DTF Transfers: The Printing Innovation Taking Over 2023

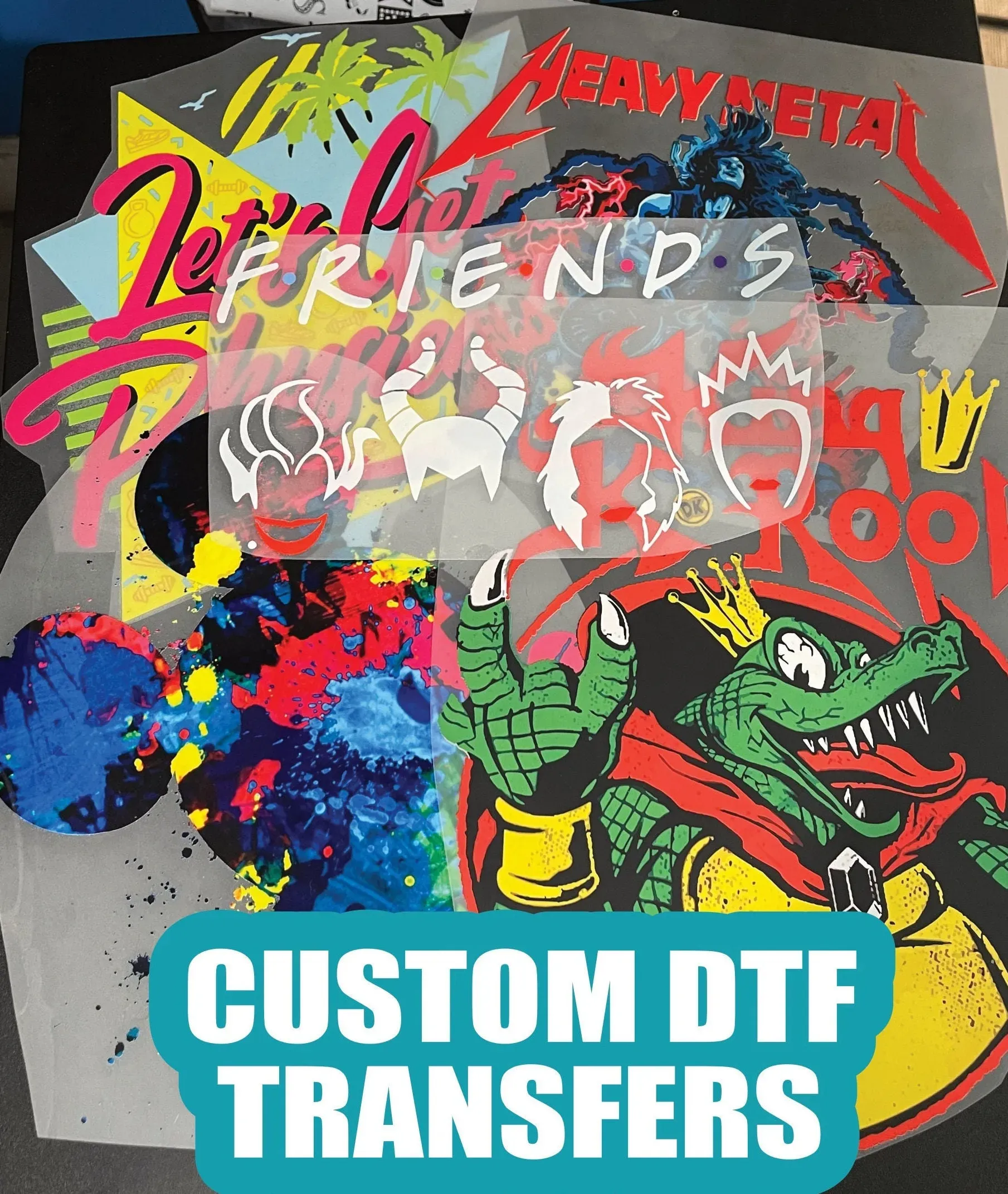

DTF Transfers, or Direct-to-Film transfers, are quickly becoming the go-to method for custom apparel printing, revolutionizing the textile industry. This innovative printing technique allows designs to be printed onto a transparent film using cutting-edge technology, resulting in stunning, high-quality prints that adhere to various fabric types. As businesses increasingly recognize the array of DTF printing benefits—such as vibrant colors, durability, and the ability to handle intricate designs—this market continues to experience significant growth. Moreover, DTF’s alignment with eco-friendly printing practices has attracted environmentally-conscious companies seeking sustainable solutions in their production processes. With the rise of personalized merchandise, DTF transfers are paving the way for a new era of customization in the world of printing.

