DTF Gangsheet Builder: A Comparison with Traditional Printing

In the fast-evolving world of apparel printing, DTF Gangsheet Builder has emerged as a revolutionary tool that is transforming how custom designs are created and applied to fabrics. This innovative software harnesses the power of DTF printing technology, offering a user-friendly interface for designers, crafters, and small businesses looking to enhance their product offerings. Unlike traditional printing methods, DTF provides a more sustainable printing solution by significantly reducing waste and chemical usage. With the ability to create vibrant, detailed prints on demand, the DTF Gangsheet Builder stands out as a screen printing alternative that meets the needs of today’s eco-conscious consumers. As we explore the benefits and opportunities presented by this advanced technology, it’s clear that embracing DTF can elevate any apparel printing endeavor.

As the demand for personalized and eco-friendly apparel grows, tools like the Direct-to-Film (DTF) Transfer Builder are revolutionizing the garment printing landscape. This software enables users to generate custom prints efficiently, making it a desirable choice for entrepreneurs and artists in the custom apparel printing realm. By capitalizing on the advantages of DTF printing, users can achieve high-quality results that surpass many traditional printing methods, such as plastisol and screen printing, while adhering to sustainable practices. The ability to produce unique designs on demand not only caters to the rising consumer preferences for customization but also aligns with the industry’s movement towards greener practices. As we delve deeper into the features of the DTF Transfer Builder, its impact on textile printing will become increasingly evident.

The Evolution of Apparel Printing: DTF vs. Traditional Methods

Apparel printing has undergone significant transformations over the years, evolving from traditional methods such as screen printing to modern digital solutions like **Direct-to-Film (DTF)** printing. Traditional printing methods often involve labor-intensive processes and require significant setup times which can result in higher production costs and waste. For businesses that thrive on efficiency and innovation, DTF offers a streamlined alternative that not only reduces ink usage but also minimizes the need for extensive materials, thus aligning with current sustainability trends in manufacturing.

Moreover, DTF technology allows for quicker production turnaround, making it an ideal choice for businesses looking to meet rapid consumer demands. With the utilization of DTF Gangsheet Builder tools, designers can produce high-quality custom prints efficiently, promoting a shift away from time-consuming techniques. As the apparel printing landscape continues to evolve, it’s clear that methods like DTF will play a pivotal role in meeting both aesthetic and environmental requirements for brands.

Traditional printing methods, while established, often struggle with their limitations regarding customization and flexibility. Brands looking to cater to niche markets or those requiring small batch productions are finding DTF an invaluable resource. By enabling direct film transfers that can be applied to various fabrics with intricate designs and colors, DTF challenges the traditional norms of bulk production, making personalized apparel more accessible to both consumers and small businesses alike.

In conclusion, as the demand for unique and eco-conscious products heightens, the evolution towards DTF technologies becomes not just a trend but a necessary shift in the garment industry. Embracing DTF’s capabilities offers businesses the competitive edge needed to stay relevant in a dynamic market, especially for those competing with traditional methods of screen printing.

Understanding DTF Printing Technology: How It Works

The mechanics of **Direct-to-Film (DTF)** printing involve a fascinating blend of technology and creativity. Unlike traditional screen printing, which uses frames and stencils, DTF employs a specialized film where prints are created digitally. Once the design is printed onto the film with vibrant, eco-friendly inks, heat and pressure are applied to transfer the design directly onto the chosen fabric. This process not only ensures superior color brightness and detail but also allows for the production of complex designs that screen printing may struggle to replicate effectively.

