DIY DTF Transfers: Step-by-Step Guide for Home Crafters

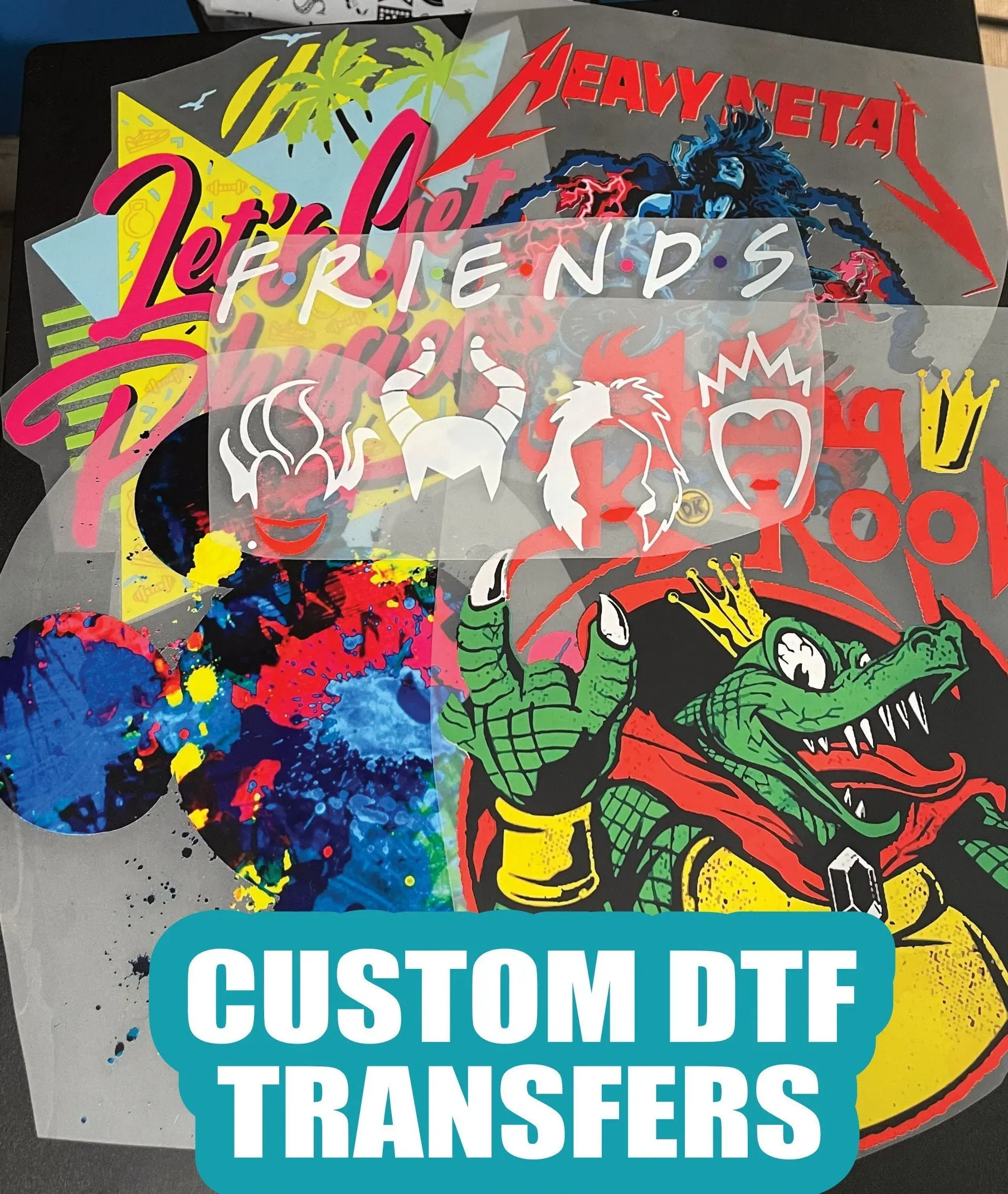

DIY DTF transfers are revolutionizing the craft world, allowing enthusiasts to bring their unique designs to life on fabric in an exciting and accessible way. This innovative printing method, known for its durability and vibrant color reproduction, enables crafters to easily customize clothing and fabric-related projects right at home. Whether you’re a beginner exploring DTF printing for beginners or simply eager to learn how to DTF transfers, this guide is your go-to resource. Dive into our DTF transfer printing guide to discover the essential materials, printing techniques, and pro tips for successful DIY fabric transfers. Transform your creations into stunning custom fabric printing masterpieces that truly reflect your style and creativity.