The world of custom textile production is evolving, notably with the emergence of Direct-to-Film printing—a method that transcends traditional printing techniques. This approach involves utilizing specialized films to produce detailed designs that bond effortlessly with various materials. As the trend towards personalized apparel accelerates, the demand for innovative printing methods, such as film-based transfers, has surged. Alongside its capacity for producing high-quality outputs, the rise of this technology also emphasizes the importance of sustainability in printing practices, appealing to a growing demographic of eco-friendly consumers. The ongoing advancements in the DTF landscape are set to reshape how businesses approach custom design and fulfill client desires for unique and sustainable products.

Understanding Direct-to-Film (DTF) Transfers

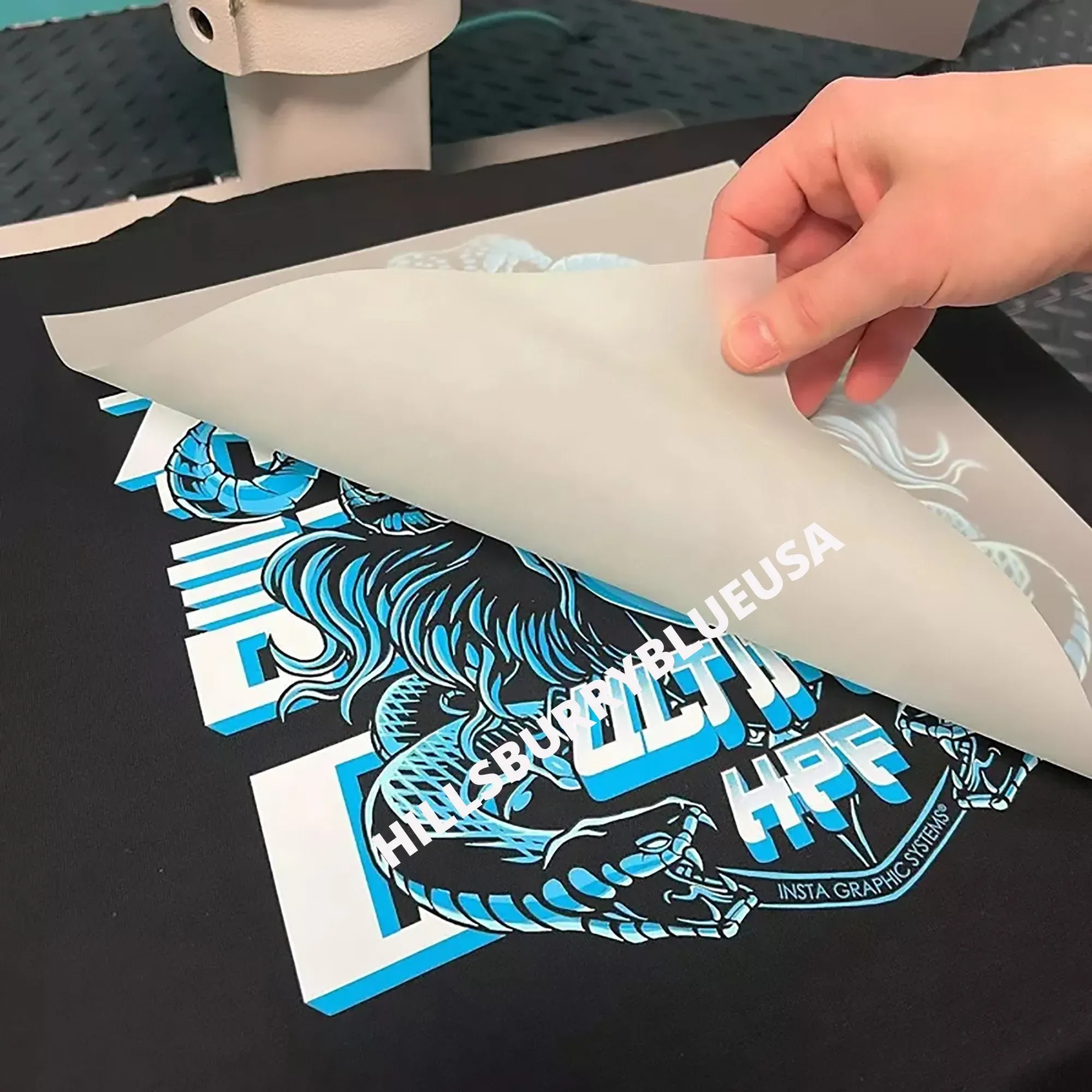

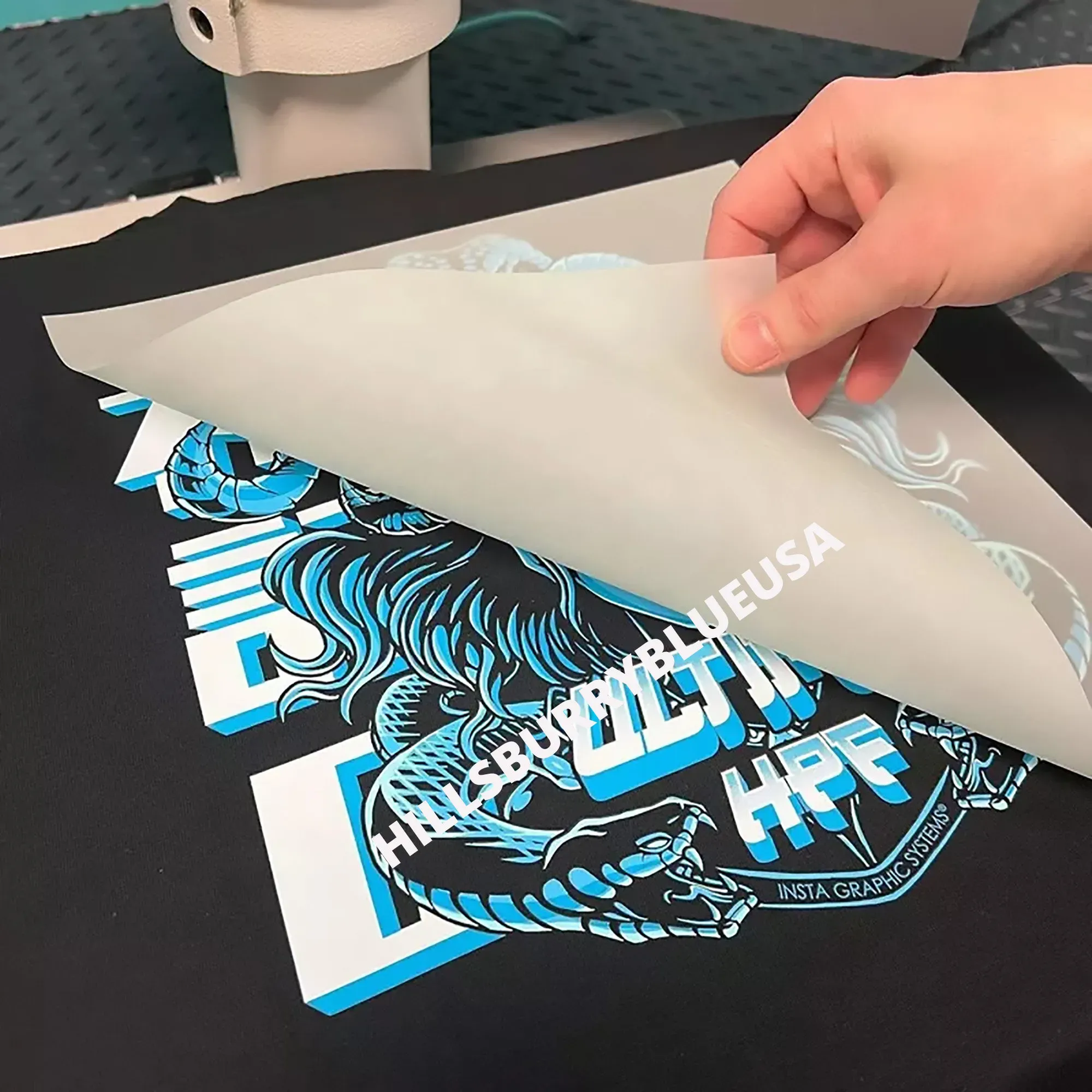

Direct-to-Film (DTF) transfers have emerged as a revolutionary method in the printing industry, redefining how designs are applied to fabric. This innovative printing technique involves printing high-resolution images onto a special film which is then coated with a heat-activated adhesive. The process allows for stunningly vibrant designs, rich colors, and precise detailing that appeals to both businesses and consumers alike. Thanks to DTF transfers, custom apparel printing has never been more efficient, as it accommodates various materials such as cotton, polyester, and blends, making it ideal for a wide array of products.

Moreover, DTF printing’s versatility extends beyond traditional fabric, offering potential for use on unique materials like leather or canvas. This flexibility not only enhances creative possibilities for designers but also enables businesses to cater to diverse market demands. As consumers increasingly seek personalized items, DTF transfers provide an attractive solution that combines quality and customization, positioning this printing technique as a key player in the future of apparel production.

