DTF Printing: A Step-by-Step Guide to Get Started

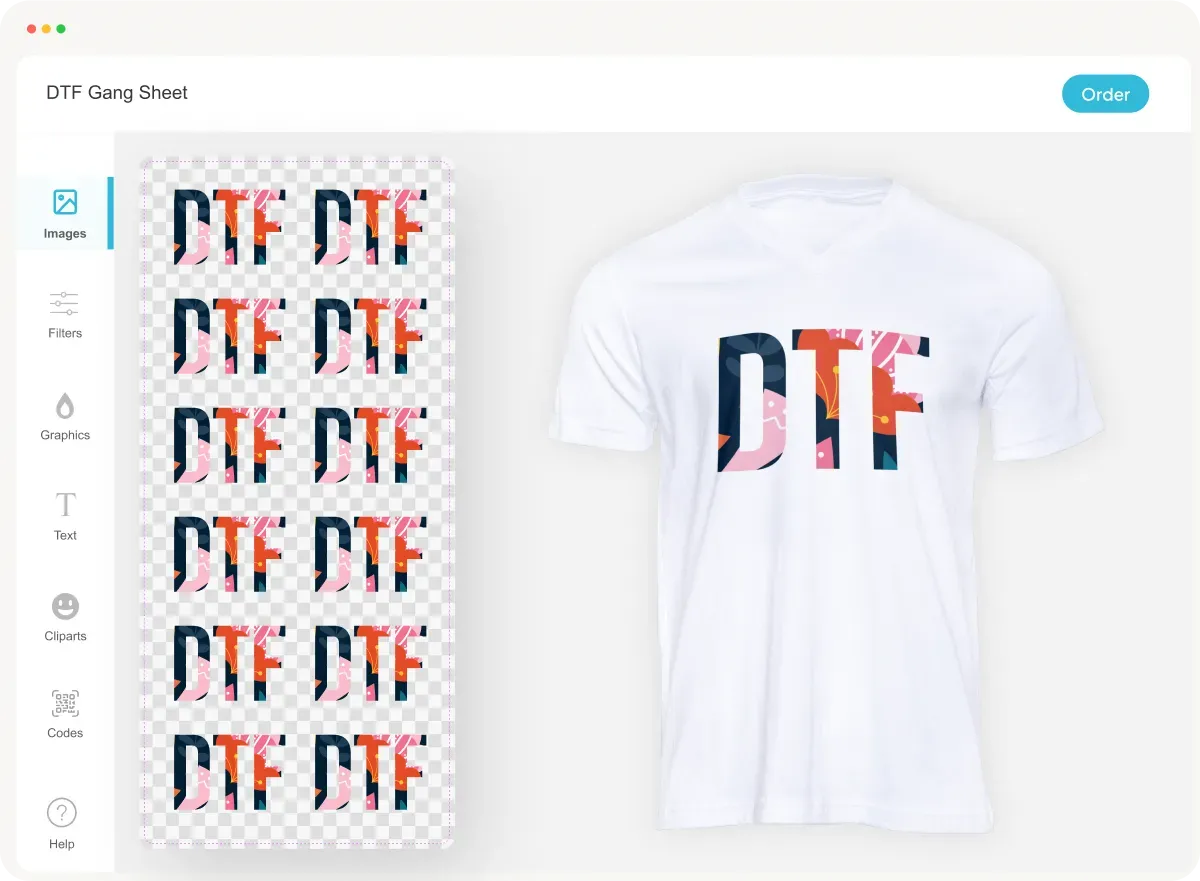

DTF printing, or Direct to Film printing, is positioned at the forefront of the modern textile printing landscape, delivering exceptional quality and durability. This innovative printing method involves transferring vibrant designs from a specially coated film onto various fabrics using a heat press, making it a versatile choice for custom apparel and promotional items. With the right DTF printing equipment, such as a dedicated DTF printer and high-quality adhesive powder, you can produce stunning results that rival traditional printing techniques. As the demand for personalized textiles continues to rise, understanding the DTF printing process becomes essential for anyone looking to carve a niche in this exciting industry. In this comprehensive guide, we will explore everything you need to know about getting started with DTF printing and how to maximize your output with efficient practices.