When it comes to transferring designs onto textiles, various techniques exist, but few stand out like the DIY approach to Direct to Film (DTF) printing. This process empowers crafters to print intricate graphics onto a special film, paving the way for vibrant and durable fabric designs that withstand the test of time. As you delve into the world of personalized fabric creations, consider exploring this dynamic method that combines ease of use with exceptional results. From fabric transfers that can enhance apparel to comprehensive guides detailing every step of this exciting craft, the possibilities are limitless. Join the growing community of creators who are exploring the beauty of custom fabric printing through DTF transfers, unlocking new avenues for artistic expression.

Exploring the Basics of DTF Printing

**DTF printing for beginners** is an exciting frontier for crafters willing to create custom designs with ease. At its core, DTF printing refers to the method of printing designs onto a special film, which can then be heat transferred onto various fabric types. This technique stands apart from traditional methods like vinyl or screen printing, offering unique advantages such as cost-effectiveness and ease of use. With DTF, you can achieve stunning, full-color prints that maintain their vibrancy over time, making it an ideal choice for everyone from hobbyists to small business owners.

As you embark on your DTF journey, understanding the workflow is key. From selecting the right printer to finding quality adhesive powders, every step matters. The beauty of DTF is its simplicity; with just a few key materials, you can begin experimenting with different designs, colors, and fabrics. Additionally, the technique is less labor-intensive than traditional methods, allowing crafters to produce intricate designs without excessive effort.

Getting Started with DIY DTF Transfers

To kick off your DIY DTF transfers, ensuring you have all the essential materials is crucial. As previously mentioned, a **DTF printer** equipped with special DTF inks and films is required. This printer allows for high-resolution printing, which is crucial when it comes to capturing fine details. Alongside the printer, you’ll need adhesive powder that bonds the ink to the fabric, and a heat press for transferring your designs. Each of these components plays a vital role in achieving that professional finish that home crafters aspire to.

Moreover, understanding how to prepare your designs is key in this process. It’s essential to acquire design software that suits your needs, whether you’re creating from scratch or modifying existing designs. Knowing how to format your images for printing, especially mirroring text, will ensure that your transferred designs look their best on your chosen fabric. Taking the time to familiarize yourself with these tools sets the foundation for successful DTF printing.

The Art of Printing Your Design

Printing your design is a fundamental aspect of the **DIY fabric transfers** process. It involves adjusting your printer settings to accommodate the DTF film’s compatibility. This may include selecting the appropriate media type, print quality, and ensuring that your printer uses the right color profiles to achieve the desired outcome. It’s also helpful to run a few test prints before committing to your final design, as this can help in troubleshooting any potential issues before transferring to the fabric.

As you print, ensure your designs are loaded properly in the printer, taking care to use a mirrored setting if text or detailed graphics are included. This will prevent errors and ensure that the final appearance on fabric is as intended. Many users find that experimenting with different design layouts during this phase can lead to unexpected and delightful results, enhancing the creative process.