The Environmental Impact of DTF Printing

In the current age of eco-consciousness, businesses are under increasing pressure to adopt sustainable practices. DTF printing stands out in this regard as it uses significantly less water and fewer harmful chemicals compared to traditional dye-sublimation methods. The eco-friendly printing practices associated with DTF transfers not only appeal to environmentally minded consumers but also help brands differentiate themselves in a competitive market.

Further contributing to its environmental benefits, DTF printing eliminates the need for multiple setups for different fabrics, reducing waste generated during the printing process. By utilizing fewer resources, companies can enhance their sustainability profile while still delivering high-quality products. This makes DTF an appealing option for brands looking to minimize their carbon footprint while attracting a growing segment of eco-aware customers.

The Advantages of DTF Printing

DTF printing offers a multitude of advantages that contribute to its growing popularity within the custom apparel printing market. One key benefit is its user-friendly nature; compared to techniques like Direct-to-Garment (DTG) printing, DTF requires less specialized equipment and training. This accessibility allows businesses of all sizes to effectively implement DTF technology into their operations, thereby increasing their production capabilities without incurring excessive costs.

Additionally, the rapid drying process of DTF transfers eliminates long waiting times typically associated with other printing methods. This efficiency translates into faster turnaround times for customers, ultimately enhancing satisfaction and loyalty. Coupled with the ability to print intricate designs and a broad spectrum of colors, DTF printing effectively meets the demands of modern consumers who seek both customization and quality.