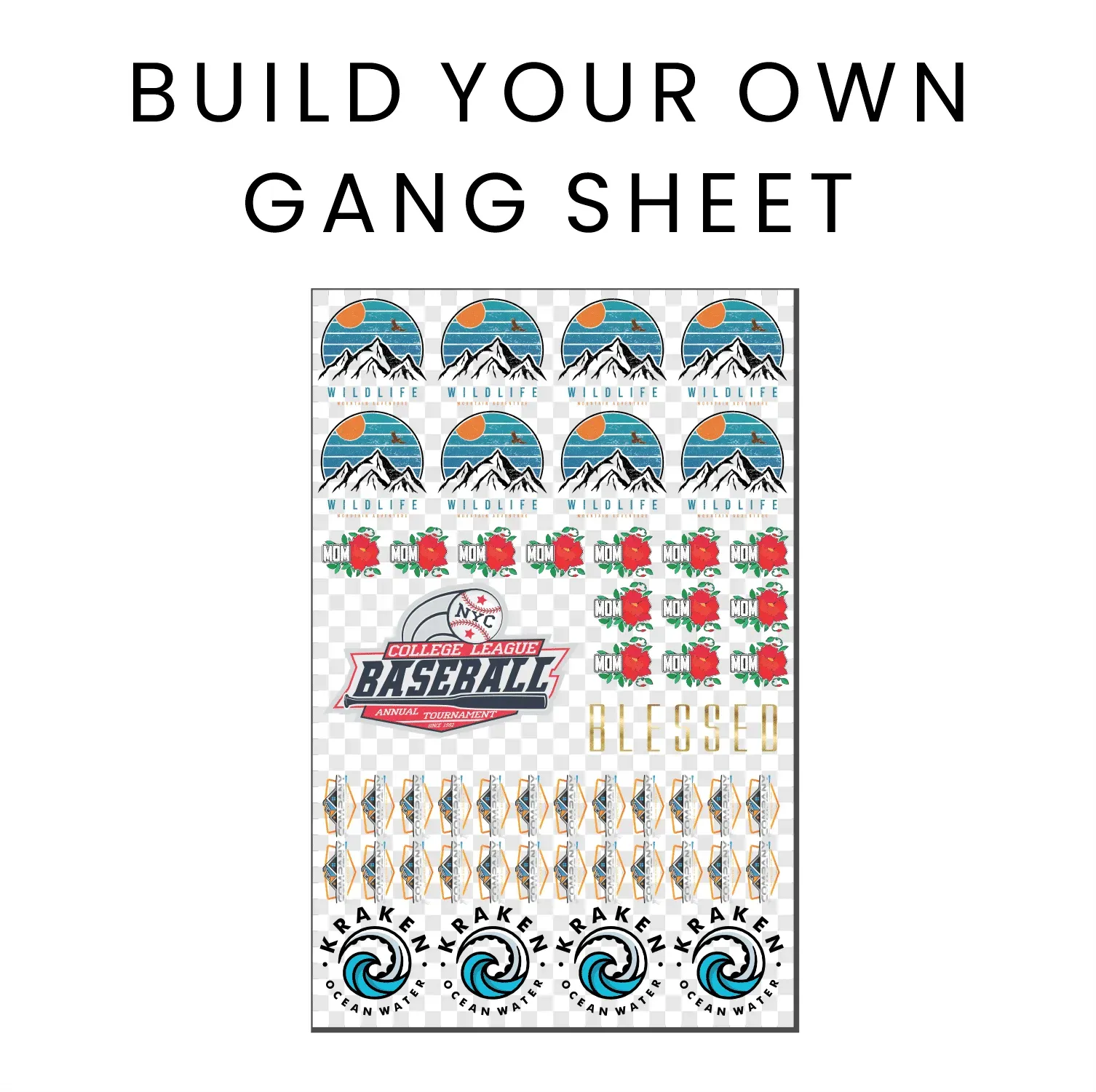

This innovative method reduces material waste, as there’s no need for multiple screens (as in screen printing) for different colors, making it more environmentally friendly. By utilizing a DTF Gangsheet Builder, users can produce multiple designs in one go, maximizing efficiency and providing endless possibilities for customization. The advantages of reduced setup time, coupled with lower environmental impact, illustrate why DTF technology is emerging as a preferred choice for those looking to modernize their apparel printing processes.

Benefits of DTF Gangsheet Builder for Custom Apparel

One of the standout features of the **DTF Gangsheet Builder** is its capacity to adapt to various printing demands, making it an essential tool for custom apparel creators. Crafters and small business owners can take advantage of this technology to manufacture short runs of specialized products without the financial burden of traditional printing methods. This flexibility makes it possible for designers to keep their offerings fresh and tailored to consumer preferences, enhancing their overall market competitiveness.

The customization capabilities of the Gangsheet Builder means that users can experiment with diverse designs, colors, and fabric types, appealing to a broad audience looking for unique fashion items. As consumer interest in personalized apparel grows, leveraging the DTF Gangsheet Builder empowers businesses to deliver products that fulfill individual customer desires while also adhering to sustainable production practices.

Traditional Printing Methods: Their Challenges and Limitations

While traditional printing methods such as screen printing have their advantages, they also come with substantial challenges that can hinder creative expression and operational efficiency. For instance, the required setup time and costs associated with screen printing often discourage small businesses from producing limited-run products or custom designs. This results in overproduction and unsold inventory, which can lead to significant environmental consequences, especially when inks and materials are discarded.

Moreover, many conventional methods rely heavily on chemicals and inks that pose environmental risks. These factors push businesses toward exploring alternatives that are not only efficient but also eco-friendly, and this is where DTF technology shines. By minimizing the use of harmful substances and offering a more agile production model, DTF directly addresses the shortcomings of traditional printing methods, aligning perfectly with the industry’s shift towards sustainable practices.