The world of Direct to Film printing, commonly referred to as DTF printing, is expanding rapidly as a preferred choice for fabric decoration among entrepreneurs and artists alike. This technique leverages advanced methods to create high-definition images on a unique transfer material, ensuring maximum color vibrancy and detail. Getting acquainted with DTF printers and the necessary tools such as heat presses and transfer films can significantly streamline the production process. The ability to print on various fabric types sets this printing approach apart, offering unparalleled versatility in the world of garment decoration. As we delve deeper into this guide, you will discover valuable insights into the DTF printing equipment required and the step-by-step processes for achieving the best results.

The Basics of DTF Printing: How It Works

Direct to Film (DTF) printing is an innovative method transforming the landscape of fabric designs. By utilizing a special transfer film, this technique allows for the application of vibrant graphics onto various materials, producing outputs that are not only visually appealing but also durable. The process begins with high-resolution designs printed on the film, ensuring that color fidelity and detail are preserved. This film is then paired with a heat press, allowing the ink to transfer seamlessly onto the fabric in a process that ensures long-term adhesion.

Unlike traditional printing methods such as screen printing, which can be limited to certain fabric types, DTF printing offers unparalleled flexibility. It is compatible with a broader range of materials, including cotton, polyester, and blends, which makes it an excellent choice for custom garment production. Additionally, the DTF printing process significantly reduces setup time, making it perfect for smaller production runs or on-demand printing needs.

Essential Equipment for DTF Printing Success

To embark on your DTF printing journey, acquiring the right equipment is crucial. An essential component of this setup is a dedicated DTF printer, optimized for printing on transfer films. These printers are designed to utilize specialty inks that adhere effectively to the film and produce vibrant colors that stand out on various fabrics. Furthermore, when considering a DTF printer, it’s important to evaluate the printing speed and quality capabilities, as these factors will directly influence your production efficiency.

In addition to the printer, a high-quality heat press is indispensable in the DTF printing process. The heat press must provide consistent temperature and pressure settings suitable for various fabric types to ensure effective ink transfer. Investing in a reliable heat press not only streamlines your printing process but also enhances the overall quality of the final product. Lastly, don’t overlook the importance of adhesive powders and transfer films, as these materials play a vital role in securing your designs onto fabrics.

Step-by-Step Guide to DTF Printing

The DTF printing process involves a series of well-defined steps that, when followed correctly, yield stunning results. The first step is designing your artwork using software like Adobe Illustrator, ensuring high resolution for clarity. Once your design is finalized, you’ll load your DTF printer with transfer film and print your artwork. Remember to adjust the settings according to the specific requirements of your printer and film to achieve optimal results.

After printing, it is critical to immediately sprinkle adhesive powder over the wet ink. This step enhances the ink’s adherence when placed under the heat press. Following the application of the adhesive, curing the design is essential to bind the ink and adhesive effectively. Using a heat press at the recommended settings for your ink contributes to a successful transfer, allowing you to achieve a professional finish on your fabric.

Maintenance and Care for DTF Printed Fabrics

Proper maintenance and care of DTF printed fabrics can make a notable difference in the longevity and appearance of your designs. After completing the printing process, it’s essential to follow specific washing instructions. Machine washing in cold water without fabric softeners will help maintain the quality of the print and prevent degradation. Opting for a gentle tumble dry or line drying is advisable as high heat can adversely affect the printed design.

Additionally, it’s beneficial to educate your customers about the care of DTF printed items to extend the life of their garments. Recommended practices include avoiding prolonged exposure to direct sunlight and ironing directly on the printed area. By taking these measures, both you and your customers will enjoy the benefits of high-quality DTF prints, allowing designs to remain bright and intact for extended periods.