The Rapid Growth of the DTF Market

The DTF printing market is experiencing unparalleled growth, projected to expand at a compound annual growth rate (CAGR) of over 20% through 2027. This surge is driven by the increasing demand for custom apparel and promotional products, as more consumers seek personalized items that reflect their individuality. The scalability of DTF technology enables businesses to meet this rising demand without compromising on quality or speed, setting the stage for further market expansion.

Furthermore, the DTF market’s growth is indicative of broader trends in consumer behavior, where personalization has taken center stage. Brands that incorporate DTF printing into their offerings stand to benefit not only from increased sales but also from the enhanced customer engagement that customization brings. As more companies recognize these opportunities, the future of DTF printing looks bright, paving the way for innovation and unique product offerings.

Challenges Faced by DTF Transfers

Despite the many advantages, the DTF printing process does have its challenges. Initial setup costs can be relatively low; however, businesses often overlook the ongoing expenses tied to inks, films, and adhesive powders. Moreover, as DTF technology gains traction, increased competition may pressure prices and profit margins, making it crucial for businesses to strategize effectively.

Additionally, while DTF transfers can produce high-quality prints, they still require a certain level of skill and expertise to ensure flawless execution. Companies must invest in training and knowledge to effectively utilize DTF printing to its full potential, particularly as technology continues to evolve. Addressing these challenges is essential for firms to thrive in the dynamic landscape of the printing industry.