Mastering the Application of Adhesive

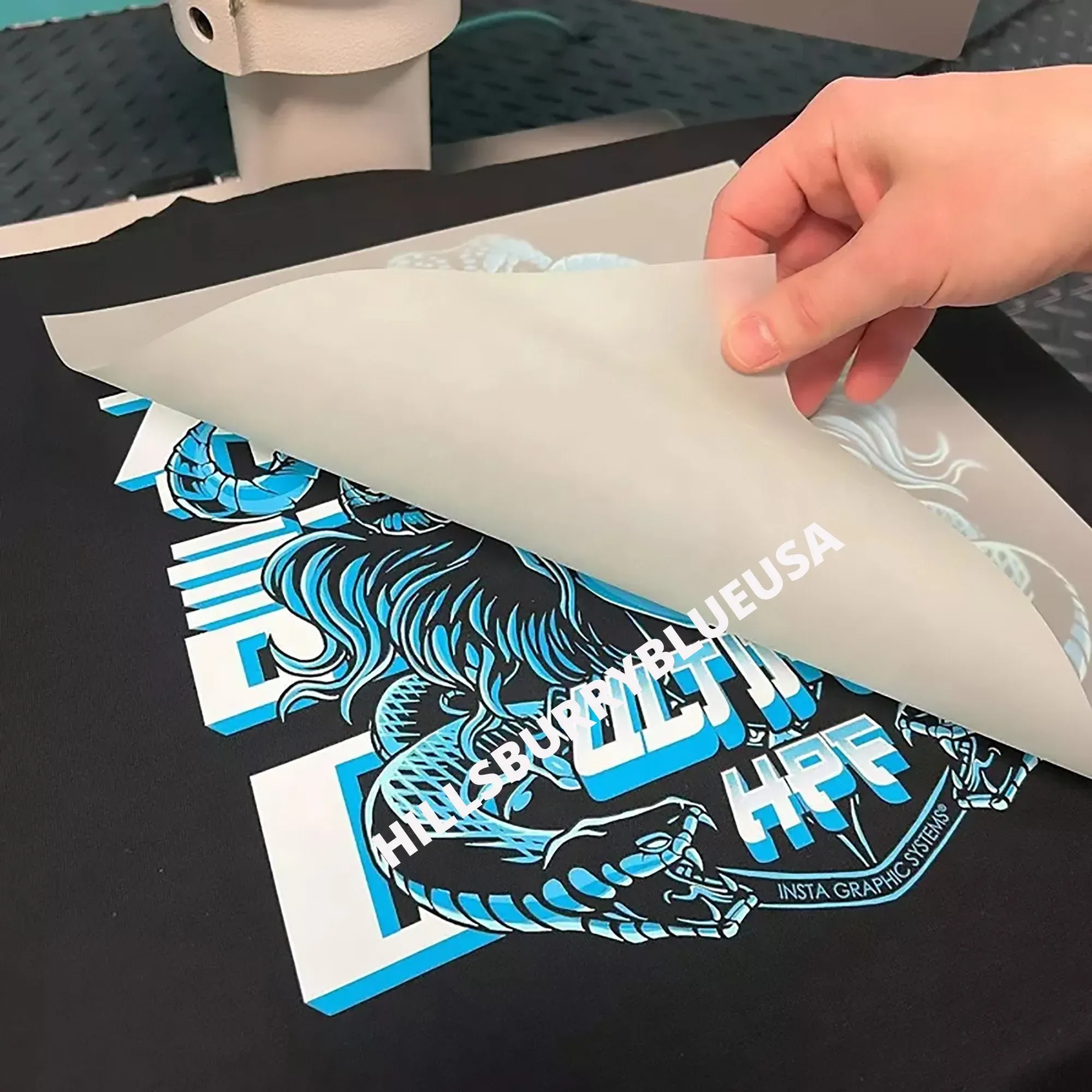

Once your design is printed, the next critical step involves applying the adhesive powder. This phase is pivotal as it determines how well the transfer adheres to the fabric. After printing, sprinkle the adhesive evenly over the wet ink on the film, ensuring full coverage without clumps. Any excess can lead to uneven transfers, which may detract from your project’s overall quality. This meticulous application plays an instrumental role in achieving a durable, high-quality transfer.

Furthermore, curing the adhesive involves placing the film in the heat press at a specified temperature and duration. This step solidifies the bond between the ink and the adhesive, setting the stage for a successful transfer. It’s worth noting that the right settings may vary based on different types of DTF films and inks, so keeping track of successful parameters will benefit you in future projects.

Navigating Recent Trends in DIY DTF Transfers

The landscape of DIY DTF transfers is continually evolving, with numerous trends enhancing its appeal. One notable trend is the increasing accessibility of DTF kits, which provide everything from the printer to the necessary supplies in one package. This convenience is particularly beneficial for newcomers looking to delve into custom fabric printing without the overwhelm of individual sourcing. As the demand for DIY DTF solutions grows, various suppliers are recognizing the need for comprehensive packages aimed at beginners.