The Shift Towards Sustainable Printing Solutions

As global awareness surrounding sustainability increases, industries are rapidly adapting their practices to meet the demands of eco-conscious consumers. In the realm of printing, **DTF technology** has emerged as a sustainable solution, minimizing waste and employing inks that are less harmful to the environment than those used in many traditional printing processes. This trend not only aligns with consumer expectations but also encourages businesses to pursue greener operational methods.

By investing in sustainable printing solutions like DTF, companies can significantly reduce their carbon footprints while still delivering high-quality products. The continued adoption of DTF processes illustrates a collective movement towards responsible manufacturing that benefits both businesses and the planet. As preferences shift favoring eco-friendly practices, brands that prioritize sustainability will position themselves favorably within their markets.

Exploring Future Trends in Custom Apparel Printing

The future of custom apparel printing is undeniably leaning towards technological advancements like DTF printing. The convenience and efficiency that DTF Gangsheet Builder brings to small-scale print operations cannot be overlooked. With advancements in technology, the fashion industry anticipates a rise in demand for custom, on-demand printing capabilities that keep pace with fast-changing consumer trends.

As more brands begin to embrace DTF printing technology, we can expect a diversification of offerings within the market. This shift allows businesses to focus more on individual customer experiences rather than mass production, promoting creativity and allowing consumers to express their unique identities through personalized apparel. With increasing consumer awareness surrounding the impact of fashion on the environment, DTF could redefine the standards of custom printing, steering the industry toward a more sustainable and innovative future.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve custom apparel printing?

The DTF Gangsheet Builder is a tool designed for Direct-to-Film (DTF) printing technology that allows users to create custom transfer prints efficiently. Unlike traditional printing methods, the DTF Gangsheet Builder streamlines the process of producing vibrant and detailed designs on-demand, catering to small businesses and independent crafters who seek to offer unique apparel without extensive inventory.

How does DTF printing technology compare to traditional printing methods like screen printing?

DTF printing technology offers several advantages over traditional printing methods, particularly screen printing. It reduces setup and material waste, allowing for quicker turnaround and lower production costs. DTF allows for short runs, which means businesses can operate on a just-in-time basis, minimizing inventory and aligning with eco-friendly initiatives.

Can the DTF Gangsheet Builder support sustainable printing solutions?

Yes, the DTF Gangsheet Builder supports sustainable printing solutions by significantly reducing ink and material waste compared to traditional printing methods. This technology minimizes the use of harmful chemicals, aligning with the growing consumer demand for eco-conscious apparel production and promoting more sustainable practices in the industry.

What are the benefits of using DTF technology over heat transfer methods in apparel printing?

DTF technology surpasses heat transfer methods in that it does not require extensive pre-press treatment and allows for richer color saturation and finer details. Furthermore, the DTF Gangsheet Builder enables customizable and quick production of designs, which is crucial for artists and small businesses adapting to fluctuating consumer preferences.

Is the DTF Gangsheet Builder suitable for small business owners in the custom apparel printing market?

Absolutely! The DTF Gangsheet Builder is highly suited for small business owners as it allows for customization without large upfront investments. It facilitates on-demand production, enabling these businesses to meet customer demands with diverse designs while avoiding the pitfalls of overproduction common in traditional printing methods.

Are there any disadvantages of DTF printing technology compared to conventional printing methods?

While DTF printing technology offers many benefits, some disadvantages include the need for specific equipment and materials, which can have an initial cost. Additionally, the longevity of prints compared to traditional methods might vary depending on application and care. However, the DTF Gangsheet Builder addresses many traditional printing challenges by offering a more flexible and efficient solution.

| Key Point | Description |

|---|---|

| Introduction to DTF Technology | DTF printing allows for vibrant colors and finer details, enhancing sustainability by reducing waste. |

| Advantages of DTF Gangsheet Builder | Efficiency in production and customization for small businesses, with a focus on eco-friendliness. |

| Limitations of Traditional Methods | Traditional methods require extensive setup and create excess waste, limiting flexibility. |

| Future of Apparel Printing | DTF is expected to reshape industry standards, emphasizing sustainable and customizable solutions. |

| Consumer Impact | Growing demand for personalization and sustainability may shift market preferences towards DTF. |

Summary

DTF Gangsheet Builder revolutionizes the apparel printing landscape by offering unparalleled efficiency and customization options. As businesses and designers increasingly seek sustainable solutions, this innovative technology provides a compelling alternative to traditional methods. In a world where eco-conscious practices and personalized products are becoming essential, the DTF Gangsheet Builder stands out as a preferred choice for small businesses and independent creators looking to thrive in a competitive market. This not only signifies a shift in printing technology but also highlights the growing consumer demand for unique and environmentally friendly offerings, ultimately transforming the future of the apparel industry.