Innovative DTF Supplies: Elevate Your Printing Skills

Innovative DTF supplies are at the forefront of revolutionizing the custom apparel printing industry, harnessing the power of Direct to Film (DTF) technology to enhance the quality and efficiency of textile printing. This cutting-edge approach allows for the seamless transfer of intricate designs and vibrant colors onto a variety of materials, solidifying its place as a preferred choice for creative businesses. As we explore the latest advancements in DTF inks and eco-friendly printing solutions, you’ll discover how these innovations not only cater to market demands but also align with sustainability goals. With an emphasis on durability and adaptability, innovative DTF supplies empower printers to produce high-quality garments that resonate with environmentally conscious consumers. Join us as we delve into the essentials of DTF technology and how it can elevate your printing game to new heights.

In the landscape of modern fabric printing, the emergence of Direct to Film (DTF) methods signifies a notable shift towards more efficient and sustainable solutions in custom apparel production. This technique simplifies the transfer process, ensuring that even the most complex designs remain intact and vibrant after printing. Utilizing state-of-the-art DTF materials, printers can expect enhanced durability while also appealing to a growing demographic dedicated to eco-friendly practices. As we navigate through the recent developments and innovative resources within the DTF sector, we will highlight the transformative impact these supplies have on the textile industry. Adopting these advancements will provide businesses with a competitive edge while meeting the evolving needs of today’s informed consumers.

