo not only showcase the latest innovations but also provide networking opportunities and valuable insights from industry leaders. Attending such events can inspire businesses to adopt new strategies and tools that will enhance their printing capabilities.

Moreover, as customer demands shift and the market becomes increasingly competitive, adapting to trends in the printing industry will be vital. Embracing new technology and tools, like improved versions of the DTF Gangsheet Builder, can enable businesses to innovate and meet the changing preferences of consumers more effectively. Looking to the future, staying ahead of these trends will be essential in sustaining business growth within the DTF printing sector.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized tool that allows users to compile multiple graphic designs into a single printable sheet. This method significantly reduces production time and costs in DTF printing by enabling the simultaneous printing of various designs, ensuring efficient use of materials and maintaining print quality.

What are some key DTF printing tips to consider when using a DTF Gangsheet Builder?

When using a DTF Gangsheet Builder, it’s essential to optimize your heat press settings, typically around 325°F to 350°F for 8 to 15 seconds. Always perform test prints to ensure design fidelity on different materials, and arrange designs strategically on the gang sheet to minimize waste and maximize output.

What materials are compatible with the DTF printing process using a Gangsheet Builder?

DTF printing, especially when using a DTF Gangsheet Builder, is versatile and compatible with various fabric types including cotton, polyester, blends, and even leather. This versatility enables users to cater to a wide range of products such as t-shirts and bags.

How can I maximize efficiency when using a DTF Gangsheet Builder for print production?

To maximize efficiency with a DTF Gangsheet Builder, cluster your designs closely on the sheet while leaving adequate space between them to prevent merging during printing. Additionally, use the Auto DTF Gang Sheet Builder feature for automated layout to speed up the process.

What should I know about DTF print settings when using a Gangsheet Builder?

DTF print settings are crucial for achieving high-quality prints. Ensure that your heat press is set to the recommended temperature (325°F to 350°F) and pressure for optimal adhesion. Adjust settings based on your specific materials to enhance print durability and vibrancy.

Where can I find more insights about DTF printing and the DTF Gangsheet Builder?

To explore more insights about DTF printing and effectively using the DTF Gangsheet Builder, attend industry events like the DTF Expo 2025, where you can learn about the latest technologies, tools, and best practices directly from industry experts.

| Key Point | Description |

|---|---|

| What is DTF Gangsheet Builder? | A tool for compiling multiple designs into a single printable sheet, reducing production time and cost. |

| Auto Gang Sheet Builder | Automates the creation process for more efficiency and reduced manual adjustments. |

| Essential Tips | Optimize heat settings, leverage material versatility, always test prints, and adjust design arrangement. |

| DTF Expo 2025 | An opportunity for industry professionals to explore advancements and network within the DTF printing community. |

Summary

The DTF Gangsheet Builder is an essential tool that transforms the DTF printing process by maximizing efficiency and producing stunning prints. This innovative approach allows users to effortlessly compile multiple designs into a coherent printable sheet, saving time and reducing costs. By adhering to optimized heat press settings, utilizing material versatility, and rigorously testing prints, users can enhance their printing outcomes dramatically. Whether you’re just starting in the printing business or have extensive experience, the capabilities offered by the DTF Gangsheet Builder are pivotal for elevating your projects. Staying engaged with industry events like the DTF Expo ensures you remain at the forefront of printing advancements, enabling continual improvement in your craft.