UV DTF Gangheet Innovations: The Future of Fabric Printing

In the rapidly evolving landscape of fabric printing technology, UV DTF Gangheet Innovations stand out as a transformative force. This cutting-edge process merges the advantages of the UV printing process with Direct to Film (DTF) techniques, offering unprecedented opportunities for customization and sustainability in the fabric industry. As businesses and consumers increasingly prioritize unique, eco-friendly solutions, UV DTF Gangheet Innovations provide a perfect answer by enabling vibrant and durable custom fabric printing. The enhanced capabilities of these printing methods not only deliver exceptional color vibrancy but also promote responsible practices. With a focus on sustainable fabric printing, this innovative approach is set to revolutionize how we think about printed textiles.

Delving into the advancements in printing fabrics, UV DTF Gangheet Innovations represent a remarkable integration of digital and traditional methods. Often referred to as a breakthrough in direct film application, this approach harnesses the power of UV light to cure inks instantly, resulting in high-quality, customized prints that resonate with modern consumer demands. By harnessing the benefits of DTF technology, businesses now have a reliable avenue for producing eco-friendly, vibrant designs with minimal environmental impact. As we further explore this innovative realm, the potential for sustainable fabric printing processes grows, enabling creators and brands to connect more authentically with their audiences.

Exploring UV DTF Gangheet Innovations

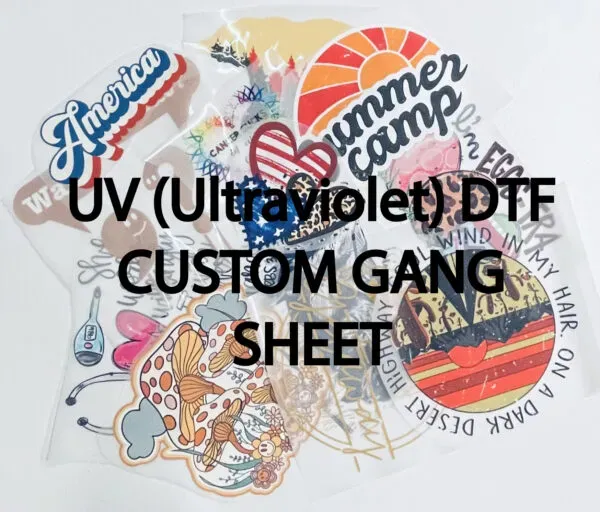

UV DTF Gangheet innovations represent a transformative leap in the field of fabric printing technology. By integrating advanced techniques with the UV DTF process, this innovation enables manufacturers to achieve higher precision and variety in fabric design. The ability to print intricately detailed designs on diverse fabric materials not only enhances the aesthetic appeal of the final product but also opens up new possibilities for custom fabric printing. As the demand for personalized items rises, the role of UV DTF Gangheet gets increasingly significant, making it a cornerstone for future fabric printing projects.

Moreover, UV DTF Gangheet innovations encapsulate sustainability within the fabric printing industry. Utilizing eco-friendly inks and production methods aligns with the global shift toward environmentally responsible practices. This includes reducing waste during production and increasing the longevity of printed materials. As consumers become more discerning about the environmental impact of their purchases, brands embracing these innovations can appeal to a broader audience that values sustainability alongside quality.