Understanding the Impact of DTF Technology on Custom Apparel Printing

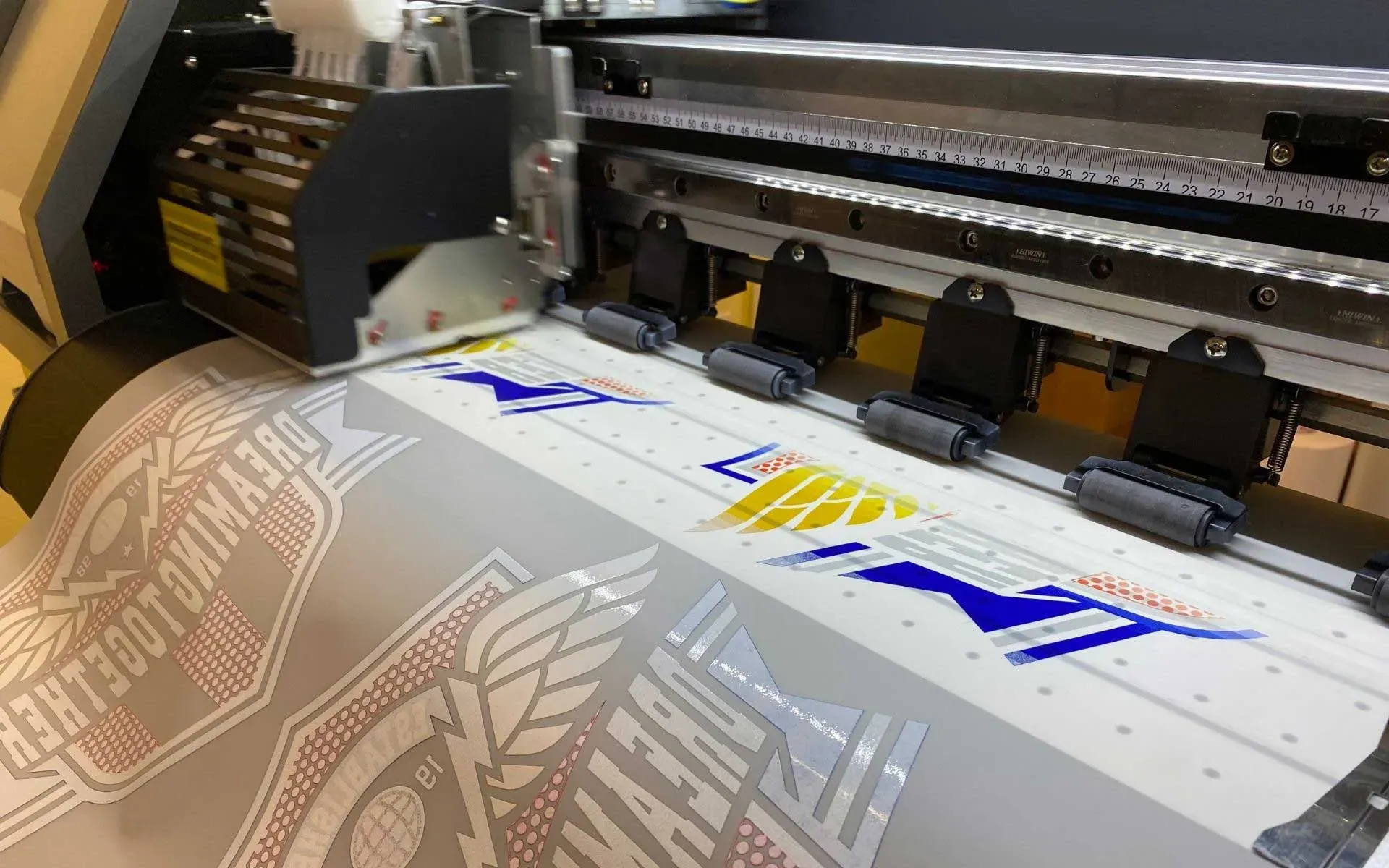

DTF technology has revolutionized the landscape of custom apparel printing by introducing a seamless process that allows for high-quality designs to be transferred onto fabric with remarkable efficiency. The ability of DTF printers to utilize films that adhere to various surfaces expands creative possibilities for designers, from T-shirts to athletic wear. This innovative method not only produces vibrant colors but also ensures durability, making it a preferred choice for businesses looking to deliver premium products to their clients.

Furthermore, the advancements in DTF technology enable a level of detail in printing that was previously unattainable with traditional methods. As companies continue to innovate within this space, the result is a robust selection of materials and processes that cater to a diverse market. The growing popularity of DTF technology means more businesses are adopting these systems to meet consumer demand for unique and personalized apparel.

The Latest Innovations in DTF Inks and Films

The landscape of DTF printing has been significantly enhanced by advancements in DTF inks and films. These latest innovations focus on improving adhesion, vibrancy, and durability, which are crucial for high-quality output. Suppliers are continuously researching and developing DTF inks that not only elevate print quality but also retain their vivid colors through multiple washes, ensuring that the prints maintain their integrity over time.

In addition to improved ink formulations, the introduction of new DTF films has transformed the printing process. Companies are now offering films designed to minimize common transfer issues like cracking and peeling, which are often encountered with older technology. By investing in these advanced materials, businesses can guarantee a reliable output that meets consumer expectations, all while facilitating a more efficient production process.

Embracing Eco-Friendly Practices in DTF Printing

The push for sustainability in the printing industry has reached the DTF printing sector, with many companies now focusing on eco-friendly options. The introduction of biodegradable DTF inks and films reduces the environmental impact of printing while ensuring high-quality results. This aligns well with the increasing consumer demand for products that are both stylish and sustainable, making eco-friendly DTF supplies a smart choice for modern businesses.

In creating environmentally responsible printing solutions, manufacturers are also working to reduce the levels of harmful substances such as Volatile Organic Compounds (VOCs) in their products. The development of water-based DTF inks exemplifies this effort, offering a safer alternative for both printers and consumers. As sustainability continues to shape industry standards, adopting eco-friendly practices will not only appeal to environmentally conscious shoppers but also elevate a brand’s reputation in a competitive market.

Automating DTF Printing: Enhancements and Benefits

Automation in DTF printing is transforming how businesses approach production, making processes more seamless and efficient. With new automated systems, businesses can now minimize labor costs and significantly reduce production time, allowing for quicker turnaround times on orders. Large manufacturers like Epson and Roland have introduced technology that integrates advanced digital workflows, streamlining the entire printing process.

By leveraging automated DTF printing systems, businesses can also enhance customization options, responding swiftly to market trends. The ability to adjust designs and quickly produce tailored merchandise means businesses can maintain a competitive edge, especially in the on-demand printing sector. This adaptability is crucial for meeting the evolving preferences of consumers who increasingly seek personalized apparel options.

Current Market Trends in DTF Printing

The DTF printing market is experiencing rapid growth, driven by the surging demand for custom apparel and promotional products. Projections indicate an annual growth rate of approximately 22%, largely fueled by consumers’ cravings for unique and personalized items. As brands aim to distinguish themselves in a crowded marketplace, superior quality and innovative DTF supplies become vital components for success.