Business Considerations for Starting DTF Printing

Starting a DTF printing business can be an exciting venture, but it’s important to evaluate several key factors before diving in. Understanding the initial investment needed for DTF printing equipment is essential, as it can vary widely based on the quality and capabilities of the machines you choose. Budgeting for a DTF printer, heat press, and other materials like films and powders will help ensure you’re financially prepared to launch your business.

In addition to upfront costs, consider the necessity for training. Though DTF printing is user-friendly, familiarity with the equipment and printing processes can significantly affect your results. Participating in workshops, online courses, or community groups can enhance your skills and knowledge, setting you up for success in a competitive market. Furthermore, conducting thorough market research helps you identify trends and customer preferences, enabling you to tailor your offerings effectively.

The Future of DTF Printing Technology

The DTF printing industry is on an upward trajectory, with new advancements continually emerging. Technologies are evolving to enhance printing speed and quality, making it increasingly accessible for small businesses and hobbyists alike. Innovations in DTF printers, such as improved print heads and better ink formulations, are enabling richer colors and sharper images, making this technology even more desirable.

As the market for DTF printing grows, expect to see expanded applications in personalized items, promotional products, and custom apparel. Staying updated with the latest technology trends and customer demands will be crucial for your DTF business’s success. Embracing advancements in printing equipment and techniques will not only improve your efficiency but also position you as a leader within this dynamic field.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a modern textile printing technique where designs are printed on a special film. The printed film is then heat pressed onto the fabric, allowing for vibrant colors and detailed designs on various materials.

What equipment do I need for DTF printing?

To start DTF printing, you’ll need specific equipment, including a DTF printer designed for this process, a heat press for transferring designs, transfer film for printing, adhesive powder to help the ink adhere, and DTF inks which are specially formulated for high quality and durability.

How do I prepare my design for DTF printing?

Prepare your design for DTF printing by using graphic design software like Adobe Illustrator or CorelDRAW. Ensure your artwork is high resolution and compatible with your DTF printer settings before printing it onto the transfer film.

What are the benefits of using a heat press for DTF printing?

Using a heat press for DTF printing is essential as it allows for precise control over temperature and pressure, which ensures an effective transfer of the design from the film to the fabric without damaging the material.

How should I care for my DTF prints after they are applied?

To maintain DTF prints, machine wash them in cold water, avoid fabric softeners that could damage the print, and either line dry or tumble dry on low heat to preserve the vibrancy and durability of the design.

What should I consider before starting a DTF printing business?

Before starting a DTF printing business, consider the costs of DTF printing equipment, the importance of training in the printing process, and conduct market research to understand your target audience for your printed products.

| Key Point | Details |

|---|---|

| Introduction | DTF printing is a modern textile printing technology known for high quality and versatility. |

| Understanding DTF Printing | Involves printing on a special film and heat pressing onto fabric, offering vibrant colors and easy use. |

| Equipment Required | Key equipment includes a DTF printer, heat press, transfer film, adhesive powder, and DTF inks. |

| Step-by-Step Process | Includes design creation, printing, applying adhesive powder, curing, and transferring to fabric. |

| Post-Printing Care | Machine wash in cold water and avoid fabric softeners to maintain print durability. |

| Considerations Before Starting | Consider costs, necessary training, and market research for a successful DTF printing business. |

| Recent Developments | Innovations are enhancing speed and quality in DTF printing, broadening its accessibility. |

Summary

DTF printing is an exciting and innovative approach to textile printing that offers tremendous potential for creativity and business. As you embark on your DTF printing journey, embracing the technology’s unique capabilities, understanding the necessary equipment, and mastering the printing process will be crucial to your success. With ongoing advancements in the field, staying informed about new trends and tools will further enhance your ability to create stunning designs that stand out in the market. Therefore, whether for personal projects or a budding business, DTF printing can open up a world of possibilities.