Understanding the UV Printing Process

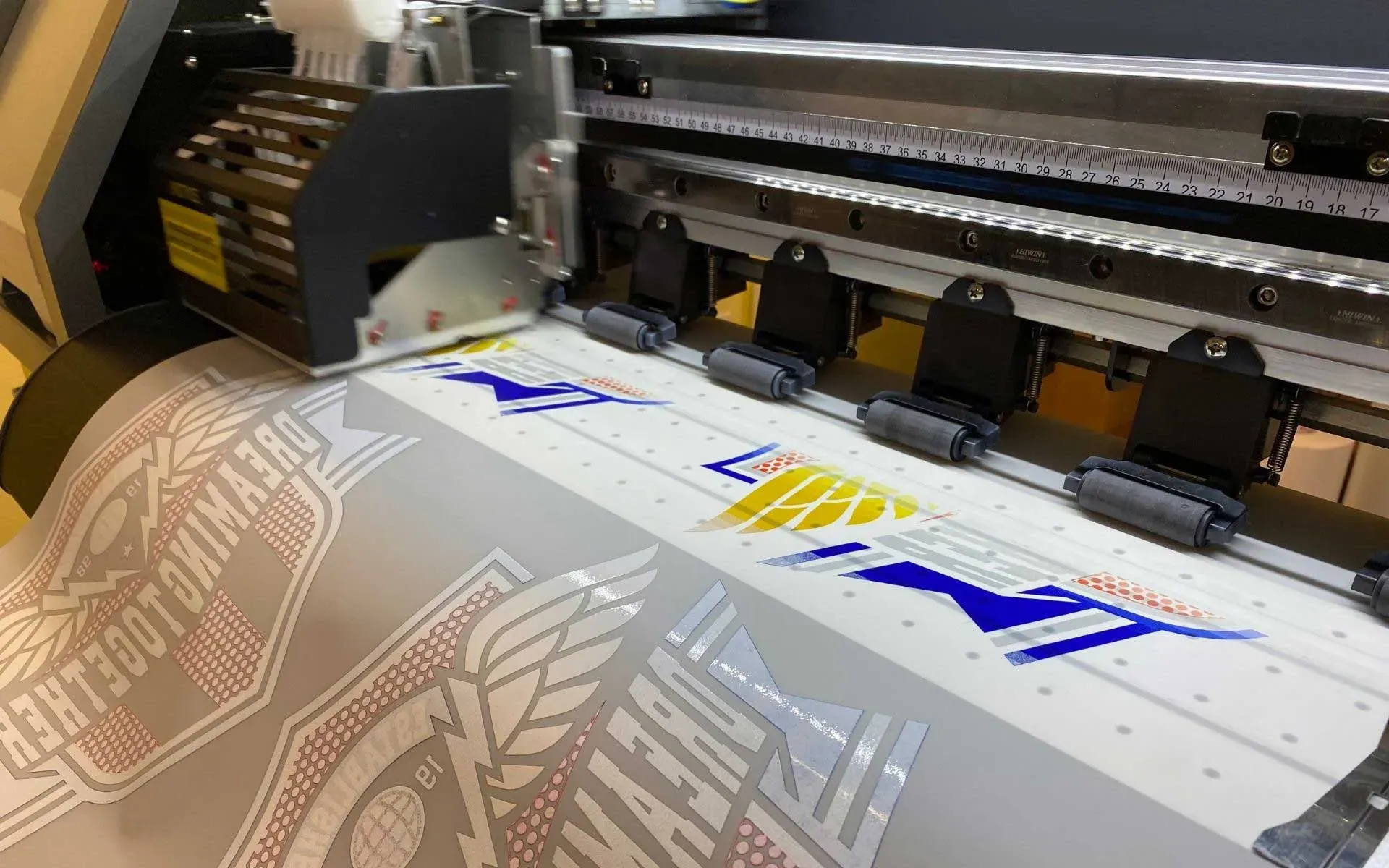

The UV printing process serves as the backbone of UV DTF technology, utilizing ultraviolet light to cure inks onto specific substrates instantly. This method stands out for its ability to produce designs with vibrant colors that are not just visually appealing but also durable. The instant curing process prevents common issues faced in traditional fabric printing, such as smudging or color bleeding, thereby enhancing the overall print integrity. By leveraging UV ink formulations that ensure better adhesion and resistance to wear, brands can deliver products that retain their visual appeal over time.

In essence, understanding the UV printing process is crucial for appreciating the benefits of innovations like UV DTF Gangheet. The ability to achieve high-quality custom fabric printing relies heavily on the effectiveness of UV curing technologies. As manufacturers continue to refine this process, the potential for creating complex designs becomes more accessible, allowing designers and artisanal brands to experiment with their artistic visions without the limitations imposed by older technologies.

The Rise of Custom Fabric Printing

The rise of custom fabric printing has reshaped the landscape of the textile industry, giving customers more options than ever before. This growth can be attributed to advancements in printing technology such as UV DTF, which reduces turnaround times and allows for the production of limited runs of unique designs. Businesses that harness the capabilities of custom fabric printing can respond swiftly to trends, enabling them to capitalize on market demands effectively. This agility is especially crucial in the fashion industry, where the ability to create strikingly vibrant prints quickly can set a brand apart from its competitors.

Custom fabric printing through UV DTF also enhances customer engagement, allowing clients to become directly involved in the design process. This personalization fosters brand loyalty as customers feel a sense of ownership over their custom products. The positive response from customers regarding their personalized items reinforces the importance of custom printing as a core strategy for modern textile brands aiming for differentiation in a crowded marketplace.

Benefits of DTF Printing Technology

DTF printing technology encompasses several benefits that set it apart from traditional methods. One of the most notable advantages is its ability to produce vibrant, high-quality images with exceptional detail. This is achieved through the use of specialized inks and transparent films, which work harmoniously to transfer designs onto various fabric types. Colors produced through DTF techniques tend to be more intense and long-lasting, making them ideal for fashion apparel and merchandise where appearance is paramount.

Additionally, DTF printing offers increased versatility when it comes to fabric choices. From cotton to blends and synthetic materials, DTF technology seamlessly adapts to print on various substrates without compromising print quality. This flexibility is especially advantageous for businesses looking to diversify their product ranges, catering to different customer preferences and fabric applications.