Moreover, businesses that utilize DTF technology effectively can cater to the fast-paced nature of consumer trends, particularly those in e-commerce and on-demand production. By staying attuned to the latest market dynamics and investing in the right DTF materials, companies will not only fulfill customer expectations but can also anticipate future demands, positioning themselves favorably within the competitive landscape.

The Future of DTF Printing: Innovations on the Horizon

As the DTF printing industry continues to evolve, exciting innovations are on the horizon. Technological advances such as improved printing hardware, new types of eco-friendly inks, and refined techniques for film application are paving the way for even more creative possibilities. Businesses that stay ahead of these trends will be better equipped to offer cutting-edge solutions to their customers.

Looking to the future, the integration of smart technologies into DTF printing processes is anticipated to enhance operational efficiency and product quality further. With the ever-increasing emphasis on sustainability and personalization in consumer choices, businesses must embrace these innovations to remain relevant and competitive. For those willing to adapt, the possibilities in DTF printing are bound to be vast and rewarding.

Frequently Asked Questions

What are Innovative DTF Supplies and how do they enhance custom apparel printing?

Innovative DTF Supplies refer to advanced materials and technologies used in Direct to Film (DTF) printing, which enhance the quality and vibrancy of custom apparel printing. These supplies include high-quality DTF inks and films that allow for better adhesion and durability, enabling businesses to produce intricate designs and rich colors that last.

How do the latest DTF inks improve textile printing innovations?

The latest DTF inks are formulated to provide excellent adhesion and durability, making them a significant part of textile printing innovations. These inks are resistant to washing and wear, ensuring that designs remain vibrant over time. By utilizing innovative DTF supplies, printers can achieve high-quality outputs that meet industry standards.

Are there eco-friendly options available in Innovative DTF Supplies?

Yes, there are eco-friendly options within Innovative DTF Supplies. Many manufacturers are now offering biodegradable DTF inks and films with low levels of Volatile Organic Compounds (VOCs). These sustainable materials align with the growing demand for eco-friendly printing solutions, making it easier for businesses to operate responsibly.

What advancements in DTF technology are changing the landscape of custom apparel printing?

Recent advancements in DTF technology include improved printing systems that automate workflows and produce high-quality prints efficiently. Innovations such as advanced printers and high-performance DTF films are allowing businesses to streamline production, reduce costs, and enhance the personalization options available in custom apparel printing.

How do Innovative DTF Supplies support market trends in apparel customization?

Innovative DTF Supplies are at the forefront of market trends in apparel customization by providing high-quality printing options that cater to consumer demand for personalized products. As the DTF printing market grows, these supplies enable businesses to offer unique and intricate designs that appeal to a wide range of customers, driving market growth.

Why is investing in Innovative DTF Supplies crucial for textile printers today?

Investing in Innovative DTF Supplies is crucial for textile printers as these materials improve print quality, adapt to sustainable practices, and enhance production efficiency. With the continuous growth of the DTF printing market, utilizing the latest supplies not only helps businesses stand out but also meets the increasing demand for high-quality, eco-conscious products.

| Key Points | Details |

|---|---|

| Growth in DTF Technology | Recent advancements have improved quality and efficiency, allowing high-quality films to adhere to various surfaces. |

| New DTF Inks and Films | New inks provide better adhesion and durability. Companies like Avery Dennison have improved transfer quality and reduced issues like cracking. |

| Sustainability Initiatives | Introduction of eco-friendly inks and biodegradable materials. Water-based inks promote healthier working conditions. |

| Easier Automation | Automation streamlines workflows, reduces labor costs, and enhances adaptability for quick adjustments in design. |

| Market Trends and Customer Demand | The DTF printing market is projected to grow by 22% annually, driven by demand in custom apparel and personalization. |

Summary

Innovative DTF Supplies are revolutionizing the printing industry by offering cutting-edge technology, sustainable practices, and enhanced automation capabilities. As businesses strive to meet the growing demand for personalized and eco-friendly products, investing in the latest DTF materials is crucial. This evolution not only sets a new standard for quality in custom apparel printing but also fulfills the consumer desire for environmentally responsible production. By embracing these innovations, companies can improve their offerings, boost customer satisfaction, and maintain a competitive edge in a rapidly changing marketplace.