The Bright Future of DTF Transfers

Looking ahead, the future of DTF transfers is filled with promise as technological advancements continue to reshape production methods. Improved ink formulations and printing techniques are anticipated, leading to enhanced quality, efficiency, and cost-effectiveness. This continuous evolution will support businesses in maintaining a competitive edge while meeting the ever-changing demands of consumers.

Furthermore, as marketing strategies increasingly focus on customization and personalization, the DTF printing method will be integral to fulfilling these consumer desires. Brands that proactively adopt DTF transfers will likely tap into a lucrative market segment, all while reinforcing their commitments to sustainability and innovation. Overall, the trajectory of DTF printing indicates a vibrant future within the broader printing industry, offering exciting possibilities for creativity and growth.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto transparent film using specialized inks. The films are then treated with adhesive powder which bonds with fabric through a heat transfer process. This method allows for versatile printing on various materials, such as cotton and polyester, offering flexibility over traditional printing methods.

What are the benefits of DTF printing for custom apparel?

DTF printing offers numerous benefits for custom apparel, including high-quality prints, the ability to print on diverse materials, and a user-friendly process that enables bulk production. Additionally, DTF printing’s durability and vibrant color output enhance customer satisfaction, positioning it as a preferred choice in the custom apparel market.

How does DTF printing support eco-friendly practices?

DTF printing is more eco-friendly than traditional dye-sublimation methods as it uses significantly less water and generates less waste. This sustainable approach makes DTF transfers an attractive option for companies looking to minimize their environmental impact while still delivering quality products to consumers.

What factors contribute to the rapid growth of the DTF printing market?

The DTF printing market is expected to experience notable growth due to rising demand for customized apparel and promotional goods. With advancements in technology, coupled with businesses seeking efficient and cost-effective printing solutions, DTF printing is becoming a dominant force in the industry, projected to grow at over 20% CAGR through 2027.

How does DTF printing compare to other printing methods like DTG and screen printing?

Compared to DTG and screen printing, DTF printing is more versatile, allowing for prints on a wider range of fabrics. It also has a simpler setup process, making it easier for businesses to produce high-quality prints without extensive training. Furthermore, DTF transfers typically result in less waste, supporting sustainability efforts in printing.

What challenges do businesses face when adopting DTF transfers?

While DTF transfers offer many advantages, businesses may face challenges such as ongoing costs related to inks, films, and adhesive powders. Additionally, as the DTF printing market expands, increased competition could impact pricing and profit margins, necessitating strategic planning for sustainability in operations.

| Key Point | Details |

|---|---|

| Definition of DTF Transfers | DTF printing involves transferring designs printed on transparent film using heat and adhesive powder. It accommodates various fabrics. |

| Technological Advancements | Improved ink quality and adhesives enhance durability and washability, meeting the vibrant design needs of businesses. |

| Market Growth | Projected CAGR of over 20% through 2027 due to increased demand for customized products and promotional items. |

| User-Friendliness | DTF printing is easy to use, requiring less training compared to DTG, allowing for efficient bulk production without heavy investments. |

| Sustainability | DTF uses significantly less water than traditional methods, appealing to eco-conscious consumers and businesses looking to minimize environmental impact. |

| Industry Adoption | Growing integration in custom apparel production, leading to higher customer satisfaction due to vibrant designs and color fidelity. |

| Challenges | Ongoing costs of materials and increasing competition could affect prices and profit margins for businesses adopting DTF. |

| Future Prospects | Continued technological advancements are expected, with increased training resources and a shift toward customization in marketing strategies. |

Summary

DTF Transfers are revolutionizing the printing industry by offering a modern, efficient, and eco-friendly option for fabric printing. The rise of DTF transfers can be attributed to their unique advantages, such as their flexibility in material use, ease of production, and increased sustainability compared to traditional printing processes. Businesses are embracing DTF printing not only for its ability to produce high-quality designs but also for its economic viability in a rapidly growing market. As technology continues to advance, the future of DTF transfers looks promising, paving the way for further innovation and consumer satisfaction in the printing sector.