Sustainability in Fabric Printing Solutions

Sustainability has become a focal point in modern fabric printing solutions, with manufacturers seeking to minimize their environmental footprint. Innovations in UV DTF technology facilitate eco-friendly practices by utilizing low-VOC inks and minimizing waste during the production process. As awareness regarding environmental issues rises among consumers, brands embracing sustainable fabric printing solutions can build strong equity and loyalty among their clientele, positioning themselves as responsible industry leaders.

Incorporating sustainable methods is not solely beneficial for the environment; it also provides competitive advantages in the market. Companies that adopt eco-friendly printing technologies, such as UV DTF, not only appeal to conscious consumers but can also potentially reduce operational costs through more efficient resource management. This dual benefit underscores the crucial role of sustainability within the future of fabric printing and the importance of ongoing innovations in this domain.

Automation and Efficiency in Fabric Printing

Automation is revolutionizing the fabric printing industry, enhancing efficiency in production workflows. With the integration of automated systems, UV DTF printing can streamline processes, reduce turnaround times, and increase output without sacrificing quality. This transition to automated fabric printing not only cuts labor costs but also allows for consistent printing results, meeting the demands of fast-paced fashion sectors and promotional campaigns.

Furthermore, the implementation of budding technologies such as artificial intelligence and machine learning in automated printing systems leads to improved accuracy in design placement and color matching. These advancements enable manufacturers to focus on creativity and innovation while ensuring that production runs smoothly and efficiently. As automation becomes more integrated into fabric printing, brands that leverage these systems stand to gain significant advantages in a highly competitive market.

Frequently Asked Questions

What is UV DTF Gangheet Innovations in fabric printing technology?

UV DTF Gangheet Innovations refer to advancements in UV Direct to Film (DTF) printing that enhance the quality and versatility of custom fabric printing. This technology combines traditional methods and digital techniques, allowing for vibrant, durable prints on various fabrics with unique designs.

How does the UV printing process used in UV DTF Gangheet work?

In the UV printing process for UV DTF Gangheet, specially formulated inks are cured with UV light as they are applied to a transfer film. This immediate curing helps maintain color vibrancy and clarity while reducing ink bleeding, ensuring high-quality results for custom fabric printing.

What are the sustainability benefits of UV DTF Gangheet Innovations?

UV DTF Gangheet Innovations support sustainable fabric printing through the use of eco-friendly inks and materials that reduce waste. This environmentally responsible approach is increasingly important in the fabric printing industry, making UV DTF an attractive option for businesses seeking to minimize their ecological impact.

What are some advantages of using DTF printing benefits in UV DTF Gangheet technology?

The DTF printing benefits in UV DTF Gangheet technology include exceptional color vibrancy, durability against fading and washing, and the capability for highly customizable designs with short lead times, making it an ideal choice for fashion brands and promotional products.

How has UV DTF Gangheet Innovations impacted the market for custom fabric printing?

UV DTF Gangheet Innovations have revolutionized the custom fabric printing market by allowing for on-demand printing with low minimum order quantities. This flexibility has led many companies to adopt this technology, resulting in increased satisfaction from consumers who demand quality and personalization in their fabric products.

What challenges do businesses face when adopting UV DTF Gangheet Innovations?

Businesses may encounter challenges such as the initial investment required for specialized UV DTF equipment and the need for staff training on new processes. However, ongoing support and training programs can help ease this transition, ensuring a successful integration of UV DTF technology into existing operations.

| Key Features | Details |

|---|---|

| UV DTF Printing | Uses UV light to cure ink directly onto film for seamless transfers onto fabric. |

| Benefits | 1. **Color Vibrancy**: Produces vivid colors, prevents dulling. 2. **Durability**: Resistant to fading and scratching. 3. **Customizability**: Minimal setup time for personalized designs. 4. **Eco-Friendly**: Utilizes sustainable inks and materials. |

| Innovations | 1. Enhanced ink formulations for better adherence. 2. Improved heat transfer films for texture and quality. 3. Automation of processes reducing costs. 4. Integration with advanced design software. |

| Market Adoption | Fashion brands and promotional companies are leveraging UV DTF for custom and vibrant prints. |

| Challenges | Investment in equipment and training, along with a learning curve. |

| Solutions | Training sessions and consulting services help businesses transition smoothly. |

Summary

UV DTF Gangheet Innovations are revolutionizing the fabric printing industry by providing brighter colors, increased durability, and sustainable options. As manufacturers and designers embrace this advanced technology, they can create highly customized fabric products with ease. The integration of enhanced materials and automation into the UV DTF process signifies a substantial leap forward, which not only boosts productivity but also meets the rising demand for personalized pieces in the market. Despite the challenges in adopting this innovative method, the commitment to training and support ensures that the transition into UV DTF printing is not only feasible but also profitable. Consequently, the future of fabric printing, driven by UV DTF Gangheet Innovations, appears promising as it fosters creativity and environmental mindfulness.