Another exciting development is the improvement in ink and film quality. Recent innovations have resulted in more vibrant colors and longer-lasting results, greatly enhancing the finished product’s durability. These advancements mean that home crafters are not only more satisfied with their creations but can also take pride in delivering high-quality merchandise that rivals professional printing services.

Overcoming Common Challenges in DTF Printing

While DIY DTF transfers are straightforward, several challenges may arise during the learning phase. For instance, the **learning curve** associated with getting the timing and temperature right on your heat press can lead to a lot of trial and error. Many new users recommend creating a log of different settings that work well for their materials, allowing for more consistent results in subsequent projects. Overcoming these hurdles can be a rewarding experience, leading to greater understanding and mastery of the craft.

Additionally, the initial investment in a DTF printer and high-quality materials can be significant. However, many creators find that the return on investment is worthwhile. The ability to produce customized items from home allows for creativity and cost-saving in the long term. As crafters gain confidence and skill in using DTF printing, the initial costs become a small price for the unique creative outlet it provides.

Frequently Asked Questions

What is DIY DTF transfer printing and how can beginners start?

DIY DTF transfer printing is a technique that allows you to create custom designs on fabrics using a specialized printer and transfer film. For beginners, starting off requires obtaining a DTF printer, DTF film, ink, adhesive powder, and a heat press. Follow a step-by-step guide to print your designs, apply adhesive, and transfer them onto fabric. Tutorials and kits available online can help you smoothly begin your DIY DTF journey.

What materials are essential for successful DIY DTF transfers?

To successfully execute DIY DTF transfers, essential materials include a DTF printer, special transfer film, DTF ink, adhesive powder, and a heat press machine. These tools are crucial for printing, adhering, and transferring your designs onto fabric with vibrant colors and durability.

How do I ensure my designs are printed correctly for DTF transfers?

When preparing designs for DIY DTF transfers, it’s important to print them in mirrored format, especially if they contain text or intricate graphics. This way, the design will appear correctly on the fabric after the transfer process. Make sure your printer settings are optimized for DTF printing as well.

What are the common challenges faced when starting with DIY DTF transfers?

Common challenges in DIY DTF transfers include mastering the heat press settings, as timing and temperature can affect the quality of the transfer. Additionally, the initial investment in equipment can be daunting, but many find that the cost is justified by the high-quality, custom items they can produce at home.

How can I improve the durability of my DIY DTF transfers?

To enhance the durability of your DIY DTF transfers, ensure you use high-quality DTF ink and film, and follow the curing process correctly by applying the right heat and pressure through your heat press. Experimenting with settings and adhering to the recommended guidelines will yield better results.

Where can I find resources and tutorials for DIY DTF transfer printing?

Numerous online resources are available for DIY DTF transfer printing, particularly on platforms like YouTube and craft-focused websites. These tutorials provide tips, troubleshooting advice, and project ideas to help you navigate the process, making it easier for beginners to get started with their custom fabric printing.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfer printing prints designs on film and transfers them onto fabrics using heat. It’s popular for its versatility and durability. |

| Materials Needed | Essential items include a DTF printer, adhesive powder, and a heat press machine. |

| Step 1: Printing Your Design | Print your design on the DTF film, ensuring text is mirrored. |

| Step 2: Applying Adhesive | Sprinkle adhesive powder onto wet ink and shake off excess. |

| Step 3: Curing the Adhesive | Cure in the heat press at 160°C for a few seconds. |

| Step 4: Transferring to Fabric | Position the design on fabric and apply heat and pressure for 15-20 seconds. |

| Step 5: Peeling Off the Film | Peel the film off while warm to reveal the design. |

| Recent Trends | Increased kit accessibility, improved ink/film quality, and more DIY tutorials. |

| Common Challenges | Learning curve for heat settings and initial investment costs. |

Summary

DIY DTF transfers provide an innovative solution for home crafters eager to create custom designs on fabrics. This method combines vibrant imagery and durable results while being accessible and affordable. With a straightforward step-by-step guide, crafters can confidently navigate the process from printing to transferring designs onto various materials. As trends move towards improved quality and accessibility, the DIY DTF transfer technique is set to continue its rise in popularity, offering creative opportunities for personalized crafting. Whether you’re a seasoned professional or a beginner, the world of DIY DTF transfers invites you to explore your artistic vision and brings your ideas to life.